Porosity and surface roughness simulation of nickel-aluminum coating in plasma spray forming

ZENG Hao-ping(曾好平)1, 3, FANG Jian-cheng(方建成)2, XU Wen-ji(徐文骥)1,

ZHAO Zi-yu(赵紫玉)2, WANG Li(王 莉)2

1. Key Laboratory for Precision and Non-traditional Machining Technology of Ministry of Education,

Dalian University of Technology, Dalian 116024, China;

2. College of Mechanical Engineering and Automation, Huaqiao University, Quanzhou 362021, China;

3. College of Mechanical Engineering, University of Science and Technology Liaoning, Anshan 114051, China

Received 28 July 2006; accepted 15 September 2006

Abstract: As the important evaluation parameters concerning the spray qualities, the porosity and surface roughness of the coatings obtained by thermal spray forming have great influence on their forming accuracy, mechanical properties and service lifetime. But it is difficult to predict or control the two parameters for such a highly nonlinear process. A two-dimensional simulation of coating porosity and surface roughness of nickel-aluminum alloy (Ni-5%Al) in plasma spray forming was presented, which was based on the multi-dimensional statistical behaviors of the droplets as well as the simplification and digitization of the typical splat cross sections. Further analysis involving the influence of the droplet diameters and the scanning velocities of the spray gun on the two parameters was conducted. The simulation and analysis results indicate that the porosity and surface roughness are more influenced by the droplet diameters, but less influenced by the spray gun velocities. The results will provide basis for the prediction or control of coating mechanical properties by depositing parameters.

Key words: porosity; surface roughness; simulation; nickel-aluminum alloy; plasma spray forming

1 Introduction

Plasma spray forming is a process, in which a continuous coating is fabricated by melting the consumable materials into droplets, and then depositing these droplets on the substrate[1]. Compared with traditional manufacturing methods, it is characteristic of fast coating deposition, low production cost and excellent material versatility[2-3]. Among the common materials applied in this technology, the nickel-aluminum alloy Ni-5%Al (mass fraction) is typically used as bond coat or dimensional restoration for its good bonding property and high coating density. But the prediction or control of the coating microstructure properties, such as the porosity and surface roughness, remain difficult in this highly nonlinear process, in which too many influencing factors are involved. Therefore, the numerical simulation of the coating deposition becomes a common and effective method to solve such problems.

In the existing coating growth simulation methods, the droplet properties prior to the impact on the substrate were usually considered to follow the normal distribution function, whereas various splat shapes, pore generating mechanisms and accumulating rules were applied by different researchers. WU et al[4] simulated that the coating formation of plasma spray forming by simplifying the splats of the flattened droplets was circular flatten cylinders. GHAFOURI-AZAR et al[5] presented a three-dimensional simulation of the coating formation based on the assumption that the porosity was solely due to the curl-up of the splats. ZHU et al[6] modeled the deposition process by reducing the flattened droplets to be a single element in a finite difference grid, in which no pores presented.

In this paper, we described a two-dimensional simulation of nickel-aluminum alloy Ni-5%Al (mass fraction) coating porosity and surface roughness in plasma spray forming based on the multi-dimensional statistic behaviors of droplets as well as the simplification and digitization of typical splat cross sections.

2 Numerical model

The coating formation of plasma spray forming is a stochastic process, in which 50-60 spray parameters are related to the coating properties[1]. Among these parameters, such as the diameters, temperatures, velocities of the in-flight droplets and their landing positions on the substrate, are the directly associated factors. Therefore, the large spraying parameter set is reduced to the four direct parameters in the simulation. The statistic behaviors of these multi-dimensional parameters are proved to follow the normal distribution function by both numerical simulation and experiments [7-8]:

(1)

(1)

where β is the average value; σ is the standard deviation.

At the impact on the substrate, the droplet will be flattened to be a splat. By neglecting the influence of liquid–solid contact angle, the maximum spread factor can be formulated as[9]

(2)

(2)

where Dsplat is the flattened splat diameter; D0 is the droplet diameter; We is the Weber number; ρ is the density; v0 is the droplet velocity; γ is the liquid-gas surface tension; Re is the Reynolds number; μ is the viscosity. A typical plasma spray forming splat collected on a smooth, flat and preheated substrate without splashing is shown in Fig.1. Below the splat are the simplified and digitized cross sections, which will be used in the simulation as the basic splat shapes.

Fig.1 Typical splat and simplified and digitized cross sections

The following assumptions and rules are adopted in the simulation of coating formation:

1) The oxidation of the in-flight droplets is negligible.

2) The droplets are fully melted prior to the impact on the substrate.

3) The substrate is preheated so that no splashing occurs when the droplets deposit.

4) Pores are only generated when a splat deposits on a rough surface.

5) The splat will be completely detached when it deposits on a step higher than 2 times of its thickness.

6) When depositing on a step without higher than twice of its thickness, the splat will generate different pores based on a stochastic model considering the difference in droplet velocities.

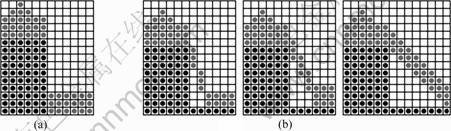

Fig.2 shows the different cases when a splat deposits on steps.

3 Simulation results

The simulation is implemented on a grid of 1 000×3 000, and the surface of the substrate is assumed to be flat and smooth. The spray gun moves alternately from left to right and right to left with velocities from 0.2 m/s to 1.0 m/s. The depositing parameters applied in the simulation are listed in Table 1.

Fig.2 Different cases during splat depositing on steps: (a) Splat detached; (b) Generating different pores considering velocity difference

Fig.3 shows part of the simulated coating. From Fig.3, when the average diameter of the droplet is 30 μm and the spray gun velocity is 0.2 m/s, the statistically-averaged porosity on the coatings in 5 simulations is 5.65%, which is similar to the experimental results with similar spray parameters in Ref.[10]. The corresponding average surface roughness of the coatings is 13 μm under the following definition.

(3)

(3)

where hm is the mean height of the coating as shown in Fig.3.

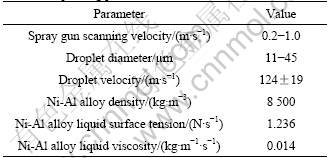

Table 1 Depositing parameters

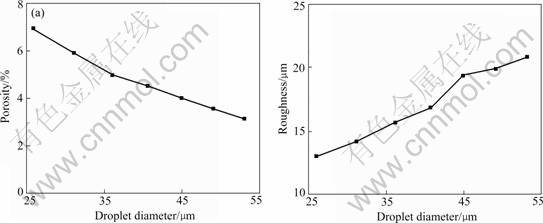

Further analysis is conducted to investigate the influence of droplet diameters and spray gun velocities on the porosity and surface roughness of coatings, as shown in Figs.4 and 5. It can be seen from Fig.4, when the droplet diameters increase from 25 to 54 μm, the porosities decrease from 6.88% to 3.10%. The reason for this trend is because the pore-generating probability of a coating with the same thickness decreases with the increase of droplet diameters. By contrast, the surface roughness increases from 12.93 to 20.74 μm when the droplet dimension varies between the same range.

Fig.3 Cross section of simulated coating

Fig.4 Effects of droplet diameter on porosity (a) and roughness (b) of simulated coatings

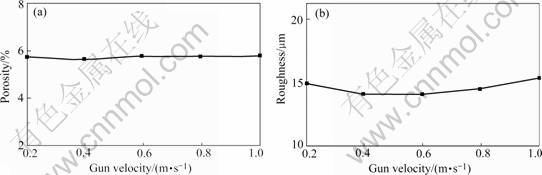

Fig.5 Effects of gun velocity on porosity (a) and roughness (b) of simulated coatings

As to the influence of spray gun scanning velocity on the coating properties, it can be seen from Fig.5, the porosity and surface roughness are little influenced even when the scanning velocities increase from 0.2 to 1.0 m/s.

4 Conclusions

The porosity and surface roughness of the simulated coatings compare favorably with the experimental data. Further analysis reveals that two parameters are more affected by the droplet diameters and less affected by the gun scanning velocity. The simulation suggests a new way to predict or control the coating porosities and surface roughness with a certain set of depositing parameters.

References

[1] FAUCHAIS P. Understanding plasma spraying [J]. Journal of Physics D: Applied Physics, 2004, 37: 86-108.

[2] FANG Jian-cheng, XU Wen-ji. Plasma spray forming [J]. Journal of Materials Processing Technology, 2002, 129: 288-293.

[3] GEIBEL A, Froyen L, DELAEY L. Plasma spray forming: An alternate route for manufacturing freestanding components [J]. Journal of Thermal Spray Technology, 1996, 5: 419-429.

[4] WU Xin-can. CHEN Xi. Simulation of coating formation during plasma spraying [J]. Journal of Tsinghua University (Science and Technology), 2003, 43: 1503-1506. (in Chinese)

[5] GHAFOURI-AZAR R, MOSTAGHIMI J, CHANDRA S, CHARMCHI M. A stochastic model to simulate the formation of a thermal spray coating [J]. Journal of Thermal Spray Technology, 2003, 12: 53-69.

[6] ZHU You-li, LIAO Han-lin, CODDET C. Transient thermal analysis and coating formation simulation of thermal spray process by finite difference method [J]. Surface and Coatings Technology, 2006, 200: 4665-4673.

[7] LIU B, ZHANG T, BAO Y, GAWNE D T. Numerical modelling of motion and heating of particles during plasma spraying [J]. Surface Engineering, 2002, 18: 350-357.

[8] GUESSASM S, GHISLAIN M, CODDET C. Velocity and temperature distributions of alumina-titania in-flight particles in the atmospheric plasma spray process [J]. Surface and Coatings Technology, 2005, 192: 70-76.

[9] MOSTAGHIMI J, PASANDIDEH-FARD M, CHANDRA S. Dynamics of splat formation in plasma spray coating process [J]. Plasma Chemistry and Plasma Processing, 2002, 22: 59-84.

[10] DESHPANDE S, SAMPATH S, ZHANG H. Mechanisms of oxidation and its role in microstructural evolution of metallic thermal spray coatings—Case study for Ni-Al [J]. Surface and Coatings Technology, 2006, 200: 5395-5406.

(Edited by LI Yan-hong)

Foundation item: Project(50675072) supported by the National Natural Science Foundation of China; Project(2006J0165) supported by the Natural Science Foundation of Fujian Province of China; Project(20062178) supported by the Natural Science Foundation of Liaoning Province of China

Corresponding author: FANG Jian-cheng; Tel: +86-595-22529537; E-mail: fangjiancheng@263.net