基于接触摩擦的少片变截面钢板弹簧的刚度分析

唐应时1,柴 天1,和进军1,苏嘉理1,李恩报2

(1. 湖南大学 汽车车身先进设计制造国家重点实验室,湖南 长沙,410082;

2. 湖南易通汽车配件科技发展有限公司,湖南 长沙,410137)

摘 要:根据每一片变截面钢板弹簧在自由状态下的三维尺寸、曲率半径和自由弧高,利用Unigraphics的二次开发功能,建立每一片钢板弹簧的实体模型。在ANSYS软件中,采用映射单元划分法,建立钢板弹簧的有限元模型,并在钢板弹簧的接触面中应用接触理论添加接触单元,模拟板间摩擦和计算钢板弹簧的刚度。对钢板弹簧试验分析结果表明:刚度仿真计算值和试验测量值基本吻合,相对误差为5.58%,说明该模型可以用于研究考虑钢板之间存在摩擦作用力时的变截面钢板弹簧的受力情况,可用于探讨非线性有限元分析过程中接触刚度系数和接触算法收敛的相互匹配关系,以及分析少片变截面钢板弹簧的刚度。

关键词:少片变截面钢板弹簧;接触单元;有限元;刚度

中图分类号:U463.218 文献标识码:A 文章编号:1672-7207(2009)03-0694-05

Analysis of stiffness of taper leaf spring based on contact friction

TANG Ying-shi1, CHAI Tian1, HE Jin-jun1, SU Jia-li1, LI En-bao2

(1. State Key Laboratory of Advanced Design and Manufacturing for Vehicle Body,

Hunan University, Changsha 410082, China;

2. Hunan Yitong Automobile Parts Science&Technology Development Company Limited, Changsha 410137, China)

Abstract: Parametric model of taper leaf spring was constructed by developing program of Unigraphics. Through inputting the parameters such as dimensions, curvature and arc height, a solid model of each leaf spring was constructed automatically and respectively. Using the solid model, FEM model of the taper leaf spring could be constructed by mapped mesh in the software of ANSYS. The friction between leaves was simulated based on contact theory by adding contact elements to the contact surface of each leaf spring, and setting all kinds of relevant parameters, and then the stiffness of taper leaf spring was calculated. Comparing the differences between test result and simulation results, it is found that the simulated calculation results by the program are in good agreement with the field data, the relative error is 5.58% which proves that these models can be used to study the stress on taper leaf spring in case of frictional force. They can be used to study the matching coefficient of contact stiffness with convergence of contact algorithm in nonlinear FEM analysis. In addition, they can be used to analyze stiffness of taper leaf spring.

Key words: taper leaf spring; contact element; FEM; stiffness

钢板弹簧是一种常见的弹性元件,主要用于汽车的非独立悬架中,它传递垂直载荷和其他的作用力及力矩,并抑制、缓和由冲击载荷引起的振动,保证车辆正常行驶。其中,钢板弹簧的刚度是悬架特性中最主要的参数。目前,钢板弹簧主要有2种类型:一种是等厚度、宽度不变的传统多片钢板弹簧;另一种是等宽度、厚度呈现两端薄、中间厚的钢板弹簧。而少片变截面钢板弹簧是指少片(1~4片)其截面如上所述发生变化的钢板弹簧[1]。弹簧片间的摩擦随着金属材料的研究而越来越受到研究者的关注,材料的表面经证明有大量的摩屑,其形状互不一致,摩屑形状有块状、片状、颗粒状、针状、条状等,而摩屑以颗粒状、针状为主,体积比另外3种形状的摩屑体积大,并且有纤维[2]。目前,国外对钢板弹簧的研究基于有限元数值计算方法,通过建立钢板弹簧的有限元模型,充分考虑结构的大变形和片间的接触状态,来分析钢板弹簧的强度。国内对钢板弹簧的强度分析,大多是借助简化的力学模型,基于材料力学的小挠度梁线弹性理论的基础进行计算,通过把问题抽象成简单的数学、力学模型,在一定假设条件下进行计算[3]。同时,一些研究者利用多刚体动力学理论,研究钢板弹簧动刚度随静载荷、动载荷及激振频率和振幅的关系[4]。随后,还有些研究者则利用ANSYS有限元软件进行接触模拟,分析钢板弹簧的迟滞特性,分析不同摩擦因数对钢板弹簧迟滞特性和阻尼特性的影响[5]。综合考虑国内对钢板弹簧的研究现状,对少片变截面钢板弹簧分析计算时很少考虑钢板弹簧片间摩擦的实际情况,本文作者根据有限元理论,利用ANSYS有限元软件,在对少片变截面钢板弹簧分析时充分考虑钢板弹簧的片间接触摩擦,以实现对钢板弹簧的刚度分析。

1 少片变截面钢板弹簧有限元模型的建立

传统钢板弹簧分析是采用简化力学模型,基于材料力学小挠度梁的线弹性理论。这里利用钢板弹簧 固有特性和固有特性总刚度理论,进行参数化建模[6]。为节省有限元模型在ANSYS软件中的计算时间,以及提高模型的计算精度,有限元分析采用映射法,即利用六面体单元进行单元划分。该六面体单元有8个节点,每个节点具有X, Y, Z 3个方向的平动自由度。把弹性模量设置为2.1×1011 Pa,泊松比为0.3[7]。

少片变截面钢板弹簧的分块情况如图1所示。把已经分割好的实体模型导入到有限元分析软件中。对模型进行单元划分,划分单元时在实体与实体的断开接触面上采用完全一致的网格密度,因为刚刚划分成功的有限元模型被分为很多份,本文采用合并的办法,把这些分块重新连接在一起,这样,就可以把各分块合并为一整体[8]。单元划分情况如图2所示。

图1 少片变截面钢板弹簧的分块

Fig.1 Block of taper leaf spring

图2 少片变截面钢板弹簧单元划分

Fig.2 Division of taper leaf spring unit

2 少片变截面钢板弹簧的有限元方程和接触定义

2.1 一般的有限元方程

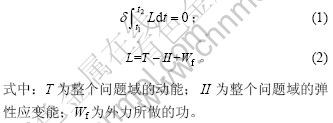

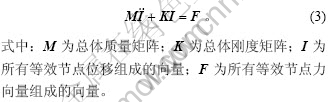

根据哈密尔顿原理,在所有可能的随时间变化的位移中,最精确的解是使拉格朗日泛函L取得最小 值[9],即

根据位移变分的任意性,并经过方程的组装,得出整体有限元系统方程:

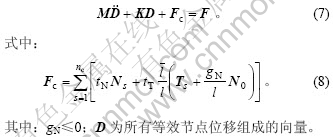

2.2 添加摩擦接触单元后的有限元方程

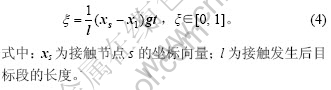

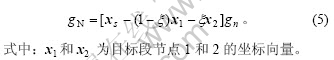

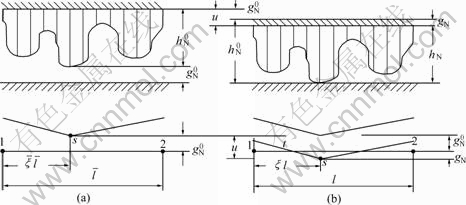

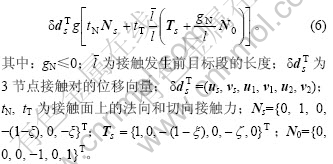

为了模拟片与片之间的接触摩擦问题,分别在簧片接触面上加一层摩擦接触单元,其节点固定在相接触实体的节点上。对整体而言,增加摩擦单元后,整体结构的总节点数不增加,总体自由度数也不增加,但是单元总数增加。为了简化接触摩擦问题的描述,下面将2个面接触的问题简化为由3个节点组成的接触对。如图3所示,接触对由接触面和目标面组成,分别简化为1个接触节点s和由节点1、节点2组成的目标段[10-11]。n和t为目标段的法向和切向的单位向量,定义自然坐标系ξ,则

首先定义接触节点s和目标段的距离gN:

(a) 接触前;(b) 接触后

图3 接触对接触原理

Fig.3 Contact principles of contact surface

根据各节点的虚位移,可得1个接触对的虚功方程:

假设接触面上参加接触的节点数为nc,添加摩擦接触单元后的有限元整体方程为[12]:

2.3 少片变截面钢板弹簧的接触定义

图4所示为隐藏掉实体单元的接触面单元。整个钢板弹簧总成共定义了3个接触对,每一对包含1个目标面和1个接触面,定义凹面为目标面,凸面为接触面。为了使少片变截面钢板弹簧之间产生接触,直接在接触面上添加接触单元,使接触面承受接触力。由于其有限元分析计算属于状态非线性有限元分析,在穿透量达到下极限时,接触刚度应定义得较小。在接触刚度的定义中,接触刚度定义太大会导致结果不收敛,太小则会降低计算精度。为此,采用下面方法:先选取较小的刚度系数进行试运算,如果程序提示需要更多的迭代步来完成残余力和位移的收敛,表明需要降低刚度系数;当得到收敛的计算结果时,若程序提示渗透过多,则需要加大刚度系数。通过反复调试,以满足计算精度的要求[13]。经调试以后,接触刚度系数选取为0.001。

图4 接触面单元

Fig.4 Contact surface element

3 少片变截面钢板弹簧有限元模型的仿真刚度计算

3.1 少片变截面钢板弹簧有限元模型的仿真装配

由于每片钢板弹簧有限元模型之间是离散的,则在钢板弹簧仿真中,需要把各簧片装配成一体。为了提高仿真的正确性,本文采用下面的模拟方法:在第1片簧片与平直夹板接触部位设置位移约束为零,然后,测量所有簧片之间的间隙,把这些间隙加起来以位移约束的形式施加在第4片簧片与平直夹板接触的部位,以模拟簧片的夹紧过程。

3.2 少片变截面钢板弹簧有限元模型的仿真计算

根据GB/T 19844—2005,仿真过程至少要分成8个载荷步:第1个是弹簧的装配;第2~8个载荷步就是把加载过程分解为7次,逐级加载。

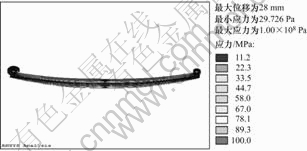

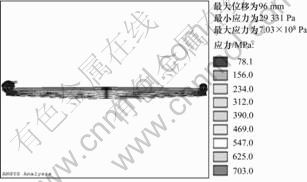

为了使运算能够顺利进行,在Newton-Raphson options的设置上,先选择Full,然后,选择UNSYM,以提高收敛速度[14]。在求解器选择方面,选择了SPARSE SOLVER。该求解器可被应用于非线性或线性分析,特别适用于在非线性分析中经常遇到矩阵不确定的情况。同时,还适用于在接触分析中,接触状态会改变网格布局的情况。图5和图6所示分别为第1次和第8次加载的应力云图。

图5 第1次加载应力云图

Fig.5 The first loading stress nephogram

图6 第8次加载应力云图

Fig.6 The eighth loading stress nephogram

图5和图6所示为加载应力云图。仿真共分为8次逐级加载,图中只给出第1次加载和第8次加载,先从装配开始,再从空载一直到静载的1.5倍。可以看到,随着载荷的增加,最大应力也在增加。最大应力主要出现在第1、第4片簧片与平直夹板的接触处附近。当负载为静载的1.5倍时,模型的最大应力为703 MPa,小于材料的许用应力,说明少片变截面钢板弹簧有限元模型符合强度要求。

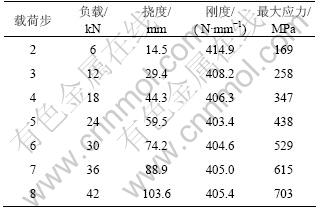

钢板弹簧仿真运算结果如表1所示。可以看出,在加载过程中,钢板弹簧的负载和挠度基本上是线性变化的,而弹簧的静态刚度没有发生明显变化,符合该型号钢板弹簧的设计要求(390±30) N/mm。7个载荷步的刚度平均值为406.8 N/mm。

表1 钢板弹簧的负载、挠度、静态刚度和最大应力

Table 1 Load, deflection, static stiffness and maximum stress of taper leaf spring

4 少片变截面钢板弹簧的试验分析

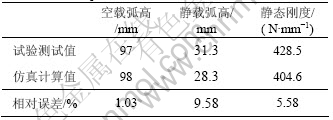

在进行弹簧特性试验时,用夹紧机构对钢板弹簧的卷耳进行夹紧支承。卷耳以销轴支承在装有滚轮的滑车上,以验证载荷缓慢、连续地对弹簧加载、卸载,同时,记录载荷和弹簧的变形量[15]。其试验结果如表2所示。

表2 仿真结果与试验结果的对比

Table 2 Comparison of simulation results with test results

从表2可以看到,仿真计算值和试验测试值在空载弧高、静载弧高和静态刚度的相对误差分别为1.03%,9.58%和5.58%。三者的相对误差主要是由仿真中材料设置的是各向同性材料,而试验测试中使用的材料由于受到热处理、喷丸等工艺处理后,微观上金属晶体受到相互挤压并发生变形,使得材料性能体现为各向异性,从而影响了仿真计算值与试验测试值的一致性。另外,由于静态刚度和静载弧高都直接与钢板弹簧的加载载荷相关,而材料的各向异性性能对材料受力变化影响比较大,所以,静载弧高和静态刚度的相对误差比空载弧高的相对误差偏大。同时,因为弹簧的片内阻尼是不可忽略的,实际上它们通过热量的方式散失在空气中,而仿真计算中并没有考虑这一点,这样就加大了静载弧高的相对误差,使得静载弧高的相对误差在三者之中为最大。

5 结 论

a. 利用UG的二次开发功能进行参数化建模。在建立有限元模型时,通过实体模型的预先分割,简化映射单元的划分,节约对有限元ANSYS软件中的分析计算时间,也为建立有限元模型提供便利。

b. 应用接触理论方法,在有限元模型中添加接触单元,通过设定各种接触参数,来模拟钢板弹簧的片间摩擦,以计算少片变截面钢板弹簧的刚度。

c. 通过对钢板弹簧总成进行弹簧刚度试验,仿真计算值与试验测量值相对误差仅为5.58%,充分证实基于接触摩擦的少片变截面钢板弹簧有限元仿真计算的可信性。

参考文献:

[1] 林小瑛. 少片不等长变截面钢板弹簧的优化设计[J]. 福州大学学报, 2001, 29(1): 56-59.

LIN Xiao-ying. An optimum design of the few different lengths of taper leaf spring[J]. Journal of Fuzhou University, 2001, 29(1): 56-59.

[2] 肖 鹏, 付美英, 熊 翔. 刹车速度对RMI-C/C-SiC复合材料摩擦磨损行为的影响[J]. 中南大学学报: 自然科学版, 2007, 38(4): 602-607.

XIAO Peng, FU Mei-ying, XIONG Xiang. Effect of sliding speed on friction and wear behaviors of RMI-C/C-SiC composites[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 602-607.

[3] 秦志敏, 潘宇臣. 变截面钢板弹簧的设计计算[J]. 汽车工程, 1995, 17(2): 108-112.

QIN Zhi-min, PAN Yu-chen. Design and calculation of the taper-leaf spring[J]. Automotive Engineering, 1995, 17(2): 108-112.

[4] 王其东, 方锡邦, 钱立军, 等. 基于虚拟样机技术的汽车钢板弹簧设计及分析研究[J]. 机械工程学报, 2001, 37(12): 63-66.

WANG Qi-dong, FANG Xi-bang, QIAN Li-jun, et al. Research on the analysis and synthesis of automobile leaf spring based on virtue prototypes technique[J]. Chinese Journal of Mechanical Engineering, 2001, 37(12): 63-66.

[5] 丁能根, 马建军. 钢板弹簧迟滞特性的有限元分析[J]. 汽车工程, 2003, 25(1): 12-14.

DING Neng-gen, MA Jian-jun. Finite element analysis on the hysteresis behavior of leaf springs[J]. Automotive Engineering, 2003, 25(1): 12-14.

[6] 唐应时, 占良胜, 方其让, 等. 基于动态仿真的副变速器箱体有限元分析[J]. 中南大学学报: 自然科学版, 2006, 37(4): 769-774.

TANG Ying-shi, ZHAN Liang-sheng, FANG Qi-rang, et al. Finite element analysis of sub-transmission case based on dynamic analysis[J]. Journal of Central South University: Natural Science, 2006, 37(4): 769-774.

[7] 唐应时, 李立斌, 何友朗, 等. 基于动力学仿真的后桥壳改进设计计算[J]. 湖南大学学报: 自然科学版, 2006, 33(4): 42-45.

TANG Ying-shi, LI Li-bing, HE You-lang, et al. A design for improving the vehicle rear axle housing based on dynamic simulation[J]. Journal of Hunan University: Natural Science, 2006, 33(4): 42-45.

[8] 张建乔, 刘永红, 吕广忠. 基于参数化模型特征的有限元网格划分方法研究[J]. 制造业自动化, 2005, 27(9): 33-35.

ZHANG Jian-qiao, LIU Yong-hong, L? Guang-zhong. The FEM mesh generation method based on characteristic manufacturing automation[J]. Manufacturing Automation, 2005, 27(9): 33-35.

[9] 刘桂荣. 有限元法实用教程[M]. 长沙: 湖南大学出版社, 2004: 110-130.

LIU Gui-rong. The finite element method: A practical course[M]. Changsha: Hunan University Press, 2004: 110-130.

[10] Wriggers, VuVan, Stein. Finite element formulation of large deformation impact-contact problems with friction[J]. Computers and Structures, 1990, 37(3): 319-331.

[11] Osipenko M A, Nyashin Y I, Rudakov R N. A contact problem in the theory of leaf spring bending[J]. International Journal of Solids and Structures, 2003, 40(12): 3129-3136.

[12] Wriggers P. Computational contact mechanics[M]. John Wiley & Sons, Ltd, 2002: 6-13.

[13] 谷安涛. 应用CAE 技术进行钢板弹簧精确设计[J]. 汽车工程, 2002, 24(1): 73-75.

GU An-tao. Precise design for laminated spring using CAE[J]. Automotive Engineers, 2002, 24(1): 73-75.

[14] Moaveni S. Theory and application with ANSYS[M]. Publishing House of Electronics Industry, 2003: 312-324.

[15] 苏嘉理. 少片变截面钢板弹簧计算机模型建立及其性能研究[D]. 长沙: 湖南大学机械与运载工程学院, 2007: 26-33.

SHU Jia-li. Computational modeling of taper leaf spring and its performance research[D]. Changsha: College of Mechanical and Vehicle Engineering, Hunan University, 2007: 26-33.

收稿日期:2008-06-15;修回日期:2008-09-20

基金项目:“985工程”汽车先进设计制造技术科研创新平台资助项目

通信作者:唐应时(1946-),男,湖南湘乡人,教授,从事汽车底盘结构设计与优化研究;电话:0731-8821841;E-mail: ystang_hnu@126.com