文章编号: 1004-0609(2005)02-0184-08

点焊镀锌钢板时电极表面熔敷TiC涂层对电极失效的影响

董仕节, ZHOU Norman

(湖北汽车工业学院 材料工程系, 十堰 442002)

摘 要: 利用SEM、 EDX和XRD等方法分析了在点焊镀锌钢板时电极表面熔敷TiC涂层对电极失效的影响。 结果表明: 点焊镀锌钢板时电极的失效机制主要是电极和镀锌板之间局部焊接的断裂发生在电极表面而导致的电极磨损, 以及电极和镀锌板表面的锌之间的合金化。 表面涂敷TiC的CuCrZr电极的寿命(1200点)是CuCrZr电极寿命(500点)的2.4倍, 表面处理能提高电极寿命的主要原因是在点焊镀锌钢板时表面涂敷的TiC层能阻碍电极和镀锌板之间的局部焊接和阻碍电极和镀锌板表面的锌之间的合金化。

关键词: 电极失效; 点焊; 镀锌钢板; TiC涂层 中图分类号: TG431

文献标识码: A

Effect of TiC coating on electrode tip surface on electrode degradation during resistance spot welding zinc coated steel

DONG Shi-jie, ZHOU Norman

(Department of Materials Engineering,

Hubei Automobile Industrial Institute, Shiyan 442002, China)

Abstract: The effect of TiC coating on electrode tip surface on electrode degradation during resistance spot welding zinc coated steel was investigated by SEM, EDX and XRD. The results show that the electrode degradation mechanism is basically caused by wear due to the fracture of local welding between the electrode tip surface and zinc coated sheet steel happened at electrode surface and alloying between electrode and zinc on coated steel during resistance spot welding zinc coated steel. The service life of CuCrZr electrode with TiC coating (1200 welds) is 2.4 times of that of uncoated CuCrZr electrode (500 welds). The reason of the TiC coating increasing electrode service life is that the TiC particles contained in the coating deposits can stop local welding between the electrode tip surface and zinc coated sheet steel and decrease alloying between electrode and zinc on zinc coated steel during resistance spot welding zinc coated steel.

Key words: electrode degradation; resistance spot welding; zinc coated steel; TiC coating

随着汽车工业的发展, 普通钢板已不能满足汽车耐蚀性能不断提高的要求。 各种镀层钢板, 特别是镀锌钢板在汽车上应用愈来愈广泛。 由于点焊镀锌钢板时, 低熔点的锌减小了接触电阻, 与点焊普通钢板(非镀层钢板)相比, 需增大焊接电流[1-4]或延长焊接时间[4], 电极工作部分在热和力的联合作用下, 易与钢板表面的低熔点的锌发生反应, 形成低熔点的合金, 加快电极失效[5-7]。 为了延长电极寿命, 在电极头部熔敷一层高熔点、 高强度、 高电导率且与锌结合力低的陶瓷材料, 能阻碍或减缓电极与钢板表面的锌镀层发生反应。 本文作者研究了电极表面熔敷的TiC涂层在点焊镀锌钢板时对电极失效的影响。

1 实验方法

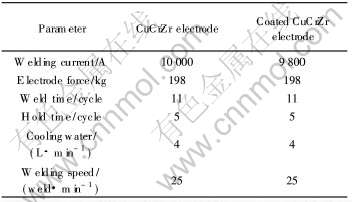

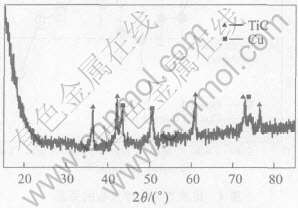

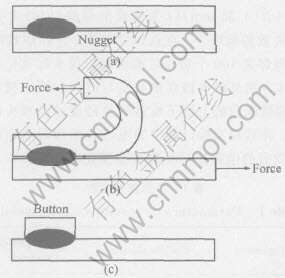

点焊采用的是250kVA的交流点焊机, 点焊镀锌钢板的厚度为0.7mm, 成分为Fe-0.002%C-0.18%Mn-0.04%Al-0.006%Nb-0.006%Ti(质量分数), 表面镀锌层的成分为98.3%Zn-1%Fe-0.7%Al, 表面镀锌层的厚度为10μm, 焊接所采用的电极结构见图1, 所实验的电极为Cu-0.84%Cr-0.05%Zr(简称CuCrZr电极)以及表面处理后的CuCrZr电极。 由于电极表面处理后改变了电极的点焊特性, 所以两种电极的点焊规范有所差别(见表1)。 对电极表面处理采用的是振动电火花熔敷的方法, 其处理主要集中在电极的头部, 表面处理后得到的涂敷层厚度为10~15μm, 涂层的主要成分是铜基TiC, 见图2所示。 对焊接过程中焊点熔核直径和电极头部直径进行跟踪, 具体方法是每100个焊点中的前5个焊点用来做焊接撕裂实验, 撕裂实验是在自制的实验机上进行的, 测量撕裂后焊点熔核的大小(撕裂实验见图3), 以焊点熔核直径下降到4[KF(]t[KF)](3.35mm)(t为钢板的厚度)时作为判断电极失效的标准[8]。 在点焊过程中, 开始焊接时和以后每焊完100个焊点后都测量电极头部直径的大小, 其方法是将电极在垫有复写纸的白纸上敲打一下, 测量在白纸上留下痕迹的直径就是电极头部的直径。 并且对实验过程中的电极表面和焊点表面以及失效后的电极进行形貌观察及能谱分析。

图1 电极结构图(a)及表面处理后的电极(b)(单位: mm)

Fig.1 Structure map of electrode(a) and coating electrode(b)(unit: mm)

表1 点焊规范参数

Table 1 Parameters of resistance spot welding

图2 电极表面涂层的X射线衍射谱

Fig.2 XRD pattern of deposits on electrode surface

2 实验结果

图4所示为CuCrZr电极和表面处理的CuCrZr电极在点焊镀锌钢板时焊点熔核直径随焊点数的变化曲线。 从图4可以看出, 随焊点数的增加, 两种电极点焊的焊点的熔核直径都下降, 但没有表面处理的电极所焊的焊点熔核直径下降要快得多, 当焊到第500个焊点时, 焊点的熔核直径已经接近到可以接受的最小熔核直径(3.35mm), 即CuCrZr电极的寿命为500点, 而此时表面处理的电极所焊的焊点熔核直径才到5.45mm左右。 从图4还可以看出表面处理后CuCrZr电极的寿命达到了1200点, 是没有表面处理的CuCrZr电极寿命的2.4倍。

图3 撕裂实验示意图

Fig.3 Schematic view of peel testing

图4 熔核直径与焊点数的关系

Fig.4 Relationships between nugget diameter and welds

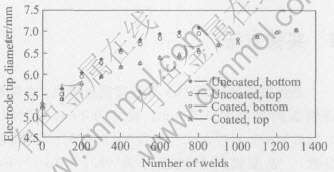

图5所示为两种电极在使用过程中电极头部直径的变化曲线。 从图5可以看出, CuCrZr电极和表面处理后的CuCrZr电极头部的直径随焊点数的增加都增加, 但表面处理后的电极头部直径增加的速度明显小于没有表面处理后的电极头部直径增加的速度。

3 分析与讨论

3.1电极的失效机制

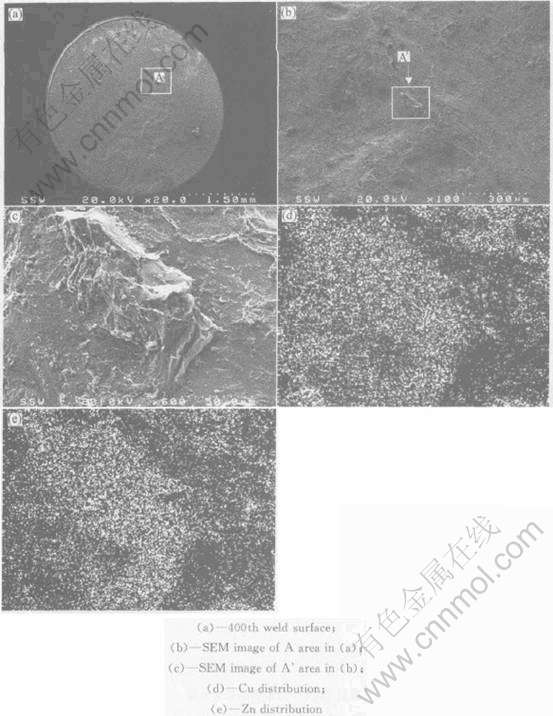

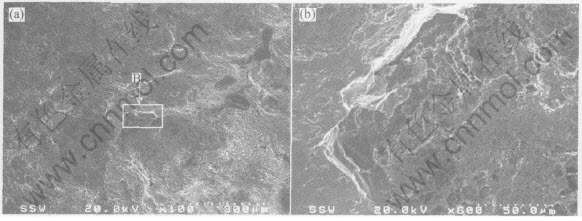

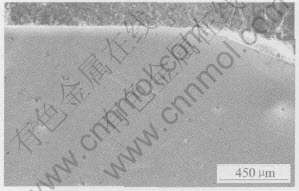

在点焊镀锌钢板时, 焊点熔核直径随焊点数增加而下降的主要原因是电极头部直径随焊点数增加而增加, 电极头部直径的增加使得点焊时电极头部的电流密度下降, 从而产生不了满足工艺要求的点焊熔核致使电极失效[9]。 普通点焊时, 焊件与焊件之间之所以能形成点焊熔核, 是因为在焊件与焊件之间存在较大的接触电阻并且有电流通过。 同样, 在电极与焊件之间也存在接触电阻和有电流通过, 因而电极与焊件之间也存在焊接的可能, 只不过是由于电极与焊件的接触电阻小于焊件与焊件的接触电阻[10], 和电极的导热快(电极的导热率高)并且有冷却水通过, 使得电极与焊件之间的焊接没有焊件与焊件之间的焊接容易。 但在点焊镀锌钢板时, 由于点焊的电流(或点焊的通电时间)较普通点焊要大(或长), 导致电极与焊件之间产生焊接的可能性大于普通的点焊。 图6所示为CuCrZr电极点焊的焊点表面形貌, A区域的SEM照片和相应Cu、 Zn元素的面扫描(第400个焊点)。 从图6可以看出, A区域是一个凸点, 在凸点处有大量的Cu、 Zn元素, 而对相应的电极头部的SEM图片显示(图7), A区域和图7中的B区域能很好的对应, 表明A区域的凸点就是电极表面的B区域的凹点。 仔细对比图6中的A区域及其Cu元素的面扫描和图7中的B区域就可以看出, A区域有Cu、 Zn元素聚集, 说明在点焊时电极和镀锌板之间在局部产生了焊接而且在此处形成合金层。 点焊完成后在外力的作用下电极和镀锌板之间的分离使得局部焊接的部位产生断裂, 断裂发生在电极次表面上, 所以造成了焊点表面有较多的Cu元素。 焊点表面的Cu来自于电极表面, 即发生了电极表面的Cu向焊点表面的转移, 这种转移的结果就是电极磨损[11, 12]。 每次点焊电极磨损的积累使得电极头部直径随焊点数增加而增加, 最终成为导致电极失效的主要原因。 从电极失效后的纵向剖面金相照片分析可知(图8), 此类电极在点焊过程中基本上不产生塑性变形。

图5 电极头部直径与焊点数的关系

Fig.5 Relationships between electrode tip diameter and welds

图6 第400焊点表面的SEM照片及Cu、 Zn元素面扫描

Fig.6 SEM images of 400th weld surface and Cu, Zn distributions

图7 第400焊点后CuCrZr电极表面的SEM照片

Fig.7 SEM images of 400th electrode surface

图8 CuCrZr电极失效后纵向剖面金相

Fig.8 SEM image of cross section of uncoated electrode after electrode failure

Holliday[13]认为, 点焊电极在使用过程中的失效除了磨损和塑性变形两种最基本的机制外, 还有第三种机制, 即被焊金属和电极之间产生的合金产物粘附存在于电极表面而导致电极头部的直径增加。 在点焊镀锌钢板时没有发现 Holliday发现的第三种机制。 但发现在点焊镀锌钢板时点焊电极头部产生了合金化(见图9), 合金化的产生将增加点焊电极头部的电阻, 提高点焊过程中电极表面的温度, 加快合金化的进程, 而且会影响电极表面的电流分布, 使电极失效。

图9 点焊500点后CuCrZr电极表面的合金层

Fig.9 SEM image of deposits alloying of

uncoated CuCrZr electrode after 500 welds

3.2 表面处理对电极失效的影响

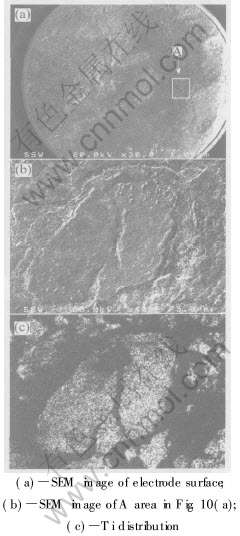

图10所示为表面处理后的CuCrZr电极在点焊镀锌钢板时电极表面形貌和相应Ti元素的面扫描(第400个焊点), A区域的面扫描显示A区域存在TiC。 图11为与图10相对应的焊点表面的SEM形貌和相应的Cu、 Zn元素的面扫描。 对比图10和图11可以发现, 图10中的A区域和图11能很好地对应, 并且发现有TiC的区域在焊点表面就没有Cu元素。 这是由于TiC是高熔点(3433℃)和高硬度的陶瓷[14], 在点焊的焊接温度下, TiC不可能和焊件表面产生局部焊接, 所以电极表面涂敷TiC颗粒能阻碍点焊时电极和焊件的局部焊接[12, 15], 从而减少电极表面的Cu元素向焊点表面转移来降低电极的磨损速度。

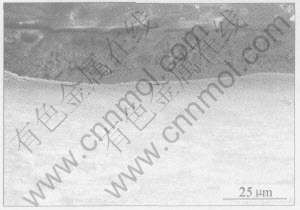

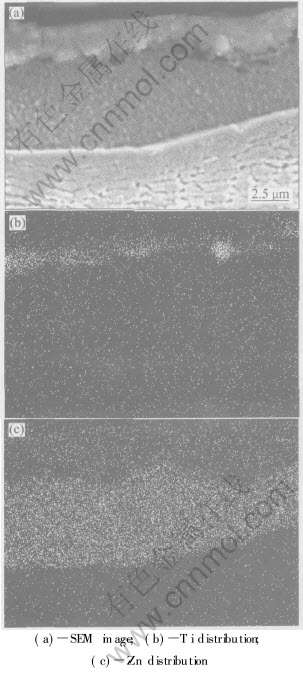

此外, 由于点焊时电极表面的温度较高, 电极表面在焊接时较软, 在焊接压力作用下电极表面大多数TiC颗粒总是镶嵌在电极的表面而不是被磨损, 图12所示是表面处理的电极失效后(1300点)电极在FeCl3水溶液中腐蚀0, 60和180s后表面的形貌及面扫描的谱线, 从中可以看出TiC颗粒存在于电极表面而不是被磨损了。 图12(d)是图12(c)中区域放大后的面扫描, 从图12(d)就更能说明这点。 既然在点焊过程中TiC颗粒总是存在于表面处理的电极的表面, 使得电极的表面好像有一层TiC增强铜基复合材料一样, 这层复合材料的存在, 对降低电极头部的磨损有一定的作用。 正是由于电极表面涂敷TiC能阻碍电极的磨损, 并且TiC颗粒总是存在表面处理的电极的表面, 所以使得电极头部直径的增加速度小于没有表面处理的电极头部直径的增加速度(图5), 从而提高了电极的使用寿命。 此外, 电极表面的TiC层能阻碍电极基体与镀锌板之间的合金化进程, 对提高电极寿命也有较大的作用, 图13就能说明这一点。 图13为点焊电极表面振动电火花熔敷TiC层的电极在点焊1300点后的纵向剖面金相及其相应的Ti、 Zn元素的面扫描。 从图13可以看出, TiC层存在于电极的外表面, 在TiC层下有CuZn合金层存在, TiC层肯定会减缓镀锌钢板表面的锌与电极基体之间的合金化的进程[16], 这对提高电极寿命是有作用的。

图10 第400焊点后电极表面SEM照片及

A区的SEM照片和Ti元素面扫描

Fig.10 SEM images of coated electrode surface at 400th weld details of

A area and its Ti distribution

图11 第400焊点表面与图6相对应区域的SEM照片及Cu、 Zn元素面扫描

Fig.11 SEM image of 400th sheet weld surface of

corresponding coated electrode and its Cu, Zn distributions

图12 表面处理后的电极失效后表面腐蚀后的SEM照片和能谱图

Fig.12 SEM images and EDX of electrode tip surface after etching at 0, 60 and 180s

图13 表面处理的电极失效后

纵向剖面的SEM 和Ti、 Zn元素的面扫描

Fig.13 SEM image of cross section of coated electrode after electrode

failure and its Ti and Zn distributions

4 结论

1) 点焊镀锌钢板时电极失效的机制主要是电极头部的磨损和电极头部的合金化。 磨损主要是由于电极和焊点局部焊接的断裂发生在电极头部表面造成的。

2) 表面涂敷TiC的CuCrZr电极的寿命(1200点)是CuCrZr电极寿命(500点)的2.4倍, 表面处理能提高电极寿命的主要原因是表面涂敷的TiC层能阻碍电极和镀锌板之间的局部焊接以及涂敷的TiC层能减缓电极和镀锌板之间的合金化。

REFERENCES

[1]Holliday R, Parker J D, Williams N T. Electrode deformation when spot welding coated steels[J]. Welding in the World, 1995, 35(3): 160-164.

[2]Takahashi Y, Saito T. Electrode tip wear and tip life in resistance spot-welding of organic composite coated steels, study of resistance spot-welding of coated steels(1)[J]. Welding International, 1994, 8(4): 262-268.

[3]Chatterjee K L, Waddell W. Electrode wear during spot welding of coated steel[J]. Welding & Metal Fabrication, 1996(3): 110-114.

[4]Tanaka Y, Sakaguchi M, Shirasawa H, et al. Electrode life in resistance spot welding of zinc plated steel sheets[J]. International Journal of Materials and Product Technology, 1987, 2 (2): 286-291.

[5]Gedeon S A, Eagar T W. Resistance spot welding of galvanized steel: partⅠ. Material variations and process modifications[J]. Metallurgical Transactions B, 1986, 17B (12): 879-885.

[6]Gedeon S A, Eagar T W. Resistance spot welding of galvanized steel: partⅡ. Mechanisms of spot weld nugget formation[J]. Metallurgical Transactions B, 1986, 17B (12): 887-901.

[7]Holliday R J, Parker J D, Williams N T. Prediction of electrode campaign life when spot welding zinc coated steels incorporating electrode tip dressing operations[J]. Ironmaking and Steelmaking, 1996, 23 (2): 157-163.

[8]Holliday R, Parker J D, Williams N T. Relative contribution of electrode tip growth mechanisms in spot welding zinc coated steels[J]. Welding in the World, 1996, 36(4): 186-193.

[9]Dong P, Li M V, Kimchi M. Finite element analysis of electrode wear mechanisms: face extrusion and pitting effects[J]. Science Technology of Welding and Joining, 1998, 3(2): 59-64.

[10]Obrien R L. Welding Handbook(Vol.2)[M]. 8th edition. Miami: American Welding Society, 1991.

[11]Parker J D, Williams N T, Hollidag R J. Mechanisms of electrode degradation when spot welding coated steels[J]. Science and Technology of Welding and Joining, 1998, 3(2): 65-74.

[12]Dong S J, Zhou Y. Effect of TiC conposite coating on electrode degradation in microresistance welding on nickel-plated steel[J]. Metallurgical and Materials Transactions A, 2003, 34(7): 1501-1511.

[13]Holliday R, Parker J D, Williams N T. Relative contribution of electrode tip growth mechanisms in spot welding zinc coated steels[J]. Welding in the World, 1996, 37(4): 186-193.

[14]Shackelford J F, Alexander W. Materials Science and Engineering Handbook[M]. 3rd ed. Florida: CRC Press LLC, 2001.

[15]Dong S J, Kelkar G P, Zhou Y. Electrode sticking during micro-resistance welding of thin metal sheets[J]. IEEE Transactions on Electronics Packaging Manufacturing, 2002, 25(4): 355-361.

[16]Prabhjit S. Wear Mechanism and Technology Improvement of TiC Cap Electrode for Resistance Spot Welding[D]. Waterloo: The University of Waterloo, 2002.

基金项目: 湖北省教育厅创新团队资助项目(鄂教科[2003]7号); 教育部留学回国人员科研启动基金资助项目(教外司留[2004]527号)

收稿日期: 2004-08-10; 修订日期: 2004-12-02

作者简介: 董仕节(1965-), 男, 教授, 博士.

通讯作者: 董仕节, 教授; 电话: 13508683572; E-mail: dongsjsj@sina.com

(编辑袁赛前)