从废旧高温合金中浸出镍钴的实验研究

行卫东1,范兴祥1, 2, 3,董海刚2, 3,吴跃东1,赵家春2, 3,安中庆2,李博捷1,童伟锋1,吴晓峰1

(1. 昆明贵金属研究所,云南 昆明,650106;

2. 贵研铂业股份有限公司,云南 昆明,650106;

3. 稀贵金属综合利用新技术国家重点实验室,云南 昆明,650106)

摘要:在比较国内外废旧高温合金的处理工艺的基础上,针对废旧高温合金的物相组成,提出“雾化喷粉-硫酸浸出镍钴”的工艺,重点考察并讨论在镍钴浸出过程中硫酸质量分数、温度、浸出时间、搅拌速度和合金粒度等因素对废旧高温合金中镍钴浸出率的影响。试验确定了从废旧高温合金中浸出镍钴的工艺优化条件。试验结果表明:当硫酸质量分数为40%,浸出温度为85 ℃,浸出时间为5 h时,镍浸出率为96.68%,钴浸出率为96.63%,浸出渣中镍钴的质量分数分别为6.77%和0.96%,含镍和钴的浸出液可作为加工镍和钴产品的原料。

关键词:废旧高温合金;酸浸;镍;钴;浸出率

中图分类号:TM 344.1 文献标志码:A 文章编号:1672-7207(2014)02-0361-06

Experimental study on leaching of nickel and cobalt from waste superalloys

XING Weidong1, FAN Xingxiang1, 2, 3, DONG Haigang2, 3, WU Yuedong1, ZHAO Jiachun2, 3,

AN Zhongqing2, LI Bojie1, TONG Weifeng1, WU Xiaofeng1

(1. Kunming Institute of Precious Metals, Kunming 650106, China;

2. Sino-platinum Metals Co., Ltd., Kunming 650106, China;

3. State Key Laboratory of Advanced Technology of Comprehensive Utilization of Platinum Metals, Kunming 650106, China)

Abstract: By comparing with the processing technologies of superalloys between domestic and abroad, the atomized spray-sulfuric acid leaching nickel and cobalt technology was proposed considering the composition of waste superalloys. The leaching parts of the process was studied. The effects of sulfuric acid content, temperature leaching time, stirring speed and size of superalloys on leaching of Ni and Co were mainly studied. The optimum conditions of the process of leaching Ni and Co from waste superalloys were determined through pilot study. The results show that at the optimum conditions of sulfuric acid content of 40%, temperature of 85 ℃, leaching time of 5 h, the leaching rates are 96.68% for nickel, and 96.63% for cobalt, in leaching residues, the mass fractions of nickel and cobalt are left 6.77% and 0.96% respectively. The leaching solution containing nickel and cobalt can produce nickel and cobalt products.

Key words: waste superalloys; acid leaching; nickel; cobalt; leaching rate

镍和钴具有优良的物理化学性能和机械性能,具有耐高温、耐腐蚀、高强度和强磁性等特点,在航空、航天以及其他相关工业部门的高温合金等新材料[1]生产中起着关键性作用。随着我国航空航天事业不断发展,对高温合金的需求越来越大,其中对镍和钴的需求日益增加,而镍和钴矿产资源的日益匮乏,因而对废旧高温合金中镍和钴资源的二次回收显得尤为重要,但是,在我国高温合金料的回收循环再利用却还处于一个较低水平,导致很多优质资源浪费[2]。目前提取镍和钴的主要方法有:在硫酸、盐酸、硝酸等体系下采用常压酸浸和高压酸浸或氨法加压浸出;氯气浸出镍钴等[3-12],还有采用硫化物沉淀法[13-14];电解沉积法[15-16]等湿法工艺;采用碳热还原[17];酸焙烧后浸出[18]等火法或火法与湿法相结合的工艺。这些工艺主要是针对各种原矿、废旧离子电池、废旧催化剂等原料,用来处理废旧高温合金物料的较少。本文针对废旧高温合金物料,提出熔炼—雾化喷粉—常压硫酸浸出的工艺,重点研究影响镍和钴浸出的各种因素,旨在确定最佳的工艺条件,为废旧高温合金综合利用镍钴提供参考。

1 试验

1.1 试验物料

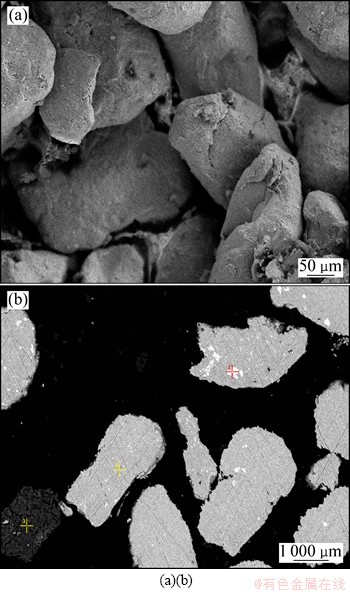

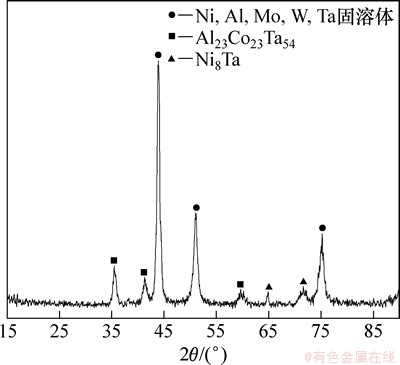

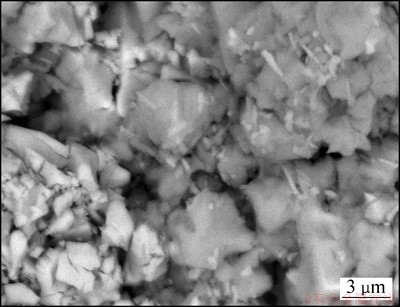

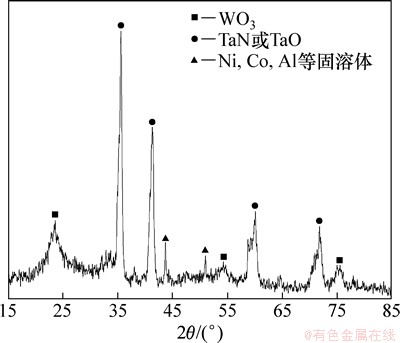

废旧高温合金物料的主要组成元素如表1所示,采用扫描电镜对废旧高温合金物料进行表征,结果见图1。从图1(a)可看出:废旧高温合金物料的形貌不规整,颗粒粒度不一,从图1(b)可以看出:Ta,Nb和W等被镍钴等包覆在内部。采用X线衍射对废旧高温合金物料进一步表征,结果见图2。从图2可以看出:该废旧高温合金的主要元素为Co,W,Mo,Ta和Al等与Ni形成固溶体。

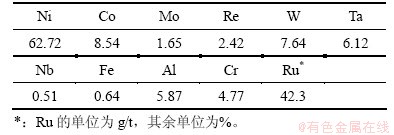

表1 废旧高温合金物料元素分析结果(质量分数)

Table 1 Chemical compositions of waste superalloys %

1.2 试验设备

试验中选用的设备有:全固态超音频感应加热设备(成都市金牛区华安达高中频设备厂制造,型号为CYP-40);冷雾化制粉设备(贵研铂业股份有限公司制造,型号为LWH-6);振动磨样机(武汉探矿机械厂制造,型号为XZM-100);多功能数显电动搅拌器(巩义市予华仪器有限责任公司制造,型号为DW-3);电热套(巩义市予华仪器有限责任公司制造,型号为118305);双配套循环水式多用真空泵(巩义市予华仪器有限责任公司制造,型号为SHZ-2000);以及滤纸、洗瓶、玻璃棒、pH试纸、50 mL容量瓶、温度计烧杯、量筒。

图1 废旧高温合金粉末的SEM照片

Fig. 1 SEM images of waste superalloys

图2 废旧高温合金XRD衍射分析结果

Fig. 2 XRD pattern of waste superalloys

分析检测设备:X线衍射仪(XRD)(日本理学公司制造,型号为D/max-2200);电子扫描显微镜(SEM)(日立高新技术(上海)国际贸易有限公司制造,型号为S-3400N);原子吸收光谱仪(日立高新技术(上海)国际贸易有限公司制造,型号为Z-2300);X荧光光谱仪(赛默飞世尔科技制造,型号为ARL3460)。

1.3 试验方法

1.3.1 试验工艺流程

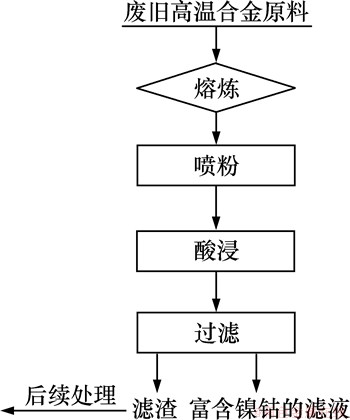

废旧高温合金浸出镍、钴工艺流程如图3所示。

图3 废旧高温合金浸出镍和钴的工艺流程图

Fig. 3 Flow sheet of leaching Ni and Co from waste superalloys

1.3.2 试验方法

试验在900 mL烧杯中进行,加入稀硫酸,加热,配置可变速式搅拌器,称取一定量的废旧合金物料,待试验温度达到后,并伴随机械搅拌的状态下,加入物料,反应结束后过滤,洗涤,滤渣烘干、称质量待检测用,浸出液量体积,并分析浸出渣和浸出液中Ni和Co的含量,计算出镍和钴的浸出率。

1.3.3 试验原理

根据废旧合金物料的成分以及镍、钴、铁都以金属的状态存在,采用硫酸进行浸出,浸出过程中,金属镍、钴、铁、铝、铬与硫酸反应生成硫酸盐,并产生氢气,浸出过程中化学反应主要有以下反应:

Ni+H2SO4=NiSO4+H2↑ (1)

Co+H2SO4=CoSO4+H2↑ (2)

Fe+H2SO4=FeSO4+H2↑ (3)

2Al+3H2SO4=Al2(SO4)3+3H2↑ (4)

Cr+H2SO4=CrSO4+H2↑ (5)

2 结果讨论

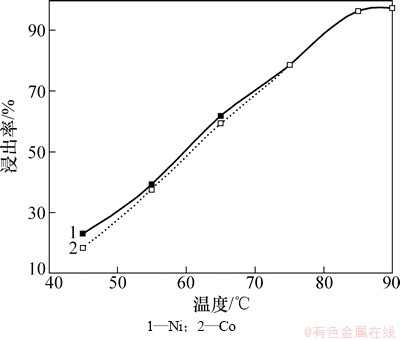

2.1 酸浸温度对浸出率的影响

图4所示为酸浸温度对镍钴浸出率的影响。试验条件如下:硫酸质量分数为40%,硫酸加热到试验温度,加入一定量粒径为120~180 μm物料,反应时间为5 h,搅拌速度为250 r/min。由图4可看出:酸浸温度对浸出率的影响非常明显,随着温度的升高,浸出率增长幅度非常明显。这是因为随着温度的升高,硫酸的活度不断增强,分子运动加快,活化分子数增多,有效碰撞次数增多,有效提高了化学反应速率。但由于硫酸加热到85 ℃时,镍钴浸出率已经达到96%以上,再继续加热,镍钴浸出率虽然还在上升,但上升比较缓慢,能耗会相应增加,所以,为减少能耗,选择85 ℃为最佳实验温度。

图4 酸浸温度对镍和钴浸出率的影响

Fig. 4 Effect of temperature on leaching rate of nickel and cobalt

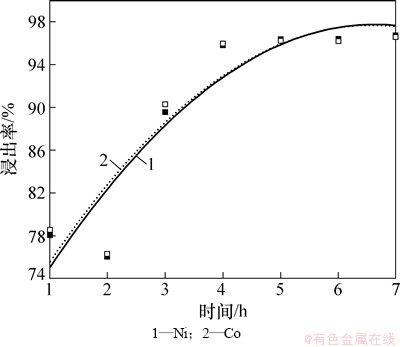

2.2 浸出时间对浸出率的影响

在反应温度为85 ℃,硫酸质量分数为40%下,称取一定量的120~180 μm物料,搅拌速度为250 r/min时考察浸出时间对镍钴浸出率的影响,结果如图5所示。由图5可以看出:镍钴的浸出率在反应初期增长幅度表现尤为明显,延长时间能有效提高物料与硫酸接触的时间,达到充分反应;当浸出时间达到5 h时,镍浸出率达到96.68%,钴浸出率达到96.63%,之后再延长时间,镍钴浸出率增长相对缓慢,镍钴浸出过程基本完成,确定浸出时间为5 h。

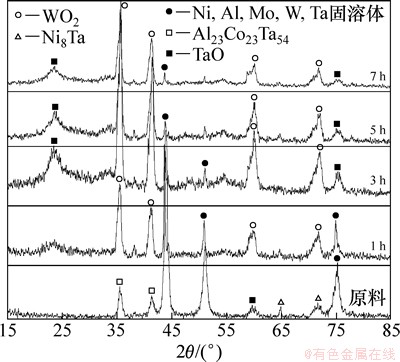

不同浸出时间时浸出渣与原料的XRD对比分析结果见图6。从图6可以明显看出:随着浸出时间的延长,镍的固溶体(含有Co和Al等)的峰不断减弱,从而可知物料中Ni和Co的含量不断减少,达到了浸出的效果。同时其他元素诸如Ta、W的峰则相对增强,说明在渣中其含量相对升高,并有些新的物相或固溶体生成。

图5 浸出时间对镍和钴浸出率的影响

Fig. 5 Effect of leaching time on leaching rate of nickel and cobalt

图6 不同浸出时间时浸出渣与原料的XRD对比分析图

Fig. 6 XRD patterns of material and leaching residue at different time

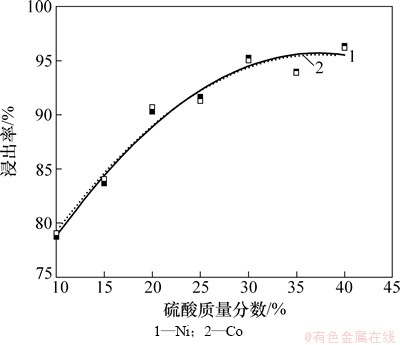

2.3 硫酸初始质量分数对浸出率的影响

固定酸浸温度为85 ℃,浸出时间为5 h,搅拌速度为250 r/min时,称取一定量粒径为120~180 μm的物料,考察硫酸质量分数对镍钴浸出率的影响,结果如图7所示。由图7可知:硫酸质量分数越高越有利于镍钴的浸出,因为硫酸质量分数升高,单位体积中与物料颗粒反应的硫酸的活化分子增多,有效提高了反应速率。随着硫酸质量分数不断增加,当质量分数达到40%时,浸出率达到96%以上,浸出率基本趋于平缓,变化不明显,再考虑到硫酸质量分数越高对设备腐蚀越严重,能耗也越来越大,所以,选择浓度40%为最佳试验浓度。

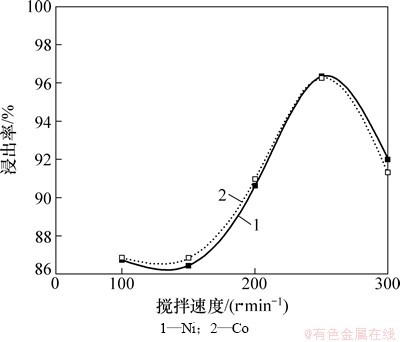

2.4 搅拌速度对浸出率的影响

图8所示为固定硫酸质量分数为40%,浸出时间为5 h,酸浸温度为85 ℃,称取一定量粒径为120~180 μm废旧合金物料,在不同搅拌速度的试验条件下,浸出镍钴的试验结果。从图8可以看出:随着搅拌速度不断调高,镍钴的浸出率增长幅度非常明显,因为加强搅拌能减小扩散层的厚度,可以加快硫酸溶液与物料颗粒的传质速度;当搅拌速度达到250 r/min时,镍钴浸出率达到最高值,之后再加大搅拌速度,浸出率反而下降,由于搅拌速度过大,反而使物料贴附在烧杯壁,随着溶液打旋,不能得到充分搅拌,因而镍钴浸出率反而减小,所以,选择搅拌速度250 r/min为最优值。

图7 硫酸初始质量分数对镍和钴浸出率的影响

Fig. 7 Effect of sulfuric acid concentration on leaching rate of nickel and cobalt

图8 搅拌速度对镍和钴浸出率的影响

Fig. 8 Effect of stirring speed on leaching rate of nickel and cobalt

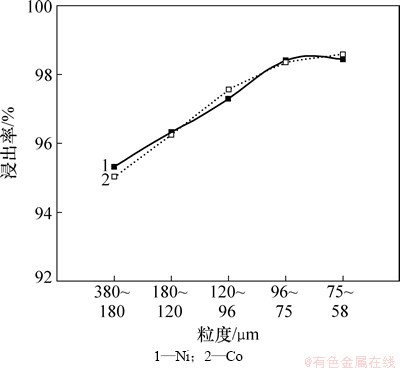

2.5 合金粒度对浸出率的影响

在固定酸浸温度为85 ℃,硫酸质量分数为40%,浸出时间为5 h,称取一定量粒径为120~180 μm的废旧合金物料,搅拌速度试验条件下,考察不同的粒度对镍钴浸出的影响,结果见图9。

图9 粒度对镍和钴浸出率的影响

Fig. 9 Effect of size on leaching rate of nickel and cobalt

从图9可以看出:随着粒度不断减小,镍钴的浸出率不断提高,粒度达到75~96 μm时,镍钴浸出率就可以达到98%以上,再减小物料粒度,在反应过程中物料会发生团聚现象,浸出率已经趋于平缓,增长幅度不明显。所以,从实际试验考虑,制备粒度为75~96 μm的物料,成本会有所增加,设备损坏也有所提高,而制备120~180 μm相对容易,而已镍钴浸出率已经达到96%以上,达到实际生产的需求,所以选择120~180 μm为最优物料粒度。

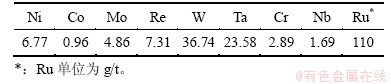

3 综合实验

通过实验,确定了在硫酸浸出温度为85 ℃,浸出质量分数为40%,浸出时间为5 h,搅拌速度为250 r/min,物料粒度为120~180 μm的实验条件下,镍和钴的浸出率分别为96.68%和96.63%,浸出渣中镍的钴的质量分数分别为6.77%和0.96%。浸出渣中主要元素化学分析结果如表2。

结合图10与图1(a)比较可以看出:颗粒明显变得细小,镍钴等的包覆层已经消失,浸出渣中W和Ta等显露出来,成为主要成分。从图11也可以看出:镍钴等固溶体的峰明显减弱,说明硫酸浸出之后物料中的镍、钴、铝等主要元素已经基本完全浸出,W和Ta等元素的峰明显突出,使W和Ta达到了富集的效果,为后续回收W和Ta等元素提供了良好的准备。

表2 浸出渣中主要元素分析结果(质量分数)

Table 2 Chemical compositions of leaching residues %

图10 浸出渣的SEM形貌

Fig. 10 SEM graph of leaching residues

图11 浸出渣的XRD分析结果

Fig. 11 XRD pattern of leaching residues

4 结论

(1) 通过对于废旧高温合金采用硫酸浸出进行研究,得到了合理的浸出工艺参数:浸出温度为85 ℃,浸出质量分数为40%,浸出时间为5 h,搅拌速度为250 r/min,物料粒度为120~180 μm。在此实验条件下,镍浸出率能达到96.68%,钴浸出率达到96.63%。

(2) 镍钴基本能浸出完全,说明提出的工艺是可行的,对废旧高温合金综合回收镍和钴提供了一定的借鉴作用。

参考文献:

[1] 李爱兰, 曾變榕, 曹腊梅. 航空发动机高温材料的研究现状[J]. 材料导报, 2003, 17(2): 26-28.

LI Ailan, ZENG Xierong, CAO Lamei. Current status of reseach on high temperatature metarials for advanced aircraft engines[J]. Materials Review, 2003, 17(2): 26-28.

[2] 苏庆伦, 史战旺, John Hunsaker. 我国高温合金循环利用的现状与思考[J]. 有色金属再生与利用, 2006(4): 19-20.

SU Qinglun, SHI Zhanwang, John Hunsaker. Status and consideration of recycling of superalloys in our country[J]. Non-ferrous Metals Recycling and Utilization, 2006(4): 19-20.

[3] SHEN Yongfeng, XUE Wenying, NIU Wenyong. Recovery of Co(Ⅱ)and Ni(Ⅱ) from hydrochloric acid solution of alloy scrap[J]. Transaction of Nonferrous Metals Society of China, 2008, 18: 1262-1268.

[4] LI Jinhui, LI Xinhai, HU Qiyang. Study of extraction and purification of Ni, Co and Mn from spent battery material[J]. Hydrometallurgy, 2009, 99: 7-12.

[5] van Tonder G J, Cilliers P J. Cobalt and nickel removal from zinc or impure electrolyte by molecular recognition technology(MRT)-pilot plant demonstration[J]. The Journal of the South African Institute of Ming an Metalleurgy, 2002(2): 11-18.

[6] 喻正军, 冯其明, 欧乐明, 等, 常压下硫酸体系中钴冰铜的浸出[J]. 中南大学学报(自然科学版), 2006, 37(4): 675-679.

YU Zhengjun, FENG Qiming, OU Leming. Leaching of cobalt bearing metallic matte in sulfhuric acid at normal pressure[J]. Journal of Central South University (Science and Technology), 2006, 37(4): 675-679.

[7] Rane M V, Bafna V H, Sadanandam R. Recovery of high purity cobalt from spent ammonia cracker catalyst[J]. Hydrometallurgy, 2005, 77: 247-251.

[8] 郑雅杰, 滕浩, 闫海泉. 硝酸氧化浸出难冶炼高砷钴矿[J]. 中国有色金属学报, 2010, 20(7): 1418-1423.

ZHENG Yajie, TENG Hao, YAN Haiquan. Nitric acid oxidation leaching og cobalt from refractory high-arenic cobalt ores[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(7): 1418-1423.

[9] 康南京. 我国镍钴冶炼应用热压浸出技术的进展[J]. 中国有色冶金, 1995, 24(2): 1-7.

KANG Nanjing. Development of application of hot pressure leaching technology in recovery of nickel and cobalt in China[J]. China Nonferrous Metallurgy, 1995, 24(2): 1-7.

[10] 刘建华, 张焕然, 王瑞祥. 氨法加压浸出钴铜氧化矿工艺[J]. 稀有金属, 2012, 36(1): 149-153.

LIU Jianhua, ZHANG Huanran, WANG Ruixiang. Process of ammonium leaching oxidation ore of cobalt and copper at high pressure[J]. Chinese Journal of Rare Metals, 2012, 36(1): 149-153.

[11] Shen Y F, Xue W Y, Li W. Selective recovery of nickel and cobalt from cobalt-enriched Ni-Cu matte by two-stage counter-current leaching[J]. Separation and Purification Technology, 2007, 60: 113-119.

[12] 侯小川, 肖连生, 高从堦. 从废高温镍钴合金中浸出镍和钴的试验研究[J]. 湿法冶金, 2009, 28(3): 164-169.

HOU Xiaochuan, XIAO Liansheng, GAO Congjie. Experimental study on leaching of nickel and cobalt from waste high-temperature Ni-Co alloys[J]. Hydrrometallurgy of China, 2009, 28(3): 164-169.

[13] 周雍茂, 胡宝磊. 从钴冰镍浸出液中回收镍钴[J]. 有色金属(冶炼部分), 2012, 6: 11-13.

ZHOU Yongmao, HU Baolei. Nickel and cobalt recovered from cobalt-nickel matte leaching lixivium[J]. Nonferrous Metals (Extractive Metallurgy), 2012, 6: 11-13.

[14] XU Yanbin, XIE Yanting, LIU Junshen. Enrichment of valuable metals from the sulfuric acid leach liquors of nickeliferous oxide ores[J]. Hydrometallurgy, 2009, 95(1/2): 28-32.

[15] Pradhan N, Singh P, Tripathy B C. Electrowining of cobalt from acidic sulphate solutions-effect of chloride ion[J]. Minerals Engineering, 2001, 14(7): 775-783.

[16] 张外平. 电溶法处理低钴硬质合金废料的研究[J]. 硬质合金, 2006, 23(2): 107-109.

ZHANG Waiping. Study on the processing of low-co cemented carbide scraps by electrochemical method[J]. Cenmented Carbide, 2006, 23(2): 107-109.

[17] Jones R T, Denton G M, Reynolds Q G. Recovery of cobalt from slag in a DC arc furnace at chambishi, zambia[J]. The Journal of the South African Institute of Mining and Metallurgy, 2002(1/2): 5-10.

[18] Arslan C, Arslan F. Recvery of copper,cobalt and zinc from copper smelter an converter slags[J]. Hydrometallurgy, 2002, 67(1/2/3): 1-7.

(编辑 何运斌)

收稿日期:2013-02-26;修回日期:2013-04-26

基金项目:国家高技术研究发展计划(“863”计划)项目(2012AA063204)

通信作者:范兴祥(1974-),男,副研究员,硕士生导师,从事有色金属冶金研究;电话:0871-8329545;E-mail:fanxingxiang@tom.com