文章编号:1004-0609(2017)-02-0225-09

Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头显微组织、力学性能及腐蚀性能

徐国富1, 2, 3,段雨露1,钱 健1,唐 磊1,邓 英1, 2,尹志民1, 2

(1.中南大学 材料科学与工程学院,长沙 410083;

2.中南大学 有色金属材料科学与工程教育部重点实验室,长沙 410083;

3.中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用硬度测试、金相显微、透射电镜、慢应变速率拉伸、扫描电镜和极化曲线对2 mm厚Al-Mg-Mn-Sc-Zr冷轧-退火板材搅拌摩擦焊接头的显微组织、力学性能及腐蚀性能进行了研究。结果表明:焊接接头的硬度相比母材有所降低,硬度最低值出现在前进侧搅拌区与热机影响区的交界处;焊接接头在空气中和3.5% NaCl(质量分数)溶液中的抗拉强度和伸长率均低于母材的,且应力腐蚀敏感性增加。此外,在焊接接头中,热机影响区是耐蚀性最差的区域,但是在空气和3.5% NaCl溶液中的拉伸试样均断裂在厚度最薄的搅拌区而不是耐蚀性最差的热机影响区,可见应力腐蚀对试样断裂的影响有限,说明Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头具有较好的抗应力腐蚀性。

关键词:Al-Mg-Mn-Sc-Zr合金;搅拌摩擦焊;应力腐蚀;显微组织;力学性能

中图分类号:TG174.3 文献标志码:A

Al-Mg-Mn系合金是不可热处理强化合金,因具有较高的强度和韧性、良好的抗蚀性和可焊性,是重要的轻质耐蚀可焊结构材料[1-4]。但是,由于该类合金不可热处理强化,主要通过加工硬化来提高强度,不仅提高强度的效果有限,而且冷轧后的合金内部位错、空位等缺陷急剧增加,自由能升高,使合金处于不稳定状态。当合金在较高温度使用时会发生回复和再结晶,使加工硬化效果大打折扣[5]。增加Mg的含量也可以在不牺牲塑性的前提下提高Al-Mg-Mn合金的强度,但是,当Mg的含量超过3%(质量分数)时,合金的应力腐蚀敏感性会大大增加,因此,应力腐蚀是限制Al-Mg-Mn合金应用的一个桎梏[4]。

研究发现,将微量钪添加在Al-Mg-Mn合金中能显著提高该合金的综合性能,这是由于Sc极易与Al形成初生和次生的Al3Sc粒子,这些粒子弥散地分布在基体中,可以有效地细化晶粒、抑制再结晶、提高合金的强度、改善合金的可焊性[6-10]。但是钪的价格昂贵,高昂的成本限制了含钪铝合金的推广与应用。后来,科学家们发现,在铝合金中复合添加Sc和Zr,Zr可以取代一部分Sc的位置,形成与基体共格、具有L12结构的Al3Sc1-xZrx粒子,这种粒子抑制再结晶的效果比Al3Sc粒子更好[11-14]。因此,在铝合金中复合添加Sc和Zr,可以在改善合金性能的同时,降低成本。如今,添加Sc和Zr的Al-Mg-Mn系合金已被广泛应用于航空航天、核能和船舰等国防军工尖端领域。

作为结构材料,在保证足够强度的同时,也需要具有良好的焊接性能。搅拌摩擦焊(Friction stir welding,简称FSW)是一种新型固态连接技术,与传统的熔化极焊接方法相比,具有连接温度低、焊后残余应力小、接头性能高等优点,是一种极具前景的焊接方法[15-18]。搅拌摩擦焊接头不同位置由于在焊接过程中受到的热和力的影响不同,表现出了不同的微观组织,进而表现出了不同的力学性能和腐蚀性能。本文作者研究了Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头中各区域的显微组织及其对力学性能和腐蚀性能的影响,填补了国内外对于Al-Mg-Mn-Sc-Zr合金在这一方面研究的空白,力求为该合金在航空航天的应用提供理论基础。并找出了该合金摩擦搅拌焊接头性能最薄弱的区域,旨在为日后进一步提高该合金搅拌摩擦焊接头的性能提供理论依据和改善方向。

1 实验

焊接试验所用母材为冷轧退火的Al-Mg-Mn- Sc-Zr合金板材,厚度为2 mm,其化学成分为Al-5.8%Mg-0.4%Mn-0.25%Sc-0.1%Zr(质量分数,%)。搅拌摩擦焊在中国搅拌摩擦焊中心(北京赛福斯特技术有限公司)的搅拌摩擦焊设备(型号:FSW-LM-AM16)上进行,选用直径为2 mm的螺旋形搅拌针,轴肩直径为10 mm,搅拌针旋转速度为600 r/min,焊接速度为200 mm/min,单面焊,焊接方向平行于母材的轧向。

拉伸性能采用MT858 万能拉伸试验机进行测试,拉伸速率为2 mm/min,测量3个试样后取平均值;拉伸试样按照相应的规定(母材:GB 6397—86;焊接接头:GB 2651—81)进行线切割成标距为50 mm的“工”字型标准试样,然后将试样用金相800号砂纸打磨以去除表面缺陷。焊接接头的硬度测试在HVS-1000型数显显微硬度计上进行,负荷为1.961 N,载荷保持时间为10 s,沿垂直焊接方向,每隔1 mm测量5个值取平均,获得焊接接头不同区域的硬度。用Leica DMIL LED型倒置金相显微镜观察焊接接头横截面的显微组织。在此之前,需要将被观察面水磨、抛光并阳极覆膜。覆膜液成分为4 mL 40%HBF4(体积分数)+100 mL蒸馏水,电压为16 V,时间为30 s。透射电镜(TEM)试样在母材以及焊接接头不同区域取样,机械减薄至约80 μm后,在30%硝酸+70%酒精(体积分数)的混合溶液中进行双喷电解减薄,利用液氮将温度控制在-30℃左右。制好样后在TECNAI G220透射电镜下进行观察,加速电压为200 kV。采用LETRY WOML-1 (10 kN)应力腐蚀试验机进行慢应变速率拉伸(SSRT)试验,来评价母材和焊接接头的抗应力腐蚀能力。试样尺寸如图1所示,标距为 15 mm,焊接试样的拉伸方向垂直于焊接方向。试验在室温下进行,介质环境分别为干燥空气和3.5% NaCl溶液,拉伸应变速率为1×10-6 s-1;为了减小误差,每组实验测试试样3个。试样断裂后,利用FEI Sirion200扫描电镜对断口进行观察和分析。极化曲线测试是在Im6ex电化学工作站上进行,采用的三电极体系,工作电极为样品裸露面,辅助电极为铂电极,参比电极为饱和甘汞电极。腐蚀溶液为3.5% NaCl溶液,扫描速率为0.5 mV/s,扫描范围为-0.8~-0.2 V (vs SCE),为了减小误差,每组实验测试试样5个。

图1 应力腐蚀拉伸试样尺寸

Fig. 1 Dimensioned schematics of tensile specimens (Unit: mm)

2 结果与讨论

2.1 拉伸性能

Al-Mg-Mn-Sc-Zr合金板材及其FSW接头的拉伸力学性能如表1所示。从表1中可以看出, FSW接头的抗拉强度(σ)和伸长率(δ)相比基材都有所下降,说明焊接会导致合金力学性能下降。通常用焊接系数来判断焊接接头性能的好坏,σJ/σM(σJ为接头的抗拉强度,σM为基材的抗拉强度)的值即为该接头的焊接系数。由于接头的性能一般相比基材会有所下降,通常情况下,焊接系数的值大于0小于1。焊接系数越大,代表该接头的焊接性能越好。本研究中FSW接头的焊接系数为和0.93。

表1 Al-Mg-Mn-Sc-Zr合金板材及其FSW接头的力学性能

Table 1 Mechanical properties of Al-Mg-Mn-Sc-Zr alloy sheet and its friction stir welded

2.2 显微硬度

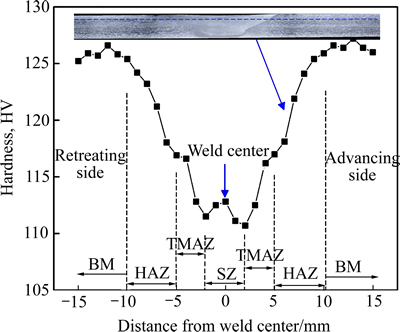

图2所示为Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头距焊缝中心不同距离处的硬度分布曲线。从图2中可以看出,焊接接头的硬度以焊缝为中心,呈近似对称分布。搅拌摩擦焊接头根据其硬度分布可以分为4个区:搅拌区(SZ)、热机影响区(TMAZ)、热影响区(HAZ)和母材(BM)。从焊缝中心往母材方向,硬度值先略微降低,在前进侧的搅拌区与热机影响区的交界处达到最低值,约为111HV。随后硬度值平稳上升,在母材区达到最高值并趋于平稳,母材区的硬度值约为126HV。

图2 Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头硬度分布图

Fig. 2 Microhardness distribution of FS welded Al-Mg-Mn- Sc-Zr alloy

2.3 显微组织

图3所示为Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头金相照片。如图3(a)所示,整个焊缝区呈碗状,在焊缝中心处厚度最薄,往两侧逐渐变厚,并在热影响区达到母材的厚度。薄区长度约为10 mm,与轴肩直径一致。这可能是由于在焊接过程中轴肩有一定的下压量,将焊缝中心的金属挤压了出去。此外,在低倍图上还可以看到,热机影响区与搅拌区在前进侧(AS)的分区界限窄且较明显,而在后退侧(RS)的分区界限不明显。这是由于在前进侧,搅拌针的旋转方向与前进方向一致,搅拌区与热机影响区晶粒的相对位移较大,引发的变形量也较大,因此界限窄而清晰。反之,在后退侧,搅拌针的旋转方向与前进方向相反,晶粒之间相对位移较小,晶粒变形量小,热塑金属过渡较为均匀,因此分区界限比较模糊。

由图3(b)~(e)可以看出,搅拌区、热机影响区、热影响区和母材的组织各有其特点。搅拌区的晶粒细小均匀,这是由于这个区域的晶粒受搅拌针的作用,温度较高、应变速率较大,不断的形成再结晶晶核,并只能发生有限的长大。此外,搅拌头的旋转对晶粒也有一定的破碎作用,使得该区晶粒细小;热机影响区的晶粒由于受到搅拌针的热剪切力作用,晶粒变得狭长,且发生明显的弯曲变形,同时由于受热的作用,晶粒也发生了长大,其中靠近搅拌区的晶粒长大尤其明显;热影响区的组织与母材相似,都是冷轧后的纤维状组织,但是热影响区由于受焊接热的作用,晶粒略有长大。

图3 Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头金相图

Fig. 3 OM images of FS welded Al-Mg-Mn-Sc-Zr alloy

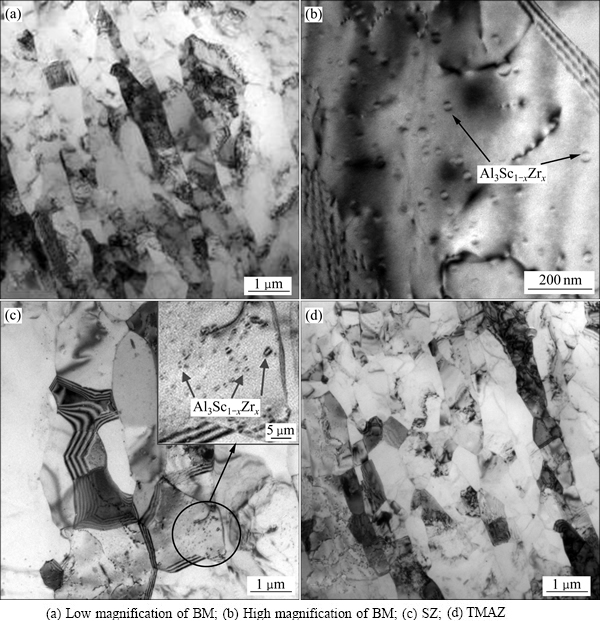

图4所示为Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头不同区域的TEM像。从图4(a)可以看出,母材由拉长的扁平状(亚)晶粒组成。从图4(b)的放大图可以看出,晶粒内弥散分布着大量马蹄状Al3Sc1-xZrx粒子[19-20]。这些粒子可以钉扎位错及晶界,强烈抑制再结晶[11-14];搅拌区由等轴晶组成,放大可以发现,晶粒内仍旧弥散分布着大量Al3Sc1-xZrx粒子,可见Al3Sc1-xZrx粒子具有很好的热稳定性。由图4(d)可以看到,热机影响区的晶粒比母材的更细,宽度约为0.5 μm,但由于受剪切力的作用,部分晶粒发生断裂,因此长度较母材的短。

由于搅拌摩擦焊不需要焊丝,焊接温度也较低,在焊接过程中,Mg、Mn元素的含量没有变化,因此,固溶强化的效果没有变。Al3Sc1-xZrx粒子有很好的热稳定性,在500 ℃下都不会粗化、溶解,依然可以很好地钉扎晶界、位错,阻碍再结晶。但在摩擦搅拌焊接过程中,搅拌针与金属的摩擦产生热,搅拌区的最高温度可以达到530 ℃,此时部分Al3Sc1-xZrx粒子会溶解,因Al3Sc1-xZrx粒子形成的析出强化效果会弱化,因此,虽然这个区域的晶粒显著细化,但硬度仍较母材有很大的降低。而在搅拌区的边缘,搅拌针的线速度最大(其中又以前进侧最大),因此产生的温度最高,Al3Sc1-xZrx粒子溶解的也最多。此外,从搅拌区到热机影响区,晶粒形貌变化大,晶粒之间结合力弱,也会导致硬度降低。这就解释硬度最低值出现在搅拌区与热机影响去的交界处的原因。在焊接过程中,热机影响区和热影响区分别由于晶粒变形和晶粒长大,使这两个区域发生一定程度的软化;但是Al3Sc1-xZrx粒子在两个区域中仍然保持稳定。故而它们的硬度都高于搅拌区。

图4 Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接头的TEM像

Fig. 4 TEM images of FS welded Al-Mg-Mn-Sc-Zr alloy

2.4 应力腐蚀

2.4.1 慢应力拉伸

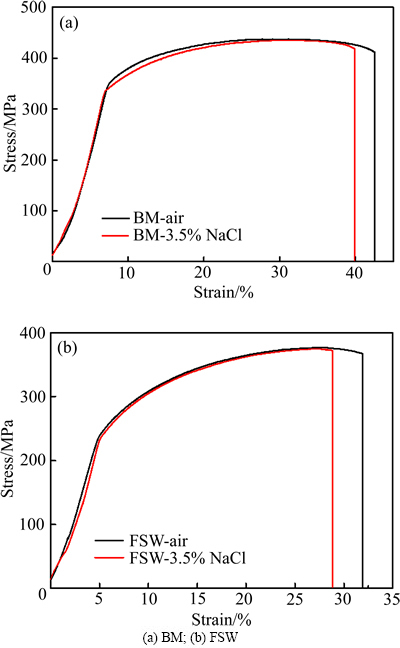

图5所示为在空气及3.5% NaCl溶液两种介质中母材及搅拌摩擦焊接头的慢应变速率拉伸曲线。从图5中可以看出,在同一介质中,母材的断裂强度和伸长率均明显大于焊接接头的;但是,对比在空气中的力学性能,母材和焊接接头在3.5% NaCl溶液中的伸长率大大降低,然而,屈服强度和抗拉强度虽有所降低却变化不明显,这可能是由于合金强度具有较低的应力腐蚀敏感性[21]。

为了更清晰地比较母材和焊接接头的应力腐蚀敏感性,本研究中采用式(1)来计算材料的应力腐蚀敏感因子ISSRT。ISSRT数值越大,代表材料对应力腐蚀越敏感,反之亦然。

ISSRT=1-[σs(1+δs)]/[σA(1+δA)] (1)

式中:σA、δA分别为空气中的抗拉强度和伸长率;σs、δs分别为腐蚀溶液中的抗拉强度和伸长率。

图5 Al-Mg-Mn-Sc-Zr合金母材及搅拌摩擦焊接接头的慢应变速率拉伸曲线

Fig. 5 SSRT curves of the base metal and FS welded Al-Mg-Mn-Sc-Zr alloy

表2所列为根据图5及式(1)得到的材料的抗拉强度、伸长率及应力腐蚀敏感因子。根据计算可得,母材和焊接接头的应力腐蚀敏感因子分别为0.021和0.057,说明焊接接头对应力腐蚀较母材敏感。

表2 慢应变速率拉伸试验结果

Table 2 Testing results of SSRT

2.4.2 断口形貌

图6所示为拉伸断口的扫描图片和能谱分析结果。从图6中可以看出,4种试样的断口上均有许多大小不等的圆形或椭圆形韧窝,可以判定其断裂方式均属于韧性断裂。通过图6(a)和(c)的对比可以发现,母材断口的韧窝较深,表明其塑性较好。且图6(a)中可观察到一些第二相颗粒,经能谱分析推断为Al3Sc1-xZrx粒子。从图6(b)和(d)可知,在3.5% NaCl溶液中的试样,韧窝更加浅平,甚至有部分区域十分平滑,表现出脆断的特点,可见其塑性较差。图6(d)中出现了许多内壁平滑的大坑,这可能是第二相粒子溶解或脱落形成的,这会进一步降低材料的塑性。这个推论也与慢应力拉伸实验得到的结果一致。

2.5 电化学腐蚀性能

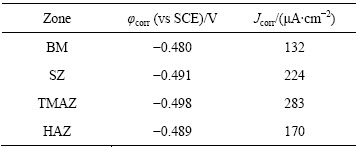

对焊接头拉伸试样进行观察,发现在空气和3.5% NaCl溶液两种介质中,试样的断裂位置均在焊缝中心处。考虑到焊缝中心是焊接头厚度最薄的位置,不能单纯根据断裂位置判断应力腐蚀敏感区,因此结合硬度曲线的分区对焊接头进行切割,分别测量各区的极化曲线,对各区的抗腐蚀性能进行进一步检测。

图7所示为焊接头不同区域的极化曲线,根据极化曲线得到的拟合数据列举在表3中。自腐蚀电流密度(Jcorr)通常用来作为判定材料耐蚀性的依据,Jcorr越小,代表材料越耐腐蚀。从表3 可以看出,搅拌摩擦焊接头耐蚀性的排序由大到小依次为BM、HAZ、SZ、TMAZ。耐蚀性最差的是热机影响区,其次是搅拌区。

由于搅拌摩擦焊是一种固态连接技术,搅拌区在焊接过程中受热最大,但从透射电镜照片(图4(c))可以看出,搅拌区仍存在大量马蹄状Al3(Sc, Zr)粒子,这些细小的粒子弥散分布在基体中,能够强烈地钉扎位错和亚晶界,从而起到稳定合金亚结构并抑制合金再结晶的作用,从而能带来更多畸形亚晶以及位错。BALYANOV等[22]研究发现,钝化是从表面晶格缺陷开始的。而高密度的亚晶界以及亚晶中的位错,都有利于钝化膜在样品表面的形成。因此,添加Sc和Zr在一定程度上可起到提高Al-Mg-Mn合金耐蚀性的作用。此外,由于搅拌针对晶粒的搅拌和破碎作用,使该区晶粒细小均匀,这也会在一定程度上增加其耐蚀性。

图6 Al-Mg-Mn-Sc-Zr合金母材及搅拌摩擦焊接头断口扫描照片及能谱分析

Fig. 6 SEM images and EDS result of fracture surface of BM and FS welded Al-Mg-Mn-Sc-Zr alloy

图7 Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接接头不同区域的极化曲线

Fig. 7 Polarization curves of different zones of FS welded Al-Mg-Mn-Sc-Zr alloy

表3 Al-Mg-Mn-Sc-Zr合金搅拌摩擦焊接接头中不同区域的极化参数

Table 3 Polarization parameters of different zones of FS welded Al-Mg-Mn-Sc-Zr alloy

热机影响区晶粒弯曲变形严重,这也是FSW接头中残余应力最大的区域[19];TORIBIO等[23]指出,残余应力是氢(H)的析出以及扩散的驱动力,残余应力越大,H越集中,因此从氢脆敏感性来看,热机影响区是应力腐蚀较敏感区域。此外,SUN等[24]指出,残余应力的不均匀分布,能够诱导裂纹尖端的电化学活性更高,并促进阳极溶解速率,进而导致热机影响区更易被腐蚀,阳极溶解活动随着应力的增加而增加,这也是热机影响区和焊核区更容易比基材和热影响区发生腐蚀的一个重要因素。

3 结论

1) 搅拌摩擦焊接头的焊接系数为0.93,其硬度以焊缝为中心,呈近似对称分布。其中,焊缝区的硬度相比母材有所降低,这是因为在焊接过程中,焊缝中心受热,部分Al3Sc1-xZrx粒子发生溶解,使得由于Al3Sc1-xZrx粒子形成的析出强化效果弱化。硬度最低值出现在前进侧搅拌区与热机影响区的交界处, 由于此处搅拌针的线速度最大,晶粒之间结合力弱,且Al3Sc1-xZrx粒子溶解最多。

2) 在空气和3.5% NaCl溶液中进行慢应变速率拉伸,根据应力腐蚀敏感因子计算公式得出的,母材和焊接接头的应力腐蚀敏感因子分别为0.021和0.057,说明焊接接头比母材对应力腐蚀更为敏感。

3) 根据各自的自腐蚀电流密度,搅拌摩擦焊接头耐蚀性的排序由大到小依次为母材、热影响区、搅拌区、热机影响区。耐蚀性最差的是热机影响区,其次是搅拌区。

REFERENCES

[1] LATHABAI S, LLOYD P G. The effect of scandium on the microstructure, mechanical properties and weldability of a cast Al-Mg alloy[J]. Acta Materialia, 2002, 50: 4275-4292.

[2] YANG D X, LI X Y, HE D Y, HUANG H, ZHANG L. Study on microstructure and mechanical properties of Al-Mg-Mn-Er alloy joints welded by TIG and laser beam[J]. Materials and Design, 2012, 40: 117-123.

[3] 牟申周, 徐国富, 王 森, 尹志民, 聂 波, 蒋蓉蓉, 张 俊. 退火温度对Al-6Mg-Sc-Zr合金组织与性能的影响[J]. 中国有色金属学报, 2007, 17(11): 1827-1832.

MOU Shen-zhou, XU Guo-fu, WANG Sen, YIN Zhi-min, NIE Bo, JIANG Rong-rong, ZHANG Jun. Influence of annealing temperature on structure and properties of Al-6Mg-Sc-Zr alloy[J].The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1827-832.

[4] POPOVIC M, ROMHANJI E. Stress corrosion cracking susceptibility of Al-Mg alloy sheet with high Mg content[J]. Journal of Materials Processing Technology, 2002, 125/126: 275-280.

[5] 陈 琴, 潘清林, 王 迎, 彭 虹, 张志野, 尹志民. 微量Sc和Zr对Al-Mg-Mn合金组织与力学性能的影响[J]. 中国有色金属学报, 2012, 22(6): 1555-1563.

CHEN Qin, PAN Qing-lin, WANG Ying, PENG Hong, ZHANG Zhi-ye, YIN Zhi-min. Effects of minor scandium and zirconium on microstructure and mechanical properties of Al-Mg-Mn alloys[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1555-1563.

[6] 陈继强, 尹志民, 何振波. 微量钪对 Al-Zn-Mg-Zr 热轧板搅拌摩擦焊接头组织与性能的影响[J]. 中国有色金属学报, 2010, 20(10): 1883-1888.

CHEN Ji-qiang, YIN Zhi-min, HE Zhen-bo. Effects of minor Sc on microstructure and mechanical properties of Al-Zn-Mg-Zr hot rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 1883-1888.

[7] FILATOV Y A, YELAGIN V I, ZAKHAROV V V. New Al-Mg-Sc alloys[J]. Materials Science and Engineering A, 2000, 280(1): 97-101.

[8] 陈苏里, 姜 锋, 尹志民, 雷学锋, 聂 波. 含钪与不含钪铝镁钪合金焊接接头的组织与性能[J]. 中国有色金属学报, 2006, 16(5): 835-840.

CHEN Su-li, JIANG Feng, YIN Zhi-min, LEI Xue-feng, NIE Bo. Microstructure and properties of Al-Mg-Sc alloy weld joints filled with Al-Mg-Zr and Al-Mg-Zr-Sc weld wires[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 835-840.

[9] 陈显明, 潘青林, 周昌荣, 尹志民. 微量钪对Al-Mg-Mn合金组织与性能的影响[J]. 稀有金属, 2003, 27(3): 403-405.

CHEN Xian-ming, PAN Qing-lin, ZHOU Chang-rong, YIN Zhi-min. Effects of minor scandium addition on microstructure and tensile property of Al-Mg-Mn alloy[J]. Chinese Journal of Rare Metals, 2003, 27(3): 403-405.

[10] MUNOZ C A, RUCKERT G, HUNEAU B, SAUVAGE X, MARYA S. Comparison of TIG welded and friction stir weldedAl-4.5Mg-0.26Sc alloy[J]. Journal of Materials Processing Technology, 2008, 197: 337-343.

[11] DENG Y, YIN Z M, ZHAO K, DUAN J Q, HE Z B. Effects of Sc and Zr microalloying additions on the microstructure and mechanical properties of new Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2012, 530: 71-80.

[12] 尹志民, 高拥政, 潘青林, 张永红, 尹松波. 微量Sc和Zr对Al-Mg合金铸态组织的晶粒细化作用[J]. 中国有色金属学报, 1997, 7(4): 75-78.

YIN Zhi-min, GAO Yong-zhen, PAN Qing-lin, ZHANG Yong-hong, YIN Song-bo. Effect of trace Sc and Zr on grain refinement of as-cast Al-Mg alloys[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 75-78.

[13] WANG Y, PAN Q L, SONG Y F, LI C, LI Z F, CHEN Q, YIN Z M. Recrystallization of Al-5.8Mg-Mn-Sc-Zr alloy[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(11): 3235-3241.

[14] DENG Y, YIN Z M, ZHAO K, DUAN J Q, HU J, HE Z B. Effects of Sc and Zr microalloying additions and aging time at 120 ℃ on the corrosion behaviour of an Al-Zn-Mg alloy[J]. Corrosion Science, 2012, 65: 288-298.

[15] CAVALIERE P, CABIBBO M, PANELLA F, SQUILLACE A. 2198 Al-Li plates joined by friction stir welding: Mechanical and microstructural behavior[J]. Materials and Design, 2009, 30: 3622-3631.

[16] HWANG Y M, KANG Z W, CHIOU Y C, HSU H H. Experimental study on temperature distributions within the workpiece during friction stir welding of aluminum alloys[J]. International Journal of Machine Tools & Manufacture, 2008, 48: 778-787.

[17] CHEN C M, KOVACEVIC R. Finite element modeling of friction stir welding-thermal and thermomechanical analysis[J]. International Journal of Machine Tools & Manufacture, 2003, 43: 1319-1326.

[18] BEATE H, BIRGIT S. Characterization of a friction-stir-welded aluminum alloy 6013[J]. Metallurgical and Materials Transaction B, 2002, 33: 489-498.

[19] DENG Y, YE R, XU G, YANG J, PAN Q, PENG B, CAO X, DUAN Y, WANG Y, LU L, YIN Z. Corrosion behaviour and mechanism of new aerospace Al-Zn-Mg alloy friction stir welded joints and the effects of secondary Al3ScxZr1-x nanoparticles[J]. Corrosion Science, 2015, 90: 359-374.

[20] DENG Y, XU G F, YIN Z M, LEI X F, HUANG J W. Effects of Sc and Zr microalloying additions on the recrystallization texture and mechanism of Al-Zn-Mg alloys[J]. Journal of Alloys and Compounds, 2013, 580: 412-426.

[21] 邓 英. 微量钪锆对高强耐蚀可焊铝锌镁合金组织和性能的影响[D]. 长沙: 中南大学, 2012: 96-100.

DENG Ying. Effects of minor Sc and Zr additions on the microstructures and properties of high-strength, corrosion-resistant and weldable A1-Zn-Mg alloys[D]. Changsha: Central South University, 2012: 96-100.

[22] BALYANOV A, KUTNYAKOVA J, AMIRKHANOVA N A, STOLYAROV V V, VALIEV R Z, LIAO X Z, ZHAO Y H, JIANG Y B, XU H F, LOWE T C, ZHU Y T. Corrosion resistance of ultra fine-grained Ti[J]. Scripta Mater, 2004, 51: 225-229.

[23] TORIBIO J, KHARIN V, LORENZO M, VERGARA D. Role of drawing-induced residua stresses and strains in the hydrogen embrittlement susceptibility of prestressing steels[J]. Corrosion Science, 2011, 53(10): 3346-3355.

[24] SUN M, XIAO K, DONG C, LI X, ZHONG P. Effect of stress on electrochemical characteristics of pre-cracked ultrahigh strength stainless steel in acid sodium sulphate solution[J]. Corrosion Science, 2014, 89: 137-145.

Microstructure, mechanical properties and corrosion properties of friction stir welded Al-Zn-Mg-Sc-Zr alloy

XU Guo-fu1, 2, 3, DUAN Yu-lu1, QIAN Jian1, TANG Lei1, DENG Ying1, 2, YIN Zhi-min1, 2

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Materials Science and Engineering, Ministry of Education, Central South University, Changsha 410083, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The microstructure, mechanical properties and corrosion properties of friction stir welded (FSW) Al-Mg-Mn-Sc-Zr alloy were studied by hardness test, optical microscope (OM) analysis,transmission electron microscope (TEM) analysis,slow-strain-rate tensile (SSRT) test, scanning electron microscope (SEM) analysis and polarisation curve testing. The results show that the microhardness of FSW joint is lower than that of the base metal (BM), and the lowest hardness appears in the thermo-mechanical affected zone (TMAZ). Moreover, according to the SSRT test, the tensile strength and elongation of FSW joint are lower than those of the BM both in air and in 3.5%NaCl (mass fraction) solution. The polarization curve results reveal that the TMAZ exhibits lowest corrosion resistance, the samples are subjected to slow strain rate stretching in air or in 3.5% NaCl (mass fraction) solution, the fracture area is always observed in the thinnest stirred zone (SZ) rather than the TMAZ with worst corrosion resistance. It can be concluded that the stress corrosion does not dominant the cracking, and the friction stir welded Al-Zn-Mg-Sc-Zr alloy exhibits preferable stress corrosion resistance.

Key words: Al-Mg-Mn-Sc-Zr alloy; friction stir welding; stress corrosion cracking; microstructure; mechanical property

Foundation item: Project(G2005CB623705) supported by the National Basic Research Program of China; Project (CX2016B041) supported by Hunan Provincial Innovation Foundation for Postgraduate, China; Project(CSUZC201614) supported by Open-End Fund for the Valuable and Precision Instruments for Central South University, China; Project supported by Open-End Fund for the State Key Laboratory of Powder Metallurgy of Central South University, China

Received date: 2016-02-24; Accepted date: 2016-10-08

Corresponding author: DENG Ying; Tel: +86-731-88877217; E-mail: csuxgf66@csu.edu.cn

(编辑 李艳红)

基金项目:国家重点基础研究发展计划资助项目(G2005CB623705);湖南省研究生科研创新项目(CX2016B041);中南大学贵重仪器设备共享开放基金资助项目(CSUZC201614);中南大学粉末冶金国家重点实验室开放基金资助课题

收稿日期:2016-02-24;修订日期:2016-10-08

通信作者:邓 英,讲师,博士;电话:0731-88877217;E-mail: csuxgf66@csu.edu.cn