流态化分离洗涤对熟料高质量浓度溶出浆液二次反应的影响

彭志宏,陈彦虎,周秋生,刘桂华,李小斌,齐天贵

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘要:采用流态化方式对烧结法熟料高质量浓度溶出浆液分离和赤泥洗涤进行研究。研究结果表明:对于Al2O3质量浓度为240~270 g/L的熟料溶出浆液,经流态化分离洗涤,可以同时实现浆液的固液分离和赤泥的洗涤,获得的溢流(粗液)Al2O3质量浓度为170~190 g/L,底流液固质量比为2.5~3.0,底流附液Na2O质量浓度为6~9 g/L,平均分离洗涤效率在99%以上,平均二次反应损失为0.16%;烧结法赤泥的流态化分离洗涤是抑制二次反应的有效途径。

关键词:烧结法;浆液;流态化;分离;洗涤;二次反应

中图分类号:TF821 文献标志码:A 文章编号:1672-7207(2012)06-2036-07

Effect of fluidized separating-washing of red mud on secondary reactions of leached slurry with high alumina concentration

PENG Zhi-hong, CHEN Yan-hu, ZHOU Qiu-sheng, LIU Gui-hua, LI Xiao-bin, QI Tian-gui

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The simultaneous separation and washing of red mud of the leached slurry with high alumina concentration in the sintering process was studied by employing the fluidization technique. The results show that the separation and washing of red mud can be achieved at the same time by fluidization method. When Al2O3 mass concentration of the leached slurry is 240-270 g/L, Na2O mass concentration of the underflow liquor and the liquid-solid mass ratio of the underflow can reach 6-9 g/L and 2.5-3.0, respectively, and Al2O3 mass concentration of the overflow is 170-190 g/L. The average efficiency of separating-washing is more than 99% with the average secondary reaction loss of 0.16%. It can be concluded that the fluidized separating-washing of red mud is an effective way to restrain secondary reactions.

Key words: sintering process; slurry; fluidization; separation; washing; secondary reaction

在烧结法生产氧化铝的溶出赤泥分离和洗涤过程中,由于熟料中存在原硅酸钙,不可避免地会发生二次反应,并且随着液固接触时间的延长和溶液质量浓度的增加,二次反应损失可能很大[1]。目前,烧结法赤泥分离与洗涤均采用沉降槽工艺,设备占地面积大,投资大,分离洗涤时间长,二次反应损失大,造成碱耗增加,氧化铝净溶出率下降[2-3]。研究人员致力于研究能实现赤泥快速分离和洗涤的新的工艺。烧结法生产的发展趋势是提高湿法系统质量浓度,以提高生产的经济技术指标,但必须采取有效的工艺措施,实现高质量浓度浆液的快速分离,并减小二次反应的发生。固体流态化现象是一种由于流体向上流过固体颗粒堆积的床层,使得固体颗粒具有一般流体性质的现象,该技术已广泛应用于物理操作、矿物资源综合利用、煤的燃烧与转化、石油加工、有机合成、材料、环境工程等行业[4]。流态化浸出洗涤技术从20世纪60年代开始研究,并相继用于工业实践[5]。姜方卫等[6]进行了碱浸铀矿浆的流态化洗涤实验研究,发现当吨浸出渣的洗水用量为0.8 t时,洗涤效率达99%;肖连生 等[7]利用密实移动床-流化床离子交换技术从钨酸钠溶液中除钼,除钼率可达99%以上;李小斌等[8]采用流态化技术进行了拜耳法赤泥的洗涤研究,当赤泥浆液中Na2O质量浓度为125~180 g/L,每吨赤泥用水量为4.2~4.9 t时,底流附碱质量浓度可降低至0.25~5.00 g/L,底流液固质量比为2.2~2.7,溢流Na2O质量浓度为90~150 g/L,并建立了流态化洗涤的数学模型,可预测洗涤过程浆液中Na2O质量浓度轴向分布和洗涤效果。以上研究都表明,流态化洗涤具有洗液量小、处理量大、工艺设备简单等优点。在此,本文作者对烧结法高质量浓度溶出浆液流态化分离和洗涤过程中的二次反应进行研究。

1 二次反应机理及其影响因素

1.1 二次反应的机理

二次反应损失的根本原因是熟料中的原硅酸钙在溶出、分离以及洗涤过程中被铝酸钠溶液分解,分解产物Na2SiO3和Ca(OH)2又与NaAl(OH)4相互作用,生成含氧化铝的不溶物进入赤泥而造成氧化铝的损 失[9-11]。溶出过程的二次反应主要有:

2CaO·SiO2+2Na2CO3+aq=

Na2SiO3+2CaCO3+2NaOH+aq (1)

2CaO·SiO2+2NaOH+aq=2Ca(OH)2+Na2SiO3+aq (2)

3Ca(OH)2+2NaAl(OH)4=3CaO·Al2O3·6H2O+2NaOH(3)

3CaO·Al2O3·6H2O+xNa2SiO2(OH)2=

3CaO·Al2O3·xSiO2·(6-2x)H2O+2xNaOH(x=0.5~0.8) (4)

3Ca(OH)2+2NaAl(OH)4+xNa2SiO3=

3CaO·Al2O3·xSiO2·(6-2x)H2O+(1+x)NaOH+xH2O (5)

2Na2SiO3+2NaAl(OH)4+aq=

Na2O·Al2O3·2SiO2·2H2O+4NaOH+aq (6)

1.2 二次反应的影响因素

在熟料溶出、分离和洗涤过程中,二次反应及其损失是不可避免的[12-15],影响二次反应的主要因素有以下几个方面。

(1) 质量浓度。浆液中Na2O、氧化铝、碳酸钠和二氧化硅等的质量浓度都对工业熟料二次反应有重要的影响。杨重愚[1]认为,在氧化铝质量浓度一定的情况下,提高Na2O质量浓度,将加快NaOH按照反应(2)对2CaO·SiO2的分解,从而使SiO2进入溶液,而且反应产物Ca(OH)2的溶解度随NaOH质量浓度的提高而显著降低,反应(2)的平衡将向右移动,促进2CaO·SiO2的分解。当溶液中的SiO2达到一定质量浓度时,便会发生如式(5)和式(6)的脱硅反应,从而导致Al2O3的质量浓度降低。当Na2O质量浓度低于50 g/L时,二次反应损失较小。另外,随着氧化铝质量浓度的提高,SiO2溶出率逐步上升,进入液相的SiO2质量浓度也逐渐增大。陈滨[11]认为,当氧化铝质量浓度提高到160 g/L以上时,SiO2溶出率由30.59%升高到47.81%。这主要是因为NaOH和Al(OH)4-按反应(2)和(3)分解2CaO·SiO2,Al(OH)4-质量浓度越高,2CaO·SiO2被分解的程度越大,二次反应也随之加剧;当Na2CO3质量浓度超过一定限度时会促进2CaO·SiO2的分解和钠硅渣的析出。从Na2O-Al2O3-CaO-CO2-H2O五元系平衡状态图[16]可以看出:Na2CO3质量浓度控制在30~35 g/L为宜。

(2) 时间和温度。熟料中氧化铝的溶出率在5~10 min达到最高,2CaO·SiO2的分解在10 min后才趋于强烈[17-18]。随着赤泥与溶液接触时间的延长,二次反应加剧,导致氧化铝净溶出率下降,因此,尽快地使赤泥与溶液分离是减小二次反应损失的重要措施。溶出过程温度提高通常使二次反应加剧。通常熟料的溶出是在70~80 ℃进行,Na2O和Al2O3有足够的溶出速度。但是,若温度太低,则溶液的黏度增大,会妨碍赤泥与溶液的分离;而若赤泥与熟料接触时间延长,则2CaO·SiO2的分解也随之增加。

(3) 溶出液固比、熟料质量和粒度。熟料溶出时是通过熟料添加量来控制溶出液氧化铝质量浓度,而二次反应的程度与铝酸钠溶液质量浓度有关,溶液中氧化铝质量浓度高,则黏度大,分离困难,接触时间长,二次反应程度加大[19-20]。若熟料粒度过大,会使有用成分溶出不完全;若过小,则由于赤泥比表面积的增大,加剧2CaO·SiO2与溶液的反应,并且造成赤泥与溶出液分离困难,延长赤泥与溶液接触时间。

综上所述,质量浓度和液固接触时间是影响二次反应的主要因素,其他因素是通过影响质量浓度或液固接触时间来影响二次反应的。控制适宜的条件,能在一定程度上减少二次反应损失。

2 实验

2.1 原料及设备

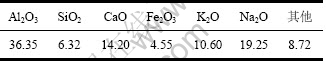

用工业级氢氧化钠和氢氧化铝配制调整液。实验所用熟料来自中铝中州分公司氧化铝厂,化学成分见表1,经球磨机球磨后粒度组成(质量分数)见表2。

主要实验仪器与设备为:球磨机(武汉洛克粉磨设备制造有限公司制造);电热鼓风干燥器(上海跃进医疗仪器厂制造);SHB-3循环水多用真空泵(郑州杜甫医疗仪器厂制造);搅拌溶出槽(中南大学制造)。根据流态化原理设计制作的流态化分离洗涤实验装置示意图见图1。

表1 熟料的化学成分(质量分数)

Table 1 Chemical composition of clinker %

表2 熟料的粒度组成分布(质量分数)

Table 2 Particle size distribution of clinker %

图1 实验装置示意图

Fig.1 Schematic diagram of experimental apparatus

2.2 实验方法

熟料溶出实验在搅拌溶出槽里进行,采用连续溶出方式,溶出温度为70 ℃,溶出时间为5~6 min,洗水温度为90 ℃。

在实验开始时先关闭底流阀门,打开高质量浓度溶出浆液、絮凝剂和洗水阀门,在形成一定高度的压缩层后,打开底流阀门,此时,高质量浓度溶出浆液持续从上部加入,底流持续流出,保证床层高度不变,赤泥絮团在压缩层内形成均匀分布的液固两相体系,洗水从下部经赤泥絮团间隙向上流动,经传质带走赤泥附液中的碱和铝,由上部溢出,快速完成赤泥分离和洗涤过程。

实验时,在进出浆液和洗水的流量稳定后,开始取样。测定参数包括进料高质量浓度溶出浆液、底流、溢流的Na2O和Al2O3质量浓度,底流、进料高质量浓度溶出浆液液固质量比,洗水、高质量浓度溶出浆液、溢流、底流流量,熟料、高质量浓度溶出浆液干赤泥和底流干赤泥中的Al2O3和Fe2O3含量。

3 实验结果及讨论

3.1 流态化分离洗涤效果

目前,工业上熟料溶出后的浆液经过分离后得到的粗液Al2O3质量浓度仅为120~130 g/L,若能提高到180 g/L以上,则在保证赤泥分离和脱硅的条件下,以相同的碳酸化分解率计算,1 m3溶出液可增产50~60 kg氧化铝。因此,提高湿法系统的质量浓度是改善烧结法生产技术经济指标和提高生产效率的主要措施,也是烧结法生产的发展趋势。然而,目前工业上采用的沉降槽方案难以分离高质量浓度的溶出浆液。

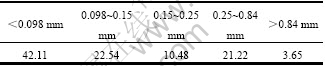

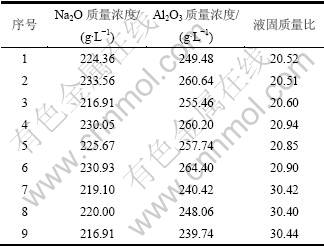

实验研究了高质量浓度溶出浆液流态化分离洗涤的效果。通过控制调整液质量浓度和溶出液固质量比,使溶出料浆Na2O质量浓度为210~240 g/L, Al2O3为240~270 g/L,如表3所示。调节料浆流量为22.86~28.42 L/h,洗水流量12~15 L/h,能一步获得Al2O3质量浓度较高的溢流(粗液),同时得到附液Na2O质量浓度较低的底流,分离洗涤效率按式(7)计算,试验结果如表4所示。

(7)

(7)

式中: 为料浆液固质量比;

为料浆液固质量比; 为底流赤泥液固质量比;

为底流赤泥液固质量比; 为料浆质量浓度(g/L);

为料浆质量浓度(g/L); 为底流附液质量浓度(g/L);

为底流附液质量浓度(g/L); 为料浆自由液体密度(kg/m3);

为料浆自由液体密度(kg/m3); 为底流附液密度(kg/m3)。

为底流附液密度(kg/m3)。

目前,工业上的沉降槽只能处理Al2O3质量浓度为120~130 g/L的浆液,并且分离后的赤泥要经过7~8次反向沉降洗涤,才能得到附液Na2O质量浓度小于 4 g/L的底流。由表3和表4可以看出:流态化方式能处理Al2O3质量浓度为240~270 g/L的高质量浓度溶出浆液,并且将分离与洗涤过程一步完成,能得到Al2O3质量浓度平均为183 g/L的溢流(粗液),底流附液Na2O平均质量浓度为7.58 g/L,平均分离洗涤效率为99.45%。这主要是因为在溶出赤泥的流态化分离洗涤过程中,赤泥颗粒附液与洗水之间始终存在质量浓度差,且流化床中传质系数较大,所以,赤泥颗粒附液与洗水能在整个流态化系统中充分传质,达到较好的洗涤效果。

表3 溶出料浆成分

Table 3 Composition of slurry

表4 分离洗涤后的粗液和底流附液成分

Table 4 Composition of overflow liquor and underflow liquor

3.2 流态化分离洗涤过程的二次反应损失

生产上二次反应损失通常由熟料的分离溶出率和净溶出率的差值表示。目前,工业上的溶出浆液经过沉降分离后,还要经过7~8次反向沉降洗涤,总时间约20 h。孙建峰[21]的研究表明:熟料溶出过程中Al2O3的损失并不大,仅为0.81%。但是,溶出后赤泥分离、赤泥洗涤过程Al2O3的损失却达到1.64%和2.1%。由此可以看出:二次反应损失主要集中在赤泥分离及洗涤过程中。

在本实验过程中,高质量浓度溶出浆液和絮凝剂同时由顶部进入流态化分离洗涤设备,洗水由底部进入设备,经过传质,快速完成赤泥的分离与洗涤。因此,二次反应损失可以用按溶出浆液中赤泥成分换算的初溶出率和按分离洗涤后底流赤泥成分换算的净溶出率的差值表示。分析赤泥中的Al2O3和Fe2O3含量,以Fe2O3为内标,计算各阶段的溶出率,如表5所示。

由表5可以看出:在溶出后的赤泥中,Al2O3含量为5%~8%,Fe2O3含量为11%~12%,以Fe2O3为内标计算的平均初溶出率ηA1为92.69%。在分离洗涤后的赤泥中,Al2O3含量为6%~8%,Fe2O3含量为11%~12%,由此计算得平均净溶出率ηA2为92.53%。可以看出:在流态化分离洗涤过程中,二次反应损失率平均仅为0.16%,与采用沉降分离洗涤相比,二次反应损失显著减少,二次反应得到有效抑制。

由二次反应的影响因素可知:质量浓度和液固接触时间是影响二次反应损失的主要因素。质量浓度越高,液固接触时间越长,都会增加二次反应损失。在流态化分离洗涤过程中,通过对前期所建立的拜耳法赤泥流态化洗涤的数学模型[8]进行修正,建立了适合烧结法高质量浓度溶出浆液流态化分离洗涤的模型,如式(8)所示,并由此预测压缩层内Na2O和Al2O3的质量浓度变化,结果如图2所示。

表5 赤泥成分(质量分数)

Table 5 Composition of red mud

(8)

(8)

式中:  ;

; ;

; 。

。

式中:ρh为离压缩层顶端h处液体质量浓度(g/L);d为设备直径(m);γs为赤泥颗粒密度(kg/m3); 为料浆体积流量(L/h);

为料浆体积流量(L/h); 为洗水体积流量(L/h);H为压缩层高度(m);h为距离压缩层顶端的距离(m);

为洗水体积流量(L/h);H为压缩层高度(m);h为距离压缩层顶端的距离(m); 为料浆的空隙度;

为料浆的空隙度; 为底流的空隙度;v为固体颗粒的下降速度(m/h);K为混合传质系数(s-1)。

为底流的空隙度;v为固体颗粒的下降速度(m/h);K为混合传质系数(s-1)。

从图2可以看出:在压缩层内从上到下,Na2O和Al2O3质量浓度随着压缩层的高度增大而迅速减小。由此可知:Na2O和Al2O3质量浓度对二次反应的影响也迅速随之减小。这从一个方面抑制了二次反应损失。

根据二次反应的影响因素,当Na2O质量浓度降低到50 g/L以下时,对二次反应的影响就非常小。由图2可以看出:当赤泥压缩层下降约20 cm时,此时赤泥所在的溶液Na2O质量浓度降到50 g/L以下,而此时的接触时间应为赤泥颗粒下降的距离除以颗粒下降速度。在实验过程中,一般底流排出的速度为1.5~3.0 m/h,可以计算出赤泥颗粒在Na2O质量浓度50 g/L以上区域的停留时间仅为4~8 min,固液接触时间非常短。采用流态化分离洗涤可以快速实现赤泥与铝酸钠溶液分离,这是二次反应损失显著减少的主要原因。

图2 压缩层内Na2O质量浓度和Al2O3质量浓度的轴向分布

Fig.2 Axial Na2O and Al2O3 mass concentration distribution in compressed layer

3.3 单位赤泥洗水量对洗涤效果和二次反应的影响

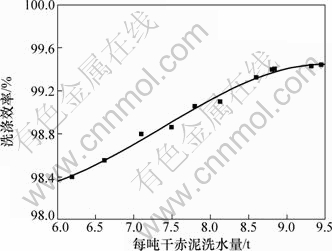

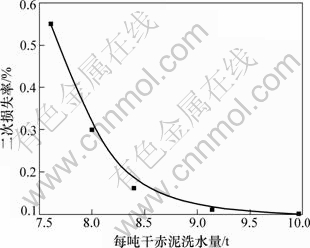

根据流态化洗涤原理,洗涤是通过压缩层内赤泥附液与洗液之间的传质完成的。单位赤泥洗水量增大,则赤泥附液与洗液之间的质量浓度差越大,传质越充分,洗涤效果越好。洗水量的变化也会影响分离洗涤过程中的二次反应损失。当压缩层高度一定时,固定浆液进料流量不变,改变洗水进料流量,增大单位赤泥洗水量,分离洗涤过程洗涤效率的变化情况如图3所示,二次反应损失的变化情况如图4所示。

从图3可见:随着单位赤泥洗水量的增加,洗涤效率提高;但当每吨干赤泥洗水量大于8.5 t时,这种影响便不太明显。因此,在流态化分离洗涤系统中应控制合适的洗水量,洗水量太大将使所得的溢流(粗液)质量浓度降低。由图4可以看出:随着单位赤泥洗水量的增大,二次反应损失逐渐减小;当洗水流量增大到某一定值时,二次反应损失几乎不再发生变化。总体看来,整个流态化分离洗涤阶段,二次反应损失都较小。这是因为随着洗水流速的增大,压缩层内赤泥颗粒附液的苛性碱质量浓度迅速降低,同时,液固接触时间短,对二次反应的影响越来越小。

图3 洗涤效率和单位赤泥洗水量的关系

Fig.3 Relationship between washing efficiency and mass of washing water per ton red mud

图4 二次损失率与单位赤泥洗水量的关系

Fig.4 Relationship between secondary loss rate and mass of washing water per ton red mud

综合考虑洗涤效率和二次反应损失,每吨赤泥洗水量宜为7.5~8.5 t,既可获得较高的洗涤效率,同时又可确保二次反应损失较小。但在试验室装置上所确定的单位赤泥洗水量,与工业生产上沉降槽分离洗涤赤泥的单位洗水量相比有一定差距,还需要进一步优化流态化分离洗涤研究,以降低单位赤泥洗水量。

4 结论

(1) 采用流态化方式可以实现熟料高质量浓度溶出浆液的分离洗涤,当溶出浆液Al2O3质量浓度为240~270 g/L时,可以获得平均Al2O3质量浓度为183 g/L的溢流(粗液),底流液固比为2.78,底流附液Na2O平均质量浓度为7.58 g/L,平均分离洗涤效率为99.45%。

(2) 高质量浓度溶出浆液流态化分离和洗涤过程二次反应损失较小,平均为0.16%。采用流态化分离洗涤可以显著抑制熟料高质量浓度溶出浆液分离洗涤过程中二次反应的发生。

(3) 随着单位赤泥洗水量的增大,流态化分离洗涤效率提高,二次反应损失减小。

参考文献:

[1] 杨重愚. 氧化铝生产工艺学[M]. 北京: 冶金工业出版社, 1993: 245-246.

YANG Zhong-yu. Technology of alumina production[M]. Beijing: Metallurgical Industry Press, 1993: 245-246.

[2] 李秋生. 烧结法赤泥快速分离科研与产业化探索[J]. 轻金属, 2009(10): 14-17.

LI Qiu-sheng. Study of the rapid separation of red mud in sintering process and its industrialization[J]. Light Metals, 2009(10): 14-17.

[3] 张哲新, 尹周澜, 温金德, 等. 高效沉降槽在烧结法氧化铝生产中的应用[J]. 山东冶金, 2005, 27(5): 20-23.

ZHANG Zhe-xin, YIN Zhou-lan, WEN Jin-de, et al. Application of high-efficient precipitation tank in alumina production with sintering process[J]. Shandong Metallurgy, 2005, 27(5): 20-23

[4] 金涌, 祝京旭, 汪展文, 等. 流态化工程原理[M]. 北京: 清华大学出版社, 2001: 1-19, 460-520.

JIN Yong, ZHU Jing-xu, WANG Zhan-wen, et al. Fluidization engineering principles[M]. Beijing: Tsinghua University Press, 2001: 1-19, 460-520.

[5] 郭慕孙. 流态化浸取和洗涤[M]. 北京: 科学出版社, 1979: 10-59.

GUO Mu-sun. Fluidization leaching and washing[M]. Beijing: Science Press, 1979: 10-59.

[6] 姜方卫, 邹懋森, 管秀瑛. 流态化技术在铀湿法冶金中的应用—碱浸铀矿浆流态化洗涤试验研究[J]. 铀矿冶, 1986, 5(1): 30-36.

JIANG Fang-wei, ZOU Mao-sen, GUAN Xiu-ying. Application of fluidization technique to uranium hydrometallurgy: Washing of alkaline-leached uranium ore slurry in fluidized bed[J]. Uranium Mining and Metallurgy, 1986, 5(1): 30-36.

[7] 肖连生, 张启修, 龚柏藩, 等. 密实移动床-流化床离子交换技术从钨酸盐溶液中除钼试验研究[J]. 矿冶工程, 2001, 21(3): 66-68.

XIAO Lian-sheng, ZHANG Qi-xiu, GONG Bo-fan, et al. Separation of molybdenum from tungstate solution by a combination of moving packed bed and fluid bed ion exchange technique[J]. Mining and Metallurgical Engineering, 2001, 21(3) :66-68.

[8] 李小斌, 李斌, 彭志宏, 等. 赤泥流态化洗涤[J]. 过程工程学报, 2010, 10(3): 445-450.

LI Xiao-bin, LI Bin, PENG Zhi-hong, et al. Fluidization washing of the red mud[J]. The Chinese Journal of Process Engineering, 2010, 10(3): 445-450.

[9] LIU Gui-hua, LI Xiao-bin, PENG Zhi-hong, et al. Behavior of calcium silicate in leaching process[J]. Transactions of Nonferrous Metals Society China, 2003, 13(1): 213-216.

[10] 李小斌, 徐华军, 刘桂华, 等. 氧化铝熟料溶出过程中SiO2的行为[J]. 过程工程学报, 2006, 6(3): 431-434.

LI Xiao-bin, XU Hua-jun, LIU Gui-hua, et al. Behavior of SiO2 during leaching process of alumina sinter[J]. The Chinese Journal of Process Engineering, 2006, 6(3): 431-434.

[11] 陈滨. 熟料溶出过程二次反应与高浓度粗液制备技术[D]. 长沙: 中南大学冶金科学与工程学院, 2008: 9-14.

CHEN Bin. Study on secondary reaction during clinker-leaching and the preparation technology of pregnant liquor with high Al2O3 concentration in alumina production process[D]. Changsha: Central South University. School of Metallurgical Science and Engineering, 2008: 9-14.

[12] 郭琴珍, 王军. 二次反应对熟料中氧化铝溶出率的影响[J]. 轻金属, 2003(12): 10-12.

GUO Qin-zhen, WANG Jun. Effect of secondary reaction on leaching rate of alumina in sinter[J]. Light Metals, 2003(12): 10-12.

[13] 张建. 碱石灰铝土矿熟料高浓度溶出过程中二次反应的研究[D]. 长沙: 中南大学冶金科学与工程学院, 2008: 37-47.

ZHANG Jian. Study on secondary reaction occurred in leaching process with high concentration by sintering process[D]. Changsha: Central South University. School of Metallurgical Science and Engineering, 2008: 37-47.

[14] LI Xiao-bin, ZHAO Zhuo, LIU Gui-hua, et al. Behavior of calcium silicate hydrate in aluminate solution[J]. Transactions of Nonferrous Metals Society of China, 2005, 15(5): 1145-1149.

[15] 李太昌. 二次反应抑制剂及其添加工艺技术研究[J]. 有色金属: 冶炼部分, 2002(1): 26-28.

LI Tai-chang. Technical research of secondary reaction inhibitor and it’s sweetening process[J]. Nonferrous Metals: Extractive Metallurgy, 2002(1): 26-28.

[16] Klimesch D S, Ray A. DTA-TG study of the CaO-SiO2-H2O and CaO-Al2O3-SiO2-H2O systems under hydrothermal conditions[J]. Journal of Thermal Analysis and Calorimetry, 1999, 56(1): 24-25.

[17] 周宗科. 浅析二次反应对氧化铝生产熟料溶出的影响[J]. 世界有色金属, 2002(9): 35-38.

ZHOU Zong-ke. A preliminary analysis of influences of secondary reaction on Al extraction by leaching of sintered aluminiferous burden in alumina production[J]. World Nonferrous Metals, 2002(9): 35-38.

[18] 陈红武, 周宗科. 烧结法熟料溶出条件对二次反应影响分析[J]. 轻金属, 2001(8): 14-16.

CHEN Hong-wu, ZHOU Zong-ke. Analysis of the effect of sinter leaching conditions on the secondary reaction in sintering process[J]. Light Metals, 2001(8): 14-16.

[19] 徐华军. 氧化铝熟料溶出过程中二次反应的研究[D]. 长沙: 中南大学冶金科学与工程学院, 2006: 8-12.

XU Hua-jun. A study on the secondary reaction in sintering process[D]. Changsha: Central South University. School of Metallurgical Science and Engineering, 2006: 8-12.

[20] LIU Gui-hua, LI Xiao-bin, PENG Zhi-hong, et al. Stability of calcium silicate in basic solution[J]. Transactions of Nonferrous Metals Society of China, 2003, 13(5): 1235-1238.

[21] 孙建峰. 强化烧结法熟料溶出中赤泥的快速分离[J]. 轻金属, 2005(5): 17-20.

SUN Jian-feng. Rapid separation of red mud from the digestion of forced and calcined sinter[J]. Light Metals, 2005(5):17-20.

(编辑 陈灿华)

收稿日期:2011-06-10;修回日期:2011-08-15

基金项目:中央高校基本科研业务费专项资金资助项目(2010QZZD004)

通信作者:周秋生(1972-),男,湖南涟源人,教授,从事碱法冶金过程研究;电话:0731-88830453;E-mail:qszhou@csu.edu.cn