文章编号:1004-0609(2011)07-1713-06

自制铝土矿脱硅水力分选设备的流场模拟及实验研究

卢东方, 王毓华, 黄 鹏, 胡岳华

(中南大学 资源加工与生物工程学院,长沙 410083)

摘 要:采用Fluent6.3软件对自制水力分选设备的流场进行模拟。模拟结果表明:设备锥体内流体的旋转运动使矿浆在径向分散和分离,向上运动的流体能促使固相尤其是粒度较小和密度较低的含硅相向上运动,实现铝相和硅相在轴向上的分离;斜板能显著提高铝相在上升过程中的沉降效率。在自制设备上进行的实际矿石脱硅试验结果表明:当原矿铝硅比(质量比)为4.7时,在搅拌器转速为150 r/min、斜板高度为16 cm、给矿量为100 mL/min及底流与溢流体积比为1?3.5的条件下,经设备一次脱硅处理,可得到Al2O3回收率为90.64%、铝硅质量比为6.34?1的精矿。

关键词:铝土矿;脱硅;水力分级;模拟

中图分类号:TD952 文献标志码:A

Flow field simulation and experimental study of self-made hydraulic classification equipment for bauxite desiliconization

LU Dong-fang, WANG Yu-hua, HUANG Peng, HU Yue-hua

(School of Resources Processing and Bioengineering, Central South University, Changsha 410083, China)

Abstract:The flow field in the self-made hydraulic classification equipment was simulated by Fluent 6.3 software. The simulation results show that the slight turbulent in the cone zone makes the mineral particles disperse and separate in the radial direction. The upwelling makes the solid phase move up, especially for silicates with the small particle size and low density, leading to the separation of alumina phase and silicon phase in the radial direction. The sloping plates improve the sedimentation efficiency of aluminum solid phase greatly in the upward process. Furthermore, the experimental results on the real bauxite ores show that a concentrate with Al2O3 recovery of 90.64% and mass ratio of Al to Si of 6.34?1 can be obtained from the feed with the mass ratio of Al to Si of 4.7 based on one stage desiliconization separation. At this time, the speed of the impeller is 150 r/min, the height of sloping plates is 16 cm, the speed of the feed is 100 mL/min and the volume ratio of overflow to underflow is 1:3.5.

Key words: bauxite; desiliconization; hydraulic classification; simulation

一水硬铝石型铝土矿主要采用洗矿筛分、浮选(正浮选和反浮选)和选择性絮凝等工艺实现铝土矿选矿脱硅[1]。对于选择性絮凝脱硅工艺,除应采用高效絮凝剂外,针对铝土矿脱硅的特点,配套的水力分选设备的研制也是不容忽视的。而采用合理、有效的方法对设备内部流场进行研究,则是研制具备良好分选性能设备的关键。

研究流场的方法一般分为试验流体力学(EFD)和计算流体力学(CFD)[2]两种,通过试验流体力学可以得到非设备几何参数的准确数据,评价设备工作效果,但不能表征流体状态和设备工作过程,很难得到结构复杂设备流场的详细信息,且耗时、耗力,因此,必须借助计算流体力学对流场进行模拟,描述流体状态和预测设备工作效果。

自20世纪90年代以来,CFD技术在选矿及相关领域的研究中得到了极大发展。PINELLI等[3]采用拉氏方法并结合固体沉降速度模型和多相流模型,分别在标准搅拌槽和多层叶轮搅拌槽内对固体颗粒的分布进行模拟,模拟结果与实验结果吻合较好。ZHANG等[4]用低雷诺数(Re) k—ε二元方程模型和颗粒随机轨道模型模拟了垂直管内固、液两相流运动对材料避免冲刷腐蚀过程的机理。结合单相流动场计算结果,MONTANTE等[5]对搅拌槽内固、液两相体系的固液浓度分布进行了模拟。MICALE等[6]使用Euler模型对单层桨和多层桨的搅拌槽内中、低浓度固体颗粒分布进行了研究,其模拟结果和实验测量的固体颗粒的轴向浓度分布基本一致。OSHINOWO和BAKKER[7]使用Euler 颗粒多相流模型(EGM)对搅拌槽内固体悬浮物进行研究,所研究颗粒的浓度范围为 0.5%~50%(质量分数)。DEGLON和MEYER [8]采用旋转叶轮多重参考系模型(MRF)和标准k—ε湍流模型模拟了搅拌槽中流体的运动。

本文作者采用商业软件Fluent 6.3对自制铝土矿脱硅水力分选设备的流场进行模拟;采用标准k—ε模型对流场的湍动耗散率进行分析;采用混合模型[9-15]预测设备内部不同位置物相的体积分数分布。通过实际矿石试验,对CFD模拟结果进行验证,模拟结果及试验研究均表明,自制水力分选设备能够高效地脱除铝土矿中的硅质矿泥。

1 数值模拟模型

自制铝土矿脱硅水力分选设备剖面图如图1所示。设备由锥体、柱体、斜板和搅拌器4部分组成,锥体高10.4 cm,锥角69?,柱体高26.8 cm,两层斜板高度分别为5和4 cm,呈60°夹角放置。为了避免斜板与柱体相交处出现死角,斜板与柱体之间留有0.5 cm的缝隙。给矿速度为720 mL/min,搅拌器转速为150 r/min。

1.1 网格生成

为便于采用MRF方法进行模拟,将设备内部划分成两个区域:搅拌器及靠近搅拌器的区间为内区,内部的其他区间为外区。用非结构四面体网格划分设备内部区域,网格节点约1.2×106个,网格的划分如图2所示。

图1 铝土矿脱硅水力分选设备剖面图

Fig.1 Profile of hydraulic classification equipment for bauxite desiliconization

图2 设备的网格划分

Fig.2 Mesh of equipment

1.2 湍流模型控制方程

由于拟研制的水力分选设备内流体的湍流强度远小于旋流器内流体的湍流强度,而其下部装有低速转动叶轮与搅拌槽相似,因此,采用用于搅拌槽模拟的标准k—ε模型对其流场进行模拟比较合适。

标准k—ε模型是在关于湍动能k的方程基础上,再引入一个关于湍动耗散率ε的方程。在该模型中,湍动耗散率ε的定义为

(1)

(1)

式中:μ为流体湍动黏度;u为流体湍动速度;ρ为流体密度;x为尺度量。

在标准k—ε模型中,k和ε是两个基本未知量,与之对应的运输方程为

(2)

(2)

(3)

(3)

式中:Gk是由于平均速度梯度引起的湍动能k的产生项;Gh是由于浮力引起的湍动能k的产生项;YM代表可压湍流中脉动扩张的贡献;C1ε、C2ε和C3ε为经验常数;δk和δε分别是与耗散动能k和耗散率ε对应的Prandtl数;Sk和Sε为自定义源项。

对于不可压流体,Gh=0,YM=0,在不考虑源项,即Sk=0、Sε=0时,标准k—ε模型方程为

(4)

(4)

(5)

(5)

式中: ,模型常数C1ε、C2ε和C3ε及δk和δε的取值为C1ε=1.44、C2ε=1.92、C3ε=0.09、δk=1.0、δε=1.3。

,模型常数C1ε、C2ε和C3ε及δk和δε的取值为C1ε=1.44、C2ε=1.92、C3ε=0.09、δk=1.0、δε=1.3。

计算物系为水—一水硬铝石(铝相)—含硅矿物(硅相)的三相体系。一水硬铝石颗粒的平均直径为38 μm,密度为3 200 kg/m3,体积分数为1.8%;含硅矿物颗粒的平均直径为10 μm,密度为2 700 kg/m3,体积分数为3.6%;水相为主相。

2 模拟结果与讨论

2.1 近搅拌器区域径向截面的模拟结果与分析

图3所示为设备内径向截面流体的湍动耗散率分布。从图3可以看出,湍动耗散率较高的区域主要分布在搅拌器周围,最高耗散率为0.1 m2/s2,搅拌器转动使周围流体产生强烈湍动,湍动通过对流和扩散的方式传输到其他位置,使流体产生旋转运动。近搅拌器区流体的离心速度最快,矿浆进入设备后,固相随流体一起进行离心运动,密度高、粒度大的铝相在离心力作用下,向器壁运动的速度较快,导致近壁区铝相的体积分数远高于远壁区的,而截面上硅相的体积分数变化不大,其结果如图4和5所示,从而实现铝相和硅相在径向截面的分离。

图3 径向截面流体的湍动耗散率分布

Fig.3 Turbulent dissipation rate distribution of fluid in radial section

图4 径向截面铝相体积分数分布

Fig.4 Volume fraction distribution of alumina phase in radial section

图5 径向截面硅相体积分数分布

Fig.5 Volume fraction distribution of silicon phase in radial section

2.2 轴向(X=0)截面模拟结果和分析

图6所示为轴向截面铝相的体积分数分布。由图6可知,给矿时铝相体积分数为1.8%,进入设备锥体后,随着靠近底流口距离的减小,铝相体积分数迅速增大,底流出口处铝相的体积分数为2.9%,铝相主要分布在斜板部位和锥体部位,靠近上端溢流区的铝相体积分数最小。图7所示为轴向截面硅相的体积分数分布。从图7可以看出,给矿时硅相体积分数为3.6%,进入设备锥体后,随着靠近底流口距离的减小,混合相中的硅相体积分数逐渐减小,在底流出口处硅相体积分数为3.45%。这说明设备中流体的湍动不利于硅相的沉降,有利于铝相和硅相在轴向的分离。对两相在斜板上的体积分数进行比较可知,铝相经过斜板层时实现了更好的沉降,最高体积分数为3.5%,这是由铝相与硅相密度和粒度差异所致。

图6 轴向截面铝相体积分数分布

Fig.6 Volume fraction of alumina phase on axial section

图7 轴向截面硅相体积分数分布

Fig.7 Volume fraction of silicon phase on axial section

3 实验

3.1 实验矿样和药剂

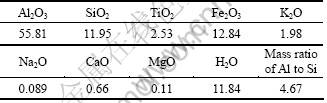

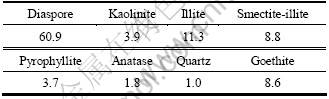

河南汇源铝土矿的主要矿物组成为一水硬铝石、伊利石、蒙脱-伊利石及针铁矿,其次为高岭石、锐钛矿以及少量的石英和方解石。矿石多元素分析和矿物组成分析结果分别见表1和2。

表1 汇源矿样的多元素分析结果

Table 1 Multi-element analysis results of ore samples in Huiyuan(mass fraction,%)

表2 汇源矿样矿物组成

Table 2 Mineral composition of ore samples in Huiyuan (mass fraction,%)

使用工业0.05%聚丙烯酸钠为絮凝剂、0.5%碳酸钠为分散剂。

3.2 实验设备

水力分选设备由锥体、柱体、斜板和搅拌器4部分组成(见图8)。其中,搅拌器的搅拌速度可调,柱体部分由多个柱体单元通过法兰连接而成,斜板部分则由多层斜板单元交错叠加而成,柱体高度和斜板层数根据实验要求调整。

铝土矿脱硅实验设备及流程见图9。矿样经磨矿作业后加入给料桶中,添加分散剂和絮凝剂,在给料桶中搅拌均匀后通过阀门进入蠕动泵,采用蠕动泵控制进入设备的矿浆流量,通过蠕动泵8控制底流流量,矿浆通过设备中心套桶进入主体设备,由于铝相矿物和硅相矿物的密度、粒度差别,在设备产生的复合力场中进行分离,密度高、粒度粗的铝相矿物沉降至设备底部,通过蠕动泵抽吸从底流口排出,而粒度细、密度低的硅相矿物随上升水流向上运动,由溢流口流出。

图8 新型铝土矿脱硅设备及主要部件

Fig.8 New classification equipment in laboratory for bauxite desiliconization and its major components: 1—Classification equipment; 2—Tilting plate; 3—Stirrer

图9 铝土矿脱硅实验装置及流程示意图

Fig.9 Schematic diagram of testing equipment and chart flow of process for bauxite desiliconization: 1—Feed barrel; 2, 4, 6, 7—Valve; 3, 8—Peristaltic pump; 5—Main equipment

3.3 实验方法

改变给料量和底流与溢流的体积比,考察设备的脱硅能力。试验过程中,设备斜板高度为16 cm,搅拌器转速为150 r/min,磨矿细度为-0.074 mm的比例为90%,用Na2CO3作分散剂,用量为2 500 g/t,聚丙烯酸钠作絮凝剂,用量为10 g/t,给矿浓度为10%(质量分数),对精矿(底流)和尾矿(溢流)分别取样,经过滤、烘干和制样后送分析化验,并计算回收率和铝硅质量比。

3.4 实验结果和讨论

3.4.1 给矿量实验

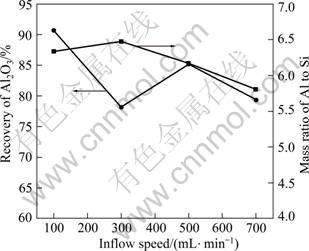

当底流与溢流的体积流量比为1?3.5时,给矿量实验结果如图10所示。当给矿量从100 mL/min增加到300 mL/min时,精矿铝硅比略有升高, Al2O3回收率则大幅度下降,当给矿量增至500 mL/min时,铝硅比开始下降,而Al2O3回收率上升,再增大给矿量到700 mL/min,精矿铝硅比和回收率都下降。由给矿量实验结果可知,当给矿量为100 mL/min时,精矿的Al2O3回收率最高,为90.64%;当给矿量为300 mL/min时,精矿铝硅比最高,为6.47?1。综合来看,给矿量为100 mL/min时,指标最好,原矿铝硅比为4.7时,可得到Al2O3回收率为90.64%、铝硅比为6.34的精矿,对铝土矿脱硅,设备具备良好的分选性。这也说明了对于试验设备来说,100 mL/min的给矿量比较合适,处理量过大则会导致设备分选性能下降。

图10 给矿量对精矿氧化铝回收率和铝硅比的影响

Fig10 Effect of inflow speed on Al2O3 recovery and mass ratio of Al to Si of concentrate

3.4.2 底流与溢流体积流量比试验

当给矿量为100 mL/min时,底流与溢流体积流量比试验结果如图11所示。当底流与溢流体积流量比由1?2变为1?3.5时,精矿Al2O3回收率略有降低而铝硅比明显增大。当底流与溢流体积流量比增至1?5时,精矿Al2O3回收率明显降低,而铝硅比变化不大。据底流与溢流体积流量比试验结果可知,当其比值为1?2时,精矿回收率最高,为90.79%;当其比值为1?5时,精矿铝硅比最高,为6.37?1。综合来看,当底流与溢流体积流量比为1?3.5时,精矿指标最好。这说明在一定范围内,增大溢流量、减小底流量能够提高精矿铝硅比,此时精矿中Al2O3的回收率略有下降;但当溢流量过大、底流量过小时,不但不能明显提高精矿铝硅比,反而会使精矿Al2O3回收率大幅度降低。这是由于溢流量增大,导致上升水流速度增大,使含硅脉石矿物随溢流排出,有利于提高精矿铝硅比,但溢流量过大则会导致上升水流速度过快,使部分一水硬铝石矿物来不及沉降即随溢流排出,反而不利于精矿Al2O3回收率和铝硅比的提高。

图11 底流与溢流体积流量比对精矿氧化铝回收率和铝硅比的影响

Fig.11 Effect of volume ratio of underflow to overflow on Al2O3 recovery and mass ratio of Al to Si of concentrate

4 结论

1) 搅拌使锥体内的流体旋转运动产生离心力场,有利于矿浆的分散、铝相和硅相在径向的分离,搅拌作用使锥体中颗粒在分散状态下沉降,减小了硅相的沉降速度,大大减缓了铝相在沉降过程中对硅相的夹杂。Z型斜板层的添加不仅有利于混合相中固相尤其是密度、粒度大铝相的沉降,而且有利于大幅度增加设备的沉降面积,提高设备的分选效率。

2) 试验结果表明,对于实验室小型设备而言,当给矿量为100 mL/min,底流与溢流体积流量比为1?3.5时,设备脱硅综合指标最好。当原矿铝硅比为4.7时,经1次脱硅处理可得到Al2O3回收率为90.64%、铝硅比为6.34的精矿。

REFERENCES

[1] 谢 珉. 论铝土矿选矿的必要性和可行性[J]. 国外金属矿选矿, 1991(7): 69-76.

XIE Min. Discussion on the necessity and feasibility of the bauxite ore dressing[J]. Foreign Metal Ore Dressing, 1991(7): 69-76.

[2] BRENNAN M S, NARASIMHA M, HOLTHAM P N. Multiphase modelling of hydrocyclones-prediction of cut-size[J]. Minerals Engineering, 2007, 20: 395-406.

[3] PINELLI D, MONTANTE G, MAGELLI F. Dispersion coefficients and settling velocities of solids in slurry vessels stirred with different types of multiple impellers[J]. Chemical Engineering Science, 2004, 59: 3081-3089.

[4] ZHANG Zheng, CHENG Xue-wen, ZHENG Yu-gui, KE Wei, YAO Zhi-ming. Numerical simulation of the erosion-corrosion of liquid-solid flows[J]. Journal of Beijing University of Chemical Technology, 2000, 8(4): 347-335.

[5] MONTANTE G, PINELLI D, MAGELLI F. Scale-up criteria for the solids distribution in slurry reactors stirred with multiple impellers[J]. Chemical Engineering Science, 2003, 58: 5363-5372.

[6] MICALE G, MONTANTE G, GRISAFI F, BRUCATO A, GODFREY J. CFD simulation of particle distribution in stirred vessels[J]. Institution of Chemical Engineers, 2000, 78: 435-444.

[7] OSHINOWO L M, BAKKER A. CFD modeling of solids suspensions in stirred tanks[C]//Proceedings of Symposium on Computational Modeling of Metals, Minerals and Meterials. Seattle: Institute of Mechanical Process Engineering, 2002: 9-20.

[8] DEGLON D A, MEYER C J. CFD modeling of stirred tank: Numerical considerations[J]. Minerals Engineering, 2006, 19: 1059-1068.

[9] MUKHERJEE A K, SRIPRIYA R, RAO P V T, DAS P. Effect of increase in feed inlet pressure on feed rate of dense media cyclone[J]. Mineral Processing, 2003, 69: 259-274.

[10] BRENNAN M S. Multiphase CFD simulations of dense medium and classifying hydrocyclones[C]//Proceedings of Third International Conference on CFD in the Minerals and Process Industries. Melbourne: Commonwealth Scientific and Industrial Research organization, 2003: 59-64.

[11] NARASIMHA M, BRENNAN M S, HOLTHAM P N, PURCHASE A, NAPIER-MUNN T J. Large eddy simulation of a dense medium cyclone-prediction of medium segregation and coal partitioning[C]//Proceedings of the Fifth International Conference on CFD in the Process Industries. Melbourne: Commonwealth Scientific and Industrial Research organization, 2006: 1-6.

[12] 单永波, 李玉星. 雷诺应力(RSM)模型对旋流器分离性能预测研究[J]. 炼油技术与工程, 2005, 35(1): 18-22.

SHAN Yong-bo, LI Yu-xing. The separation performance prediction and study of using the Reynolds stress model (RSM) to simulate the hydrocyclone[J]. Petroleum Refinery Engineering, 2005, 35(1): 18-22.

[13] NARASIMHA M, BRENNAN M S, HOLTHAM P N, NAPIER-MUNN T J. A comprehensive CFD model of medium cyclone performance[J]. Minerals Engineering, 2007, 20: 414-426.

[14] SCHUETZ S, MAYER G, BIERDEL M, PIESCHE M. Investigations on the flow and separation behaviour of hydrocyclones using computational fluid dynamics[J]. Mineral Processing, 2004, 73: 229-237.

[15] DELGADILLO J A, RAJAMANI R K. A comparative study of three turbulence-closure models for the hydrocyclone problem[J]. Mineral Processing, 2005, 77: 217-230.

(编辑 陈卫萍)

基金项目:国家重点基础研究发展计划资助项目(2005CB623701)

收稿日期:2010-08-25;修订日期:2010-11-22

通信作者:王毓华,教授,博士;电话:0731-88830545;E-mail: wangyh@mail.csu.edu.cn