文章编号:1004-0609(2007)09-1465-05

可降解镁植入材料表面涂层的制备及其性能

黄晶晶1, 2,任伊宾1,张炳春1,杨 柯1

(1. 中国科学院 金属研究所,沈阳 110016;

2. 中国科学院 研究生院,北京 100864)

摘 要:采用浸涂法制备Mg植入材料表面聚乳酸涂层,通过选择不同相对分子质量的聚乳酸并采用硅烷偶联剂对Mg植入材料表面进行预处理,提高Mg植入材料与聚乳酸的结合力。利用扫描电镜得出浸涂时间、聚合物浓度及浸涂次数对涂层厚度的影响。发现Mg植入材料表面涂覆相对分子质量为20万的聚(乳酸?羟基乙酸)能够满足降解条件和结合力的要求。经聚乳酸表面处理的试样在Hank’s 溶液中浸泡10 d后,计算试样质量损失,发现表面处理后的试样质量损失明显降低。实验表明,镁表面涂覆聚乳酸涂层,可以有效提高其在模拟体液中的耐蚀性。

关键词:浸涂;Mg植入材料;结合力;耐蚀性

中图分类号:R318.08 文献标识码:A

Preparation and property of coating on degradable Mg implant

HUANG Jing-jing1, 2, REN Yi-bin1, ZHANG Bing-chun1, YANG Ke1

(1. Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China;

2. Graduate School of Chinese Academy of Sciences, Beijing 100864, China)

Abstract: To be an implant material, it is necessary to have good corrosion resistance for magnesium and magnesium alloy in the period of tissue healing process. To improve corrosion resistance of pure magnesium, dipping technology was employed in the present work to prepare the poly (lactic acid) coating on Mg implant. Different molecular mass poly (lactic acid) and a surface pretreatment technology applying silane coupling agents on Mg implant was used to improve adhesion strength between Mg implant and poly lactic acid. Scanning electron microscopy (SEM) was used to gain the effect of dipping time, polymer concentration and dipping times for the thickness of coating. The results show that poly (DL-lactide-co-glycolide) (PLGA) with relative molecular mass of 200 thousand can meet the need of degradation condition and strength adhesion of biodegradable implant. The mass loss of PLGA film coated Mg implant is decreased obviously after they are immersed in Hank’s solution. It can be concluded that PLGA coating can effectively protect magnesium from corrosion in simulation biology solution.

Key words: dipping technology; Mg implant; adhesion strength; corrosion resistant

镁及镁合金作为金属植入材料已越来越受到人们的重视,因为它与现已临床使用的植入材料相比具有许多突出的优点[1?2],而且大量的研究发现,镁具有诱导骨生长的作用[3?5]。

但是在人体充满Cl?的腐蚀环境中,镁及镁合金可能会因为降解速率较快而提前失效。通常临时植入器件要求3个月到1 a的服役时间,可推算出镁及镁合金作为植入材料降解速率应控制在0.1 mm/a内,但本实验室前期研究发现纯镁在模拟体液内的降解速率为0.2~1.0 mm/a[6],并且在动物实验中也发现纯镁在未经保护下降解较快,因此可能会在服役时间内失效,所以本文作者计划通过表面涂层的方法来减小镁植入体内后的降解速率。有关镁及镁合金表面涂层的制备方法很多,但是镁作为可降解植入材料,其涂层必须保证无毒性、良好的生物相容性,以及可降解性,这就限制了已有表面处理方法在镁合金作为植入材料上的应用。国内有人通过碱热处理法有效改善了纯镁的耐蚀性,并证明改性后的镁没有对小鼠骨髓细胞的增殖产生明显的毒副作用[7]。但由于镁作为生物材料仍属于一种新材料,许多生物学性能,尤其是镁对生物体组织的长期生物相容性还未见报道,所以选用一种生物相容性好的材料作为防护性涂层更有研究前景。本文作者选用聚乳酸作为镁植入材料的表面涂层,采用浸涂法制作镁植入材料的防护层。

1 实验

实验材料为锻造态纯镁,纯度为99.95%,其中Fe<0.003%,Ni:0.0002%,Cu:0.0010%,Si:0.029%。涂层中的聚合物分别是相对分子质量为8万、20万和50万的聚乳酸PLLA以及相对分子质量为20万的聚(乳酸-羟基乙酸)共聚物PLGA,它们具有良好的血液相容性,已被用作药物控释载体、外科手术缝合线、骨科内固定板等医疗器械。涂层中使用KH?550硅烷偶联剂,溶剂为三氯甲烷。

实验材料经砂纸打磨至1200#,首先用丙酮超声清洗进行充分去污,然后将实验材料在蒸馏水中超声一定时间,采用浸涂法制备表面涂层,并用偶联剂改善表面状态。

聚合物与金属基体的粘结强度根据GB7124— 1986进行测试,所用拉力实验机为Zwick/Roell Z050电子万能试验机,拉伸速率为0.5 mm/min。在S?3400N扫描电镜下观察实验材料在不同条件下的涂层厚度。并将未做任何处理的纯镁对照组样品及PLGA涂覆后样品分别在Hank’s溶液中浸泡10 d,保持溶液恒温在(37±0.5) ℃。Hank’s人工模拟体液[8],组成为:NaCl 8.0 g+KCl 0.4 g+CaCl2 0.14 g+NaHCO3 0.35 g+C6H12O6 (葡萄糖)1.0 g+MgCl2?6H2O 0.1 g+MgSO4?7HO 0.06 g +KH2PO4 0.06 g+Na2HPO4?12H2O 0.06 g+1 L H2O。用HCl和NaOH溶液调节pH为7.5。所用化学试剂全部为分析纯。浸泡实验结束后,取出样品称量,并计算其质量损失。

2 结果与讨论

用于植入器件的材料必须保证植入材料与其植入位置周围组织有良好的相容性[9?10]。而改善材料相容性最有效的办法就是在表面涂覆一层已知生物相容性良好的材料[11]。聚乳酸已在临床广泛应用,有良好的生物相容性,而且镁合金作为制作可降解支架的材料时[12],聚乳酸可作为镁合金支架的带药载体,从而控制药物释放速度。

2.1 涂层和基体的结合力

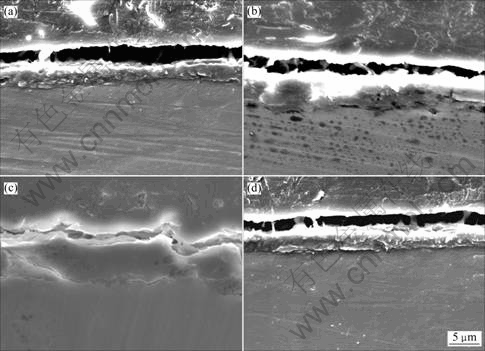

图1所示为表面涂覆不同相对分子质量聚乳酸后的扫描电镜像。可看出相对分子质量为50万的PLLA和相对分子质量为20万的PLGA涂覆后镁表面非常平整致密。聚乳酸不仅起到了防护层的作用,同时减小了镁的表面粗糙度,降低了镁在与血液接触时引起凝血的可能性,为其作为可降解支架材料的研究提供了依据。

图1 不同相对分子质量的PLLA和PLGA涂覆镁后表面扫描电镜像

Fig.1 SEM images of 80 thousand(a), 200 thousand(b), 500 thousand(c) relative molecular mass of PLLA and 200 thousand relative molecular mass of PLGA surface treated Mg(d)

镁表面涂覆不同相对分子质量聚乳酸后界面情况如图2所示。对于聚乳酸PLLA,相对分子质量越小,聚乳酸与镁结合情况越好、涂层越薄,而聚(乳酸-羟基乙酸)PLGA虽然相对分子质量较大,但与镁结合也较好。

图2 不同相对分子质量的PLLA和PLGA涂覆镁后截面扫描电镜像

Fig.2 SEM images on interface of 80 thousand(a), 200 thousand(b), 500 thousand(c) relative molecular mass of PLLA and 200 thousand relative molecular mass PLGA surface treated Mg(d)

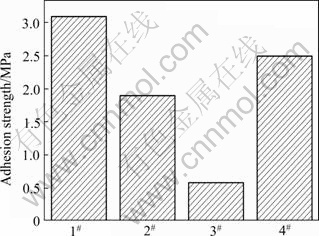

图3所示为不同相对分子质量的聚乳酸与镁的结合力,1#~4#分别为相对分子质量为8、20和50万的PLLA,以及相对分子质量为20万的PLGA。涂层结合力包括涂层与基体的结合力以及涂层本身所具有的内聚力。实验中用弱酸对基体进行表面预处理,使表面粗化,提高了粘接面积,同时对基体表面起到了活化作用,有利于增大基体与涂层之间的结合力。图3进一步证明,在选用的几种聚乳酸中,相对分子质量越小,结合强度越大。因为不同相对分子质量的聚合物在浓度相同的情况下,其黏度差别很大,其中相对分子质量为50万的PLLA浓度为1%时黏度为20 mPa·s左右,实际操作中发现该PLLA很难溶于溶剂。而相同相对分子质量的聚乳酸和聚(乳酸-羟基乙酸),在同样浓度下后者的黏度更小,可以得到更大的溶解度,更方便通过调节浓度来改变涂层厚度。虽然图3显示相对分子质量越小,结合力越好,但相对分子质量小的聚合物在体内降解时间也会减少,聚乳酸涂覆后镁表面形貌显示,8万相对分子质量聚乳酸涂层与另外3种涂层相比,明显保护镁基体的作用较差,所以最终选用20万相对分子质量的PLGA进行进一步研究。

图3 聚乳酸相对分子质量对结合强度的影响

Fig.3 Effect of different relative molecular mass poly-lactic acid on adhesion strength between Mg implant and poly-lactic acid

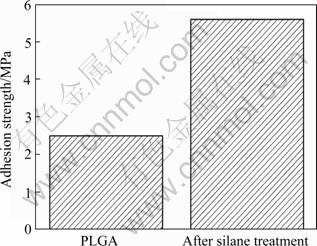

图4所示为偶联剂表面处理对结合强度的影响。可见,镁表面经过偶联剂处理后,与聚乳酸的结合力显著提高。由于直接在基体表面涂覆聚合物,结合力很难有显著提高,所以本文中选择硅烷偶联剂对镁进行表面改性。硅烷偶联剂也具有一定的防腐效果,并且优于传统的磷化、钝化工艺。已有研究表明[13],硅烷特殊的结构特征决定了它可以与金属形成Si—O—Me化学结合键,从而提高涂层与金属基体的化学结合力。所以通过进一步优化表面偶联剂处理工艺,可以实现使镁表面与聚乳酸良好的结合。

图4 偶联剂表面处理对结合强度的影响

Fig.4 Effect of silane coupling agents pretreatment on adhesion strength between Mg implant and poly-lactic acid

2.2 涂层厚度

聚乳酸涂层可以在镁植入初期对镁起到保护作用。另外,为了保证服役期结束后两者在人体可接受的安全范围内尽快完全降解,聚乳酸涂层的厚度存在一个最优值。

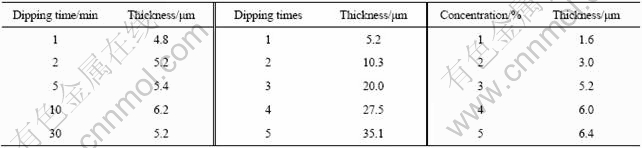

本研究中选择20 mm?10 mm?3 mm的纯镁块作为涂覆基体,研究了浸涂时间、浸涂次数、聚合物浓度对材料表面涂层厚度的影响,得到了表1所列的研究结果。

表1 浸涂时间、浸涂次数和聚合物浓度对涂层厚度的影响

Table 1 Effect of dipping time, dipping times and effect of polymer concentration on coating thickness

由表1可知,浸涂时间对涂层的厚度影响很小,对涂层厚度影响最大的因素是浸涂次数。其中PLGA含量的变化是在保证该物质溶解后溶液流动性仍很好的范围内进行的,可以看出在较小粘度范围内,PLGA含量的变化对涂层厚度改变不明显。因此只要确定聚合物浓度,就可以通过改变浸涂次数来控制涂层的厚度。

虽然本研究得出了浸涂时间、聚合物浓度及浸涂次数对涂层厚度的影响规律,但由于聚乳酸也是一种可降解材料,涂覆聚乳酸的镁植入体内后,其表面上的聚乳酸的降解会使表面涂层变为多孔状,可能会使镁基体发生提前降解,所以还需要深入研究涂层厚度与降解速率之间的关系。

2.3 在模拟体液中的实验

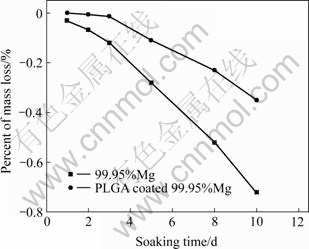

由图5可以看出,PLGA涂覆后的纯镁耐蚀性有明显提高,较未经任何处理的纯镁提高将近1倍。聚合物涂层可以保证纯镁在3 d内基本不发生降解。但作为可降解镁植入材料的表面涂层,要求其在镁植入1周内达到良好的保护作用。因为手术过程会引起人体在手术部位周围的组织受损,受损组织周围会聚集大量巨噬细胞吞噬坏死组织,手术造成的组织破坏需要约1周时间恢复[14],所以镁的表面涂层必须在植入后1周内达到良好的抗腐蚀能力,否则镁植入材料的腐蚀速度会加快,使其提前失效。由于人体环境是十分复杂的,Witte等[15]研究发现镁合金在体外的腐蚀与动物体内腐蚀结果相差4个数量级。所以,虽然在本文中纯镁表面的聚乳酸涂层仅保证纯镁在3 d内基本不发生降解,但考虑到体内环境的复杂性,可以认为涂层已达到基本要求。而且可以通过增加浸涂次数来增加涂层厚度,从而使镁植入材料耐蚀性进一步提高。

图5 样品质量损失随浸泡时间的变化

Fig.5 Variations of mass loss of sample with soaking time during immersed in Hank’s solution

3 结论

1) 采用浸涂法可以在镁的表面制备聚乳酸涂层。在确定浸涂时间及聚合物浓度情况下主要通过改变浸涂次数来控制镁表面的可降解涂层厚度。

2) 镁表面在涂覆聚乳酸前通过偶联剂处理表面可以提高镁与聚乳酸的结合力。

3) 经过聚乳酸处理后的镁,耐蚀性明显提高。

REFERENCES

[1] Staiger M P, Pietak A M, Huadmai J, Dias G. Magnesium and its alloys as orthopedic biomaterials: A review[J]. Biomaterial, 2006, 27: 1728?1734.

[2] 邵美珍. 镁的基础与临川[M]. 成都: 四川科学技术出版社, 1996.

SHAO Mei-zhen. The fundamental and clinical of magnesium[M]. Chengdu: Sichuan Science and Technology Press, 1996.

[3] Cerre C M, Papillard M, Chavassieux P, Voegel J C, Boivin G. Influence of magnesium substitution on a collagen-apatite biomaterial on the production of a calcifying matrix by human osteoblasts[J]. J Biomed Mater Res, 1998, 42(4): 626?633.

[4] Rude R K, Gruber H E, Wei L Y, Frausto A, Mills B G. Magnesium deficiency: Effect on bone and mineral metabolism in the mouse[J]. Calcif Tissue Int, 2003, 72: 32?41.

[5] Zreiqat H, Howlett C R, Zannettino A, Evans P, Schulze-Tanzil G, Knabe C. Mechanisms of magnesium-stimulated adhesion of osteoblastic cells to commonly used orthopaedic implants[J]. J Biomed Mater Res, 2002, 62: 175?184.

[6] 任伊宾, 黄晶晶, 杨 柯, 王 浩, 张炳春, 姚治铭. 纯镁的生物腐蚀研究[J]. 金属学报, 2005, 41: 1228?1232.

REN Yi-bin, HUANG Jing-jing, YANG Ke, WANG Hao, ZHANG Bing-chun, YAO Zhi-ming. Study of bio-corrosion of pure magnesium[J]. Acta Metallurgica Sinica, 2005, 41: 1228

[7] 高家诚, 李龙川, 王 勇, 乔丽英. 表面改性纯镁的细胞毒性和溶血率[J]. 稀有金属材料与工程, 2005, 34: 903?906.

GAO Jia-cheng, LI Long-chuan, WANG Yong, QIAO Li-ying. Biocompatibility of magnesium after surface modification by heat-organic films-treatment[J]. Rare Metal Materials and Engineering, 2005, 34: 903?906.

[8] 牟战旗. 不同模拟体液及pH值变化对人体用金属生物材料耐蚀性能的影响[J]. 中国腐蚀与防护学报, 1998, 18(2): 126?130.

MOU Zhan-qi. Effect of different artificial body fluids and their pH on corrosion of biomedical metallic materialsl[J]. Journal of Chinese Society for Corrosion and Protection, 1998, 18(2): 126?130.

[9] Gristina A G. Biomaterial-centered infection—Microbial adhesion versus tissue integration[J]. Science, 1987, 237: 1588?1595.

[10] Hench L L, Polak J M. Third-generation biomedical materials[J]. Science, 2002, 295: 1014?1017.

[11] Gollwitzer H, Thomas P, Diehl P,Steinhauser E, Summer B, Barnstorf S, Gerdesmeyer L, Mittelmeier W S. Biomechanical and allergological characteristics of a biodegradable poly(D,L-lactic acid) coating for orthopaedic implants[J]. Journal of Orthopaedic Research, 2005, 23: 802?809.

[12] Heublein B, Rohde R, Kaese V, Niemeyer M, Hartung W H. Biocorrosion of magnesium alloys: A new principle in cardiovascular implant technology[J]. Heart, 2003, 89: 651?656.

[13] 王雪明, 李爱菊, 李国丽, 管从胜. 硅烷偶联剂在防腐涂层金属预处理中的应用研究[J]. 材料科学与工程学报, 2005, 23: 146?150.

WANG Xue-ming, LI Ai-ju, LI Guo-li, GUAN Chong-sheng. Studies on the application for SCA in the metal pretreatment of anti-corrosion coatings[J]. Journal of Materials Science & Engineering, 2005, 23: 146?150.

[14] Deeb M, Holmes R E. Tissue response to facial contour augmentation with dense and porous hydroxylapatite in Rhesus monkeys[J]. Oral Maxillofac Surg, 1989, 47: 1282?1289.

[15] Witte F, Fischer J, Nellesen J, Crostack H A, Kaese V, Pisch A, Beckmann F, Windhagen H. In vitro and in vivo corrosion measurements of magnesium alloys[J]. Biomaterials, 2006, 27(7): 1013?1018.

收稿日期:2007-03-30;修订日期:2007-07-13

通讯作者:黄晶晶,博士研究生;电话:024-23971676;E-mail: jjhuang@imr.ac.cn

(编辑 李向群)