钢轨打磨压力波动的影响机理

聂蒙,李建勇,沈海阔,智少丹

(北京交通大学 机械与电子控制工程学院,北京,100044)

摘要:钢轨打磨列车作业过程中由于车身晃动以及钢轨的不平顺等原因会带来打磨的压力波动,从而影响打磨质量甚至导致钢轨损伤。为研究降低钢轨打磨压力波动的方法,从工作机理入手,对钢轨打磨作业系统以及作业过程进行分析,建立打磨压力输出的数学模型,通过模型分析影响打磨压力波动的主要因素,并通过数值仿真对改变打磨气缸无杆腔容积、打磨单元质量与气源压力降低压力波动影响的有效性进行验证。

关键词:钢轨打磨;气动系统建模;打磨压力波动

中图分类号:TD853.391 文献标志码:A 文章编号:1672-7207(2013)08-3546-06

Grinding pressure fluctuation of rail grinding

NIE Meng, LI Jianyong, SHEN Haikuo, ZHI Shaodan

(School of Mechanical & Electronic Control Engineering, Beijing Jiaotong University, Beijing 100044, China)

Abstract: During the rail grinding operation, the pressure fluctuation caused by vehicle vibration and track irregularities will affect the grinding quality or damage the rail even worse. To find out how to reduce the pressure fluctuation, based on the working mechanism of the rail grinding operation process, the mathematical model of the grinding pressure was built, which is the output of the grinding control system. According to the model, the main factors affecting the grinding pressure include non-rod cylinder capacity of the chamber, quality of the grinding motor and pressure of the air supply. The mathematical simulation verifies that by changing these factors the pressure fluctuation can be effectively reduced.

Key words: rail grinding; pneumatic system modeling; grinding pressure fluctuations

钢轨打磨列车是高速、重载铁路整修的重要技术装备,随着我国高速铁路和城市轨道交通建设的迅猛发展,钢轨打磨列车的作用日益体现[1]。早期的打磨列车如PGM48/3等型号在打磨压力输出方面均采用液压传动的方式[2]。近年来,随着气动技术的发展,由于其本身具有压力柔顺性好、清洁度高等特点,在钢轨打磨方面有着逐渐取代液压传动系统的趋势[3],如目前世界上最先进的GMC-96型钢轨打磨列车上已采用气动传动作为打磨压力输出的方式[4]。然而由于钢轨打磨作业过程中车身晃动以及钢轨自身不平顺等原因带来的打磨压力波动[5],最终会导致打磨后的钢轨在一些作业地段反而出现不平顺增大的现象[6]。因此,对钢轨打磨过程中影响气动系统打磨压力输出波动的因素进行研究对于钢轨打磨列车国产化设计以及提高打磨质量有着重要的意义。关于气动系统压力与位置输出的理论研究与工程应用经过国内外几十年的不断发展逐步得到完善,并应用在不同领域中,Noritsugu等[7]在气动位置伺服控制系统中引入压力反馈,构建压力干扰观测器以加快系统对外负载力干扰的响应速度;Sanville[8]将通过阀口的气体流动过程近似为理想气体通过收缩喷管的一维等熵流通从而得到阀口流量公式;郭浩等[9]通过对压缩气体高压化的优势进行分析得出一系列高压气体流动下气动元件特 性[9];许宏光[10]采用滑模变结构控制策略,对采用压力比例阀的气动系统进行位置伺服控制;Lin等[11]对无杆气缸的电/气控制系统的建模进行了研究;黄俊等[12]对气缸爬行问题进行建模与仿真,用以分析气缸爬行现象的主要影响因素。这些研究对于本文的建模与分析具有一定的指导作用,然而由于其各自研究领域的局限性,对于钢轨打磨领域并不完全适用。本文作者建立了单个打磨头打磨作业过程中气动系统打磨压力输出的数学模型,并对该数学模型进行线性化,进而建立起打磨外扰动与打磨压力之间传递函数,并通过对传递函数的分析,找出系统中对能够对打磨压力波动起到影响的因素,从而找到有效控制打磨压力波动的方法,最后利用系统仿真对其进行验证。

1 打磨作业压力控制原理

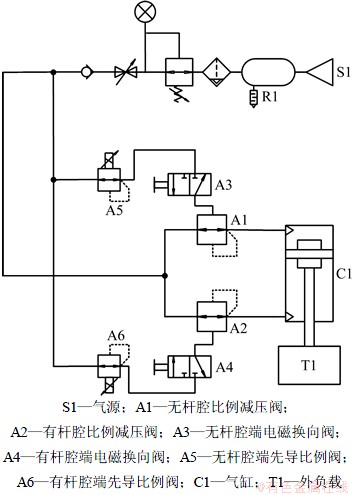

该系统应用于钢轨打磨列车单打磨头打磨压力输出部分,通过控制无杆腔与有杆腔端先导比例阀的出口压力来控制两端比例减压阀开口进而实现调整气缸两腔压力,以两腔的压力差作为输出作用在打磨砂轮上从而实现打磨压力输出。打磨作业过程中,先通过打开有杆腔端比例减压阀实现抬起与气缸活塞杆相铰接的打磨电机,后关闭有杆腔端比例阀,打开无杆腔端比例阀输出压力。系统原理如图1所示。

图1 单打磨头压力输出气动系统

Fig. 1 Pneumatic system with singles grinding head

2 单打磨头作业压力模型

2.1 模型假设

由于实际气体受到众多因素的影响,为了便于分析与研究,在建模过程中作如下假设[13]:

(1) 介质气体为理想气体。

(2) 气体的动能与势能忽略不计。

(3) 气体的流动状态为绝热过程。

(4) 忽略气缸内外气体泄漏。

2.2 模型建立

该系统数学模型由以下几部分组成。

2.2.1 气缸活塞力平衡方程

根据牛顿第二定律,建立气缸活塞力平衡方程:

(1)

(1)

式中:Aa为无杆腔压力作用面;Ab为有杆腔压力作用面;Pa为无杆腔端压力;Pb为有杆腔端压力;M为气缸活塞及打磨电机质量;θ为气缸倾斜角度;F为气缸输出打磨压力;a为气缸活塞杆在外扰动下受迫运动的加速度。

2.2.2 有杆腔容腔压力方程

有杆腔内预充一定气体后阀口关闭,其内部气体压力遵从理想气体状态方程:PV=nRT,

(2)

(2)

式中:pb0为有杆腔初始预充压力, ;p为供气端压力;pe为额定输出压力;Vb0为有杆腔初始体积;T为当前气体温度;T0为气体初始温度;xb为无杆腔初始长度;x为系统扰动,

;p为供气端压力;pe为额定输出压力;Vb0为有杆腔初始体积;T为当前气体温度;T0为气体初始温度;xb为无杆腔初始长度;x为系统扰动, 。

。

2.2.3 无杆腔容腔压力流量方程

流量连续方程:

(3)

(3)

式中:qm为容腔流量;m为无杆腔容腔质量;V为无杆腔容腔体积;ρ为无杆腔容腔密度。

容腔压力微分方程:

(4)

(4)

式中:qmcpT为单位时间内流入容腔的能量;dW/dt为单位时间内传入容腔的热量;pdV/dt为单位时间控制腔对外做功;pdV/dt为控制腔内总能量变化率;W为外界传入容腔的热量;E为容腔内总能量, ;cp为气体等压比热容;cv为气体等容比热容。

;cp为气体等压比热容;cv为气体等容比热容。

根据以上2个方程建立无杆腔容腔压力流量方程:

(5)

(5)

式中:R为摩尔气体常数,R=cp-cv;xa为无杆腔初始长度。

2.2.4 无杆腔阀流量方程

根据Sanville的流量方程[8],建立无杆腔阀口流量方程。

(6)

(6)

式中:A为阀开口面积控制函数;pa为无杆腔容腔压力;k为气体绝热指数,Ct为临界压力比, 。

。

2.3 系统扰动-打磨压力传递函数

为了研究对于打磨压力波动有影响的系统参数,选用气缸活塞杆在外扰动下受迫运动的加速度作为系统地输入值,以压力作为系统输出值,建立传递函数。

对各模块方程进行线性化处理并求拉式变换:

(1) 对有杆腔容腔压力方程进行线性化,对于小的压力变化,从T0到T的变化忽略不计,对方程进行泰勒展开并求拉氏变换得:

(7)

(7)

(2) 对无杆腔阀流量方程进行线性化并求拉氏变换:

(8)

(8)

式中: ,

, 。

。

(3) 对无杆腔压力流量方程进行线性化,其中x+xa项由于x项相对于xa项较小,简化为xa项,而 项中的pa简化为p并求拉氏变换:

项中的pa简化为p并求拉氏变换:

(9)

(9)

(4) 对力平衡方程求拉氏变换:

(10)

(10)

建立起系统传递函数:

(11)

(11)

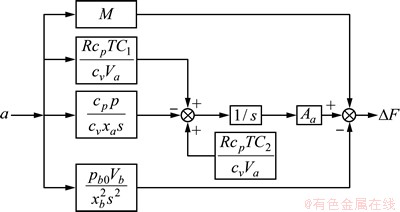

系统方框图如图2所示。

图2 系统方框图

Fig. 2 Block scheme of system

2.4 模型分析

通过传递函数可以看出:该系统为一个比较复杂的非线性系统,经过大量简化后得出的线性化数学模型为3阶系统。

根据系统方框图可以看出:影响打磨压力的因素主要分为3个部分。其中惯量部分为比例环节,主要参数为气缸活塞及打磨电机质量M,可以看出该环节对压力输出属于负扰动,即当打磨压力变化量为负时该环节对于压力波动起推动作用而当打磨压力变化量为正时起缓冲作用,对于周期性的外扰动,增大该参数会直接导致压力波动增大。

无杆腔部分由2个部分并联而成,第1个部分为带有正反馈的积分环节,主要参数为无杆腔容腔体积Va,该环节对压力输出属于正扰动,同时正反馈增大该环节对系统输出影响,可以看出对于周期性的外扰动,增大容腔能够有效降低压力波动。第2部分为带有负反馈的二阶惯性环节,主要参数为气源压力p,该环节对压力输出属于负扰动,对于周期性的外扰动,增大该参数会导致压力波动增大。

有杆腔部分为二阶积分环节,主要参数为有杆腔容腔体积Vb以及有杆腔初始压力pb0,该环节对压力输出属于负扰动,对于周期性的外扰动,增大该环节参数会导致压力波动增大,由于

(12)

(12)

可以看出:参数p与M的变化趋势对前几部分的变化起推动作用,增大无杆腔容腔体积Vb会导致压力波动增大。

3 系统仿真

选用未线性化的系统数学模型,以钢轨波磨带来的外扰动为例,利用Matlab对系统进行仿真,由于钢轨不平顺带来的打磨气缸活塞杆受迫运动[14],则

(13)

(13)

式中:A为波磨深度;v为作业速度;γ为波磨波长。

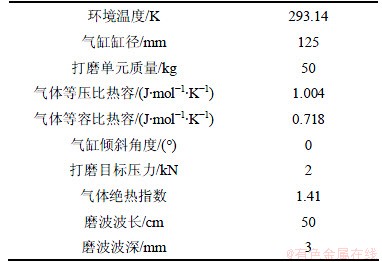

相关参数选取如表1所示。

表1 仿真关键参数

Table 1 Key parameters of simulation

3.1 无杆腔容腔体积对压力波动的影响

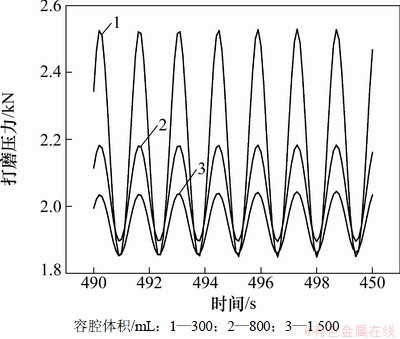

设定打磨速度为8 km/h,气源压力为3.1 MPa,气缸活塞及打磨电机质量为50 kg,通过选取不同无杆腔容腔体积进行压力输出仿真,选取压力输出已经达到稳定时的曲线如图3所示。

根据仿真结果进行对比可以看出,随着无杆腔容腔体积的增大,压力波动逐渐降低,与分析相符合。

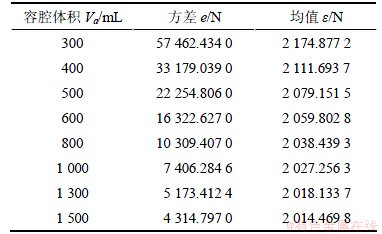

用压力稳定输出后的方差来标定打磨压力的波动,选取不同容腔体积进行仿真并进行对比,结果如表2所示。

表2中, ;

; (14)

(14)

根据以上仿真结果可以更进一步看出,随着容腔体积的不断增大,压力输出的方差体积不断降低,同时压力输出的均值也不断降低。

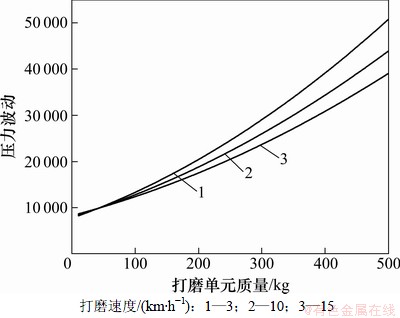

选取不同速度下400~2 000 mL的容腔体积进行仿真,结果如图4所示。

根据上面的仿真结果可以较直接地看出,相同的打磨速度下,打磨压力波动随着无杆腔容腔体积的增大不断降低并逐渐趋于稳定;同时随着容腔体积的增大,不同的打磨速度对于打磨压力波动逐渐减小,因此,在适当范围利用相应手段增大无杆腔容腔体积(如增大无杆腔端管路直径等)能够有效降低打磨压力波动。

图3 不同容腔体积下打磨压力对比

Fig. 3 Grinding pressure under different chambers

表2 不同容腔体积下压力输出方差及均值对比

Table 2 Mean value and variance under different chambers

图4 不同打磨速度下容腔体积-压力波动对比

Fig. 4 Chamber value-pressure oscillation under different grinding speeds

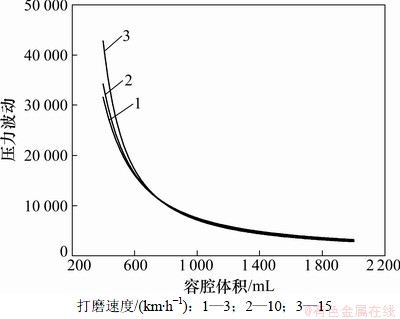

3.2 打磨单元质量对压力波动的影响

设定打磨速度为8 km/h,气源压力为0.2 MPa,容腔体积为300 mL,通过选取不同无杆腔容腔体积进行压力输出仿真,如图5所示。

图5 不同打磨单元质量下打磨压力对比

Fig. 5 Grinding pressure under different grinding unit quality

根据仿真结果选取压力输出已经达到稳定时的曲线(见图5)进行对比可以看出,压力波动随着打磨单元质量的增大而增大,与分析相符合。

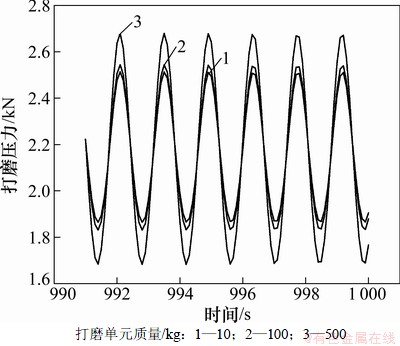

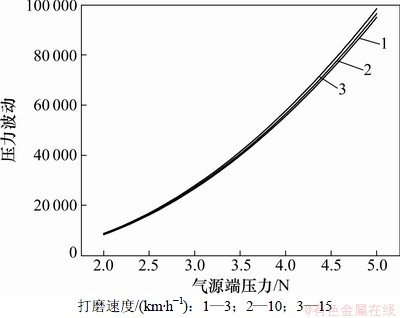

用压力稳定输出后的方差来标定打磨压力的波动,选取不同速度下 10~500 kg打磨单元质量进行仿真,结果如图6所示。

图6 不同打磨速度下打磨单元质量-压力波动对比

Fig. 6 Grinding unit quality-pressure oscillation under different grinding speeds

根据上面的仿真结果可以看出:相同的打磨速度下,打磨压力波动随着打磨单元质量的增大不断增大。同时随着打磨单元质量的增大,不同打磨速度对于压力波动的影响逐渐增大。因此,在允许范围内适当降低打磨单元质量能够有效降低打磨压力波动。

3.3 气源压力对压力波动影响

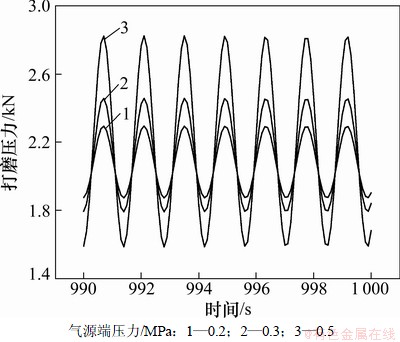

设定打磨速度为8 km/h,无杆腔容腔体积为300 mL,气缸活塞及打磨电机质量为50 kg,通过选取不同无杆腔容腔体积进行压力输出仿真如图7所示。

根据仿真结果选取压力输出已经达到稳定时的曲线如图7进行对比可以看出,随着气源端压力的增大,压力波动逐渐增大,与分析相符合。

用压力稳定输出后的方差来标定打磨压力的波动,选取不同打磨速度,在0.2~2 MPa气源端压力下进行仿真,结果如图8所示。

图7 不同气源端压力下下打磨压力对比

Fig. 7 Grinding pressure under different supply pressure

图8 不同打磨速度下气源端压力-压力波动对比

Fig. 8 Supply pressure-pressure oscillation under different grinding speeds

根据上面的仿真结果可以较直接地看出,相同的打磨速度下,打磨压力波动随着气源端压力的增大不断增大。而不同打磨速度下。因此,在允许范围内适当降低气源端压力能够有效降低打磨压力波动。

4 结论

(1) 对钢轨打磨作业系统以及作业过程进行分析,建立起单打磨头打磨作业过程中气动系统打磨压力输出的数学模型,并以系统外扰动为输入量建立打磨外扰动与打磨压力之间的传递函数。

(2) 利用传递函数建立系统方框图,通过模型分析可知:通过增大打磨气缸无杆腔容积、降低打磨单元质量以及气源压力能够降低系统压力波动。

(3) 选用不同的打磨参量进行数值仿真,验证了上述分析的正确性。

参考文献:

[1] 金学松, 杜星. 钢轨打磨技术研究进展[J]. 西南交通大学学报, 2010, 45(1): 7-11.

JIN Xuesong, DU Xing. State of arts of research on rail grinding[J]. Journal of Southwest Jiaotong University, 2010, 45(1): 7-11.

[2] 魏长竹, 魏晨. 钢轨打磨车磨头数量及驱动方式分析[J]. 城市轨道交通研究, 2010(12): 12-13.

WEI Changzhu, WEI Chen. Analysis on the gringing wheel quantity and the drive mode of rail gringing vehicle[J]. Urban Mass Transit, 2010(12): 12-13.

[3] 曹岩. 我国高速铁路用钢轨打磨列车选型及应用研究[J]. 铁路标准设计, 2011(8): 6-8.

CAO Yan. Investigation into the type and application of rail grinding trains on high speed railway lines in China[J]. Railway Standard Design, 2011(8): 6-8.

[4] 李海滨, 唐松柏. GMC96B型钢轨打磨列车试验研究[J]. 铁道技术监督, 2011(12): 12-39.

LI Haibin, Tang Songbai. GMC96B type rail grinding train test research[J]. Railway Quality Control, 2011(12): 12-39.

[5] 方立志, 胡军科. 钢轨打磨列车恒力加载系统的分析仿真研究[J]. 铁道科学与工程学报, 2012(2): 2-9.

FANG Lizhi, HU Junke. Analysis and simulation of the constant loading system of rail grinding train[J]. Journal of Railway Science and Engineering, 2012(2): 2-9.

[6] 张建峰, 高新平. 重载铁路钢轨打磨效果分析[J]. 铁道建筑, 2009(4): 104-105.

ZHANG Jianfeng, GAO Xinping. Analysis of Heavy railway grinding effect[J]. Railway Engineering, 2009(4): 104-105.

[7] Noritsugu T, Takaiwa M. Robust positioning control of pneumatic servo system with pressure control loop[J]. IEEE International Conference on Robotics and Automation, 1965, 95(6): 2613-2618.

[8] Sanville F E. A new method of specifying the flow capacity of pneumatic fluid powervalves[C]//Second Fluid Power Symposium. England, 1997: 37-47.

[9] 郭浩, 杨钢. 新型高压电-气比例阀缓冲气控腔性能分析[J]. 机床与液压, 2008, 36(2): 32-36.

GUO Hao, YANG Gang. Characteristic analysis on large volume cushion chamber of high-pressure electropneumatic proportional valve[J]. Machine Tool & Hydraulics, 2008, 36(2): 32-36.

[10] 许宏光. 电-气伺服控制系统的研究[D]. 哈尔滨: 哈尔滨工业大学, 1992: 10-25.

XU Hongguang. Research on electric-pneumatic servo control system[D]. Harbin: Harbin Institute of Technology, 1992: 10-25.

[11] Lin X, Spettel F. Modeling and test of an electropneumatic servo valve controlled long rodless actuator[J]. Journal of Dynamic Systems, Measurement and Control, 1996(118): 457-462.

[12] 黄俊, 李小宁. 气缸爬行现象的建模与仿真[J]. 液压与气动, 2004(6): 18-20.

HUANG Jun, LI Xiaoning. Modelling and simulation of stick-slip motion in pneumatic cylinder[J]. Chinese Hydraulics & Pneumatics, 2004(6): 18-20.

[13] TAO Guoliang, WANG Xuanyin. The reaearch on electro-pneumatic-servo robot writing chinese calligraphy[C]//2th Internationals’ Fluid Technisches Kolloquium in Dresden. Germany, 2000: 4-16.

[14] 周跃清, 田常海. 高速铁路钢轨打磨关键技术研究[J]. 中国铁道科学, 2012(2): 66-69.

ZHOU Yueqing, TIAN Changhai. Research on key rail gringing technology of high-speed railway[J]. China Railway Science, 2012(2): 66-69.

(编辑 陈爱华)

收稿日期:2012-10-05;修回日期:2012-12-20

基金项目:铁道部科技研究开发计划重点项目(20100G008-C);北京交通大学校科研基金资助项目(M11JB00400)

通信作者:李建勇(1962-),男,河北唐山人,博士,教授,从事于先进制造技术研究;电话:010-51683685;E-mail:jyli@bjtu.edu.cn