用真空温压技术制备纳米金属铜块体材料

楚 广1,刘 伟1,唐永建2

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 中国工程物理研究院 激光聚变研究中心,四川 绵阳,621900)

摘 要:采用自悬浮-真空温压法制备纳米金属Cu块体材料。通过X射线衍射(XRD)、扫描电镜(SEM)、透射电镜(TEM)、正电子湮没(PAS)实验、HMV-2型显微硬度计和用Arechimedes原理等测试手段研究压制压力、保压时间、温度等工艺参数对样品密度的影响;考察其热稳定性和微结构。研究结果表明:纳米金属Cu块体材料的密度随压制压力、保压时间和温度的增加而提高,最高相对密度为96.15%;纳米金属Cu块体材料具有较好的热稳定性;在1.5 GPa 和200 ℃压制的样品的平均晶粒度为25.3 nm,微应变为0.047%。

关键词:真空温压技术;纳米金属铜;密度;显微硬度;惯性约束核聚变靶材料

中图分类号:TG113 文献标识码:A 文章编号:1672-7207(2007)05-0873-07

Preparation of nanocrystalline metallic copper with vacuum warm-pressing technique

CHU Guang1, LIU Wei1, TANG Yong-jian2

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Research Center of Laser Fusion, China Academy of Engineering Physics, Mianyang 621900, China)

Abstract: Nanocrystalline Cu bulk material was prepared with flow-levitation vacuum warm-pressing technique. The influences of compacting pressure, pressure-holding time and temperature on density, heat stability and microstructure of samples of as-compacted nanocrystalline Cu were investigated by means of X-ray diffractometer(XRD), scanning electron microscopy(SEM), transmission electron microscopy(TEM), positron annihilation spectroscopy (PAS), Vickers microhardness tester(HMV-2) and density measurements on the principle of Arechimedes. The experimental results show that the density of nanocrystalline Cu increases with the increase of compacting pressure, pressure-holding time and temperature, and a specimen of as-synthesized bulk nanocrystalline Cu with the highest relative density of 96.15% is obtained of all samples. At the same time, the nanocrystalline Cu shows higher heat stability. The sample of nanocrystalline Cu with average grain size of 25.3 nm and mean microstrain of 0.047% is produced with vacuum warm-pressing technique under 1.5 GPa and at 200 ℃ for 1 h.

Key word: vacuum warm-pressing technique; nanocrystalline Cu; density; microhardness; inertial confinement fusion target materials

纳米金属块体材料是指由纳米粒子或晶粒构成的三维固体材料,与普通粗晶材料相比,其晶粒细小 (<100 nm),大量原子处在高度无序的晶界中,材料呈现出一种亚稳结构,导致纳米块体材料在力学、电学、光学、磁学等方面具有优于常规材料的性能。近年来,国内外学者也对纳米金属块体材料进行了大量的理论和实验研究[1-8]。纳米金属块体材料的制备技术,是当今纳米金属材料的研究热点。该问题的解决不仅能促进纳米金属块体材料的制备、物性和微结构等基础研究的发展,而且还可以为三维纳米金属块材的工业化生产和应用打下基础。自悬浮-冷压法[9-11]采用自悬浮-定向流法制备纳米金属粉体和压制成型工艺,制备出了相对密度为97%的纳米金属Cu块体,但由于压制过程是在室温及常压下进行的,样品中不可避免会含有一定数量的吸附气体,导致样品的密度低于其理论密度。通过真空温压技术可以提高样品的密度[12-13]。

为此,本文作者采用自悬浮-真空温压工艺制备纳米Cu 块体材料,使其平均晶粒尺寸控制在纳米级,考察工艺参数对纳米金属块体样品密度和显微硬度的影响,同时还研究纳米金属Cu块体材料的热稳定性及电阻率。

1 实 验

1.1 制粉及装模

采用自悬浮定向流技术[12]制备纳米Cu粉体并在ZKSTX-1型真空手套箱中将其装入高强度合金模具[9]之后,在高纯Ar气(纯度>99.99%)保护下将模具放入ZM-18-10Y型真空热压机。

1.2 真空室温压制

模具放入热压机后抽真空至压力为1.3×10-3 Pa,在此真空度下使吸附在粉体上的气体脱附30 min后,在5 min 内缓慢加压至1.0~1.75 GPa,并保压20~ 60 min,然后,用另外的液压机脱模。

1.3 真空加温压制

首先对纳米金属粉体进行抽真空脱附,当真空度为1.3×10-3 Pa时,加温至压制时的温度并保温一段时间(30 min),使吸附在金属纳米粒子上的气体脱附。一般控制温度低于200 ℃,然后,在5 min 内缓慢加压至1.0~1.7 GPa,并保压保温20~60 min,最后,卸压关炉自然冷却。实验制得的纳米金属块体材料的直径为10 mm,厚度为0.8~1.5 mm,呈圆片状。

1.4 样品检测仪器及参数

a. 用Philips X’Pert Pro MPD型X射线衍射仪检测压制前、后纳米块体材料的物相组成和平均晶粒粒度,测试条件为:Cu靶(Kα1,波长λ=0.154 056 nm),管电流40 mA. 管电压40 kV,Kα2/Kα1=0.5。通过对原始衍射峰进行Kα1和Kα2射线进行分离,把由仪器引起的几何宽化和由尺寸及微观应变引起的物理宽化分离开来,对扣除了几何宽化的衍射峰用Warren-Averbach傅里叶变换分析方法[14]进行处理,求得样品的平均晶粒尺寸和微应变。上述计算可以使用相应软件自动 完成。

b. TEM测试纳米Cu块体样品用离子减薄方法制备,在Philips EM420型透射电镜上观察。

c. 用JSM-6360LV型扫描电镜观察样品表面形貌,电压为25 kV。

d. 样品硬度用HMV-2型数字显微硬度计(日本岛津)对样品进行显微硬度(维氏硬度HV0.2)检测,载荷为1.961 N,负载时间为30 s。每个样品随机测试4个点,实验误差为0.2%。

e. 正电子寿命谱是采用四川大学组装的ORTEC-583快-快符合型正电子湮没仪(PAS)进行测试。用来分析样品中的微观空隙结构状态。

f. 样品密度用Arechimedes原理测定,采用GB 5163—85国家标准,实验误差为±0.5%。

2 结果与分析

2.1 纳米Cu块体的真空室温压制工艺对密度和硬度的影响

在真空室温(15 ℃)和1.5 GPa压制得到的样品表面光洁,呈紫红色,从样品的XRD谱(图1)来看,纳米金属Cu为面心立方结构,无氧化,而粉体表面活性高,有轻微氧化。根据Warren-Averbach傅里叶变换分析方法[14]求得其平均晶粒粒度为22.8 nm,微应变为0.073%。而用于压制的纳米Cu粉的平均晶粒粒度为22.6 nm,微应变为0.039%。这说明压制压力对纳米Cu的晶粒度影响不大,微应变从0.039%上升到0.073%。

1—纳米Cu粉;2—于1.5 GPa和15 ℃压制的纳米Cu块体材料

图1 纳米Cu粉与纳米Cu块体材料的XRD谱

Fig.1 XRD patterns of nanoparticles and nonacrystalline Cu

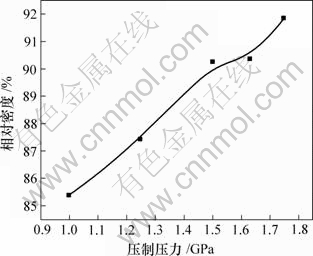

在15 ℃真空冷压下,压制压力对纳米Cu块体材料密度的影响如图2所示。可见,随着压力的增加,由于纳米粉体之间相互挤压变形,密度逐渐增大。但真空冷压法制得的纳米Cu密度并不太高,在1.75 GPa下压制只能得到略低于92%的相对密度。比以前用的精密液压机(在约5 s 内升压到指定压力)压制的纳米Cu块体材料的最高密度97%低。

图2 纳米Cu块体材料相对密度与压力的关系

Fig.2 Relationship between relative density and compacting pressure for nanocrystalline Cu by vacuum cold-pressing

在真空室温(15 ℃,40 min)条件下,压力对纳米Cu块体材料显微硬度的影响如图3所示。在压制过程中,随着压力的提高,在提高纳米Cu密度的同时,减少了微孔隙等降低样品显微硬度的缺陷数量,因此样品的显微硬度增加。在1.75 GPa的压强下成形保压20 min后,得到的纳米Cu样品的显微硬度高达2.27 GPa,是常规粗晶Cu的5倍,体现了纳米金属块体材料的高硬度特性。

图3 真空室温压制的纳米Cu块体材料的显微硬度与压力的关系

Fig.3 Relationship between microhardness and compacting pressure for nanocrystalline Cu prepared by vacuum cold-pressing

2.2 纳米Cu块体的真空温压工艺研究

2.2.1 压力、温度及时间对纳米Cu块体密度的影响

与室温压制工艺类似,在温压过程中,随着压力的增加,纳米Cu块体材料的相对密度增加。施加压力前进行加温处理,可以使吸附在纳米Cu粉上的惰性气体更容易脱附,同时原子受热后扩散运动加快,有利于纳米粒子在高压下的致密化。图4~6所示分别为压制温度、压制压力和保温时间对纳米Cu块体材料相对密度的影响,从图4可以看出,当压力在1.00~1.63 GPa范围内时,随着压制温度的提高,纳米Cu块体材料的相对密度是逐渐增大的,其中,当温度低于150 ℃时,密度的增加幅度不大;当温度高于150 ℃时,密度出现明显增加。

1—1.00 GPa; 2—1.25 GPa; 3—1.63 GPa

图4 温度与纳米Cu块体材料的相对密度的关系(保压时间为60 min)

Fig.4 Relationship between relative density and temperature for nanocrystalline Cu prepared under different pressures

1—50 ℃; 2—100 ℃; 3—150 ℃; 4—200 ℃

图5 压制压力与纳米Cu块体材料相对密度的关系(保压时间为60 min)

Fig.5 Relationship between relative density and compacting pressure for nanocrystalline Cu prepared at different temperatures

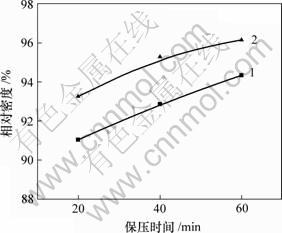

1—1.00 GPa; 2—1.63 GPa

图6 200 ℃时保压时间与纳米Cu块体材料相对密度的关系

Fig.6 Relationship between relative density and dwell-time for nanocrystalline Cu prepared under different compacting pressures at 200 ℃

从图5中可以看出,随着压力的增加,纳米Cu固体材料的相对密度是逐渐增加的,最高可达96.15%。温压过程适当延长保压(保温)时间,同样有利于原子的扩散和有充足的时间消除材料内应力,提高纳米金属块体材料的密度(见图6)。本研究中,由于温压模具材料的限制,不能再提高温度和压力。但对于压制纳米Cu而言,这里采用的温度和压力的综合实验参数已达到相当高的数值。

2.2.2 热稳定性

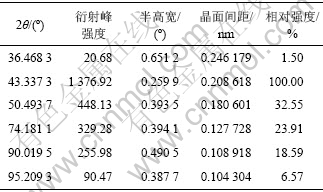

对不同温度下制备的3个纳米铜块体样品(此组样品均在1.5 GPa压力下保压20 min压制)进行XRD检测分析的结果如图7所示。由图可见,有轻微的氧化亚铜存在,得到相应的数据见表1~3,根据Warren-Averbach傅里叶变换分析方法求得其平均晶粒粒度。

(a) 15 ℃压制(样品a); (b) 150 ℃压制(样品b); (c) 200 ℃压制(样品c)

图7 不同温度下压制的纳米Cu块体的XRD谱

Fig.7 XRD patterns of nanocrystalline Cu samples compacted at different temperatures

表1 纳米Cu块体样品a的XRD实验测试相关数据

Table 1 Experimental data of XRD for sample a of nanocrystalline Cu

表2 纳米Cu块体样品b的XRD实验测试相关数据

Table 2 Experimental data of XRD for sample b of nanocrystalline Cu

表3 纳米Cu块体样品c的XRD实验测试相关数据

Table 3 Experimental data of XRD for sample c of nanocrystalline Cu

加温可以减少纳米金属块体材料内部气孔的数量,提高块体材料的密度,但由于纳米材料晶粒细小,表面活性很大,晶粒处在亚稳态,在加热时容易长大,一旦晶粒超出纳米级,就会失去纳米材料的优异特性。因此,温压过程中必须设法将材料的平均晶粒尺寸控制在纳米级。纳米Cu的平均晶粒粒度与微应变同压制温度的关系见表4。

表4 不同温度压制的纳米Cu块体材料的平均晶粒度与微应变

Table 4 Average grain size and microstrain of samples of nanocrystalline Cu prepared at different temperatures under 1.5 GPa for 20 min

从表4可以看出,温压过程中纳米Cu块体材料的平均晶粒尺寸随着温度的升高略微增大,而微应变在温度的作用下逐渐减小,说明原子排列逐渐趋于有序化,材料内部由于压制而产生的应力在逐步释放。样品的热稳定性较好,从15 ℃上升到200 ℃时晶粒尺寸仅仅长大了2.5 nm。

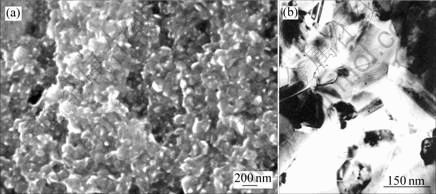

在1.5 GPa,200 ℃下保压60 min,真空温压制备的纳米Cu块体断面的扫描电镜(SEM)和透射电镜(TEM)照片如图8所示。从TEM照片(图8(b))可见,纳米Cu块体样品的晶粒度小于100 nm。SEM照片(图8(a))中的颗粒之间结构致密,晶莹发亮,但还是存在非常少的微孔。

(a) SEM照片;(b) TEM照片

图8 真空温压制备的纳米Cu块体断面的SEM照片和TEM照片

Fig.8 SEM and TEM images of nanocrystalline Cu prepared by vacuum warm-pressing technique

2.2.3 正电子湮没寿命分析

不同压制条件下纳米Cu固体材料的正电子寿命参数见表5。正电子寿命τ1对应于界面上相当于单空位的自由体积型缺陷,τ2对应于体积相当于十余个空位大小的空位簇,τ3对应于较大体积的微空隙;I1,I2和I3分别为其相应的正电子湮没强度。

真空温压法(1.5 GPa,200 ℃,保压20 min)制备的纳米Cu样品比未抽真空冷压(1.5 GPa,20 ℃,保压20 min)制备的纳米Cu样品的正电子湮没寿命分量τ1、τ2、τ3及平均寿命 都增大了;其强度I1增大,而I2减小,即材料内部单空位缺陷的数量增加,空位簇的数量有所减少。比文献[4]中的τ1和τ2增大,平均寿命

都增大了;其强度I1增大,而I2减小,即材料内部单空位缺陷的数量增加,空位簇的数量有所减少。比文献[4]中的τ1和τ2增大,平均寿命 和τ3下降,而且单空位的自由体积数量较多(由于压力增加的缘故[16]),空位簇的数量减少,微空隙的数量基本相当。说明在本实验和操作工艺条件下,真空加温对纳米块体铜的微观结构尺寸有一定的影响;其平均微观缺陷尺寸还有所增大,其原因可能与模具的材料性质和制备工艺以及纳米Cu粉的性质有关。

和τ3下降,而且单空位的自由体积数量较多(由于压力增加的缘故[16]),空位簇的数量减少,微空隙的数量基本相当。说明在本实验和操作工艺条件下,真空加温对纳米块体铜的微观结构尺寸有一定的影响;其平均微观缺陷尺寸还有所增大,其原因可能与模具的材料性质和制备工艺以及纳米Cu粉的性质有关。

表5 不同压制条件下纳米Cu固体材料的正电子寿命参数

Table 5 Positron annihilation lifetime of nanocrystalline Cu prepared under different pressing conditions

3 结 论

a. 采用自悬浮-真空温压法制备了纳米金属Cu 块体材料,其最高相对密度为96.15%,增大压力,延长保压时间,提高压制温度,均有利于纳米金属材料密度的提高。对于采用真空温压技术制备纳米金属Cu 块体材料而言,在1.63 GPa,200 ℃保压1 h的工艺条件下制得的纳米金属Cu块体材料的综合参数最高,其密度与冷压法的密度相当。

b. 纳米金属块体材料具有较好的热稳定性,XRD分析表明:在1.5 GPa 和200 ℃下压制的样品的平均晶粒度为25.3 nm,微应变为0.047%。温度从15 ℃上升到200 ℃时样品的平均晶粒粒度仅仅增大2.5 nm。从TEM照片可见,纳米Cu块体样品的晶粒度小于100 nm。

c. 真空温压法(1.5 GPa,200 ℃,保压20 min)制备的纳米Cu样品比未抽真空冷压(1.5 GPa,20 ℃,保压20 min)制备的纳米Cu样品的正电子湮没寿命分量τ1,τ2,τ3及平均寿命 都增大;前者的正电子湮没平均寿命

都增大;前者的正电子湮没平均寿命 为257.07 ps,比后者的(221.70 ps)增加36 ps,说明真空温压技术对纳米块体铜的微观结构有影响,其微观缺陷粒度也有所增大。

为257.07 ps,比后者的(221.70 ps)增加36 ps,说明真空温压技术对纳米块体铜的微观结构有影响,其微观缺陷粒度也有所增大。

参考文献:

[1] Gleiter H. Nanocrystalline materials[J]. Prog Mater Sci, 1989, 33: 223-315.

[2] Lu L, Sui M L, Lu K. Superplastic extensibility of nanocrystalline copper at room temperature[J]. Science, 2000, 287: 1463-1466.

[3] Champion Y, Gu?rin-Mailly S, Bonnentien J L, et al. Fabication of bulk nanostructured materials from metallic nanopowders: structure and mechanical behavior[J]. Scripta Mater, 2001, 44: 1609-1613.

[4] 周宇松, 吴希俊, 许国良, 等. 大尺寸纳米铜和银的制备及其微观缺陷与力学性能[J]. 中国有色金属学报, 2000, 10(4): 465-469.

ZHOU Yu-song, WU Xi-jun, XU Guo-liang, et al. Synthesis, microdefects and mechanical properties of large bulk nanocrystalline silver and copper[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(4): 465-469.

[5] 胡 杰, 肖于德, 黎文献, 等. 快速凝固AlNiCuNd金属玻璃在纳米尺度上的初始晶化行为[J]. 中南大学学报: 自然科学版, 2004, 35(6): 925-930.

HU Jie, XIAO Yu-de, LI Wen-xian, et al. Primary crystallization behaviour of rapidly solidified Al-Ni-Cu-Nd metallic glass on nanometer scale[J]. J Cent South Univ: Science and Technology, 2004, 35(6): 925-930.

[6] Swygenhoven H V. Grain boundaries and dislocations[J]. Science, 2002, 296: 66-67.

[7] Nieman G W, Weertman J R. Mechanical behavior of nanocrystalline Cu and Pd[J]. J Mater Res, 1991, 6(5): 1012-1027.

[8] Wang Y M, Wang K, Pan D, et al. Microsample tensile testing of nanocrystalline copper[J]. Scripta Materialia, 2003, 48: 1581-1586.

[9] 楚 广, 唐永建, 罗江山, 等. ICF物理实验用纳米Cu块体靶材的研究[J]. 强激光与粒子束, 2005, 17(12): 1829-1834.

CHU Guang, TANG Yong-jian, LUO Jiang-shan, et al. Research on synthesis of nanocrystalline copper target for ICF experiments[J]. High Powder Laser and Particle Beams, 2005, 17(12): 1829-1834.

[10] 楚 广, 刘 伟, 罗江山, 等. 影响纳米Cu固体材料性能的工艺参数研究[J]. 强激光与粒子束, 2005, 17(11): 1701-1704

CHU Guang, LIU Wei, LUO Jiang-shan, et al. Study on effects of processing parameters on properties of nanocrystalline Cu[J]. High Powder Laser and Particle Beams, 2005, 17(11): 1701-1704.

[11] 刘 伟, 唐永建, 楚 广, 等. 金属Cu纳米晶体的显微硬度及微结构研究[J]. 材料科学与工艺, 2006, 14(2): 127-130.

LIU Wei, TANG Yong-jian, CHU Guang, et al. Research on microhardness and microstructure of nanocrystalline Cu[J]. Materials Science & Technology, 2006, 14(2): 127-130.

[12] Sanders P G, Fougere G E, Thompson L J, et al. Improvement in the synthesis compaction of nanocrystalline materials[J]. Nanost Mater, 1997, 8(3): 243-252.

[13] Wu X J, Du L G, Zhang H F, et al. Synthesis and tensile property of nanocrystalline metal copper[J]. Nanost Mater, 1999, 12: 221-223.

[14] Guo L H, Li H. Fabrication and characterization of thin nano- hydroxyapatite coatings on titanium[J]. Surf Coat Tech, 2004, 185: 268-274.

[15] 楚 广, 罗江山, 刘 伟, 等. 纳米Cu固体材料的X射线衍射与正电子湮没研究[J]. 强激光与粒子束, 2006, 18(1): 160-164.

CHU Guang, LUO Jiang-shan, LIU Wei, et al. Investigation of nanocrystalline Cu by X-ray diffraction and positron annihilation[J]. High Powder Laser and Particle Beams, 2006, 18(1): 160-164.

[16] 张立德, 牟季美. 纳米材料和纳米结构[M]. 北京: 科学出版社, 2002.

ZHANG Li-de, MOU Ji-mei. Nano-materials and nanostructure[M]. Beijing: Science Press, 2002.

收稿日期:2006-12-02;修回日期:2007-01-25

基金项目:国家自然科学基金资助项目(10475069/A0506)

作者简介:楚 广(1958-),男,湖南长沙人,高级工程师,博士,从事金属纳米材料研究

通信作者:楚 广,男,高级工程师,博士;电话:0731-8836791; E-mail: user12134@sina.com