SKS炼铅氧气底吹炉的 分析

分析

蒋爱华1, 2,杨双欢1,梅炽1,时章明1, 2,朱小军1, 2

(1. 中南大学 能源科学与工程学院,湖南 长沙,410083;

2. 湖南节能评价技术研究中心,湖南 长沙,410083)

摘 要:为揭示SKS氧气底吹炉内、外部不可逆损失的机理,采用 平衡分析法建立SKS氧气底吹炉的

平衡分析法建立SKS氧气底吹炉的 分析模型,对SKS氧气底吹炉的能量、

分析模型,对SKS氧气底吹炉的能量、 损失分布状况以及

损失分布状况以及 效率进行计算和分析,并对热、

效率进行计算和分析,并对热、 平衡2种分析方法进行比较。研究结果表明:当没有烟气回收装置和余热利用设备时,SKS底吹炉的

平衡2种分析方法进行比较。研究结果表明:当没有烟气回收装置和余热利用设备时,SKS底吹炉的 效率仅为25.28%,排烟

效率仅为25.28%,排烟 损失、输出产品的物理

损失、输出产品的物理 和内部化学反应等不可逆

和内部化学反应等不可逆 损失达74.72%,炉子的节能潜力很大;总

损失达74.72%,炉子的节能潜力很大;总 流量为 1.527 275 2×1011 J/h,远远大于总热流量6.399 425 0×1010 J/h,说明

流量为 1.527 275 2×1011 J/h,远远大于总热流量6.399 425 0×1010 J/h,说明 平衡分析比热平衡分析更能反映SKS氧气底吹炉的物质流和能量流的本质,应推广采用

平衡分析比热平衡分析更能反映SKS氧气底吹炉的物质流和能量流的本质,应推广采用 效率来评价类似有色冶金炉窑的运行状况。

效率来评价类似有色冶金炉窑的运行状况。

关键词:SKS炼铅;底吹炉; 分析;

分析; 效率;节能

效率;节能

中图分类号:TF062 文献标志码:A 文章编号:1672-7207(2010)03-1190-06

Exergy analysis of oxygen bottom blown furnace in

SKS lead smelting system

JIANG Ai-hua1, 2, YANG Shuang-huan1, MEI Chi1, SHI Zhang-ming1, 2, ZHU Xiao-jun1, 2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Hunan Research Center of Energy-saving Evaluation Technology, Changsha 410083, China)

Abstract: In order to reveal the mechanisms of the losses as the result of internal and external irreversibility in a bottom blown furnace in SKS lead smelting process, an exergy analysis model of the furnace was developed by adopting exergy balance approach. Energy and exergy loss distribution and exergy efficiency in the procedure of the furnace were computed and analyzed, and comparison between energy conservation analysis and exergy analysis was made. The results show that the exergy efficiency of the SKS bottom blown furnace is only 25.28% if there is no flue gas recovery equipment and waste heat recovery device, whereas the total exergy loss, which includes exergy loss caused by exhaust smoke, physical exergy loss of the output production and internal exergy loss due to irreversibility factors such as chemical reaction, etc., accounts for 74.72%. Hence the furnace has great energy saving potential. The total exergy flow of 1.527 275 2×1011 J/h is much greater than the total heat flow of 6.399 425 0×1010 J/h, which shows that the essence indwelled in material and energy flow of the SKS bottom-blowing furnace is better manifested through exergy analysis than through energy conversation analysis. Therefore, the exergy efficiency approach should be widely used to assess the performance of metallurgical furnaces similar to bottom blown furnace.

Key words: SKS lead smelting; bottom blown furnace; exergy analysis; exergy efficiency; energy saving

自从蒸汽机被发明并被应用于各工业领域以来,人们对能源利用进行了大量分析和研究。为提高能量利用和转化效率、确定能量损失的性质、大小与分布,基于热力学理论对能量系统进行分析,称为能量系统的热力学分析。热力学分析方法一般可分为2种:热平衡方法和 平衡方法,也称热力学第一定律方法与第二定律方法。热力学第一定律方法是以能量守恒和转换定律为基础,运用热平衡原理,以热效率为基本准则,分析系统的热力学完善性,在量方面揭示能量转换、传递、有效利用和损失情况,确定某个系统、设备的能量利用或转换效率。

平衡方法,也称热力学第一定律方法与第二定律方法。热力学第一定律方法是以能量守恒和转换定律为基础,运用热平衡原理,以热效率为基本准则,分析系统的热力学完善性,在量方面揭示能量转换、传递、有效利用和损失情况,确定某个系统、设备的能量利用或转换效率。 平衡分析法自20世纪70年代能源危机以后逐步得到发展和应用,它是同时以热力学第一定律和热力学第二定律为依据,对能量的“量”和“质”进行统一的分析法,所依据的是能量中有效能即

平衡分析法自20世纪70年代能源危机以后逐步得到发展和应用,它是同时以热力学第一定律和热力学第二定律为依据,对能量的“量”和“质”进行统一的分析法,所依据的是能量中有效能即 的平衡关系。热平衡分析方法不能揭示系统内部存在的能量“质”的贬值和耗散,不能深刻揭示能量损耗的本质,也不能科学地表征能量利用程度。与热平衡分析法相比,

的平衡关系。热平衡分析方法不能揭示系统内部存在的能量“质”的贬值和耗散,不能深刻揭示能量损耗的本质,也不能科学地表征能量利用程度。与热平衡分析法相比, 平衡分析法是更加完善、更加科学的热力系统分析方法,它能够揭示用能系统各环节的有效能损失(做功能力损失),进而对系统的热力学完善度进行判断,以评价用能的完善程度,找出

平衡分析法是更加完善、更加科学的热力系统分析方法,它能够揭示用能系统各环节的有效能损失(做功能力损失),进而对系统的热力学完善度进行判断,以评价用能的完善程度,找出 损最大的环节和部位,为改造、优化系统和挖掘节能潜力指明方向[1]。

损最大的环节和部位,为改造、优化系统和挖掘节能潜力指明方向[1]。 分析已被国外学者广泛应用于冶金、电力、水泥等高耗能生产过程和设备的能量系统分析和评价[2-6],目前,

分析已被国外学者广泛应用于冶金、电力、水泥等高耗能生产过程和设备的能量系统分析和评价[2-6],目前, 分析已经成为评价1个行业、国家用能效率及可持续发展前景乃至地球环境资源状况的重要工具[7-9]。自20世纪90年代以来,

分析已经成为评价1个行业、国家用能效率及可持续发展前景乃至地球环境资源状况的重要工具[7-9]。自20世纪90年代以来, 分析法在我国逐渐得到应用和推广,目前已用于分析火电厂热力系统与设备、炼铁炉窑、制冷空调系统等领域中的能效状况和指导节能改造[10-12]。

分析法在我国逐渐得到应用和推广,目前已用于分析火电厂热力系统与设备、炼铁炉窑、制冷空调系统等领域中的能效状况和指导节能改造[10-12]。 分析虽然在国内高能耗工业生产过程中得到高度关注和应用,但用于冶金工业的具体生产工序、设备的分析研究很少。在有色冶金炉窑特别是炼铅工序中的应用研究更少。铅冶炼行业是典型的传统高耗能行业,而对于炼铅企业,熔炼炉是企业的心脏,其工作状况的好坏直接关系到铅生产的质量、能源消耗和成本的高低。SKS炼铅法(即水口山炼铅法)为氧气底吹熔炼-鼓风炉还原炼铅法,是我国先进炼铅方法。SKS炼铅法的最大特点是解决了传统烧结过程中SO2烟气和铅尘严重污染环境的问题。富氧底吹炉是SKS炼铅工艺的核心设备,采用SKS法的炼铅企业,其节能工作必须以氧气底吹炉炼铅工序为重点来进行。因 此,采用

分析虽然在国内高能耗工业生产过程中得到高度关注和应用,但用于冶金工业的具体生产工序、设备的分析研究很少。在有色冶金炉窑特别是炼铅工序中的应用研究更少。铅冶炼行业是典型的传统高耗能行业,而对于炼铅企业,熔炼炉是企业的心脏,其工作状况的好坏直接关系到铅生产的质量、能源消耗和成本的高低。SKS炼铅法(即水口山炼铅法)为氧气底吹熔炼-鼓风炉还原炼铅法,是我国先进炼铅方法。SKS炼铅法的最大特点是解决了传统烧结过程中SO2烟气和铅尘严重污染环境的问题。富氧底吹炉是SKS炼铅工艺的核心设备,采用SKS法的炼铅企业,其节能工作必须以氧气底吹炉炼铅工序为重点来进行。因 此,采用 分析方法对冶金工序能量利用情况进行分析,能够发现工序中不可逆

分析方法对冶金工序能量利用情况进行分析,能够发现工序中不可逆 损失较大的环节和设备,揭示其内、外部不可逆损失的机理,可为工序和炉子的进一步节能减排技术改造提供先进的理论和技术支撑,对降低SKS炼铅能耗和发展

损失较大的环节和设备,揭示其内、外部不可逆损失的机理,可为工序和炉子的进一步节能减排技术改造提供先进的理论和技术支撑,对降低SKS炼铅能耗和发展 理论都具有重要意义。

理论都具有重要意义。

1 SKS氧气底吹炉的 平衡计算

平衡计算

1.1 底吹炉熔炼系统 分析模型

分析模型

采用SKS法炼铅,铅精矿的氧化熔炼是在底吹炉中完成的。底吹炉炉内过程是涉及多种不可逆因素的化学反应过程。炉内情况复杂,在底吹炉连续生产中,既有铅精矿、铅烟尘、溶剂等固态物质的输入,又有液态铅水、高铅渣和烟尘、烟气的输出。底吹炉处于复杂的固相、液相和气相3相流动的状态。在正常运行工况下,底吹炉可以看作是1个稳定流动的开口 系统。

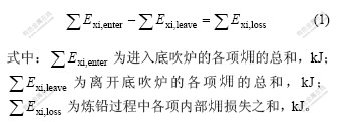

在实际热力过程中都是不守恒的,这是热力学第二定律反映的能量不断贬值的本质,只有理想的可逆过程的

在实际热力过程中都是不守恒的,这是热力学第二定律反映的能量不断贬值的本质,只有理想的可逆过程的 才保持不变。底吹炉的

才保持不变。底吹炉的 分析计算模型基于它的进、出

分析计算模型基于它的进、出 的不等性。进、出炉子的

的不等性。进、出炉子的 差为过程的内部不可逆造成的各项

差为过程的内部不可逆造成的各项 损失之和,可用下式 表示:

损失之和,可用下式 表示:

式(1)中的 损失包括化学反应、不完全燃烧和其他不可逆性如温差传热等造成的

损失包括化学反应、不完全燃烧和其他不可逆性如温差传热等造成的 损失。

损失。

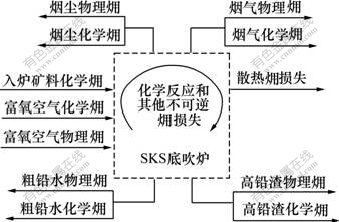

图1所示为SKS底吹炉的各股 流走向。从图1可以看出:进入底吹炉的

流走向。从图1可以看出:进入底吹炉的 流包括入炉矿料

流包括入炉矿料 和富氧空气

和富氧空气 ;离开炉子的

;离开炉子的 流包括底吹炉烟气

流包括底吹炉烟气 、烟尘

、烟尘 、高铅渣

、高铅渣 、粗铅

、粗铅 、炉壁散热

、炉壁散热 损失等。其中:高于环境温度、压力的各物质流都不仅仅有化学

损失等。其中:高于环境温度、压力的各物质流都不仅仅有化学 ,还有相对于环境的物理

,还有相对于环境的物理 。

。

图1 SKS氧气底吹炉 平衡图

平衡图

Fig.1 Exergy balance on oxygen bottom blown furnace in SKS

1.2 底吹炉 效率计算模型

效率计算模型

对 进行分析的目的是找出底吹炉炼铅工序的

进行分析的目的是找出底吹炉炼铅工序的 利用和损失情况。

利用和损失情况。 效率是反映1个工序或流程

效率是反映1个工序或流程 的有效利用程度的重要指标,可以用来衡量工序或整个流程的热力学完善程度。

的有效利用程度的重要指标,可以用来衡量工序或整个流程的热力学完善程度。 效率是熔炼过程被利用或收益的

效率是熔炼过程被利用或收益的 Ex,gain与支付或耗费的

Ex,gain与支付或耗费的 Ex,pay之比,用he表示,即

Ex,pay之比,用he表示,即

由式(1)可以计算底吹炉内部不可逆造成的 损失,这是在热平衡分析中不能反映的。但是,内部不可逆

损失,这是在热平衡分析中不能反映的。但是,内部不可逆 损失仅仅是SKS炼铅氧气底吹炉

损失仅仅是SKS炼铅氧气底吹炉 损失的一部分。因此,对于底吹炉,输出

损失的一部分。因此,对于底吹炉,输出 并不全是收益

并不全是收益 。式(2)中,收益

。式(2)中,收益 Ex,gain是指储存在出炉中间产品粗铅、高铅渣和回炉利用的烟尘中的化学

Ex,gain是指储存在出炉中间产品粗铅、高铅渣和回炉利用的烟尘中的化学 ,若建有烟气制酸系统和余热锅炉,则收益

,若建有烟气制酸系统和余热锅炉,则收益 Ex,gain还包括被有效利用的烟气

Ex,gain还包括被有效利用的烟气 ;耗费

;耗费 Ex,pay为富氧空气和投入矿料的全 部

Ex,pay为富氧空气和投入矿料的全 部 。

。

1.3  计算

计算

1.3.1 基本假设

假设输入、输出底吹炉的矿料、粗铅水、高铅渣、烟尘等载能体为多种成分组成的理想熔体,富氧空气及底吹炉烟气为理想气体混合物。

是相对于外界环境的状态参数,本文取环境参数为:环境压力p0=1.01×105 Pa,环境温度T0=293 K。

是相对于外界环境的状态参数,本文取环境参数为:环境压力p0=1.01×105 Pa,环境温度T0=293 K。 按物理

按物理 和化学

和化学 分别计算。物理

分别计算。物理 是任意状态的物质与环境仅存在热不平衡和力不平衡时具有的

是任意状态的物质与环境仅存在热不平衡和力不平衡时具有的 ,有温度

,有温度 和压力

和压力 。物质仅与环境状态处于化学不平衡时具有的

。物质仅与环境状态处于化学不平衡时具有的 为化学

为化学 。各项

。各项 计算公式如下[13-14]。

计算公式如下[13-14]。

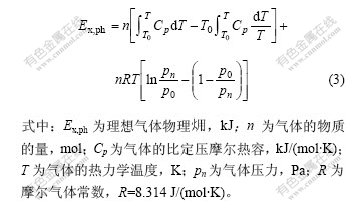

1.3.2 理想气体

理想气体 包括理想气体物理

包括理想气体物理 和理想气体化学

和理想气体化学 。

。

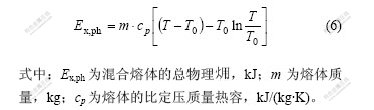

(1) 理想气体物理 :

:

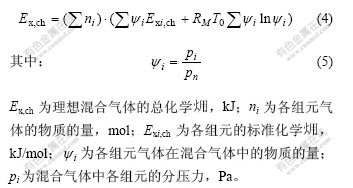

(2) 理想气体化学 :

:

1.3.3 理想熔体

理想熔体 包括理想熔体物理

包括理想熔体物理 和理想熔体化学

和理想熔体化学 。

。

(1) 理想熔体物理

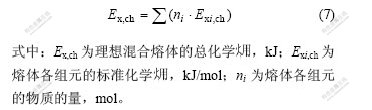

(2) 理想熔体化学 :

:

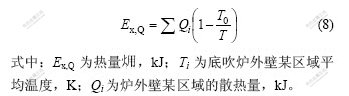

1.3.4 热量

1.4 底吹炉 平衡计算结果

平衡计算结果

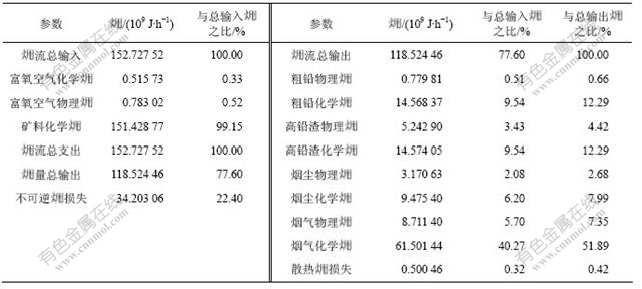

为使计算结果更准确,以SKS底吹炉正常运行2个周期(4 h)为计算基准,根据实测数据对底吹炉进行物料平衡计算。在物料平衡分析基础上所得SKS氧气底吹炉能量平衡计算结果见表1[15]。在文献[15]中的物料平衡和热平衡分析的基础上,对SKS氧气底吹炉进行 平衡计算,忽略

平衡计算,忽略 量非常小的冷却水和铅锍的

量非常小的冷却水和铅锍的 ,所得

,所得 分析结果如表2所示。

分析结果如表2所示。

1.5 底吹炉 效率

效率

由表2可知:输入底吹炉的总 流为1.527 275 2× 1011 J/h,其中主要是入炉矿料

流为1.527 275 2× 1011 J/h,其中主要是入炉矿料 ,占总输入

,占总输入 流的99.15%。收益(有效)

流的99.15%。收益(有效) 为粗铅水、高铅渣和烟尘的化学

为粗铅水、高铅渣和烟尘的化学 ,分别占总输入

,分别占总输入 流的9.54%,9.54%和6.20%。因此,在没有烟气回收装置和各项余热未得到利用时,由式(2)可得底吹炉本体的

流的9.54%,9.54%和6.20%。因此,在没有烟气回收装置和各项余热未得到利用时,由式(2)可得底吹炉本体的 效率为25.28%,即排烟

效率为25.28%,即排烟 损失、输出产品的物理

损失、输出产品的物理 和内部化学反应、温差传热等不可逆

和内部化学反应、温差传热等不可逆 损失造成的总

损失造成的总 损失为74.72%。

损失为74.72%。

表1 SKS氧气底吹炉能量平衡计算结果

Table 1 Calculation results of energy balance on oxygen bottom blown furnace in SKS

表2 SKS氧气底吹炉 平衡结果

平衡结果

Table 2 Datasheet of exergy balance on oxygen bottom blown furnace in SKS

2 SKS底吹炉 平衡计算结果及应用分析

平衡计算结果及应用分析

2.1  分析对系统耗能状况与节能潜力的反映

分析对系统耗能状况与节能潜力的反映

以上 分析计算结果表明:当没有烟气回收装置和余热利用设备时,SKS底吹炉的

分析计算结果表明:当没有烟气回收装置和余热利用设备时,SKS底吹炉的 效率仅为25.28%,炉子的总

效率仅为25.28%,炉子的总 损失为74.72%,其中,内部不可逆因素造成22.40%的

损失为74.72%,其中,内部不可逆因素造成22.40%的 损失(见表2),炉子的节能潜力很大。因此,要加强余热余能的回收,降低不可逆程度,有针对性地减少各项

损失(见表2),炉子的节能潜力很大。因此,要加强余热余能的回收,降低不可逆程度,有针对性地减少各项 损失。

损失。

(1) 减少排烟 损失。由表2可以看出:输出

损失。由表2可以看出:输出 最大的是烟气

最大的是烟气 流,为总输入

流,为总输入 的45.97%(其中,烟气物理

的45.97%(其中,烟气物理 占5.70%,烟气化学

占5.70%,烟气化学 占40.27%),占总输出

占40.27%),占总输出 的59.24%(其中,烟气物理

的59.24%(其中,烟气物理 占7.35%,烟气化学

占7.35%,烟气化学 占51.89%)。烟气的化学

占51.89%)。烟气的化学 占总输出

占总输出 的51.89%,而烟气的主要成分为SO2和N2,相对于SO2的标准化学

的51.89%,而烟气的主要成分为SO2和N2,相对于SO2的标准化学 ,N2的标准化学

,N2的标准化学 很小[14-15],烟气的化学

很小[14-15],烟气的化学 的绝大部分是SO2的化学

的绝大部分是SO2的化学 。因此,应加强烟气余热的回收利用,提高SO2的回收率。本文研究的SKS炼铅系统投运时就有制硫酸配套装置,后期的节能改造加装了余热锅炉,回收了烟气中部分余热和绝大部分SO2,做到了烟气达标排放。

。因此,应加强烟气余热的回收利用,提高SO2的回收率。本文研究的SKS炼铅系统投运时就有制硫酸配套装置,后期的节能改造加装了余热锅炉,回收了烟气中部分余热和绝大部分SO2,做到了烟气达标排放。

(2) 充分利用输出中间产品的物理 。高铅渣出炉时温度达1 200 ℃以上,冷却到常温再进入鼓风炉还原时,其占输入

。高铅渣出炉时温度达1 200 ℃以上,冷却到常温再进入鼓风炉还原时,其占输入 3.34%的物理

3.34%的物理 全部损失。若缩短工艺流程,使高铅渣出炉后直接进入下一道生产工序,则高铅渣的物理

全部损失。若缩短工艺流程,使高铅渣出炉后直接进入下一道生产工序,则高铅渣的物理 就可以得到充分利用,应加快液态高铅渣直接还原技术及还原炉的开发,减少高温物体的物理

就可以得到充分利用,应加快液态高铅渣直接还原技术及还原炉的开发,减少高温物体的物理 损失。

损失。

(3) 减少内部化学反应等不可逆 损失。化学反应、温差传热等内部不可逆因素造成的

损失。化学反应、温差传热等内部不可逆因素造成的 损失为22.40%(表2),这导致输出

损失为22.40%(表2),这导致输出 与输入

与输入 不相等。这部分

不相等。这部分 损虽然大,但有的是熔炼过程本身很难避免的。可对炉内熔炼过程的物质流、能量流进行优化控制,以减少炉内温差、压差造成的不可逆损失。此外,发展新的炼铅工艺如底吹炉低温冶炼技术,可进一步减少炉内不可逆

损虽然大,但有的是熔炼过程本身很难避免的。可对炉内熔炼过程的物质流、能量流进行优化控制,以减少炉内温差、压差造成的不可逆损失。此外,发展新的炼铅工艺如底吹炉低温冶炼技术,可进一步减少炉内不可逆 损失。

损失。

2.2  效率对炉子资源消耗和利用状况的反映

效率对炉子资源消耗和利用状况的反映

由表1可知:炉子的绝大部分热量(98%以上)收入来自炉内的化学反应过程,热平衡分析不能揭示外界投入能量实际利用情况;据热效率的定义,底吹炉有效利用的热量应该是表1中粗铅、铅锍和高铅渣等产品离开炉子时含有的占总收入能量的21.8%,但这部分热能将会随产品冷却降温到环境温度而全部消失。从表2可以看出:底吹炉的99.15%的 来自入炉矿料的化学

来自入炉矿料的化学 ,显示了外界的能量随物质的投入情况;而底吹炉的输出产品粗铅、铅锍和高铅渣的化学

,显示了外界的能量随物质的投入情况;而底吹炉的输出产品粗铅、铅锍和高铅渣的化学 是贮存在物体内部的有效能,不会随着温度降低而消失。因此,对于底吹炉这类有色冶金炉窑来说,热平衡计算分析虽然有必要,但热效率已经没有实际意义,

是贮存在物体内部的有效能,不会随着温度降低而消失。因此,对于底吹炉这类有色冶金炉窑来说,热平衡计算分析虽然有必要,但热效率已经没有实际意义, 效率更能反映炉子的能量利用状况。

效率更能反映炉子的能量利用状况。

2.3  对物质与能量流本质的反映

对物质与能量流本质的反映

任何偏离了环境状态的物质都具有 。由图1和表2可以看出:底吹炉物质的流动始终伴随着

。由图1和表2可以看出:底吹炉物质的流动始终伴随着 流,而不一定伴随着热流。比较表1和表2中的能量流可见:表2中的各项

流,而不一定伴随着热流。比较表1和表2中的能量流可见:表2中的各项 流与表1中的对应热流没有相关性,底吹炉的输入总

流与表1中的对应热流没有相关性,底吹炉的输入总 为1.527 275 2 ×1011 J/h,远远大于总热流量6.399 425×1010 J/h,这与一般能源生产或全部依靠燃料的生产过程的热和

为1.527 275 2 ×1011 J/h,远远大于总热流量6.399 425×1010 J/h,这与一般能源生产或全部依靠燃料的生产过程的热和 分析中

分析中 流总是小于热流的常规现象[10, 12, 15]存在矛盾,但这更加反映了

流总是小于热流的常规现象[10, 12, 15]存在矛盾,但这更加反映了 流与物质流动的紧密相关性;输出

流与物质流动的紧密相关性;输出 与输入

与输入 不相等,其中化学反应、温差传热等内、外部不可逆因素造成的

不相等,其中化学反应、温差传热等内、外部不可逆因素造成的 损失为22.40%(表2)。

损失为22.40%(表2)。 的不守恒揭示了能量流动过程的实质,即能量在流动过程中不断地贬值的规律。从表1还可以看出:富氧空气喷嘴冷却水带走的热量是总热量的6.83%,但是,冷却水温几乎接近环境温度,水带走热量的

的不守恒揭示了能量流动过程的实质,即能量在流动过程中不断地贬值的规律。从表1还可以看出:富氧空气喷嘴冷却水带走的热量是总热量的6.83%,但是,冷却水温几乎接近环境温度,水带走热量的 很小,可以忽略不计。但实质上冷却水与高温的氧气喷管(氧枪)之间的温差传热造成了不可逆损失,

很小,可以忽略不计。但实质上冷却水与高温的氧气喷管(氧枪)之间的温差传热造成了不可逆损失, 分析中这部分损失包含在内、外部不可逆因素造成的

分析中这部分损失包含在内、外部不可逆因素造成的 损失中。

损失中。

3 结论

(1) SKS氧气底吹炉的 效率很低,仅为25.28%,节能潜力很大,应加强SKS底吹炉的节能技术改造。回收利用烟气的化学

效率很低,仅为25.28%,节能潜力很大,应加强SKS底吹炉的节能技术改造。回收利用烟气的化学 (SO2)和物理

(SO2)和物理 (余热),充分利用高铅渣的物理

(余热),充分利用高铅渣的物理 ,减少炉内不可逆损失,可进一步提高底吹炉的

,减少炉内不可逆损失,可进一步提高底吹炉的 效率。

效率。

(2) 对于类似SKS底吹炉无需燃料投入或少量投入的冶金炉窑,热平衡分析不能准确反映物质能量的投入、支出状况,热效率没有实际意义,而 效率更能反映炉子的能量和物质有效利用状况。

效率更能反映炉子的能量和物质有效利用状况。

(3) 对于类似SKS氧气底吹炉的有色冶金炉窑,热平衡计算仍然是必要的,但热、 分析之间没有大的相关性,将出现总

分析之间没有大的相关性,将出现总 流量远远大于总热流量的现象,这说明

流量远远大于总热流量的现象,这说明 平衡分析能够更好地反映SKS氧气底吹炉等有色冶金炉窑的物质流和能量流的本质,因此,在冶金炉窑能量系统的分析中,需充分利用

平衡分析能够更好地反映SKS氧气底吹炉等有色冶金炉窑的物质流和能量流的本质,因此,在冶金炉窑能量系统的分析中,需充分利用 平衡分析方法。

平衡分析方法。

参考文献:

[1] 布罗章斯基B M.  方法及其应用[M]. 王加璇, 译. 北京: 中国电力出版社, 1997: 7-9.

方法及其应用[M]. 王加璇, 译. 北京: 中国电力出版社, 1997: 7-9.

Бrodyansky B M. Exergy analysis method and its application[M]. WANG Jia-xuan, trans. Beijing: China Electric Power Press, 1997: 7-9.

[2] Bisso G. Exergy method for efficient energy resource use in the steel industry[J]. Energy, 1993, 18(9): 971-985.

[3] Vladimir S, Sergey S. Energy use efficiency of metallurgical Processes[J]. Energy Conservation and Management, 1998, 39(16/18): 1803-1809.

[4] Verkhivker G P, Kosoy B V. On the exergy analysis of power plants[J]. Energy Conservation and Management, 2001, 42(18): 2053-2059.

[5] Rasul M G, Widianto W, Mohanty B. Assessment of the thermal performance and energy conservation opportunities of a cement industry in indonesia[J]. Applied Thermal Engineering, 2005, 25(17/18): 2950-2965.

[6] Camdali U, Erisen A, Celen F. Energy and exergy analyses in a rotary burner with pre-calcinations in cement production[J]. Energy Conversion and Management, 2004, 45(18/19): 3017-3031.

[7] Utlu Z, Hepbasli A. Analysis of energy and exergy use of the Turkish residential-commercial sector[J]. Building and Environment, 2005, 40(5): 641-655.

[8] Utlu Z,Hepbasli A. Assessment of the Turkish utility sector through energy and exergy analyses[J]. Energy Policy, 2007, 35(10): 5012-5020.

[9] Hermann W A. Quantifying global exergy resources[J]. Energy, 2006, 31(12): 1685-1702.

[10] 张晓晖, 杨茉, 卢玫, 等. 火电厂热力系统 分析计算研究[J]. 动力工程, 2004, 24(5): 703-707.

分析计算研究[J]. 动力工程, 2004, 24(5): 703-707.

ZHANG Xiao-hui, YANG Mo, LU Mei, et al. Research on exergy analysis computation of coal-fired unit thermal system[J]. Power Engineering, 2004, 24(5): 703-707.

[11] 吴复忠, 蔡九菊, 张琦, 等. 炼铁系统的物质流和能量流的 分析[J]. 工业加热, 2007, 36(1): 15-18.

分析[J]. 工业加热, 2007, 36(1): 15-18.

WU Fu-zhong, CAI Jiu-ju, ZHANG Qi, et al. Exergy analysis of energy and materials flows in the system of iron-making plants[J]. Industrial Heating, 2007, 36(1): 15-18.

[12] 甄志, 崔晓钢, 陈鸿伟, 等.  分析方法及在工程领域中的应用[J]. 电力科学与工程, 2003(1): 62-65.

分析方法及在工程领域中的应用[J]. 电力科学与工程, 2003(1): 62-65.

ZHEN Zhi, CUI Xiao-gang, CHEN Hong-wei, et al. Exergy analysis method and its application[J]. Electric Power Science and Engineering, 2003(1): 62-65.

[13] 朱自强, 徐汛. 化工热力学[M]. 2版. 北京: 化学工业出版社, 1995: 231-278.

ZHU Zi-qiang, XU Xun. Chemical engineering thermodynamics[M]. 2nd ed. Beijing: Chemical Industry Press, 1995: 231-278.

[14] 吴存真, 张诗针, 孙志坚. 热力过程( )分析基础[M]. 杭州: 浙江大学出版社, 2000: 55-74.

)分析基础[M]. 杭州: 浙江大学出版社, 2000: 55-74.

WU Cun-zhen, ZHANG Shi-zhen, SUN Zhi-jian. Elements of exergy analysis on thermal process[M]. Hangzhou: Zhejiang University Press, 2002: 55-74.

[15] 杨双欢, 蒋爱华, 时章明, 等. SKS炼铅底吹炉热平衡测试与节能措施研究[J]. 冶金能源, 2009, 28(6): 50-53.

YANG Shuang-huan, JIANG Ai-hua, SHI Zhang-ming, et al. Thermal balance test and energy saving measures research for bottom blown furnace of SKS[J]. Energy for Metallurgical Industry, 2009, 28(6): 50-53.

收稿日期:2009-08-15;修回日期:2009-10-21

基金项目:湖南省科技计划攻关重大专项(子项)项目(05SK1003-1)

通信作者:蒋爱华(1965-),女,湖南永州人,副教授,博士研究生,从事能源系统工程及智能评价研究;电话:13975165780;E-mail: jah65@163.com

(编辑 陈灿华)