文章编号:1004-0609(2012)10-2818-07

W-Mo-Ni-Fe合金的微波烧结

周承商1,易健宏1, 2,张浩泽1

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083;

2. 昆明理工大学 材料科学与工程学院,昆明 650093)

摘 要:研究微波烧结88W-5Mo-4.9Ni-2.1Fe和78W-15Mo-4.9Ni-2.1Fe两种W基合金,并与常规烧结该合金的性能进行比较。通过扫描电镜观察材料的显微组织,利用EDS能谱分析W晶粒和合金粘接相的成分,采用XRD分析样品的物相组成。结果表明:在1 480 ℃微波烧结5 min条件下,88W和78W合金的密度分别为16.70 g/cm3和15.55 g/cm3,抗拉强度分别达到1 175 MPa和1 065 MPa,伸长率分别为3.0%和6.9%,硬度值分别达40.3 HRC和32.5 HRC,其力学性能均超过常规烧结合金。微波烧结合金晶粒细小均匀,常规烧结78W合金组织中有中间相组织存在,导致其性能恶化,而微波烧结78W合金组织中未发现该中间相存在。

关键词:W-Mo-Ni-Fe合金;微波烧结;力学性能;显微组织

中图分类号:TF 125.2;TG 146.4 文献标志码:A

Microwave sintering of W-Mo-Ni-Fe alloys

ZHOU Cheng-shang1, YI Jian-hong1, 2, ZHANG Hao-ze1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Kunming University of Science and Technology,

Kunming 650093, China)

Abstract: 88W-5Mo-4.9Ni-2.1Fe and 78W-15Mo-4.9Ni-2.1Fe alloys were microwave sintered, and their properties were compared with conventional sintered alloys. The microstructure of alloys was analyzed by scan electronic microscopy. The element contents of W grains and matrix was characterized by EDS and the phase composition was determined by XRD. The results show that the 88W alloy has density of 16.70 g/cm3, tensile strength of 1 175 MPa, elongation of 3.0% and hardness of 40.3 HRC, the 78W alloy has density of 15.55 g/cm3, tensile strength of 1 065 MPa, elongation of 6.9% and hardness of 32.5 HRC after microwave sintering at 1 480 ℃ for 5 min. The properties of microwave sintered alloys excel conventional sintering. The microwave sintering results in a finer microstructure. The existence of an intermetallic phase in conventional sintered 78W alloys leads to the properties deteriorating. However, there is no intermetallic phase in the microwave sintered 78W alloys.

Key words: W-Mo-Ni-Fe alloys; microwave sintering; mechanical properties; microstructure

基金项目:湖南省研究生科研创新项目资助(CX2010B045)

收稿日期:2011-07-04;修订日期:2012-11-18

通信作者:易健宏,教授,博士;电话:0731-88876420;E-mail: yijianhong2007@sohu.com

钨基高密度合金是一类由硬质相W颗粒分布于粘结相Ni-M-W(M为其它金属元素)固溶体中的两相复合材料。该合金综合了金属W的高密度、高强度和粘结相的优良塑性,因而,它具有一系列优异物理、化学和力学性能,在尖端科学领域、国防工业和民用工业都有着广泛的应用[1]。然而,飞速发展的新技术对高密度合金性能的要求越来越苛刻。为满足目前以及将来工作条件对钨基高密度合金日益严格的要求,迫切需要不断地提高合金整体性能,使其拥有细小均匀的显微组织,既具有较高的密度、强度和断裂韧性,又保持一定的延展性。

现有的细化显微组织和强化合金的方法中,高密度合金的变形加工被认为是一种有效方法[1]。变形处理后的合金,拉伸强度可提高至1 500 MPa以上。但是,该方法工序复杂,大大提高了成本。因此,在过去的20年中,高密度合金的强韧化研究主要集中在如下3个方面。第一种方法是粉末改性和细化[2],如采用机械合金化(Mechanical alloying)[3]、喷雾干燥(Spraying drying)[4]等方法,可以制备纳米级的粉末。研究发现,纳米粉末通过固相烧结可以获得全致密的合金,但是由于纳米粉末的活性极高,在液相烧结温度下组织粗化非常明显。第二种方法是合金强 化[2],主要包括添加Co和Mn元素活化烧结并降低粘接相熔点;添加稀土氧化物及难熔碳化物的第三相强化、添加Al、Ti元素的沉淀强化、以及添加Ta、Mo、Re的固溶强化[5]等。其中,从改善合金性能和经济性等方面考虑,尤以添加Mo元素强化较有优势[6]。第三种改善合金性能的方法是采用强化烧结技术。微波烧结技术近年来在粉末冶金烧结领域受到了广泛关 注[7-8],它有着整体加热的特点,能有效地细化合金显微组织和改善合金性能,其优势已在许多粉末冶金材料体系得到了体现[9]。为了达到进一步提高钨基高密度合金力学性能的目的,将添加Mo的强化方法和新兴的微波烧结技术相结合,是一个值得探索的研究方向。本文作者对微波烧结W-Mo-Ni-Fe合金进行了研究,比较微波和常规烧结合金性能,并对二者显微组织进行分析。

化[2],主要包括添加Co和Mn元素活化烧结并降低粘接相熔点;添加稀土氧化物及难熔碳化物的第三相强化、添加Al、Ti元素的沉淀强化、以及添加Ta、Mo、Re的固溶强化[5]等。其中,从改善合金性能和经济性等方面考虑,尤以添加Mo元素强化较有优势[6]。第三种改善合金性能的方法是采用强化烧结技术。微波烧结技术近年来在粉末冶金烧结领域受到了广泛关 注[7-8],它有着整体加热的特点,能有效地细化合金显微组织和改善合金性能,其优势已在许多粉末冶金材料体系得到了体现[9]。为了达到进一步提高钨基高密度合金力学性能的目的,将添加Mo的强化方法和新兴的微波烧结技术相结合,是一个值得探索的研究方向。本文作者对微波烧结W-Mo-Ni-Fe合金进行了研究,比较微波和常规烧结合金性能,并对二者显微组织进行分析。

1 实验

实验采用还原W粉(平均粒度 2 μm,纯度>99.5%),Mo粉(平均粒度3 μm,纯度>99.5%)羰基Ni粉(平均粒度3.5 μm, 纯度>99%),羰基Fe粉(平均粒度2.5 μm,纯度>99.5%)。实验设计88W-5Mo- 4.9Ni-2.1Fe(88W)和78W-15Mo-4.9Ni-2.1Fe(78W)成分的合金,以及93W-4.9Ni-2.1Fe的不加Mo元素的合金,将原料粉末按质量分数配料,以无水酒精为介质,球料比1:1、转速150 r/min,在不锈钢筒中混合6 h。粉末在空气中干燥后以300 MPa压力压制成标准拉伸样。

微波烧结实验在微波频率2.45 GHz、功率5.5 kW的微波高温炉(型号:MW-L0616V,China)中完成。实验采用SiC作为辅助加热材料,Al2O3纤维包套作为保温材料。微波烧结过程中采用红外测温仪(型号:Raytek MM2MH,United States。测温范围:450~2 250 ℃)控制温度,探测头发射率为0.75。在整个烧结过程中通过手动调节微波输入功率来控制温度,升温速度控制在30 ℃/min左右,烧结气氛为90%N2+10%H2(体积比)。同时在钼丝炉中进行常规烧结,升温速度为5 ℃/min,烧结气氛为流动H2。微波与常规烧结结束后均随炉冷却。

首先采用排水法测定样品的密度。在LJ-3000A型机械式拉力试验机进行烧结试样的拉伸强度及伸长率测试。采用HDI-1875型(HR-150A, B scale)洛氏硬度计测试试样硬度,该硬度计的测量范围为20~100 HRC,压头直径2.5 mm,加载荷625 N。在扫描电子显微镜(JSM 6360LV,Japan) 观察样品抛光后的表面以及拉伸样品的断口形貌,并用SEM自带的EDS能谱分析成分含量。使用X射线衍射仪(D/max-r B, Japan)分析物相组成。

2 结果与讨论

2.1 W-Mo-Ni-Fe合金性能

总结微波烧结W-Ni-Fe合金的前期工作[10-12]时发现,在微波场中W-Ni-Fe合金压坯能有效地被加热。且研究发现,微波烧结条件下合金的烧结时间可以大大缩短,对W-Ni-Fe体系来说,仅需2~5 min就能获得全致密和性能良好的合金。有报道指出Mo的加入可以使高密度合金的粘结相熔点降低,进而降低烧结温度[6]。因此,实验设计了烧结温度为1 450 ℃和1 480 ℃并保温2 min、5 min的微波烧结实验。常规烧结78W和88W合金则选择在1 480 ℃保温30 min。各合金的性能见表1。密度数据显示,随着微波烧结温度升高和时间的延长,合金密度有所升高。而微波烧结合金的密度均略低于常规烧结的,这是因为微波烧结保温时间较短和升温速度较快所致。另外,比较78W和88W的相对密度发现,Mo含量较少的合金的相对密度较高,说明Mo的添加对合金致密化有一定的影响。

表1显示:78W合金1 480 ℃保温5 min的拉伸强度可达1 175 MPa,硬度为40.3 HRC,分别高于常规烧结的953 MPa,30.9 HRC。88W合金1 480 ℃保温5 min的拉伸强度可达1 065 MPa,硬度为32.5 HRC,分别高于常规烧结的952 MPa,27.5 HRC。从伸长率来看,由于Mo的加入,低于W-Ni-Fe体系的伸长率范围(约10%~20%),部分合金甚至完全为脆性断裂。而且添加Mo较多的78W合金,伸长率下降更加明显。同时表1中硬度数据显示,Mo含量较高的合金(78W)硬度高于88W合金的,微波烧结合金的硬度值均大幅高于常规烧结的。通过比较合金的拉伸强度和硬度发现,虽然1 480 ℃微波烧结5 min样品的相对密度略低于常规烧结的,但力学性能均高于常规烧结样品的。对于传统液相烧结高密度合金材料而言,孔隙度(致密 度)是影响合金力学性能的一个关键因素。但注意到78W合金在1 480 ℃烧结5 min(相对密度98.05%),88W合金在1 480 ℃烧结5 min(相对密度97.55%)已达到或接近全致密(98%)。当合金达到或接近全致密时,孔隙度对合金性能虽有一定影响,但显微组织的影响将成为主要因素。

2.2 显微组织分析

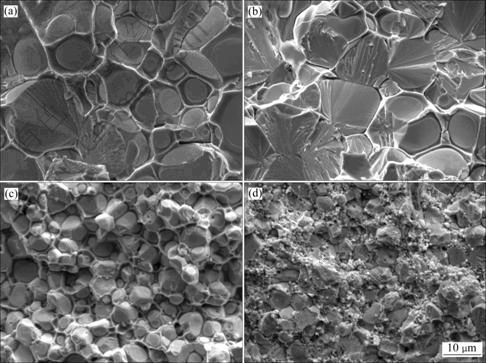

高密度合金存在4种断裂形式,即W晶粒穿晶解理断裂、W晶粒沿晶断裂、粘接相韧性撕裂和W-粘接相断裂[13]。一般地说,W-粘接相和W-W晶粒界面的强度越高,W穿晶断裂越多,从而穿晶断裂多的合金体现出较高的强度和韧性。微波烧结和常规烧结88W、78W合金的拉伸断口如图1所示。由图1(a)和(b)可见,常规烧结合金W晶粒显著粗大,可达15~30 μm,而微波烧结的晶粒细小均匀(见图1(c)和(d)),尺寸在3~8 μm之间。微波烧结合金细小的晶粒解释了其具有较高的强度和硬度,同时也能说明微波烧结合金虽然密度略低,但组织优化带来了改善性能的效果。另一方面,不论是常规烧结还是微波烧结的合金,添加Mo元素较多的78W合金(见图1(b)和(d)),W晶粒穿晶断裂比88W合金(见图1(a)和(c))更多,这是因为加入的Mo固溶在粘接相中,起到了固溶强化的作用,相应地合金的抗拉强度明显提高。然而,微波烧结的78W合金的断口组织(见图1(d))却显得与传统高密度合金不同,W晶粒的周围没有粘接相的韧性撕裂,而是出现大量非常细小的颗粒。据此推测,该颗粒的存在,可能进一步提高了W晶粒间的结合强度,并对提高合金硬度起到积极作用。

表1 W-Mo-Ni-Fe合金的力学性能

Table 1 Mechanical properties of W-Mo-Ni-Fe alloys

图1 常规烧结和微波烧结88W合金和78W合金的SEM像

Fig. 1 SEM images of fracture of conventional sintered 88W alloy(a) and 78W alloy(b), and microwave sintered 88W alloy(c) and 78W alloy(d)

2.3 成分分析

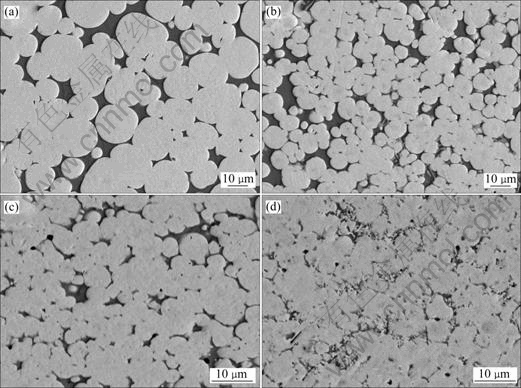

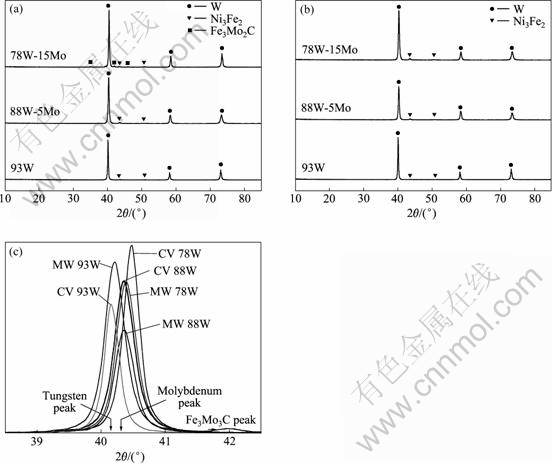

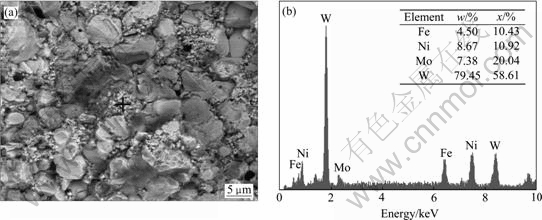

图2所示为微波烧结和常规烧结88W、78W合金的SEM像。图2进一步证明了微波烧结能够显著地细化晶粒。常规烧结78W合金粘接相组织(见图2(b))中存在针状或条状的中间相,微波烧结78W合金中深灰色的粘接相很少,大量细小的颗粒分布于W颗粒周边,同时观察不到明显的W晶粒-粘接相界面,W晶粒也失去了光滑的边缘和近球形的特征。XRD分析发现,对于88W合金,无论常规烧结还是微波烧结样品,其相组成都与未添加Mo元素93W-4.9Ni-2.1Fe合金相同,说明在添加5%(质量分数)的Mo的条件下,Mo元素固溶于W相和粘接相中,没有其他第二相的生成。然而常规烧结78W合金出现少量的η相Fe3Mo3C,如图3(a)所示,其中的C元素应来自原料粉末杂质。值得注意的是,微波烧结78W合金未观察到该相的存在(见图3(b)和(c)),其物相组成仍与88W,93W合金一致。根据文献介绍,高Mo含量的重合金基体相还有可能会生成MoNi中间相[14-15]。UPADHYAYA等[16]研究发现,微波烧结可以抑制92.5W-6.4Ni-1.1Fe合金中NiW和Fe7W6等脆性中间相的生成。对微波烧结78W合金分布于粘接相中的颗粒进行观察和成分分析,其结果如图4所示。从背散射照片的颜色初步判断,该颗粒应含有较多的W和Mo元素,成分可能接近于固溶了Mo的W相。然而,EDS分析显示其中含有10.43% Fe、10.92% Ni、20.04% Mo和58.61% W(摩尔分数)。考虑到颗粒非常细小(<100 nm),EDS难以准确地确定其成分,有待进一步的精确测量和分析研究。

图2 常规烧结和微波烧结88W合金、78W合金的SEM像

Fig. 2 SEM images of conventional sintered 88W alloy(a) and 78W alloy(b), and microwave sintered 88W alloy(c) and 78W alloy(d)

图3 常规烧结和微波烧结样品的XRD谱

Fig. 3 XRD patterns of conventional and microwave sintering samples (MV: microwave sintering; CV: conventional sintering): (a) Conventional sintering; (b) Microwave sintering; (c) XRD patterns near tungsten-molybdenum (110) peak (38.5?-42.5 ?)

图4 微波烧结78W合金的SEM像和EDS谱

Fig. 4 SEM image(a) and EDS pattern(b) of microwave sintered 78W alloy

有研究[6]指出添加的Mo元素不但能够固溶于粘接相中起到强化作用,同时它也能够固溶在W相中。 另外,粘接相、W相中Mo的溶解度和中间相生成与Mo添加量有关系。在此,对不同烧结模式和不同Mo含量的合金粘接相和W颗粒进行分析,其结果如表2所列。很明显,Mo添加量较高时,粘接相和W晶粒中的Mo含量更高:78W合金粘接相中Mo含量可达13.76%;W晶粒中约为17%~18%;88W粘接相中Mo成分约为6%~9%,W晶粒中约为5%~6%。合金Mo添加越多,W相和粘接相中Mo含量均增大。XRD分析进一步证明了这一点:图3(c)显示了不同模式烧结和不同Mo添加量的合金W相(110)衍射峰附近的XRD谱。显而易见,与不添加Mo的93W合金对比,88W-5Mo合金[W, Mo](110)衍射峰向右偏移,Mo含量较多的78W-15Mo合金此现象更加明显。因此,高Mo合金强化作用显著,从而导致抗拉强度和硬度提高,伸长率降低。

表2 W-Mo-Ni-Fe合金的EDS成分分析

Table 2 EDS analysis of W-Mo-Ni-Fe alloys

3 结论

1) 在1 480 ℃微波烧结5 min的78W-15Mo- 4.9Ni-2.1Fe合金的抗拉强度达1 175 MPa,伸长率为3.0%,硬度为40.3 HRC;在相同条件下微波烧结的88W-5Mo-4.9Ni- 2.1Fe合金的抗拉强度达1 065 MPa,伸长率为6.9%,硬度为32.5 HRC,均高于常规烧结态合金。

2) 与烧结合金相比,微波烧结合金的显微组织细小而均匀。

3) 与88W合金相比,Mo元素添加较多的78W合金的晶粒细小,抗拉强度、硬度较高,但伸长率下降;78W合金中有Fe3Mo3C中间相存在。

REFERENCES

[1] 赵慕岳, 王伏生, 范景莲. 我国钨基高密度合金发展现状[J]. 粉末冶金材料科学与工程, 2000, 5(1): 27-32.

ZHAO Mu-yue, WANG Fu-sheng, FAN Jing-lian. Review on the development and prospect of tungsten heavy alloy in China[J]. Materials Science and Engineering of Powder Metallurgy, 2000, 22(1): 27-32.

[2] 叶途明, 易健宏, 李丽娅, 彭元东, 吕豫湘, 胡礼福. 高比重钨合金研究的新发展[J]. 材料导报, 2003, 17(12): 15-18.

YE Tu-ming, YI Jian-hong, LI Li-ya, PENG Yuan-dong, L? Yu-xiang, HU Li-fu. New advances in study of tungsten heavy alloys[J]. Materials Review, 2003, 17(12): 15-18.

[3] HONG S H, RYU H J. Combination of mechanical alloying and two-stage sintering of a 93W-5.6Ni-1.4Fe tungsten heavy alloy[J]. Material Science Engineering A, 2003, 344: 253-260.

[4] FAN J L, GONG X, HUANG BY, SONG M, LIU T, TIAN J M, Densification behavior of nanocrystalline W-Ni-Fe composite powders prepared by sol spray drying and hydrogen reduction process[J]. Journal of Alloys and Compounds, 2010, 489: 188-194.

[5] BOSE A, GERMAN R M. Microstructural refinement of W-Ni-Fe heavy alloys by alloying additions[J]. Metallurgical Transactions A, 1988, 19: 3100-3103.

[6] 张兰亭, 唐志宏. 加钼的钨重合金[J]. 中国钨业, 2001, 16(3): 36-39.

ZHANG Lan-ting, TANG Zhi-hong. Tungsten heavy alloys with molybdenum additions[J]. China Tungsten Industry, 2001, 16(3): 36-39.

[7] 易健宏, 罗述东, 唐新文, 李丽娅, 彭元东, 杜 鹃. 金属基粉末冶金零件的微波烧结机理初探[J]. 粉末冶金工业, 2003, 13(2): 22-25.

YI Jian-hong, LUO Shu-dong, TANG Xin-wen, LI Li-ya, PENG Yuan-dong, DU Juan. On mechanism of microwave sintering of P/M parts[J]. Powder Metallurgy Industry, 2003, 13(2): 22-25.

[8] 彭元东, 易健宏, 罗述东, 李丽娅, 陈 刚, 冉俊铭. 微波技术在金属材料制备中的应用现状[J]. 稀有金属材料科学与工程, 2009, 38(4): 742-747.

PENG Yuan-dong, YI Jian-hong, LUO Shu-dong, LI Li-ya, CHEN Gang, RAN Jun-ming. Research on the application of microwave technology in preparation of metallic materials[J]. Rare Metal Materials and Engineering, 2009, 38(4): 742-747.

[9] 易健宏, 周承商. 金属基粉末冶金材料的微波烧结技术研究[C]//2009全国粉末冶金学术会议论文集. 张家界: 中南大学粉末冶金研究院, 2009: 14-20.

YI Jian-hong, ZHOU Cheng-shang. Research on the application of microwave technology in preparation of metallic materials[C]//2009 National Conference on P/M and its Application Technology. Zhangjiajie: Powder Metallurgy Research Institute of Central South University, 2009: 14-20.

[10] ZHOU Cheng-shang, YI Jian-hong, LUO Shu-dong, PENG Yuan-dong, LI Li-ya, CHEN Gang. Effect of heating rate on the microwave sintered W-Ni-Fe heavy alloys[J]. Journal of Alloys and Compounds, 2009, 482: 6-8.

[11] 周承商, 易健宏, 罗述东, 彭元东, 陈 刚. W-Ni-Fe高密度合金的微波烧结[J]. 中国有色金属学报, 2009, 19(9): 1601-1607.

ZHOU Cheng-shang, YI Jian-hong, LUO Shu-dong, PENG Yuan-dong, CHEN Gang. Microwave sintering of W-Ni-Fe alloys[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1601-1607.

[12] 周承商, 易健宏, 罗述东, 彭元东, 王红忠. 微波烧结W-Ni-Fe高密度合金的变形现象及显微组织[J]. 粉末冶金材料科学与工程, 2010, 15(3): 300-304.

ZHOU Cheng-shang, YI Jian-hong, LUO Shu-dong, PENG Yuan-dong, WANG Hong-zhong. Distortion and microstructure of microwave sintered W-Ni-Fe alloys[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(3): 300-304.

[13] RABIN B H, GERMAN R M. Microstructure effects on tensile properties of tungsten-nickel-iron composites[J]. Metallurgical Transactions A, 1988, 19: 1523-1532.

[14] LIN K H, HSU C S, LIN S T. Variables on the precipitation of an intermetallic phase for liquid phase sintered W-Mo-Ni-Fe heavy alloys[J]. International Journal of Refractory Metals & Hard Materials, 2002, 20: 401-408.

[15] LIN K H, HSU C S, LIN S T. Structure analysis of the constitutional phases in liquid phase sintered W-Mo-Ni-Fe heavy alloys[J]. International Journal of Refractory Metals & Hard Materials, 2003, 21: 193-203.

[16] UPADHYAYA A, TIWARI S K, MISHRA P. Microwave sintering of W-Ni-Fe alloy[J]. Scripta Materialia, 2007, 56: 5-8.

(编辑 李艳红)