CSP热连轧机板形的调控特性

李洪波1,张 杰1,曹建国1,司小明2,张树山2,李耀辉2

(1. 北京科技大学 机械工程学院,北京,100083;

2. 马鞍山钢铁股份有限公司,安徽 马鞍山,243003)

摘 要:利用ANSYS有限元模型,对某厂1.80 m紧凑式热带工艺(CSP)热连轧机基本板形调控特性进行分析,针对CSP同宽轧制的特点,采集生产现场辊形数据。研究结果表明:工作辊的磨损情况与常规热轧的磨损情况有所不同;CSP热连轧机工作辊的磨损造成辊缝四次凸度随窜辊值发生明显的非线性变化,这是工作辊服役后期复合浪频繁生成并导致换辊的主要原因;工作辊的磨损降低了低凸度轧机的控制能力,易导致带钢凸度偏大,若继续轧制窄规格板形,则可保持凸度,控制稳定性。

关键词:凸度调节域;刚度;磨损;紧凑式热带工艺;有限元分析

中图分类号:TG333.71 文献标识码:A 文章编号:1672-7207(2009)02-0422-07

Characteristics of profile control on CSP hot strip mill

LI Hong-bo1, ZHANG Jie1, CAO Jian-guo1, SI Xiao-ming2, ZHANG Shu-shan2, LI Yao-hui2

(1. School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China;

2. Maanshan Iron and Steel Co. Ltd., Maanshan 243003, China)

Abstract: The basic profile control ability for a 1.80 m compact strip production (CSP) mill was analyzed using ANSYS finite element method (FEM), the strip width and other factors’ effects on roll gap adjustment area and roll gap stiffness were proposed. Based on the characteristics of single width rolling, industrial tracing and analysis of work roll wear contour were made. The results show that the wear contours of work rolls on CSP are different from those of conventional process, and the wear contours are the main reason for the complex buckles and rolls changing at the end of the work roll service period. The work roll wear influences the low-crown control ability of the mill, and makes for the higher crown of the strip, but the wear contour can keep stability for crown control in rolling the thinner strip.

Key words: roll gap adjustment area; stiffness; wear; compact strip production (CSP); finite element method

紧凑式热带工艺(Compact strip production, CSP)是较成熟的薄板坯连铸连轧工艺之一,自1998年被引进我国以来,已有6条生产线在全国建成投产,并均采用四辊连续可变凸度(CVC)机型[1-5]。目前,人们针对CSP工艺的研究大多集中在连铸工艺的改进、新品种的开发与轧制实践、成品带钢的材料性能等方面,对板形调控性能的研究较少。由于CSP生产线具有轧制规格相对比较单一、宽度变化比较少、各机架换辊周期不同等特点,所以,轧辊磨损情况及其对板形控制的影响与常规热轧有所不同。可见,利用有限元分析软件对CSP热连轧机板形调控特性进行分析研究具有一定的理论意义与现实意义。

1 CSP热连轧机基本板形调控特性

利用ANSYS有限元软件,对热连轧机的基本板形调控特性进行分析,可以更充分地认识现场生产各种调控手段(如弯辊、窜辊等)对板形控制的意义,并可进一步分析轧辊磨损对板形调控特性的影响。

为了提高计算效率,建模时采用辊系结构的1/4,轧辊辊形按现场实际辊形录入,主要计算参数如表1 所示。

表1 主要计算参数

Table 1 Main calculating parameters

1.1 辊缝的凸度调节域

求解辊缝凸度调节域就是分析不同弯辊力、不同CVC窜辊量工况下的辊系变形,求解二次凸度Cq和四次凸度Ch的最大调节范围,以反映承载辊缝调节柔性[6-11]。

1.1.1 板宽对凸度调节域的影响

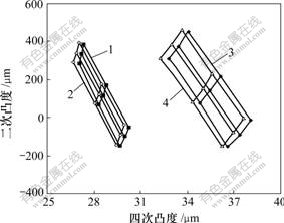

图1所示为单位轧制力q=16 kN/mm时,某1.80 m CSP热连轧机F3机架在不同板宽条件下的承载辊缝凸度调节域。可以看出,不同板宽的凸度调节域形状大致相似,板宽越大,承载辊缝凸度调节域的涵盖面积也就越大,表明轧制宽带钢时具有较强的板形调控能力。CVC辊形凸度调节能力随带钢宽度减小而急剧下降,这正是CVC辊形难以克服的1个问题,尤其对于宽带钢CVC轧机,轧制窄带时CVC将难以发挥其控制优势[12]。增加工作辊弯辊力和正窜辊均可以降低辊缝二次凸度,但增加弯辊力和正窜对四次凸度的影响有所不同,所以,可以采用弯辊和窜辊相反的调节方式实现对四次凸度的单独控制,以实现对复杂板形(如边中复合浪)的调节。

图1 板宽对凸度调节域的影响

Fig.1 Effect of strip width on roll gap adjustment area

1.1.2 单位轧制力对凸度调节域的影响

图2所示为带钢宽度B=1.2 m,单位轧制力q分别为12,16和20 kN/mm时对应的辊缝凸度调节域。可以看出,单位轧制力的变化基本不影响凸度调节域的面积,即轧机的调控能力基本保持不变,只是调节域的位置有所平移,带钢的二次凸度和四次凸度随单位轧制力的增大而略有增加。尤其对于辊缝四次凸度,虽绝对值变化不大,但相对于CVC的四次凸度调节能力,其变化较显著,四次凸度的变化易导致复杂浪形的生成。所以,对CSP轧机来说,压下率较大使轧制力偏大,导致带钢轧制过程中的板形控制更加困难。

单位轧制力q/(kN?mm-1): 1—12; 2—16; 3—20

图2 单位轧制力对凸度调节域的影响

Fig.2 Effect of rolling force on roll gap adjustment area

1.1.3 辊径对凸度调节域的影响

辊系变形随轧辊直径变化呈反比关系,辊径增大,辊系抵抗变形的能力越大,柔性越小,对应轧机的辊缝凸度调节范围也就越小。图3所示为支持辊和工作辊在不同辊径组合下(支持辊直径分别取1.50 m和1.35 m,工作辊直径分别取0.75 m和0.66 m),板宽B=1.20 m,单位轧制力q=16 kN/mm时的辊缝凸度调节域。可以看到,随着支持辊辊径的减小,辊缝凸度调节域变化不大,而工作辊辊径减小可以明显增大辊缝的凸度调节域,同时会使调节域有所偏移,因此,工作辊辊径的变化在实际轧制过程中不容忽视。从凸度变化方向来看,支持辊和工作辊辊径的减小均使辊缝的二次凸度略微增大,而支持辊辊径的减小使辊缝的四次凸度略微降低,工作辊辊径减小使辊缝的四次凸度明显增大。

支持辊辊径与工作辊辊径/m: 1—1.50与0.75; 2—1.35与0.75; 3—1.50与0.66; 4—1.35与0.66

图3 辊径对凸度调节域的影响

Fig.3 Effect of roll diameter on roll gap adjustment area

1.2 辊缝的横向刚度

轧制时由于带钢的材质、温度、来料厚度和板形等发生变化而导致轧制力出现波动,进而导致承载辊缝和机架出口带钢板形发生波动。这一波动量可以用承载辊缝的横向刚度Kg衡量[6-11]。在上游机架,采用高横向刚度的轧机,可以为下游机架提供板廓稳定的来料,为提高产品的板形质量创造条件,下游机架采用高柔性的轧机对平坦度进行控制[13-14]。

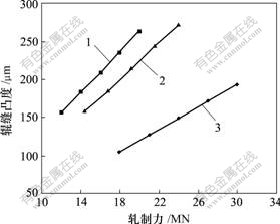

1.2.1 板宽对辊缝横向刚度的影响

带钢宽度不同,辊间有害接触区的长度不同,其辊缝的横向刚度也有所不同。图4所示是宽度B分别为1.0,1.2和1.5 m时的辊缝横向刚度特性曲线,计算时单位轧制力q分别取12,14,16,18和20 kN/mm,轧制力p=q×B。可以看出,带钢的宽度对承载辊缝横向刚度影响较大,随着带钢宽度的增加,辊间有害接触区变小,刚度特性曲线的斜率逐渐变小,辊缝横向刚度逐渐增大。

B/m: 1—1.0; 2—1.2; 3—1.5

图4 板宽对辊缝横向刚度的影响

Fig.4 Effect of strip width on roll gap stiffness

1.2.2 弯辊和窜辊对辊缝横向刚度的影响

弯辊和窜辊会对辊缝的凸度造成一定的影响,但对辊缝横向刚度的影响不大,图5和图6所示为B= 1.2 m时承载辊缝横向刚度随弯辊力(FB)和窜辊量(s)的变化关系。可以看出,弯辊和窜辊对辊缝横向刚度的影响规律性不强。

FB/kN: 1—0; 2—500; 3—1 000

图5 弯辊对辊缝横向刚度的影响

Fig.5 Effect of work roll bending force on roll gap stiffness

s/mm: 1— -100; 2—0; 3—100

图6 窜辊对辊缝横向刚度的影响

Fig.6 Effect of work roll shifting distance on roll gap stiffness

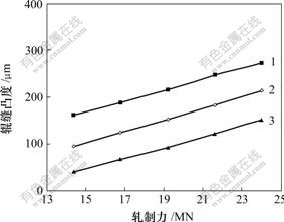

1.2.3 辊径对辊缝横向刚度的影响

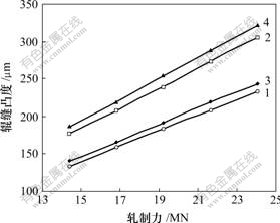

辊径对轧机辊系的辊缝横向刚度也有较大影响,图7所示为B=1.2 m时承载辊缝横向刚度随辊径的变化关系。可见,随着工作辊和支持辊辊径的减小,辊系的柔性增大,特性曲线斜率也随之增大,即辊缝的横向刚度相应减小。

支持辊辊径与工作辊辊径/m: 1—1.50与0.75; 2—1.50与0.66; 3—1.35与0.75; 4—1.35与0.66

图7 辊径对辊缝横向刚度的影响

Fig.7 Effect of roll diameter on roll gap stiffness

2 CSP热连轧机工作辊磨损特性

2.1 同宽轧制对工作辊磨损形式的影响

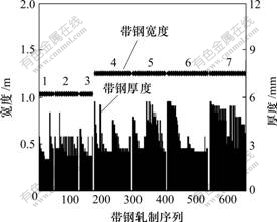

工作辊磨损是影响板形控制的重要因素。在轧制过程中,工作辊的辊形不断变化,成为板形控制中的主要变化源,其中,磨损辊形的变化又是导致辊形变化的重要因素之一。工作辊与轧件接触部分不断发生磨损,形成与轧件宽度相对应的尖锐凹槽,同时,还容易在轧件的边缘处产生“猫耳形”局部磨损,严重影响轧出成品的质量[15]。为了避免工作辊出现过大的局部磨损以至造成钢板的局部突起,同时,防止轧制宽度由窄转宽时造成边部台阶形减薄,通常轧制单位主体材的轧制顺序均遵循由宽至窄的“棺”形原则[16]。但CSP热连轧机由于连铸连轧的内在特点,使得其轧制计划编排简单得多,同一换辊周期内多为同宽轧制。图8所示为7个换辊周期内宽度和厚度变化的示意图。

图8 CSP热连轧机轧制计划

Fig.8 Rolling plan of CSP hot rolling production line

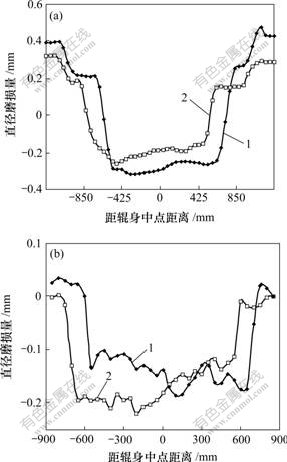

同宽轧制对工作辊磨损必将产生一定的影响,进而影响轧辊服役期内的板形控制特性,对成品质量影响最大的下游机架受此影响尤为突出。通过对常规CVC热连轧机(如图9(a)所示)和CSP热连轧机(如图9(b)所示)F7机架工作辊磨损辊形的对比分析可以看出,常规热轧CVC工作辊磨损受“棺”型轧制影响呈现出一定的阶梯箱形磨损形式,而CSP热连轧机未呈现阶梯形磨损形式;上、下工作辊磨损区域相对中心有一定偏离,磨损形式基本呈反对称分布,这主要与其服役期内的窜辊情况有关;CSP的工作辊磨损量相对较小,这是因为其服役期比常规热轧的服役期较短。CSP热连轧机工作辊的磨损对于板形控制的影响有待进一步分析和计算。

(a) 常规CVC热连轧机工作辊磨损辊形;(b) CSP热连轧机工作辊磨损辊形

1—上辊磨损辊形;2—下辊磨损辊形

图9 常规热轧与CSP工作辊磨损对比

Fig.9 Contrast of wear condition between conventional HSM and CSP

2.2 工作辊磨损对板形控制特性的影响

首先利用上、下工作辊磨损的反对称性,分析其对凸度调节域的影响。利用CVC工作辊的初始辊形和下机后的磨损辊形,以25 mm为窜辊计算间距,根据辊形反对称性,窜辊值从-100 mm变到100 mm,未加任何载荷时的辊缝形状,并进而进行曲线拟合求得辊缝凸度调节域,如图10所示。可以看到,在CVC辊形服役初期,二次凸度随窜辊量s的增大而减小,四次凸度基本为0;而CVC服役末期,一方面,其二次凸度明显变大;另一方面,其四次凸度随窜辊量s发生明显的非线性变化,这就使得在轧制过程中,为保证凸度而发生的窜辊行为却导致1/4浪或边中复合浪的生成,尤其在工作辊服役后期,复合浪的生成和难以控制成为工作辊换辊的主要原因。

1—CVC上机辊形;2—CVC下机辊形

图10 新、旧工作辊辊缝凸度调节能力变化情况

Fig.10 Contrast of roll gap adjustment ability between work roll original contour and wear contour

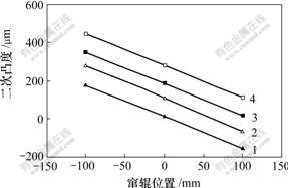

利用ANSYS辊系变形软件,利用图9所示工作辊磨损辊形具体分析CSP轧机轧制过程中轧辊磨损对板形调控性能的影响。因四次凸度变化较为复杂且呈非线性变化,所以,仅分析工作辊磨损导致的二次凸度调控范围及刚度的变化,结果见图11,其中,弯辊力分别取0和1.0 MN。可见,当轧制1.2 m带钢时,轧辊服役后期二次凸度调节范围基本不变,即工作辊的磨损对板凸度的控制能力基本没有变化,其表现形式是凸度调节能力位置的平移,这说明磨损会降低轧机的低凸度控制能力,改变轧制过程的稳定性并对凸度控制产生不良影响。随着磨损在轧辊服役期间不断积累增大,导致承载辊缝凸度实际值不断偏离初始目标值,最大偏移幅度可达58%,从而增大成品带钢凸度,导致窜辊弯辊等板形控制手段失效,结束服役期。工作辊服役末期轧制1.0 m带钢的二次凸度如图12所示。从图12可以看到,若以此轧辊继续轧制1.0 m的带钢,其凸度调节能力虽然随带钢宽度的减小而降低,但凸度调节范围仍基本在轧辊服役前期的稳定控制范围内,并未造成大幅度偏移,所以,轧辊服役后期轧机对窄带钢仍具有一定的凸度控制能力,以保证目标凸度。但CSP工艺由于一轮次浇注规格的不可改变性,限制了轧制宽度的变化,也限制了轧辊的服役期。

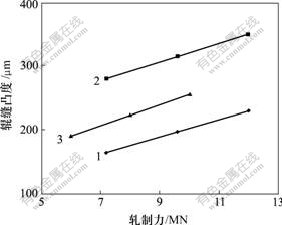

1—CVC上机辊形FB=1.0 MN;2—CVC磨损辊形FB=1.0 MN; 3—CVC上机辊形FB=0 MN;4—CVC磨损辊形FB=0 MN

图11 轧制1.2 m带钢工作辊服役初期和末期的二次凸度调节范围

Fig.11 Contrast of quadric crown adjustment ability between work roll original contour and wear contour when rolling 1.2 m strip

1—CVC上机辊形FB=1.0 MN; 2—CVC磨损辊形FB=1.0 MN; 3—CVC上机辊形FB=0 MN; 4—CVC磨损辊形FB=0 MN

图12 工作辊服役末期轧制1.0 m带钢的二次凸度调节能力

Fig.12 Quadric crown adjustment ability of work roll wear contour when rolling 1.0 m strip

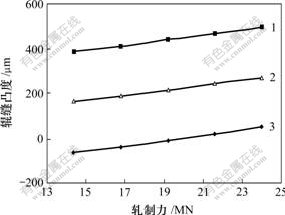

工作辊的磨损虽造成辊缝刚度下降(其中,辊缝刚度为辊缝轧制力的变化量与凸度的变化量之比),但下降幅度并不大(如图13所示)。

1—CVC上机辊形,B=1.2 m; 2—CVC磨损辊形,B=1.2 m; 3—CVC磨损辊形,B=1.0 m

图13 工作辊服役前期与末期辊缝刚度对比

Fig.13 Roll gap stiffness between work roll original contour and wear contour

3 结 论

a. 板宽减小使得CVC轧机凸度调节能力急速下降,辊缝横向刚度也有所下降;CSP热连轧机精轧机组压下率较大,使带钢轧制过程中对低凸度的控制更为困难;工作辊和支持辊辊径减小均会改变凸度调节域,并使辊缝横向刚度降低。

b. CSP同宽轧制的轧制特性导致工作辊磨损形式与常规热轧的工作辊磨损形式有所不同,工作辊的磨损造成辊缝四次凸度随窜辊量发生明显的非线性变化,是工作辊服役后期复合浪频繁生成并导致换辊的主要原因。

c. 工作辊磨损降低了轧机的低凸度控制能力,易导致带钢凸度偏大。

d. CSP热连轧机下机磨损辊形若继续服役并轧制窄规格板形,仍可保持凸度控制稳定性,但CSP工艺由于一轮次浇铸规格不可改变,限制了轧制宽度,也限制了轧辊的服役期。

参考文献:

[1] 孙决定, 丁世学. 我国薄板坯连铸连轧生产技术特点[J]. 钢铁研究, 2005(3): 58-63.

SUN Jue-ding, DING Shi-xue. Technological characteristics of thin slab continuous casting-rolling process in China[J]. Research on Iron & Steel, 2005(3): 58-63.

[2] 干 勇. 薄板坯连铸连轧生产技术若干问题[J]. 钢铁, 2004, 39(8): 24-33.

GAN Yong. On processing technologies of thin slab casting and rolling production line[J]. Iron and Steel, 2004, 39(8): 24-33.

[3] 闫 华, 冯建晖. 马钢CSP生产线采用的新技术[J]. 轧钢, 2004, 21(4): 39-41.

YAN Hua, FENG Jian-hui. New technologies applied in CSP line of Maanshan Iron and Steel Co., Ltd[J]. Steel Rolling, 2004, 21(4): 39-41.

[4] 饶添荣, 蒋昌龄. CSP工艺技术在马钢的应用[J]. 江苏冶金, 2003, 31(6): 17-20.

RAO Tian-rong, JIANG Chang-ling. The application of CSP technics in Maanshan Iron and Steel Co., Ltd[J]. Jiangsu Metallurgy, 2003, 31(6): 17-20.

[5] 唐 荻, 蔡庆伍, 米振莉. 薄板坯连铸连轧的现状和新进展[J]. 轧钢, 1999(2): 49-51

TANG Di, CAI Qing-wu, MI Zhen-li. The current situation and new development of thin slab continuous casting and continuous rolling[J]. Steel Rolling, 1999(2): 49-51.

[6] 郝建伟, 曹建国, 张 杰, 等. 2250CVC热连轧机支持辊辊形研究[J]. 中南大学学报: 自然科学版, 2007, 38(4): 734-738.

HAO Jian-wei, CAO Jian-guo, ZHANG Jie, et al. Backup roll contour of 2250 CVC hot strip mill[J]. Journal of Central South University: Science and Technology, 2007, 38(4): 734-738.

[7] 贾生晖, 曹建国, 张 杰, 等. 冷连轧机SmartCrown轧辊磨损辊形对板形调控能力的影响[J], 北京科技大学学报, 2006, 28(5): 468-470.

JIA Sheng-hui, CAO Jian-guo, ZHANG Jie, et al. Effect of SmartCrown work roll wear contour pattern on controllability of profile and flatness in tandem cold rolling mills[J]. Journal of University of Science and Technology Beijing, 2006, 28(5): 468-470.

[8] 何安瑞, 张清东, 许健勇, 等. 1 800 mm虚拟轧机板形控制性能[J]. 北京科技大学学报, 2004, 26(1): 91-94.

HE An-rui, ZHANG Qing-dong, XU Jian-yong, et al. Shape control performance of 1 800 mm virtual mills[J]. Journal of University of Science and Technology Beijing, 2004, 26(1): 91-94.

[9] CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Control of roll contour for strip profile and flatness in hot rolling[C]// The 44th Mechanical Working and Steel Processing Conference & 8th Steel Rolling International Conference Proceedings. Florida, 2002: 1001-1010.

[10] 陈先霖, 张 杰, 张清东, 等. 宽带钢热连轧机板形控制系统的开发[J]. 钢铁, 2000, 35(7): 28-33.

CHEN Xian-lin, ZHANG Jie, ZHANG Qing-dong, et al. Development in profile and flatness control system of hot strip mills[J]. Iron and Steel, 2000, 35(7): 28-33.

[11] 张清东, 陈先霖. CVC四辊冷轧机板形控制策略[J]. 北京科技大学学报, 1996, 18(4): 347-351.

ZHANG Qing-dong, CHEN Xian-lin. Flatness control strategy for CVC 4-Hi cold rolling mill[J]. Journal of University of Science and Technology Beijing, 1996, 18(4): 347-351.

[12] 魏钢城, 曹建国, 张 杰, 等. 2250CVC热连轧机工作辊辊形改进与应用[J]. 中南大学学报: 自然科学版, 2007, 38(5): 937-942.

WEI Gang-cheng, CAO Jian-guo, ZHANG Jie, et al. Optimization and application of CVC work roll contour on 2250 hot strip mills[J]. Journal of Central South University: Science and Technology, 2007, 38(5): 937-942.

[13] 陈先霖. 新一代高技术宽带钢轧机的板形控制[J]. 北京科技大学学报, 1997, 19(A02): 1-5.

CHEN Xian-lin. Flatness control in new generation high-tech mills for wide strip rolling[J]. Journal of University of Science and Technology Beijing, 1997, 19(A02): 1-5.

[14] 曹建国, 张 杰, 陈先霖, 等. 宽带钢热连轧机选型配置与板形控制[J]. 钢铁, 2005, 40(6): 40-43.

CAO Jian-guo, ZHANG Jie, CHEN Xian-lin, et al. Selection of strip mill configuration and shape control[J]. Iron and Steel, 2005, 40(6): 40-43.

[15] 牟善文. 硅钢板热轧过程中工作辊磨损及其控制方法的研究[D]. 北京: 北京科技大学机械工程学院, 2005.

MU Shan-wen. Research on work roll wear and its control methods in silicon steel hot rolling[D]. Beijing: School of Mechanical Engineering, University of Science and Technology Beijing, 2005.

[16] 唐立新. 热轧带钢轧制批量计划的实例应用[J]. 东北大学学报, 1999, 20(3): 267-270.

TANG Li-xin. Case study on the production lot planning of the hot rolling strip[J]. Journal of Northeastern University: Natural Science, 1999, 20(3): 267-270.

收稿日期:2008-04-18;修回日期:2008-06-20

基金项目:国家自然科学基金资助项目(59835170);北京科技大学科技发展专项基金资助项目(20050311890)

通信作者:李洪波(1982-),男,黑龙江哈尔滨人,博士研究生,从事板带轧机行为与控制研究;电话:010-62334898;E-mail: ustbandy@sohu.com