DOI: 10.11817/j.ysxb.1004.0609.2021-36563

氧燃比对NiCrAlY涂层的微观结构及其在KCl熔盐中热腐蚀行为的影响

胡 凯1, 2,刘 侠1, 3,张世宏1, 2,王硕煜3,吴朝军4,朱广宏3,丁 毅5

(1. 安徽工业大学 先进金属材料绿色制备与表面技术教育部重点实验室,马鞍山 243002;

2. 安徽工业大学 材料科学与工程学院,马鞍山 243002;

3. 安徽马钢表面技术股份有限公司,马鞍山 243000;

4. 中国航天材料与工艺研究所,北京 100076;

5. 马钢(集团)控股有限公司,马鞍山 243000)

摘 要:采用超音速火焰喷涂(HVOF)技术制备氧燃比分别为3.91、4.31、4.62、5.39的NiCrAlY涂层,利用XRD、SEM、EDS、显微硬度计、拉伸试验机分析表征涂层微观组织结构及力学性能的变化规律,进而研究微观组织结构的变化对涂层在KCl熔盐环境中热腐蚀性能的影响。结果表明:随着氧燃比的升高,涂层中γ/γ′峰向高角度偏移,涂层结构变得致密,未熔化粒子边界减少,涂层结合强度由49 MPa提高到62 MPa,涂层显微硬度变化较小。涂层平均热腐蚀质量增加速率常数Kp由93.37 mg2/(cm4·h)降低到1.54 mg2/(cm4·h),说明涂层抗热腐蚀性能随着氧燃比的增大而升高。这主要是由于高氧燃比涂层中较少的孔隙及未熔化粒子边界,使得Cl、O向内扩散通道减少,涂层氯化-氧化程度降低,从而赋予涂层更优异的抗热腐蚀性能。

关键词:超音速火焰喷涂;NiCrAlY涂层;氧燃比;微观结构;热腐蚀

文章编号:1004-0609(2021)-06-1545-14 中图分类号:TG178 文献标志码:A

引文格式:胡 凯, 刘 侠, 张世宏, 等. 氧燃比对NiCrAlY涂层的微观结构及其在KCl熔盐中热腐蚀行为的影响[J]. 中国有色金属学报, 2021, 31(6): 1545-1558. DOI: 10.11817/j.ysxb.1004.0609.2021-36563

HU Kai, LIU Xia, ZHANG Shi-hong, et al. Effect of oxygen-fuel ratio on microstructure and hot corrosion behavior of NiCrAlY coatings in KCl molten salt[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(6): 1545-1558. DOI: 10.11817/j.ysxb.1004.0609.2021-36563

随着化石燃料燃烧造成的环境问题日益突出,以农作物秸秆、固体废弃物为代表的生物质燃料受到人们的青睐,然而生物质燃烧过程产生的烟气温度能够达到600~1050 ℃[1],生物质燃料中富含的K、Cl等碱金属元素在700 ℃时进入气相[2],随烟气流动形成KCl结晶析出并与管壁金属反应形成碱金属氯化物沉积在锅炉四管内壁,使锅炉遭受严重的热腐蚀问题,加速了锅炉组件的失效[3-4]。因此,必须在锅炉四管表面制备高性能、长寿命的高温防护涂层。NiCrAlY涂层作为传统的高温防护涂层,具有优异的高温抗氧化和抗热腐蚀性能,同时兼备较好的韧性及与基体间较高的结合强度[5-6],使其既可以作为防护涂层单独使用,也可用作热障涂层及其他陶瓷涂层的黏接层。在高温环境中,NiCrAlY涂层形成的热力学稳定氧化物如Al2O3和Cr2O3能有效抵御锅炉运行条件下的高温氧化失效[7-8],但在含K、Cl等碱金属氯化物的热腐蚀环境中,NiCrAlY涂层的氯腐蚀机理研究较少,表面形成的Al2O3和Cr2O3在高温氯腐蚀环境中的保护作用还有待探究[9-10]。

目前,热喷涂技术如大气等离子喷涂(APS)、电弧喷涂、冷喷涂、超音速火焰喷涂(HVOF)被广泛应用于抗高温氧化及抗高温腐蚀涂层的制备[11-13]。与其他热喷涂技术相比,HVOF技术是利用煤油、丙烷等碳氢系燃料与高压氧气在燃烧室混合燃烧产生超音速焰流,将加热至熔化或半熔化状态的粉末以极高的速度喷射到基体表面,得到组织致密、结合强度高、性能优异的涂层技术[14-15]。实际生产中主要使用以氧-煤油/氧-丙烷为燃料的HVOF系统在锅炉四管表面沉积防护涂层,以煤油为燃料的HVOF系统能量密度大、沉积效率高,但其成本同样较高且无法在生产现场进行修复作业;而以丙烷、丙烯、氢气等为燃料的HVOF系统,其沉积效率和涂层性能稍逊于氧-煤油系统所制备涂层,但通过调整工艺参数可以达到与氧-煤油系统所制备涂层相近的性能,且其成本更低、设备便携,可以在生产现场进行修复作业。氧-丙烷系统的主要工艺参数为氧气与燃料的混合比例[16],氧燃比的变化会改变粒子的温度和飞行速度,影响粒子的熔融程度以及扁平化程度,进而对涂层微观结构产生影响[17-18],而涂层微观结构直接决定涂层在熔盐热腐蚀环境中服役性能的好坏[19]。因此,研究不同氧燃比工艺参数下涂层的微观结构及热腐蚀性能具有重要意义。

本文作者利用氧-丙烷超音速火焰喷涂技术制备不同氧燃比的NiCrAlY涂层,研究氧燃比对NiCrAlY涂层微观组织结构的影响规律,并研究涂层在700 ℃ KCl熔盐中的热腐蚀性能,分析了涂层的高温腐蚀机理,为提高NiCrAlY涂层的耐KCl腐蚀性能提供理论和试验依据。

1 实验

1.1 实验材料

基体材料选择12CrMoV锅炉钢,其化学成分如表1所示。利用电火花线切割机制备尺寸为15 mm×15 mm×5 mm的基体试样,并准备d 25 mm×60 mm的基体棒材。热喷涂粉末选用中科院金属所生产的气雾化NiCrAlY粉末,粉末粒径为15~45 μm,其表面形貌和化学成分分别如图1和表1所示。

图1 NiCrAlY粉末形貌图

Fig. 1 Morphology of NiCrAlY powder

1.2 涂层制备

采用北京航天振邦公司生产的ZB-2000型超音速火焰喷涂系统制备涂层,以丙烷作为燃料,氧气作为助燃剂,氮气作为送粉载气,空气作为冷却介质,具体喷涂工艺参数如表2所示。实验前用丙酮对基体试样和棒材进行除油处理,之后用酒精清洗烘干。喷涂开始前用粒径为0.71 mm棕刚玉砂对基体试样6个表面及棒材端面都进行喷砂处理,并对试样片倒角,喷涂过程中对试样6个面做全包覆喷涂,同时对棒材喷砂端面进行喷涂,分别将氧燃比为3.91、4.31、4.62、5.39的涂层标记为A1、A2、A3、A4。

1.3 涂层性能测试

使用Phenom XL扫描电镜(SEM)对涂层表面、截面及断面形貌结构进行观察,将试样冷镶嵌于低收缩环氧树脂中,待树脂固化后,磨抛试样得到涂层截面;采用电火花线切割机将试样厚度减薄到1~2 mm,掰断试样得到涂层断面。使用Ultima IV型X射线衍射仪(XRD)对涂层表面物相结构进行分析。采用维氏硬度计测量涂层显微硬度,加载载荷3 N,加载时间5 s,每组涂层硬度值取10组测量数据平均值。利用Image J软件计算涂层孔隙率,将水平场宽度为100 μm的涂层截面SEM像转换为二值图像,根据灰度百分比计算得到涂层孔隙率,随机选取涂层截面5个位置测量孔隙率并计算平均值。使用WDW-50万能电子拉伸试验机测试涂层结合强度,使用E-7胶(上海华谊树脂有限公司)黏接拉伸棒,按照GB/T 8642—2002中的测试方法进行拉伸实验,每组涂层测试3次并取平均值。热腐蚀实验在管式炉中进行,采用涂盐法测试4组不同氧燃比涂层在700 ℃下的热腐蚀性能。首先将KCl晶粒研磨成粉末,使用药匙在电子分析天平上每次称取约2 mg KCl粉末,累积称取5次后将粉末均匀涂覆在试样表面(15 mm×15 mm),涂盐总量控制在5~6 mg/cm2内,涂盐误差控制在±0.3 mg/cm2。实验过程中,试样每隔10 h出炉空冷至室温,并使用电子分析天平称取质量,称取质量后将试样放入管式炉中继续热腐蚀实验,依次循环累积热腐蚀时间达到100 h,计算热腐蚀过程中质量变化并绘制热腐蚀动力学曲线。为获得涂层截面微观结构,将热腐蚀试样冷镶嵌在低收缩环氧树脂中,待树脂固化后使用低速精密切割机将热腐蚀试样从中部切开,以防止形成的热腐蚀产物剥落,使用SEM对热腐蚀后的涂层表面和截面进行观察,采用能谱仪(EDS)对涂层和腐蚀产物组成元素进行分析,利用XRD检测热腐蚀产物物相结构。

表1 12CrMoV基材及NiCrAlY粉末化学成分

Table 1 Chemical composition of 12CrMoV substrate and NiCrAlY spraying powder

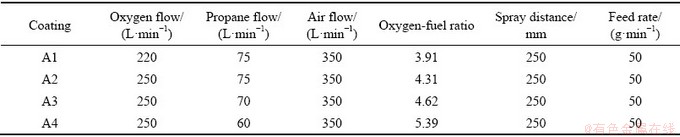

表2 超音速火焰喷涂工艺参数

Table 2 Spray parameters for HVOF process

2 实验结果

2.1 不同氧燃比NiCrAlY涂层力学性能及微观组织结构

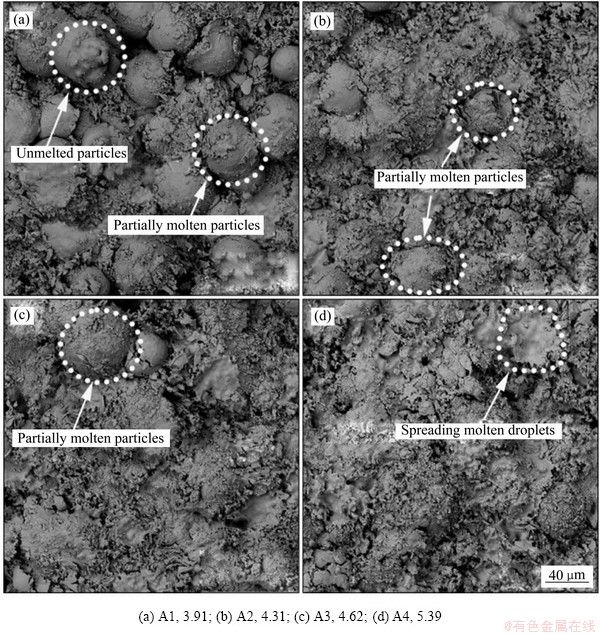

图2所示为不同氧燃比NiCrAlY涂层的表面形貌。从图2可以看出,氧燃比为3.91时,丙烷未充分燃烧,粉末在焰流中未发生熔融,A1涂层表面存在大量球状或椭球状未熔或半熔颗粒(见图2(a));氧燃比为4.31~4.62时,丙烷燃烧逐渐充分,粉末由未熔化状态向熔化状态转变,A2、A3涂层表面未熔或半熔颗粒逐渐减少(见图2(b)和(c));当氧燃比为5.39时,丙烷充分燃烧,粉末完全熔融,A4涂层表面呈现平整熔化液滴铺展状态(见图2(d))。喷涂态涂层表面EDS面扫描结果如表3所示,可以看出,随着氧燃比的增大,粉末在焰流中的熔化程度升高,相应地粉末放热氧化程度升高,涂层中氧含量变化不大。

图3所示为不同氧燃比NiCrAlY涂层的截面形貌及断面形貌。从图3可以看出,涂层平均厚度为250 μm左右,涂层结构致密,与基体结合良好。氧燃比为3.91时,A1涂层中存在较多明显的孔隙及未熔或半熔粒子边界,且在上表面处存在嵌入涂层的未熔粉末颗粒(见图3(a)和(b));氧燃比为4.31~4.62时,涂层中孔隙及未熔或半熔粒子边界数量减少,上表面未出现未熔粉末颗粒(见图3(c)~ (f));氧燃比为5.39时,A4涂层中已无明显的未熔颗粒边界,但涂层中仍存在少量孔隙(见图3(g)和(h))。同时,从涂层断面形貌可以看到,氧燃比为3.91时,A1涂层中存在大量未熔或半熔状态粒子,且未熔粒子仍保持球状或椭球状,在未熔或半熔粒子边界处存在较多孔隙,涂层结构较为疏松;氧燃比为4.31时,涂层中未熔颗粒减少,半熔化状态颗粒明显增多;氧燃比为4.62时,粉末颗粒由半熔化状态向熔化状态转变,涂层结构比较致密;当氧燃比升高到5.39时,涂层中颗粒趋近于完全熔融,涂层致密化程度进一步提高。另外,随着氧燃比的增大,涂层靠近表面及中部的未熔或半熔颗粒减少,但靠近基体侧涂层中仍然存在半熔状态颗粒,这可能是由于熔融或软化的颗粒遇到过冷基体表面来不及流动铺展即已迅速凝固,使得粒子保持原有形态[20]。

图2 不同氧燃比NiCrAlY涂层表面形貌

Fig. 2 Surface morphologies of NiCrAlY coatings with different oxygen-fuel ratios

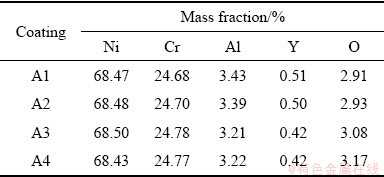

表3 喷涂态涂层表面EDS面扫描分析

Table 3 EDS data of as-sprayed coatings

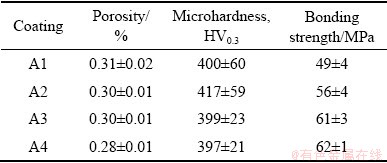

涂层孔隙率、显微硬度及结合强度如表4所示。随着氧燃比的升高,涂层孔隙率变化不大,结合强度由49 MPa升高到62 MPa;涂层显微硬度略有起伏,由氧燃比为3.91时的 400 HV升高至氧燃比为4.31时的417 HV,之后降低至氧燃比为4.62时的399 HV,最后降低至氧燃比为5.93时的397 HV。这是由于氧燃比为3.91和4.31时,未熔或半熔粉末对已沉积涂层形成类似喷丸作用,使得涂层显微硬度略有升高。随着氧燃比的升高,粉末熔化程度提高,粒子对涂层喷丸效应减弱,涂层显微硬度略有下降。同时,随着粉末熔化程度的提高,粒子扁平化程度提高,未熔粒子边界减少,孔隙率降低,粉末颗粒由未熔化状态向熔化状态的转变,有利于粉末之间发生冶金结合,使得涂层结合强度升高[21]。

图3 不同氧燃比NiCrAlY涂层截面形貌

Fig. 3 Section((a), (c), (e), (g)) and fracture((b), (d), (f), (h)) morphologies of NiCrAlY coatings with different oxygen-fuel ratios

表4 NiCrAlY涂层孔隙率、显微硬度及结合强度

Table 4 Porosity, microhardness and bonding strength of NiCrAlY coatings

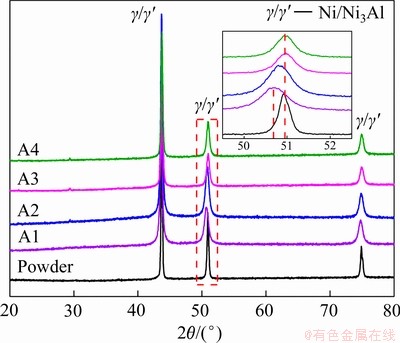

图4所示为粉末及不同氧燃比喷涂态涂层XRD谱。从图4中可以看到,粉末和喷涂态涂层中均主要为γ/γ′相[22],且相较于粉末,涂层中出现峰宽化现象,这是由于热喷涂过程中粉末的部分熔化和快速凝固导致的涂层晶粒细化[23]。此外,随着氧燃比的增大,相较于A1涂层中50.71°(PDF 50-1265) γ/γ′峰,A2、A3、A4涂层中对应γ/γ′峰分别向高角度偏移0.14°、0.24°、0.24°。这是由于随着氧燃比的升高,喷涂颗粒飞行速度和粒子温度升高[24],高速飞行的液滴/颗粒撞击涂层产生类似“喷丸强化”效果的喷丸压力,高温粒子与低温基体间的巨大温度差以及快速冷却凝固过程产生热应力[25],压应力和热应力的共同作用导致γ/γ′峰向高角度偏移。

图4 粉末及不同氧燃比喷涂态NiCrAlY涂层XRD谱

Fig. 4 XRD patterns of powder and as-sprayed NiCrAlY coatings with different oxygen-fuel ratios

2.2 涂层的热腐蚀动力学曲线

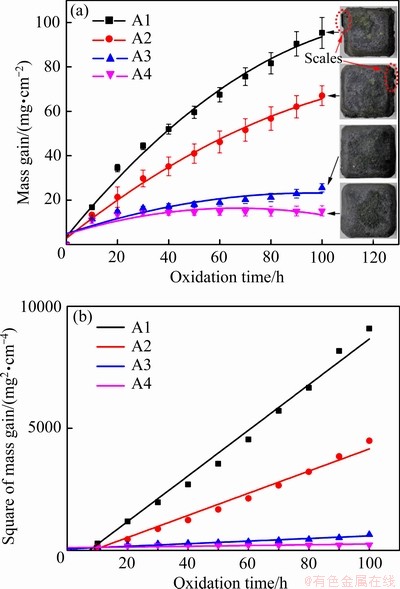

图5(a)所示为不同氧燃比NiCrAlY涂层在KCl熔盐环境下的热腐蚀动力学曲线和热腐蚀后涂层宏观形貌。从图5(a)中可以看到,4种涂层单位面积质量增加随时间变化呈现抛物线规律。热腐蚀初期(0~20 h),4种涂层质量增加较快;热腐蚀后期(20~100 h),A1、A2涂层依然处于快速质量增加阶段,而A3、A4涂层进入缓慢质量增加阶段。从宏观形貌中可见,100 h时,A1、A2涂层边缘有腐蚀剥落现象,而A3、A4涂层表面仍然完整;其中A1涂层的热腐蚀质量增加最大为95.31 mg/cm2,A4涂层的热腐蚀质量增加最小仅为15.14 mg/cm2,A4涂层表现出最好的抗热腐蚀性能。根据Wagner理论模型对NiCrAlY涂层热腐蚀动力学曲线进行线性拟合[26],如图5(b)所示,4种氧燃比涂层的平均热腐蚀质量增加速率常数Kp分别为A1涂层93.37mg2/(cm4·h)、A2涂层45.34 mg2/(cm4·h)、A3涂层5.32 mg2/(cm4·h)、A4涂层1.54 mg2/(cm4·h)。由此可见,随着氧燃比的增加,涂层热腐蚀质量增加速率明显降低;氧燃比为4.62~5.39时,涂层具有更加优异的抗KCl熔盐热腐蚀性能。

图5 不同氧燃比涂层热腐蚀动力学曲线及涂层宏观形貌和单位面积质量增加的平方与热腐蚀时间的关系

Fig. 5 Hot corrosion kinetic curves and macroscopic morphologies of NiCrAlY coatings with different oxygen-fuel ratios(a) and relationship between square of mass gain and oxidation time(b)

2.3 热腐蚀产物形貌及微观结构

不同氧燃比NiCrAlY涂层热腐蚀100 h后的XRD谱如图6所示。从图6中可以看到,不同氧燃比NiCrAlY涂层热腐蚀后表面产物基本相同,热腐蚀产物主要由Cr2O3、Al2O3和Y2O3,以及少量NiO、NiCr2O4、YAlO3和NiYO3组成[27],且涂层表面能检测到少量的KCl以及K2CrO4[28]。

图6 不同氧燃比NiCrAlY涂层热腐蚀100 h的XRD谱

Fig. 6 XRD patterns of NiCrAlY coatings with different oxygen-fuel ratios for 100 h hot corrosion

图7 不同氧燃比NiCrAlY涂层热腐蚀表面形貌

Fig. 7 Hot corrosion surface topographies of NiCrAlY coatings with different oxygen-fuel ratios

不同氧燃比NiCrAlY涂层在700 ℃的KCl熔盐腐蚀环境下的热腐蚀产物形貌如图7所示,表5所列为相应的EDS分析结果。结合EDS分析结果,从图7中可以看到,涂层表面热腐蚀产物主要由富Y、Al的白色棱柱状颗粒、富Cr的灰色片状物以及富K、Ni的类尖晶石相组成。随着氧燃比升高,热腐蚀表面形貌发生较大变化,白色棱柱状颗粒增多且密集化,同时,在A4表面观察到白色颗粒明显变大,富Cr灰色片状团簇物逐渐消失,转而形成连续富Cr氧化膜覆盖在涂层表面。热腐蚀表面含有大量Cr、Y、Al、O元素,表明涂层在KCl熔盐-空气的共同作用下发生了氧化。

结合XRD分析结果,白色棱柱状颗粒物主要为Y2O3及少量YAlO3,灰色片状物主要为Cr2O3,由于Y对O的亲和力比Al大,因而Y优先与O反应,Y2O3能与Al2O3反应生成YAlO3,因此,涂层表面Al2O3含量较少[29]。A1、A2、A3、A4涂层表面腐蚀产物主要由Cr2O3和少量Y2O3组成,Ni氧化形成的NiO及NiCr2O4尖晶石不具有保护作用[30],其在表面含量较少,同时,在涂层表面检测到较多K元素,推测其主要为未反应的KCl和反应形成的K2CrO4。

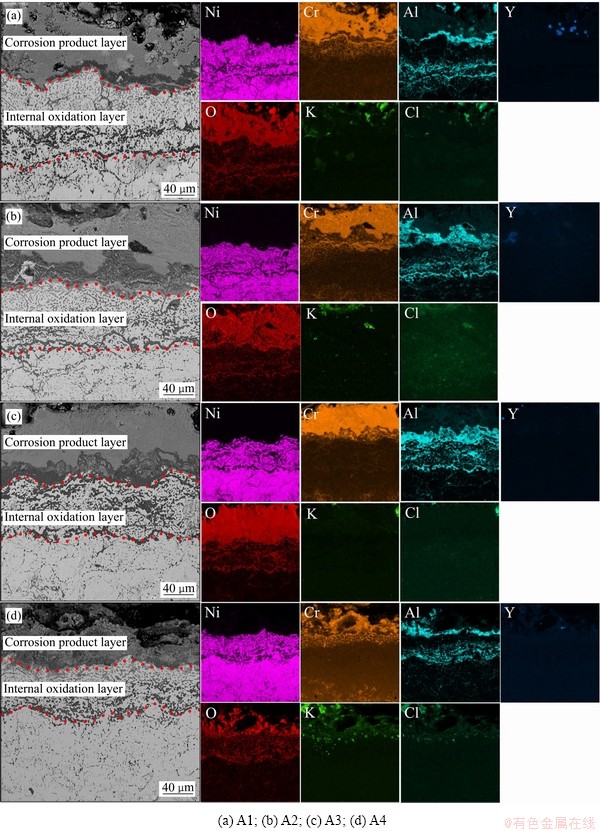

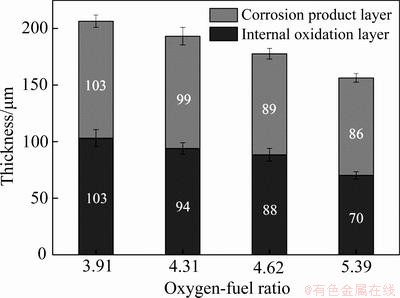

2.4 截面微观形貌及成分分析

4种不同氧燃比NiCrAlY涂层在700 ℃的KCl熔盐中腐蚀100 h后的截面形貌及EDS面扫描元素分析结果如图8所示,NiCrAlY涂层热腐蚀产物层厚度及内氧化区深度与热喷涂氧燃比关系如图9所示。从图9中可以看到,涂层经腐蚀后形成了腐蚀产物层和内氧化区,随着氧燃比的增加,腐蚀产物层厚度由氧燃比为3.91时的103 μm降低到氧燃比为5.39时的86 μm,内氧化区深度由103 μm降低到70 μm,热腐蚀产物减少以及内氧化程度降低,使得涂层热腐蚀质量增加减少,这与涂层腐蚀动力学曲线一致。从截面形貌和EDS面扫描中可以看到,热腐蚀后涂层表面形成热腐蚀产物层分为两层,外层主要是Cr、O富集区,内层界面区主要是Al、O富集区,内氧化区主要由Al、O组成。另外,Y、K、Cl元素主要分布在热腐蚀产物层,且在A1、A2涂层内氧化区以下仍能检测到少量Cl元素。结合XRD可知,腐蚀产物层的外层主要为Cr2O3,内层界面区主要为Al2O3;Al2O3层的形成在一定程度上阻止了涂层表面腐蚀的进行。涂层内氧化区的主要产物为Al2O3,在A1、A2涂层内氧化区下边缘形成了厚度约6~7 μm的连续Al2O3阻挡层,在A3、A4涂层中形成断续的Al2O3,Al2O3对O向内扩散起到了明显的阻挡作用。然而,Al2O3对Cl的阻挡作用较弱,在A1、A2涂层中孔隙、未熔粒子边界处以及Al2O3阻挡层以下仍然能检测到少量Cl的存在,A3、A4涂层中Cl主要分布在涂层表面。

表5 热腐蚀涂层表面不同区域EDS

Table 5 EDS data of coatings in different regions after hot corrosion

图8 不同氧燃比涂层热腐蚀截面形貌及EDS面扫描元素分析

Fig. 8 Cross-section morphologies of NiCrAlY coatings endured hot corrosion and EDS map analysis with different oxygen-fuel ratios

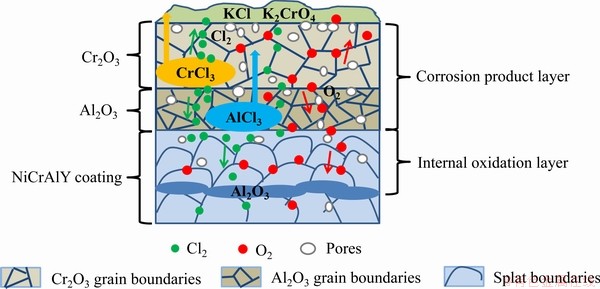

2.5 氧燃比对涂层热腐蚀机制的影响

氯化钾的熔点为770 ℃,因此,在本工作中,氯化钾以固态形式存在于表面。通常,当金属或合金表面沉积固态氯盐时,其腐蚀机制为“活化-氧化”过程[31],该过程与蒸气压高和熔点低的金属氯化物以及具有自催化作用的氯气有关。在热腐蚀过程中,涂层表面氧化形成Al2O3、Cr2O3、Y2O3和 NiO等金属氧化物(见图6),反应如式(1)~(4)所示。相较于其他金属元素,Ni在热力学上不容易与O2反应,同时涂层中Y含量较低,因此涂层表面氧化物主要成分为Al2O3和Cr2O3。

4Al+3O2=2Al2O3 (1)

4Cr+3O2=2Cr2O3 (2)

4Y+3O2=2Y2O3 (3)

2Ni+O2=2NiO (4)

如图10所示,随着表面氧化物的生成,固态KCl将与氧化物发生反应并释放出氯气,反应过程如式(5)~(6)所示。由于在热力学上KCl更容易与Cr2O3反应形成K2CrO4,而Al2O3在热力学上与KCl反应缓慢,因此涂层表面检测到明显的K2CrO4而未检测到KAlO2。在氧化层中,Cl2比O2的穿透性更强,因此,反应产生的Cl2能够穿透氧化层到达氧化层/涂层界面,与涂层金属元素反应形成金属氯化物(AlCl3、CrCl3),反应过程如式(7)~(8)所示。同时,挥发性的金属氯化物向上扩散时与O2反应再次形成氧化物并释放Cl2,反应过程如式(9)~(10)所示。重新生成的Cl2会再回到氧化层/涂层界面处,形成一个新的腐蚀循环。该过程使涂层中Al、Cr等元素不断被消耗,从图8中可以明显看到涂层上表面以下出现贫Cr区。这是由于当Al消耗到不足以维持表面Al2O3膜的生成和修复时,涂层中开始消耗Cr以生成Cr2O3膜[30, 32]。因此,KCl与氧化物发生反应破坏了氧化膜(Al2O3、Cr2O3)的完整性,使氧化膜失去保护能力。另外,在界面处形成的金属氯化物以及在氧化层内新形成的氧化物进一步破坏了氧化膜的完整性,形成的裂缝及孔洞加速热腐蚀过程。

2Al2O3+4KCl+O2=4KAlO2+2Cl2

(KAlO2)=109.2 kJ/mol at 700 ℃ for KCl(s) (5)

(KAlO2)=109.2 kJ/mol at 700 ℃ for KCl(s) (5)

2Cr2O3+8KCl+5O2=4K2CrO4+4Cl2

(K2CrO4)=77.6 kJ/mol at 700 ℃ for KCl(s) (6)

(K2CrO4)=77.6 kJ/mol at 700 ℃ for KCl(s) (6)

2Cr+3Cl2=2CrCl3 (7)

2Al+3Cl2=2AlCl3 (8)

4CrCl3+3O2=2Cr2O3+6Cl2 (9)

4AlCl3+3O2=2Al2O3+6Cl2 (10)

从图8和9中可以看到,氧燃比为3.91时的A1涂层内部遭受了严重的内氧化,结合EDS可以看到涂层内检测到较多Cl和O,涂层金属元素不断被消耗使得热腐蚀产物层厚度和内氧化区深度达到最大值。随着氧燃比的提高,涂层内氧化程度减弱,氧燃比为5.39时,A4涂层热腐蚀产物层厚度和内氧化区深度分别减小到86 μm和70 μm。这是由于提高喷涂过程中的氧燃比,粉末粒子熔化更充分(见图2),同时粒子产生的喷丸压应力更大,使得涂层微观组织结构变得致密,喷涂态涂层中孔隙及未熔或半熔粒子边界减少(见图3),使得热腐蚀过程中Cl、O扩散通道也相应减少。同时,低氧燃比涂层内部腐蚀前沿由于较多的腐蚀通道使得其有足够氧分压形成连续的Al2O3层[33],而高氧燃比涂层内部腐蚀通道较少,使得腐蚀前沿氧分压不足以形成连续的Al2O3层。这也证明了高氧燃比涂层相较于低氧然比涂层更加致密,Cl、O更难到达涂层内较深处,使得涂层内氧化区变浅。因此,在相同热腐蚀条件下,提高超音速火焰喷涂氧燃比能有效降低NiCrAlY涂层中腐蚀介质扩散通道数量,降低氯化-氧化过程,提高涂层抗KCl熔盐热腐蚀性能。

图9 不同氧燃比NiCrAlY涂层热腐蚀产物层厚度及内氧化层深度

Fig. 9 Average thickness of corrosion product layer and internal oxidation layer of NiCrAlY coatings with different oxygen-fuel ratios

图10 700 ℃大气暴露下KCl熔盐中NiCrAlY涂层热腐蚀机理示意图

Fig. 10 Schematic diagram of hot corrosion mechanism in NiCrAlY coating exposed to atmosphere with KCl molten salt at 700 ℃

3 结论

1) 随着氧燃比的升高,未熔粉末颗粒减少,涂层中γ/γ′峰向高角度偏移,涂层结合强度由49 MPa升高到62 MPa。氧燃比对涂层显微硬度影响较小,显微硬度维持在400 HV左右。

2) 热腐蚀过程中,4种涂层单位面积质量增加随时间变化呈现抛物线规律,且随着氧燃比的增加,涂层平均热腐蚀质量增加速率常数Kp由93.37 mg2/(cm4·h)降低到1.54 mg2/(cm4·h),当氧燃比为5.39时,涂层抗热腐蚀性能最优。

3) 在KCl熔盐热腐蚀过程中,高氧燃比涂层中粒子熔化更充分且粒子产生的喷丸压应力更大,使得涂层微观组织结构更加致密,其具有较少的未熔化粒子边界数量,减少了Cl、O向内扩散的通道,使得涂层氯化-氧化程度降低,从而获得更优异的抗热腐蚀性能。

REFERENCES

[1] 龚 彬. 生物质锅炉受热面沉积机理与腐蚀特性研究[D]. 杭州: 浙江大学, 2015: 7-8.

GUN Bin. Mechanism study on deposit build-up and corrosion of heating surfaces in biomass-fired boiler[D]. Hangzhou: Zhejiang University, 2015: 7-8.

[2] CHRISTENSEN K A, STENHOLM M, LIVBJERG H. The formation of submicron aerosol particles, HCl and SO2 in straw-fired boilers[J]. Journal of Aerosol Science, 1998, 29(4): 421-444.

[3] EKLUND J, PHOTHER J, SADEGH E, et al. High-temperature corrosion of HVAF-sprayed Ni-based coatings for boiler applications[J]. Oxidation of Metals, 2019, 91: 729-747.

[4] HUSSAIN T, DUDZIAK T, SIMMS N J, et al. Fireside corrosion behavior of HVOF and plasma-sprayed coatings in advanced coal/biomass Co-fired power plants[J]. Journal of Thermal Spray Technology, 2013, 22(5): 797-807.

[5] SCHüTZZ M, MALESSA M, ROHR V, et al. Development of coatings for protection in specific high temperature environments[J]. Surface and Coatings Technology, 2006, 201(7): 3872-3879.

[6] 许 安, 杨 阳, 李伟洲, 等. 扩散阻挡层对NiCrAlYSi涂层不同条件下热腐蚀行为的影响[J]. 中南大学学报(自然科学版), 2016, 47(3): 730-740.

XU An, YANG Yang, LI Wei-zhou, et al. Influence of diffusion barrier on hot corrosion behavior of NiCrAlYSi coating under different test conditions[J]. Journal of Central South University (Science and Technology), 2016, 47(3): 730-740.

[7] SADEGHIMERESHT E, MARKOCSAN N, HUHTAKANGAS M, et al. Isothermal oxidation of HVAF-sprayed Ni-based chromia, alumina and mixed-oxide scale forming coatings in ambient air[J]. Surface and Coatings Technology, 2017, 316: 10-21.

[8] RANA N, JAYAGANTHAN R, PRAKASH S. Stepwise oxidation mechanism of HVOF sprayed NiCrAlY coatings in air[J]. Transactions of the Indian Institute of Metals, 2014, 67(3): 393-400.

[9] JAFARI R, SADEGHI E. High-temperature corrosion performance of HVAF-sprayed NiCr, NiAl, and NiCrAlY coatings with alkali sulfate/chloride exposed to ambient air[J]. Corrosion Science, 2019, 160: 108066.

[10] SADEGHIMERESHT E, REDDY L, HUSSAIN T, et al. Chlorine-induced high temperature corrosion of HVAF-sprayed Ni-based alumina and chromia forming coatings[J]. Corrosion Science, 2018, 132: 170-184.

[11] NI L Y, LIU C, HUANG H, et al. Thermal cycling behavior of thermal barrier coatings with HVOF NiCrAlY bond coat[J]. Journal of Thermal Spray Technology, 2011, 20(5): 1133-1138.

[12] BALA N, SINGH H, PRAKASH S, et al. Investigations on the behavior of HVOF and cold sprayed Ni-20Cr coating on T22 boiler steel in actual boiler environment[J]. Journal of Thermal Spray Technology, 2012, 21(1): 144-158.

[13] HIDALGO V H, VARELA J B, MENENDEZ A C, et al. High temperature erosion wear of flame and plasma-sprayed nickel-chromium coatings under simulated coal-fired boiler atmospheres[J]. Wear, 2001, 247(2): 214-222.

[14] 李长久. 热喷涂技术应用及研究进展与挑战[J]. 热喷涂技术, 2018, 10(4): 8-29.

LI Chang-jiu. Application, research progresses and future challenges of thermal spray technology[J]. Thermal Spray Technology, 2018, 10(4): 8-29.

[15] 王引真, 孙永兴, 曹文军. 超音速火焰喷涂工艺参数对涂层孔隙率和耐冲蚀磨损性能的影响[C]// 第五届全国表面工程学术会议论文集. 西安: 中国机械工程学会表面工程分会, 2004: 169-171.

WANG Yin-zhen, SUN Yong-xing, CAO Wen-jun. Effect of high velocity oxygen fuel parameters on porosity and erosion resistance of coatings[C]// Proceedings of the Fifth National Academic Conference on Surface Engineering. Xi’an: Surface Engineering Institution of CMES, 2004: 169-171.

[16] PICAS J A, PUNSET M, BAILE M T, et al. Effect of oxygen/fuel ratio on the in-flight particle parameters and properties of HVOF WC-CoCr coatings[J]. Surface and Coatings Technology, 2011, 205: S364-S368.

[17] 杨 辉, 李长久. 超音速火焰喷涂的火焰速度特性[J]. 中国表面工程, 1998, 11(2): 37-39, 45.

YANG Hui, LI Chang-jiu. Characteristics of the flame velocity of supersonic flame spraying[J]. China Surface Engineering, 1998, 11(2): 37-39, 45.

[18] 赵立英, 刘平安. 氧燃比对爆炸喷涂碳化钨涂层结构和性能的影响[J]. 材料工程, 2016, 44(6): 50-55.

ZHAO Li-ying, LIU Ping-an. Effects of oxygen-fuel ratio an structure and property of detonation gun sprayed WC coating[J]. Journal of Materials Engineering, 2016, 44(6): 50-55.

[19] 周驰, 关庆丰, 蔡 杰, 等. 强流脉冲电子束作用下等离子喷涂CoCrAlY涂层热腐蚀性能[J]. 中国有色金属学报, 2017, 27(9): 1879-1888.

ZHOU Chi, GUAN Qing-feng, CAI Jie, et al. Hot corrosion resistance of plasma sprayed CoCrAlY coating irradiated by high-current pulsed electron beam[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(9): 1879-1888.

[20] 傅迎庆. 热喷涂Al-Cu-Cr准晶的粒子扁平化及涂层组织性能研究[D]. 大连: 大连海事大学, 2010: 55-59.

FU Ying-qing. Study on particle flattening, microstructure and properties of HVOF and low power plasma sprayed Al-Cu-Cr quasi crystalline coatings[D]. Dalian: Dalian Maritime University, 2010: 55-59.

[21] 韩 滔, 邓春明, 罗兵辉, 等. 喷距对低温超音速火焰喷涂WC-10Co4Cr涂层性能的影响[J]. 中南大学学报(自然科学版), 2015, 46(3): 822-828.

HAN Tao, DENG Chun-ming, LUO Bing-hui, et al. Influence of different spray distance on properties of WC-10Co4Cr coating by low temperature high velocity oxygen flame[J]. Journal of Central South University (Science and Technology), 2015, 46(3): 822-828.

[22] JIANG S M, XU C Z, LI H Q, et al. High temperature corrosion behaviour of a gradient NiCoCrAlYSi coating Ⅰ: Microstructure evolution[J]. Corrosion Science, 2010, 52(5): 1746-1752.

[23] RANA N, MAHAPATRA M M, JAYAGANTHAN R, et al. High-temperature oxidation and hot corrosion studies on NiCrAlY coatings deposited by flame-spray technique[J]. Journal of Thermal Spray Technology, 2015, 24(5): 769-777.

[24] 吴朝军, 杨杰, 王全胜. 喷距、氧-燃气比对HVOF喷涂WC/Co涂层性能的影响[C]// 2003中国国际热喷涂技术研讨会暨第十六届全国热喷涂技术经验交流会论文集. 大连: 中国表面工程协会, 2003: 65-68.

WU Chao-jun, YANG Jie, WANG Quan-sheng. Effect of spraying distance, oxygen-fuel ratio on HVOF spraying WC/Co coating performance[C]// 2003 Proceedings of China International Symposium on Thermal Spraying Technology and 16th National Symposium on Thermal Spraying Technology. Dalian: China Surface Engineering Association, 2003: 65-68.

[25] MATEJICEK J, SAMPATH S. Intrinsic residual stresses in single splats produced by thermal spray processes[J]. Acta Materialia, 2001, 49(11): 1993-1999.

[26] SADEGHIMEREST E, REDDY L, HUSSAIN T, et al. Influence of KCl and HCl on high temperature corrosion of HVAF-sprayed NiCrAlY and NiCrMo coatings[J]. Materials and Design, 2018, 148: 17-29.

[27] ZHOU Sheng-feng, XIONG Zheng, DAI Xiao-qin, et al. Microstructure and oxidation resistance of cryomilled NiCrAlY coating by laser induction hybrid rapid cladding[J]. Surface and Coatings Technology, 2014, 258(15): 943-949.

[28] PANKAJAVALLI R, SREEDHARAN O M, GNANAMOORTH J B. Thermodynamic stability of LiCrO2(s) from EMF and comparison of stability of MCrO2 (M=Li, Na or K) compounds[J]. Journal of Nuclear Materials, 1985, 127(2/3): 170-174.

[29] 银耀德, 骆继勲, 赵 齐. 钇在Fe-Cr-Al合金1200 ℃氧化中的作用[J]. 中国腐蚀与防护学报, 1982, 2(2): 35-41, 69-70.

YIN Yao-de, LUO Ji-xun, ZHAO Qi. The effect of yttrium addition on the oxidation of the Fe-Cr-Al alloy at 1200 ℃[J]. Journal of Chinese Society of Corrosion and Protection, 1982, 2(2): 35-41, 69-70.

[30] 卢旭阳, 于大千, 姜肃猛, 等. (NiCoCrAlYSiB+AlSiY)复合涂层热腐蚀行为的研究[J], 金属学报, 2012, 48(4): 461-468.

LU Xu-yang, YU Da-qian, JIANG Su-meng, et al. Hot corrosion behavior of A (NiCoCrAlYSiB+AlSiY) composite coating[J]. Acta Metallurgica Sinica, 2012, 48(4): 461-468.

[31] LEE Y Y, MCNALLAN M J. Ignition of nickel in environments containing oxygen and chlorine[J]. Metallurgical and Materials Transactions A, 1987, 18A: 1099-1107.

[32] 卢旭东, 田素贵, 王 涛, 等. 电弧离子镀NiCrAlY涂层对镍基单晶合金热腐蚀行为的影响[J]. 中国有色金属学报, 2013, 23(4): 977-986.

LU Xu-dong, TIAN Su-gui, WANG Tao, et al. Influence of NiCrAlY coatings by arc ion plating on hot corrosion behaviour of single crystal nickel-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 977-986.

[33] 李维杰, 刘 咏, 王 岩, 等. Ni-Cr-Al-Fe基合金粉末的高温抗氧化行为[J]. 中国有色金属学报, 2010, 20(12): 2327-2335.

LI Wei-jie, LIU Yong, WANG Yan, et al. High-temperature oxidation resistance behavior of Ni-Cr-Al-Fe based powders[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(12): 2327-2335.

Effect of oxygen-fuel ratio on microstructure and hot corrosion behavior of NiCrAlY coatings in KCl molten salt

HU Kai1, 2, LIU Xia1, 3, ZHANG Shi-hong1, 2, WANG Shuo-yu3, WU Chao-jun4, ZHU Guang-hong3, DING Yi5

(1. Key Laboratory of Green Fabrication and Surface Technology of Advanced Metal Materials, Ministry of Education, Anhui University of Technology, Ma’anshan 243002, China;

2. School of Materials Science and Engineering, Anhui University of Technology, Ma’anshan 243002, China;

3. Anhui Masteel Surface Technology Co., Ltd., Ma’anshan 243000, China;

4. China Aerospace Materials and Technology Research Institute, Beijing 100076, China;

5. Masteel (Group) Holding Company Ltd., Ma’anshan 243000, China)

Abstract: The NiCrAlY coatings with oxygen-fuel ratio of 3.91, 4.31, 4.62 and 5.39, respectively, were prepared by high-velocity oxygen fuel spraying (HVOF). The changes of microstructure and mechanical properties of the coating were characterized by XRD, SEM, EDS, microhardness meter and tensile testing machine. Then, the effect of microstructure on hot corrosion behaviors of coatings in KCl molten salt environment was investigated. The results show that, with the increase of the oxygen-fuel ratio, the γ/γ′ peak shifts to a high angle, the denser coating structure is obtained and the boundaries of unmelted particles decrease. The coating bonding strength increases from 49 MPa to 62 MPa, while the oxygen-fuel ratio has little effect on the microhardness of the coating. The average hot corrosion rate constant Kp decreases from 93.37 mg2/(cm4·h) to 1.54 mg2/(cm4·h), which implies that the hot corrosion resistance of the coating enhances with the increase of oxygen-fuel ratio. The lower porosity and fewer unmelted particle boundaries in the high oxygen-fuel ratio coating result in the decrease of the diffusion channels of Cl and O. So, the extent of chlorination-oxidation of the coating decreases, thereby, endowing the coating with better hot corrosion resistance.

Key words: high-velocity oxygen fuel spraying; NiCrAlY coating; oxygen-fuel ratio; microstructure; hot corrosion

Foundation item: Project(201904b11020020) supported by the Key Research and Development Program of Anhui Province, China; Project(51671002) supported by the National Natural Science Foundation of China

Received date: 2020-06-10; Accepted date: 2021-04-18

Corresponding author: ZHANG Shi-hong; Tel: +86-13637101221; E-mail: zsh13637101221@163.com

(编辑 李艳红)

基金项目:安徽省重点研究与开发计划资助项目(201904b11020020);国家自然科学基金资助项目(51671002)

收稿日期:2020-06-10;修订日期:2021-04-18

通信作者:张世宏,教授,博士;电话:13637101221;E-mail:zsh13637101221@163.com