文章编号: 1004-0609(2005)04-0637 -06

快速凝固粉末冶金TiB2颗粒增强AlFeVSi耐热铝合金

李庆勇, 王日初, 魏圣明, 黎文献, 黄伯云

(中南大学 材料科学与工程学院, 长沙 410083)

摘 要: 利用快速凝固粉末冶金方法制备了TiB2颗粒增强Al-8.5Fe-1.3V-1.7Si耐热铝合金试样以及不含TiB2颗粒的基体合金试样, 通过光学显微镜、 扫描电镜分析了其显微组织和断口形貌, 采用X射线衍射进行了物相分析, 并进行力学性能测试。 结果发现, TiB2颗粒能有效地添加到Al-8.5Fe-1.3V-1.7Si耐热铝合金基体中, 并能有效地抑制平衡相Al13Fe4的析出, 且能细化晶粒, TiB2颗粒的存在使得粒度小于74μm粉末冶金合金挤压试样的室温强度高达454.1MPa, 屈服强度达407.8MPa, 延伸率保持在7.7%; 350℃高温强度稳定在210MPa以上, 延伸率稳定在7.7%以上。

关键词: TiB2; 耐热铝合金; 快速凝固; 粉末冶金 中图分类号: TG146.2

文献标识码: A

TiB2 reinforced AlFeVSi alloy by rapid-solidified powder metallurgy

LI Qing-yong, WANG Ri-chu, WEI Sheng-ming, LI Wen-xian, HUANG Bai-yun

(School of Materials Science and Engineering,Central South University, Changsha 410083, China)

Abstract: The samples of Al-8.5Fe-1.3V-1.7Si aluminium alloy with and without TiB2 particles reinforcement were prepared by rapid-solidified powder metallurgy. The microstructure and fractography of the samples were studied by means of the optical microscope and scanning electron microscope, and the mechanical properties were analyzed by tensile experiment. The results show that TiB2 particles can be added to the AlFeVSi aluminium alloy and restrains the form of equilibrium phase Al13Fe4 . The crystal grain is refined and the mechanical properties are improved. The samples with TiB2 particles which are smaller than 74μm show the best mechanical properties.The fracture strength, yield strength and elongation reach to 454.1MPa, 407.8MPa, 7.7% respectively at room temperature. The elevated temperature strength and elongation stay stable over 210MPa and 7.7% at 350℃.

Key words: TiB2; heat-resistant aluminium; rapid-solidified; powder metallurgy

Al-Fe-V-Si系耐热铝合金具有良好的室温和高温强度、 塑性、 热稳定性、 断裂韧性以及耐腐蚀性能[1]。 其最初的开发是20世纪70年代中期, 美国海军为了寻找能取代350℃ 服役的钛合金的新型铝合金材料而进行研究, 并在20世纪90年代初相继注册了3个牌号新型合金, 即FVS0812, FVS1212, FSVS0611。 该系列合金的理想组织是以Al为基体, 弥散分布大体积分数(可达40%)的耐热强化相Al12(Fe, V)3Si, 该强化相细小均匀分布, 热力学性能稳定, 合金元素V的加入使立方结构的硅化物在高温下粗化率极低。 这样, 合金组织具有良好的热稳定性, 并且可以充分发挥弥散强化、 细晶强化和固溶强化的强化效应。 为了进一步提高 Al-Fe-V-Si系耐热铝合金的力学性能, 人们开展了在该合金中添加第二相颗粒和纤维的研究。 主要有在该合金中添加SiC颗粒[2]、 SiC晶须[3]、 Si3N[4]4、 Al18B4O[4]3以及原位生成TiC[5-7]等。 本文作者主要研究在Al-Fe-V-Si耐热铝合金体系中通过引入第二相增强的TiB2颗粒, 以期对合金显微组织和相组成有改善作用, 从而提高合金的力学性能。

1 实验

1.1 原料及成分设计

该合金的熔炼一般首先在中频感应炉中熔配Al-40Fe, Al-40Fe-10V, Al-30Si中间合金, 然后添加适量纯铝在1200℃熔配Al-Fe-V-Si耐热铝母合金。 本实验中以FVS0812为研究对象, 以名义成分(质量分数)为8.5%Fe, 1.3%V, 1.7%Si来设计中间合金的添加量。 其中, 采用市场购买铝钛硼中间合金部分或全部替代熔炼母合金时的余量纯铝来引入不同含量的TiB2颗粒。 实验中TiB2颗粒的含量为2.2%。 将含有TiB2颗粒以及不含TiB2增强相颗粒的FVS0812母合金分别在电阻炉中重熔, 并在喷射沉积设备上制备合金粉末。

1.2 冷等静压和热挤压

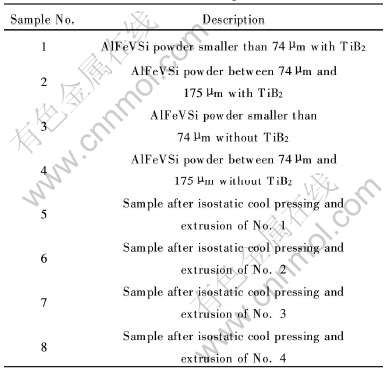

筛分得到粒度小于74μm以及74~175μm含TiB2增强相粉末和基体合金粉末, 试样编号列于表1(下同)。 1~4号粉末试样经真空除气后, 橡胶包套, 以油作为压力介质进行冷等静压, 压力为2800kN, 保压时间为60s。 去除橡皮套线切割得到d36mm×80mm试样供热挤压。 正向热挤压时在挤压筒内均匀涂敷润滑剂以减少锭坯和挤压筒内壁之间的摩擦力。 挤压系数为16∶1, 模具加热温度为400℃, 保温1h。 锭坯在400℃保温1h后快速挤压。 1~4号粉末试样经等静压并热挤压后得到的试样编号分别为: 5, 6, 7, 8。

表1 粉末及挤压试样编号

Table 1 Serial number of powder and extrusion samples

1.3 性能检测

常温拉伸实验在CSS-44100型电子万能试验机上进行, 拉伸速率为2mm/min。 高温拉伸实验在INSTRON8032电液伺服疲劳试验机上进行。 金相样品经预磨、 粗磨和细磨后用三氧化二铬抛光液进行机械抛光, 再用Keller试剂浸蚀, 在POLVAR-MET宽视野大型金相显微镜下进行组织观察。 拉伸试样断口及微观形貌的观察在KYKY-2800扫描电镜下进行。 X射线衍射物相分析在XD98全自动X射线衍射仪上进行, 采用铜靶辐射, 管压为36kV, 管流为30mA, λKα1为0.154056nm, 步进扫描, 步宽0.03°, 2θ为20°~80°。

2 结果和分析

2.1 Al-Ti-B显微组织

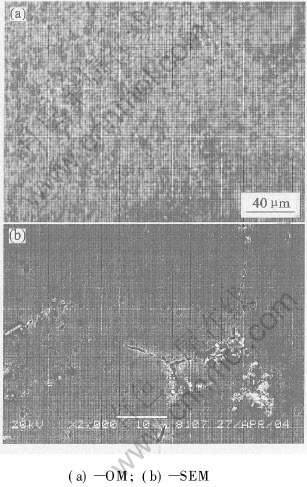

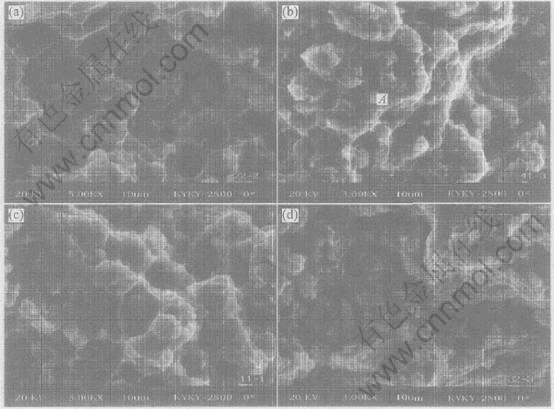

TiB2陶瓷具有极高的熔点、 硬度和弹性模量, 同时又具有良好的导电性。 近年来, 以TiB2陶瓷为增强相的金属基复合材料得到广泛的研究[8, 9]。 由于TiB2材料的共价结合特性, 很难使其致密化, 常用热压烧结或添加助烧剂烧结, 因此TiB2陶瓷的价格极其昂贵。 在选择TiB2颗粒作增强相时, 并不是直接在熔体中引入该相, 而是通过引入Al-Ti-B中间合金或者盐类反应(K2TiF6+KBF4)[10]来原位生成微米级TiB2颗粒。 图1所示为Al-Ti-B中间合金的显微组织照片。 据文献[11]报道, 在Al-Ti-B合金中随Ti和B质量比的不同, 其显微组织将出现Al3Ti和TiB2颗粒团簇, TiAl3呈长条状。 由图1分析可知, 本实验所采用的Al-Ti-B中间组织细小, 局部区域略有TiB2颗粒的团簇, 而没有大量Al3Ti等长条相的出现。 因此存在于该组织形态下的TiB2颗粒便能更好地添加到FVS0812基体中。

图1 Al-Ti-B中间合金的显微组织

Fig.1 Microstructures of Al-Ti-B master alloy

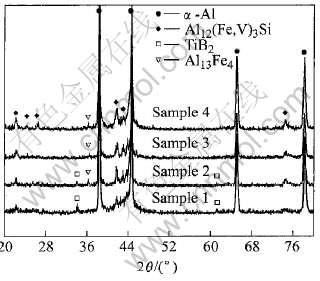

2.2 X射线衍射物相分析

图2所示为过喷粉末试样的X射线衍射谱。 可以看出1号细粉末试样主要由α(Al), Al12(Fe, V)3Si, TiB2衍射峰组成。 2号粗粉末试样除了α(Al),Al12(Fe, V)3Si, TiB2衍射峰外, 还可以检测到强度较弱的Al13Fe4衍射峰。 3, 4号粗粉末试样主要有α(Al), Al12(Fe, V)3Si衍射峰, 同时还有部分Al13Fe4相的存在。 由文献[12, 13]可知, 喷射沉积过喷粉末的主要来源有: 喷射沉积过程中细小液滴在雾化飞行阶段便凝固的粉末; 沉积过程中, 液滴颗粒与沉积层碰撞反溅而凝固的粉末, 这些细小粉末未能在沉积层停留粘附, 而越过沉积层的边缘沉积在雾化室中。 过喷粉末冷却速度较沉积层冷却速度要高, 一般直径在74μm以下的过喷粉末冷却速度可以达到103 K/s甚至更高[14], 对喷射沉积耐热铝合金而言, 当冷却速度大于103 K/s便可很好地抑制平衡相Al13Fe4[15]。 由图2分析可知, 1号细粉末试样因为TiB2的引入, 能够有效地抑制平衡相Al13Fe4的形成, 得到几乎全由α(Al), Al12-(Fe, V)3Si组成的耐热铝合金的理想组织。 2号粗粉末试样因为粉末颗粒较大, 自身的冷却速度较低, 在粉末颗粒内已经形成Al13Fe4, 所以即使有TiB2的引入也仍然不可避免的有少量的Al13Fe4相的存在。 3, 4号试样未添加TiB2增强相颗粒的过喷粉末都有Al13Fe4相的存在。 因此, TiB2颗粒在熔炼原位反应生成之后, 即使经过熔体重熔和喷射沉积, 也能有效地存在耐热铝合金基体中。 在耐热铝合金的制备过程中, 如果辅以足够的冷却速度, 便可以得到理想的组织, 充分发挥TiB2增强相的作用。

图2 1~4号过喷粉末试样的X射线衍射谱

Fig.2 XRD patterns of oversprayed powder samples 1-4 2.3 力学性能和拉伸断口分析

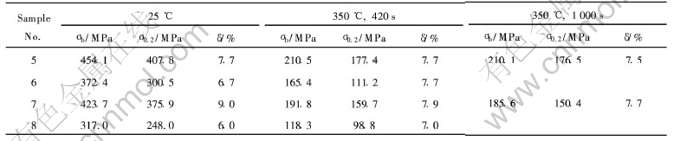

挤压后5~8号试样的室温和高温力学性能列于表2。 其中高温力学性能指在350℃保温420s以及1000s后拉伸所得数据。 5号试样室温抗拉强度最高, 达454.1MPa, 屈服强度达407.8MPa, 分别比7号试样(不含TiB2颗粒)高7.2%和8.5%, 比(含TiB2颗粒, 但粉末粒度要粗)7号试样高21.9%和35.7%。 5号试样比6号试样、 7号试样比8号试样室温延伸率高, 主要是因为5、 7号试样由细粉末压制而成, 细粉末冷却速度大, 得到的微观组织良好, 另外试样在热挤压过程中其粉末界面得到充分焊合, 达到良好的冶金结合, 塑性得到有益的改善。 5号试样于350℃保温420s时其强度最高, 达210.5MPa, 分别比7号试样(不含TiB2颗粒)高9.7%, 比6号试样(含TiB2颗粒, 但粉末粒度要粗)试样高27.2%。 在快速凝固的条件下, AlFeVSi系合金能形成大体积分数的Al12(Fe, V)3Si耐热强化相, 从而有稳定的高温强度。 7号试样的σb为191.8MPa, 而5号试样因为引入高温稳定的陶瓷相TiB2, 一方面能对硅化物耐热相在高温下粗化起到抑制作用, 另一方面细化晶粒, 并部分发挥其自身的第二相弥散强化作用, 因此进一步提高了AlFeVSi系耐热铝合金的高温力学性能。 在350℃保温1000s后, 5号试样强度、 塑性和保温420s比较相差不大, 而7号试样强度、 塑性和保温420s比较有所降低, 说明TiB2的存在对稳定FVS0812高温性能更加有利。

表2 5~8号试样的力学性能

Table 2 Mechanical properties of samples 5-8

图3所示为5~8号试样的室温拉伸断口SEM照片。 可以看到图3(a)、 3(c)断口分布着大量的韧窝, 韧窝都较深, 属于明显的韧性断裂。 7, 8号粗粉末试样的断口主要分布着大量的撕裂棱, 7号试样断口在撕裂棱中还有少量的韧窝, 在该SEM照片中可以看到断口韧窝边缘分布有第二相颗粒, A点微米级六方形貌颗粒经鉴定为TiB2。 从图3(d)可以看到断口主要由撕裂棱构成, 断口分布有明显的裂纹, 因为大颗粒的粉末界面结合较差, 因此此处首先成为裂纹源, 并迅速扩展, 最终断裂, 成为8号试样塑性较差的直接证明。

图3 室温下拉伸试样的SEM断口形貌

Fig.3 SEM fractographs of different tensile samples at room temperature

2.4 显微组织分析

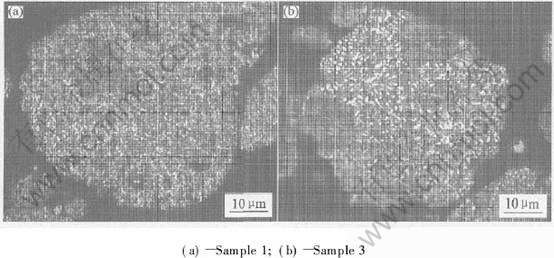

图4所示为1、 3号耐热铝合金粉末试样的金相显微组织。 可见, 粉末基本呈类球形, 没有大量方块相或针状相出现, 说明雾化冷却速度较高。 1号粉末试样组织明显比3号粉末试样组织要更细小, 说明TiB2颗粒的存在对优化耐热铝合金的组织有较显著的作用。

图4 粉末试样的显微组织

Fig.4 Microstructures of different powders

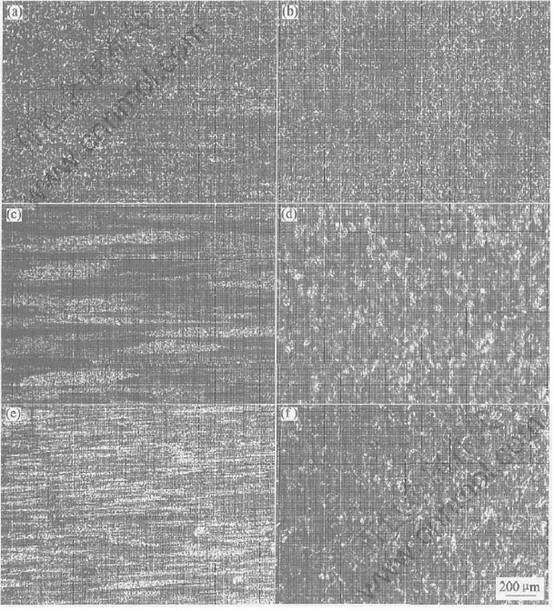

图5所示为耐热铝合金雾化粉末经包套冷等静压后延挤压方向和挤压垂直方向的显微组织。 由图5(a), 5(c), 5(e)可见粉末锭坯经挤压后沿挤压方向呈明显的流线组织, 挤压后组织细小均匀, 没发生组织粗化现象, 也没有得到明显的块状或针状组织, 这是获得良好力学性能的根本原因。

图5 试样挤压方向及挤压端面的显微组织

Fig.5 Microstructures of extrusion samples along extruding direction((a), (c) and (e)) and cross section ((b), (d) and (f)) (a), (b)—Sample 5; (c), (d)—Sample 6; (e), (f)—Sample 7

其中图5(c)为6号粗粉末试样锭坯的挤压组织, 可以明显看到整个粉末颗粒被拉长, 粉末间界面明显, 组织焊合性差, 故从宏观上表现为6号试样比5号试样、 7号试样的力学性能更差。 图5(a), 5(e)同为粒度小于74μm的粉末锭坯挤压的显微组织, 均比图5(c)更为细小均匀, 而且粉末间界面已基本消除, 达到良好的冶金结合。 虽然图5(a), 5(b)和5(e), 5(f)具有同等大小的粉末粒径, 由于前者有TiB2增强相的存在, 使得其组织得到进一步的细化, 因而性能也得到提高。

3 结论

1) TiB2颗粒能够以适当的方式添加到AlFeVSi耐热铝合金基体中, 并起到良好的强化作用。

2) TiB2颗粒的存在能有效地抑制平衡相Al13Fe4的析出, 并细化晶粒。

3) 含2.2%TiB2颗粒、 粒度小于74μm的粉末冶金合金挤压试样室温强度达454.1MPa, 屈服强度达407.8MPa, 延伸率保持在7.7%; 350℃高温强度稳定在210MPa以上, 延伸率稳定在7.7%以上。

REFERENCES

[1] Skinner D j, Bye R L, Raybould, et al. Dispersion strengthened Al-Fe-V-Si alloys[J]. Scripta Metall Mater, 1986, 20(6): 867-872.

[2] Kim I S, Kim N J, Nam S W. Temperature dependence of the optimum particle size for the dislocation detachment controlled creep of Al-Fe-V-Si/SiCp composite[J]. Scripta Metallurgical et Materials, 1995, 32 (11): 813-1814.

[3] Zhu S J, Peng L M, Ma Z Y, et al. High temperature creep behavior of SiC whisker-reinforced Al-Fe-V-Si composite[J]. Mater Sci A, 1996, 215: 120-124.

[4] 马宗义, 宁小光, 潘 进, 等. 晶须增强A1-8.5Fe-1.3V-1.7Si复合材料及晶须增强效果的评价[J]. 金属学报, 1994, 30(9): 420-426.

MA Zong-yi, NING Xiao-guang, PAN Jin, et al. Preparation of whisker reinforced A1-8.5Fe-1.3V-1.7Si composites and appraisal of reinforcing behaviour for various whisker[J]. Acta Metellurgica Sinica, 1994, 30(9): 420-426.

[5] Tong X C, Ghosh A K. Fabrication of in situ TiC reinforced aluminium matrix composites[J]. Journal of Materials Science, 2001, 36: 4059-4069.

[6] 孙玉峰, 沈宁福, 熊柏清, 等. TiC对喷射沉积Al-8Fe-1.3V-1.7Si合金显微组织和性能的影响[J]. 中国有色金属学报, 2001, 11(S2): 54-59.

SUN Yu-feng, SHEN Ning-fu, XIONG Bai-qing, et al. effect of TiC particle on microstructure and properties of spray formed Al-8Fe-1.3V-1.7Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(S2): 54-59.

[7] 胡敦芫, 黄赞军, 杨 滨, 等. TiC颗粒增强喷射沉积Al-Fe-V-Si合金的组织及力学性能[J]. 矿冶, 2002, 11(4): 59-62.

HU Dun-yuan, HUANG Zan-jun, YANG Bin, et al. Microstructure and mechanical properties of Al-Fe-V-Si reinforced with TiC in-situ reaction[J]. Mining & Metallurgy, 2002, 11(4): 59-62.

[8] 凌兴珠, 徐振民. TiB2颗粒增强铝合金复合材料研究[J]. 有色金属, 1998, 50(2): 99-103.

LING Xing-zhu, XU Zheng-ming. Study on TiB2 particulate reinforced Al metal matrix composites[J]. Nonferrous Metals, 1998, 50(2): 99-103.

[9] L L, LAI M O, SU Y, et al. In situ TiB2 reinforced Al alloy composites[J]. Scripta Materialia, 2001, 45: 1017-1023.

[10] Feng C F, Froyen L. Incorporation of Al into TiB2 in Al matrix composites and Al-Ti-B master alloys[]. Materials Letters, 1997, 32: 275-279.

[11] 马洪涛, 李建国, 张柏清, 等. Al-Ti-B合金的组织分析[J]. 中国有色金属学报, 2001, 11(5): 801-805.

MA Hong-tao, LI Jiang-guo, ZHANG Bai-qing, et al. Analysis of microstructures in Al-Ti-B alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 801-805.

[12] 谭敦强. 提高喷射沉积AlFeVSi耐热铝合金性能的若干理论问题和新工艺研究[D]. 长沙: 中南大学, 2004.

TAN Dun-qiang. Investigation on Several Theatrical Problems and Novel Preparing Process to Improve Performance of Spray Deposition AlFeVSi Heat-resistant Aluminum Alloy[D].Changsha: Central South University, 2004.

[13] Grant P S. Spray forming[J]. Progress in Materials Science, 1995, 39: 497-545.

[14] 朱宝宏, 熊柏青, 张永安, 等. 喷射成形Al-Fe-V-Si系耐热铝合金的数值模拟及组织分析[J]. 稀有金属, 2002, 26(2): 87-92.

ZHU Bao-hong, XIONG Bai-qing, ZHANG Yong-an, et al. Computer simuluation and microstructure analysis of Al-Fe-V-Si heat resistance alloy produced by spray forming[J]. Chinese Journal of Rare Metals, 2002, 26(2): 87-92.

[15] TAN Dun-qiang, LI Wen-xian, XIAO Yu-de, et al. Phase transition of Al-Fe-V-Si heat-resistant alloy by spray deposition[J]. Trans Nonferrous Met Soc China, 2003, 13(3): 568-573.

基金项目: 国家重点基础研究发展规划资助项目(G1999064900)

收稿日期: 2004-09-08; 修订日期: 2004-12-13

作者简介: 李庆勇(1982-), 男, 硕士研究生.

通讯作者: 王日初, 教授; 电话: 0731-8836638; E-mail: WRC@mail cus.edu.cn

(编辑 陈爱华)