文章编号:1004-0609(2010)07-1275-07

微观组织对2E12铝合金疲劳裂纹扩展的影响

闫 亮1, 2,杜凤山1,戴圣龙2,杨守杰2

(1. 燕山大学 机械与工程学院,秦皇岛 066004;

2. 北京航空材料研究院,北京 100095)

摘 要:研究室温大气环境下2E12铝合金微观组织与疲劳裂纹扩展行为之间的关系,并分别利用光学显微镜、透射电镜和扫描电镜对合金的微观组织及疲劳断口进行分析。结果表明:合金的疲劳裂纹扩展速率与合金中微米级第二相粒子的体积分数成正比,且随着亚微米级第二相粒子尺寸的增加及晶粒尺寸的减小,合金的疲劳裂纹扩展速率明显降低,尤其是在Pairs区及以后,其值降低30%;在低速扩展区,合金断口呈现脆性的准解理断裂特征,在中速扩展区,合金出现清晰的疲劳条纹。

关键词:2E12铝合金;疲劳裂纹扩展;晶粒;微米级第二相;亚微米级第二相

中图分类号:TG146.2;TG113.2 文献标志码:A

Effect of microstructures on fatigue crack propagation in 2E12 aluminum alloy

YAN Liang1, 2, DU Feng-shan1, DAI Sheng-long2, YANG Shou-jie2

(1. School of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China;

2. Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The interrelationship between microstructure and fatigue crack propagation behaviors of 2E12 aluminum alloys was investigated at room temperature in air. The microstructures and fatigue fracture surfaces of the alloy were examined by optical microscopy, transmission electron microscopy and scanning electron microscopy. The results show that the fatigue crack growth rate is proportional to the volume fraction of micro-sized second-phase particles. And with the increase of submicro-sized second-phase particles size and the decrease of grain size, the fatigue cracks propagate much slowly, reducing by 30% or more at Pairs region. In a low fatigue crack growth rate region, alloy shows quasi-cleavage fracture features. In a middle fatigue crack growth rate region, the fatigue striation features are clear.

Key words: 2E12 aluminum alloy; fatigue crack propagation; grain; micro-sized second-phase particles; submicro-sized second-phase particles

高强度2×24合金是航空工业中主要的结构材料,其常用状态为T3态。改进的2524铝合金是在2024合金的基础上通过降低 Fe和Si 等杂质元素的含量而开发的新型高强铝合金,与2024合金?相比,2524铝合金具有优良的断裂韧性、疲劳性能和抗应力腐蚀性能[1-2],用于取代传统的2024-T3合金。该合金首先在波音777飞机上获得应用,最近又被应用于A380大型客机[3-5],成为新一代航空结构材料,被认为是目前最理想的飞机蒙皮材料。

国内关于2524(2E12合金)合金的研究还处于研制开发阶段,相关的工艺还不成熟,近期国内出现了一些关于此合金的相关报道[6-10],系统地研究了此合金在不同条件下的耐腐蚀性能及疲劳性能,为该合金在国内的研究奠定了基础。但合金在其常用态T3态下的疲劳裂纹扩展速率(在裂纹失端就历程强度因子幅值ΔK<33 MPa?m1/2时发生断裂[6, 8]还没有达到AMS4296B的要求(在ΔK=33 MPa?m1/2时da/dN=3.05× 10-3 mm/cycle)。基于此种状况,本文作者对自行研发及进口合金的性能和微观组织进行对比研究,从影响合金疲劳裂纹扩展速率的主要微观组织(晶粒、微米级第二相粒子及亚微米级第二相粒子等)出发,研究合金的微观组织与疲劳裂纹扩展速率之间的内在联系,探讨不同微观组织对该合金疲劳裂纹扩展速率的影响 机制。

1 实验

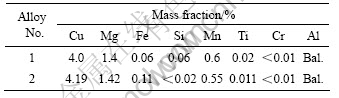

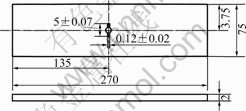

实验材料为2 mm厚的2E12-T3态铝合金薄板材,化学成分见表1。合金1为自行研制的合金板材,铸锭均匀化后经热轧、冷轧得到2.2 mm的板材,然后在(498±2) ℃固溶水淬,压光矫直至2.0 mm,室温放置96 h以上最终成T3态。合金2为进口板材。疲劳裂纹扩展速率实验按中国国家标准GB6398—86 的要求在MTS-810实验机上进行,应力比R=0.1,疲劳裂纹扩展速率试样按照北京航空材料研究院标准Q/6 S977—2004,试样示意图如图1所示。实验在室温、大气环境下进行。合金分别进行磨制 、抛光、腐蚀制成金相试样,腐蚀剂为Keller 试剂,其基本配比(体积分数)为1.0%HF+1.5%HCl+2.5%HNO3+95%H2O。

利用JSM-5600LV扫描电镜和JEM-2000FX透射电镜分别进行断口分析及微观组织分析。

表1 2E12铝合金的化学成分

Table 1 Chemical composition of 2E12 aluminum alloy

图1 疲劳裂纹扩展速率试样的示意图

Fig.1 Schematic diagram of sample for fatigue crack growth rate test (mm)

2 结果与分析

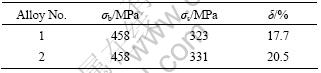

2.1 常规力学性能

表2所列为合金1和2的常规力学性能。由表2可以看出,两合金的抗拉强度一致,但是合金1的屈服强度及伸长率明显小于合金2的。

表2 2E12合金的常规力学性能

Table 2 Mechanical properties of 2E12 aluminum alloy

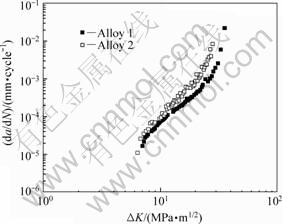

2.2 疲劳裂纹扩展速率

图2所示为合金的疲劳裂纹扩展速率da/dN与裂纹尖端应力强度因子幅值ΔK的关系。可以看出,合金2的疲劳裂纹扩展速率明显低于合金1的疲劳裂纹扩展速率,尤其是在Pairs区之后这种规律表现得更为明显。

图2 2E12铝合金的疲劳裂纹扩展速率与?K的关系

Fig.2 Relationship between fatigue crack growth rate and ?K for 2E12 Al alloy

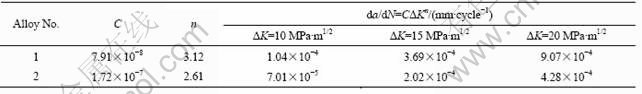

根据Pairs公式[11]对da/dN—ΔK双对数坐标关系曲线中直线部分的数据进行拟合,合金1与2相应的da/dN与ΔK数学表达式分别如式(1)与(2)所示。表3所列为与材料性质相关的常数C和n,并定量地表征在相同ΔK时,2种合金的疲劳裂纹扩展速率值,可知,合金2的疲劳裂纹扩展速率明显小于合金1的,在ΔK=10 MPa?m1/2时,其裂纹扩展速率降低了30% 以上。

表3 不同条件下合金的常数C和n以及不同ΔK时的da/dN

Table 3 C and n of alloys under different conditions and da/dN at different ΔK

(1)

(1)

(2)

(2)

2.3 合金的微观组织

2.3.1 晶粒形貌

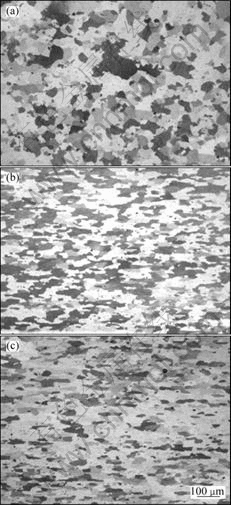

图3和4分别为合金1和2的光学金相组织。由图3和4可以看出,两种合金都发生了再结晶;同时,可以看到两种合金中有较大尺寸的微米级第二相弥散分布在晶粒内部及晶界。合金1的晶粒尺寸较大,且

图3 合金1的金相组织

Fig.3 Optical microstructures of alloy 1: (a) Rolling plane; (b) Longitudinal plane; (c) Transverse plane

图4 合金2的金相组织

Fig.4 Optical microstructures of alloy 2: (a)Rolling plane; (b)Longitudinal plane; (c)Transverse plane

轧制面上晶粒不规则,平均晶粒尺寸为150 ?m,厚度在40 ?m左右。而合金2的晶粒尺寸较小,轧制面上晶粒呈现饼状特征,平均直径约为70 ?m,厚度约为40 ?m。

2.3.2 微米级第二相粒子

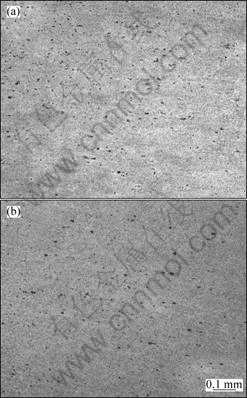

图5所示为合金1和2中微米级第二相粒子的SEM像。由图5可看出,第二相粒子主要为Al2CuMg和Al2Cu未溶相及含Fe、Si的杂质相[12],合金2中的

图5 合金中微米级第二相粒子的SEM像

Fig.5 SEM images of micro-sized second-phase particles in alloys: (a) Alloy 1; (b) Alloy 2

微米级第二相粒子数量要明显少于合金1中第二相的数量。利用Image-Pro Plus 6.0分析软件对合金中的微米级第二相粒子进行定量统计,合金1和2中微米级第二相粒子的体积分数分别为0.77%和0.38%。由此可见,合金2中的微米级第二相的体积分数比合金1中第二相粒子的体积分数减少了50%左右。

2.3.3 亚微米级第二相粒子

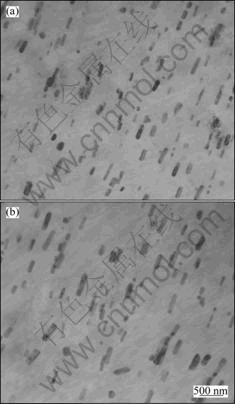

图6所示为合金1和2中的亚微米级第二相粒子的TEM像。由图6可看出,亚微米级第二相粒子第主要为棒状的AlCuMn相[12],合金1中的亚微米级棒状相平均长度在200 nm左右,合金2中的亚微米级棒状相尺寸在300 nm左右,合金2中棒状相间距较宽。

2.4 断口分析

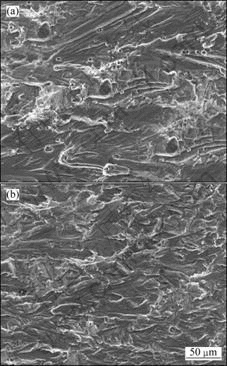

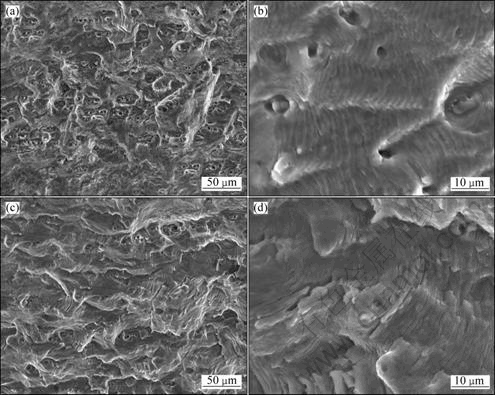

图7所示为应力强度因子幅值ΔK=7.87 MPa?m1/2处合金的断口形貌。由图7可以看出,在较小的ΔK时,两种合金的断口形貌为准解理断裂,均呈现脆性断裂的特征,合金2的断口较为粗糙,说明裂纹偏转较明显。

图8所示为ΔK=20 MPa?m1/2处合金的断口形貌。

图6 合金中亚微米级第二相粒子的TEM像

Fig.6 TEM images of submicro-sized second phase particles in alloys: (a) Alloy 1; (b) Alloy 2

图7 ΔK=7.87 MPa?m1/2处合金的断口形貌

Fig.7 Morphologies of fractures at ΔK=7.87 MPa?m1/2 for alloys: (a) Alloy 1; (b) Alloy 2

由图8可看出,随着ΔK的增大,合金疲劳断口的塑性特征增强。可以看出,合金1的断口形貌表现出疲劳条纹和韧窝混合型的特征,说明此时合金1的疲劳裂纹扩展进入稳定扩展与快速扩展阶段的过渡阶段(见图8(a));合金2的断口形貌仍以疲劳条纹特征为主(见图8(c)),并伴随少量的二次裂纹。由高倍放大图(见图8(b)和(d))可以看出,合金1的疲劳条纹间距明显大于合金2的疲劳条纹间距,这也说明合金2相对合金1具有较低的疲劳裂纹扩展速率。

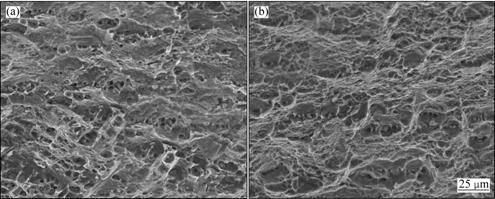

图9所示为合金瞬断区的断口形貌。由图9可以看出,瞬断区均为典型的韧窝型穿晶断裂,韧窝源于微米级第二相粒子,合金1的韧窝较多,且韧窝小而浅,而合金2的韧窝明显减少,且韧窝大而深。这是由于合金2中微米级第二相粒子的体积分数减少,粒子的间距相对增大,使断裂时各韧窝的形核间距加大, 断裂时韧窝与韧窝之间的长大及连接随着断裂形核间距的加大而推迟,继而使韧窝尺寸变大,并且在断裂前需要吸收更多的能量,使合金在较高的ΔK下不断裂。

图8 ΔK=20 MPa?m1/2处合金的断口形貌

Fig.8 Morphologies of fractures at ΔK=20 MPa?m1/2 for alloys: (a) Alloy 1; (b) Higher magnification for (a); (c) Alloy 2; (d) Higher magnification for (c)

图9 合金瞬断区的断口形貌

Fig.9 Morphologies of final fracture zone for alloys: (a) Alloy 1; (b) Alloy 2

3 讨论

对于2×××铝合金,影响其疲劳裂纹扩展速率的微观因素有晶粒尺寸、微米量级第二相粒子、纳米量级的细小时效强化相以及尺寸介于以上两相之间的亚微米量级的中间尺寸第二相颗粒等。在本研究中,因合金都为T3状态,两种合金时效析出相的影响因素相同。

1) 晶粒尺寸的影响。根据2.3.1部分对合金晶粒的定量分析可知,合金2的晶粒尺寸明显减小,则其在循环加载过程中产生的粗糙度诱发裂纹闭合的效应就更强烈,并导致强烈的裂纹屏蔽效应,使其具有较高的疲劳裂纹抗力,降低疲劳裂纹扩展速率。同时,晶界也会对裂纹扩展直接起阻碍作用,晶粒尺寸较小时,其晶界数量增多,对裂纹扩展的阻碍作用增大,导致了更大的裂纹扩展抗力,使合金的裂纹扩展速率降低。 这与FAN 等[13]及HIRAMATSU等[14]的研究结果一致。

2) 不同尺寸第二相粒子的影响。合金中的第二相粒子也会对合金的疲劳裂纹扩展速率起重要作用。由2.3.2部分可知,合金1中微米级第二相粒子的体积分越较大,则在循环载荷作用下,第二相粒子阻碍位错滑移的能力就越强,塞积在第二相粒子附近的位错数量就越多,相应产生的应力集中也越强,当局部应力集中超过第二相粒子本身的断裂强度或其与基体的结合强度时,第二相粒子破碎,或者沿界面与基体分 离[12, 15]。第二相粒子本身的这种性能为疲劳裂纹提供优先扩展的路径,这些扩展路径的出现降低疲劳裂纹扩展所需的能量,使裂纹更易于扩展,从而随着微米级第二相粒子体积分数的增多势必会降低疲劳裂纹的扩展抗力,进而提高疲劳裂纹扩展速率。

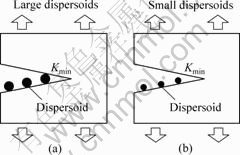

亚微米级第二相粒子尺寸的增大也可以降低疲劳裂纹扩展速率。这是由于当亚微米级第二相粒子尺寸与裂纹尖端张开位移相当时,在卸载过程中,粒子与裂纹面将发生接触,引起裂纹闭合,即发生“桥接效应”。这种中间尺寸第二相颗粒的“桥接效应”得到SURESH和RITCHIE[16]研究的证实。图10所示为亚微米级第二相粒子桥接作用的示意图,形象地表示了较大尺寸粒子的桥接效应。由2.3.3部分的分析可知,合金1中亚微米级的第二相粒子尺寸较小,在循环载荷卸载过程中不能发挥“桥接效应”,降低裂纹闭合的程度,裂纹扩展的有效驱动力相对较大,使裂纹扩展速率增大。

图10 粒子间的桥接作用示意图[16]

Fig.10 Schematic diagram of bridging effect among particles[16]: (a) Large dispersoids; (b) Small dispersoids

由此可见,减少微米级第二相粒子的体积分数及适当增加亚微米级第二相的尺寸能降低疲劳裂纹扩展速率。

4 结论

1) 2E12铝合金的疲劳裂纹扩展速率与合金中的微米级第二相的体积分数成正比,且随着亚微米级第二相尺寸的增加及晶粒尺寸的减小,合金的疲劳裂纹扩展速率明显降低,尤其是在Pairs区及以后,其值降低了30%以上。

2) 在低速扩展区,合金断口呈现脆性的准解理断裂特征;在中速扩展区,合金断口呈现清晰的条带特征;在瞬断区,断口呈现典型的韧窝特征。

REFERENCES

[1] GOLDEN P J, GRANDT A F, BRAY G H. A comparison of fatigue crack formation at holes in 2024-T3 and 2524-T3 aluminum alloy specimens [J]. International Journal of Fatigue, 1999, 21(1): S211-S219.

[2] BRAY G H, BUCCI R J, COLVIN E L, KULAK M. Effect of prior corrosion on the S/N fatigue performance of aluminum sheet alloys 2024-T3 and 2524-T3 [C]// van der SLUYS W A, PIASCIK R S, ZAWIERUCHA R. Effects of Environment on the Initiation of Crack Growth. ASTM STP 1298. Philadelphia: American Society for Testing and Materials, 1997.

[3] STARKE E A, STALEYT J T. Application of modern aluminum alloys to aircraft [J]. Progress in Aerospace Sciences, 1996, 32(2/3): 131-172.

[4] CASSADA W, LIU J, TALRY J. Aluminum alloys for aircraft structure [J]. Advanced Materials & Processes, 2002, 160(12): 27-29.

[5] 陈 文. 先进铝合金在A380上的应用[J]. 航空维修与工程, 2005(2): 40-41.

CHEN Wen. Application of advanced aluminum alloys in A380 structures [J]. Aviation Maintenance & Engineering, 2005(2): 40-41.

[6] 刘 岗, 郑子樵, 杨守杰, 戴圣龙, 李世晨. 2E12铝合金的疲劳寿命与裂纹扩展行为的研究[J]. 机械工程材料, 2007, 31(11): 65-68.

LIU Gang, ZHENG Zi-qiao, YANG Shou-jie, DAI Sheng-long, LI Shi-chen. The fatigue performance and fatigue crack propagation behavior of 2E12 Al alloy [J]. Materials for Mechanical Engineering, 2007, 31(11): 65-68.

[7] LIU Yan-bin, LIU Zhi-yi, LI Yun-tao, XIA Qin-kun, ZHOU Jie. Enhanced fatigue crack propagation resistance of an Al-Cu-Mg alloy by artificial aging [J]. Mater Sci Eng A, 2008, 492(1/2): 333-336.

[8] 孙晓旭. 2E12+Zr铝合金的热处理与微观组织及力学性能研究[D]. 长沙: 中南大学, 2008: 52-63.

SUN Xiao-xu. The heatment, microstructures and mechanical properties of 2E12+Zr aluminum alloy [D]. Changsha: Central South University, 2008: 52-63.

[9] 李 海, 王芝秀, 魏修宇, 郑子樵. 固溶处理时间对2E12铝合金组织和疲劳性能的影响[J].航空学报, 2009,30(1): 148- 152.

LI Hai, WANG Zhi-xiu, WEI Xiu-yu, ZHENG Zi-qiao. Effect of solution treatment time on microstructures and fatigue properties of aluminum alloy 2E12 [J]. Acta Aeronautica et Astronautica Sinica, 2009,30(1): 148-152.

[10] 杨 胜, 易丹青, 姚素娟, 钟 利. 热处理对2E12铝合金耐腐蚀性及力学性能的影响[J]. 金属热处理,2007, 32(9): 9-13.

YANG Sheng, YI Dan-qing, YAO Su-juan, ZHONG Li. Effect of heat treatment on corrosion resistance and mechanical properties of 2E12 aluminum alloy [J]. Heat Treatment of Metals, 2007, 32(9): 9-13.

[11] DESMUKH M N, PANDEY R K, MUKHOPADHYAY A K. Effect of aging treatments on the kinetics of fatigue crack growth in 7010 aluminum alloy [J]. Mater Sci Eng A, 2006, 435/36: 318-326.

[12] 杜凤山, 闫 亮, 戴圣龙, 杨守杰. 高强铝合金疲劳特性研究[J]. 航空材料学报, 2009, 29(1): 96-100.

DU Feng-shan, YAN Liang, DAI Sheng-long, YANG Shou-jie. Study on fatigue performance of high strength aluminum alloy [J]. Journal of Aeronautical Materials, 2009, 29(1): 96-100.

[13] FAN Xi-gang, JIANG Da-ming, ZHONG Li, WANG Tao, REN Shi-yu. Influence of microstructure on the crack propagation and corrosion resistance of Al-Zn-Mg-Cu alloy 7150 [J]. Materials Characterization, 2007, 58(1): 24-28.

[14] HIRAMATSU T, CHIKUDA M, MIYAQI Y, NAGAO K. Relationship between stress corrosion resistance and grain shape of heavy section Al-Zn-Mg extrusion [J]. J Jap Inst Light Metals, 1972, 22(12): 701-709.

[15] BROEK D. Role of inclusions in ductile fracture and fracture toughness [J]. Engineering Fracture Mechanics, 1973, 5: 55-66.

[16] SURESH S, RITCHIE R O. Propagation of short fatigue cracks [J]. International Metals Review, 1984, 29: 455-476.

(编辑 杨 华)

基金项目:国家重点基础研究发展计划资助项目(2005CB623705)

收稿日期:2009-05-12;修订日期:2010-04-18

通信作者:杜凤山,教授,博士;电话: 0335-8057040;E-mail: fsdu@ysu.edu.cn