Effect and function mechanism of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite

来源期刊:中南大学学报(英文版)2017年第1期

论文作者:储满生 王宏涛 赵伟 汪燃 柳政根 薛向欣

文章页码:39 - 47

Key words:blast furnace; sinter basicity; Cr-V-Ti magnetite; softening-melting behaviors; cohesive zone; function mechanism

Abstract: The effect of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite (Cr-V-Ti magnetite) was investigated and the function mechanism was simultaneously analyzed. The results show that with increasing sinter basicity from 1.71 to 2.36, the softening interval tends to increase from 149.3 °C to 181.7 °C while the melting interval tends to decrease from 178.0 °C to 136.7 °C. The location of cohesive zone moves downwards firstly and then ascends slightly, but the cohesive zone becomes thinner. The softening-melting characteristic value becomes small, which indicates that the permeability of burden column is improved. The dripping ratio of mixed burden tends to increase firstly and then decrease, which comes to the highest value of 74.50% when the sinter basicity is 2.13. The content and the recovery of V and Cr in dripping iron are all increased. The generation amount of components with high melting point in slag becomes little with the increase of sinter basicity, which could improve the permeability of mixed burden. Taking softening-melting behaviors of mixed burden and recovery of valuable elements into account, the proper sinter basicity is no less than 2.13 for smelting mixed burden made from Cr-V-Ti magnetite in blast furnace.

J. Cent. South Univ. (2017) 24: 39-47

DOI: 10.1007/s11771-017-3406-z

WANG Hong-tao(王宏涛), ZHAO Wei(赵伟), CHU Man-sheng(储满生), WANG Ran(汪燃),

LIU Zheng-gen(柳政根), XUE Xiang-xin(薛向欣)

School of Metallurgy, Northeastern University, Shenyang 110819, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Abstract: The effect of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite (Cr-V-Ti magnetite) was investigated and the function mechanism was simultaneously analyzed. The results show that with increasing sinter basicity from 1.71 to 2.36, the softening interval tends to increase from 149.3 °C to 181.7 °C while the melting interval tends to decrease from 178.0 °C to 136.7 °C. The location of cohesive zone moves downwards firstly and then ascends slightly, but the cohesive zone becomes thinner. The softening-melting characteristic value becomes small, which indicates that the permeability of burden column is improved. The dripping ratio of mixed burden tends to increase firstly and then decrease, which comes to the highest value of 74.50% when the sinter basicity is 2.13. The content and the recovery of V and Cr in dripping iron are all increased. The generation amount of components with high melting point in slag becomes little with the increase of sinter basicity, which could improve the permeability of mixed burden. Taking softening-melting behaviors of mixed burden and recovery of valuable elements into account, the proper sinter basicity is no less than 2.13 for smelting mixed burden made from Cr-V-Ti magnetite in blast furnace.

Key words: blast furnace; sinter basicity; Cr-V-Ti magnetite; softening-melting behaviors; cohesive zone; function mechanism

1 Introduction

Vanadium-titanium magnetite, a kind of compound mineral resources rich in valuable elements including Fe, V, Ti and Cr, etc, has a significant comprehensive utilization value [1]. These ores are mainly distributed in Russia, China, South Africa, Australia, New Zealand, Canada, America and other places [1-2]. Vanadium- titanium magnetite could be divided into two type according to the mass fraction of Cr2O3, namely ordinary vanadium-titanium magnetite (V-Ti magnetite) and chromium-bearing vanadium-titanium magnetite (Cr-V- Ti magnetite), the determining criterion of which is about 0.50% [1] in China. The blast furnace process (BF) is the predominant route for the reduction of iron-bearing materials including ordinary vanadium- titanium magnetite now and in next decades and studies have indicated that the blast furnace could be used to process Cr-V-Ti magnetite on a large scale, which is very meaningful to take full advantage of these special mineral resources [3-4].

With several decades’ development, the technologies for smelting V-Ti magnetite in BF have made great progress [5-8]. Currently, the researches on Cr-V-Ti magnetite mainly focus on sintering [9-12], pelletizing [2, 13], reduction mechanism [14-16] and slag optimization [17]. ZHOU et al [12] investigated the effect of the basicity on Cr-V-Ti magnetite sintering. It was found that with increasing basicity, the sintering rate is increased from 25.4 mm/min to 28.9 mm/min and the productivity is increased from 1.83 t/(m2·h) to 1.94 t/(m2·h). The optimal V-Ti-Cr sinter basicity for industrial application is 2.55. TANG et al [13] researched the optimized use of MgO flux in the agglomeration of Cr-V-Ti magnetite and found that the reduction disintegration index (RDI) of sinter is increased from 80.57% to 82.71% with MgO content in sinter increasing from 1.95% to 2.63% and the reduction swelling index (RSI) of pellet is decreased from 15.2% to 8.6% with MgO content in pellet increasing from 1.14% to 2.40%. CHENG et al [14-15] investigated the reduction mechanism of Cr-V-Ti magnetite pellet in blast furnace atmosphere and they obtained the reduction order of Fe,Cr, V and Ti. ZHANG et al [17] optimized the slag for Cr-V-Ti magnetite blast furnace melting and obtained the optimal slag composition, which are 10% MgO, 8% TiO2, 15% Al2O3 and binary basicity 1.15. However, the researches on the reasonable burden structure for smelting Cr-V-Ti magnetite in BF are quite few. Simultaneously, it is well-known that the smelting level of BF is associated with its burden structure [18]. Therefore, seeking a reasonable burden structure for smelting Cr-V-Ti magnetite in BF has been a crucial subject to improve the BF performance.

The reasonable burden structure could be researched by investigating the effect of sinter basicity and reduction mechanism on softening-melting behaviors of mixed burden since the interaction among different burdens could be performed in the softening-melting behaviors of mixed burden, which is more close to the actual production [19-21]. Usually, the mixed burden consists of pellet and sinter with different ratios and different values of binary basicity (R is defined as the basicity). In this work, the effect of sinter basicity on softening-melting behaviors of mixed burden made from Cr-V-Ti magnetite was investigated under the condition of simulating the heating rule and atmosphere in BF. Furthermore, the effect of sinter basicity on the content and recovery of V, Cr in dripping iron were discussed. Additionally, the function mechanism was analyzed by the chemical analysis and X-ray diffraction on residual slag and dripping slag. It could provide theoretical basis and technical support for determining reasonable burden structure of smelting Cr-V-Ti magnetite, improving blast furnace operation and increasing the recovery of V and Cr.

2 Experimental

2.1 Experimental materials

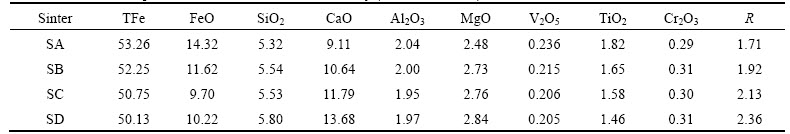

Four kinds of Cr-V-Ti magnetite sinter with different basicity values and one Cr-V-Ti magnetite pellet are used in tests, which are from Chende Jianlong Iron and Steel Cooperation. The chemical composition of sinter and pellet are listed in Tables 1 and 2, respectively. Four kinds of Cr-V-Ti magnetite sinter are specified as SA, SB, SC and SD, whose basicity values are 1.71, 1.92, 2.13 and 2.36, respectively. The Cr-V-Ti magnetite pellet is specified as PA and the total Fe content is about 59.43%.

2.2 Experimental methods

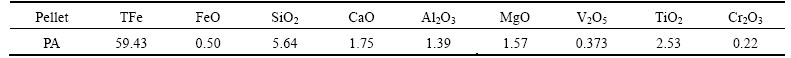

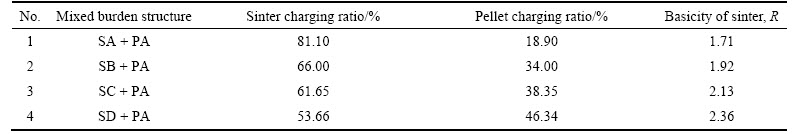

Based on the on-site production conditions, the basicity of BF slag is kept constant at 1.10. The coke ratio, coke breeze ratio and pulverized coal injection ratio are stayed constant. The structure of mixed burden is determined by reasonably adjusting the basicity of sinter and the charging ratio of sinter and pellet. Four kinds of burden structure used in tests are listed in Table 3. With increasing the basicity of sinter from 1.71 to 2.36, the charging ratio of sinter in mixed burden is decreased from 81.10% to 53.66% while that of pellet is increased from 18.90% to 46.34%. The effect of different burden structure on the softening-melting behaviors of mixed burden made from Cr-V-Ti magnetite is investigated and the migration of V, Cr is also analyzed. Then the burden structure for smelting Cr-V-Ti magnetite in BF is optimized.

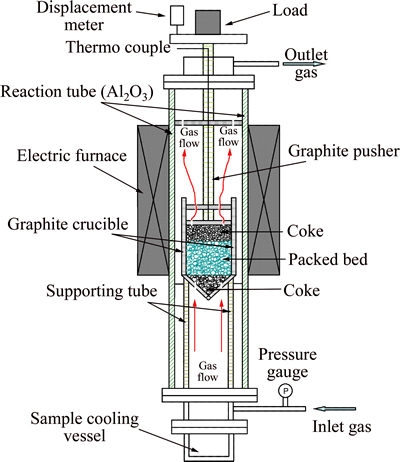

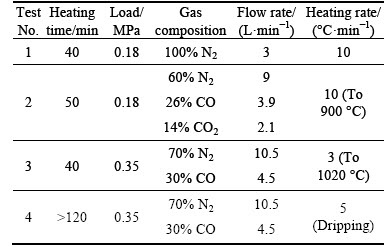

The tests are carried out by the softening-melting equipment, which is shown as Fig. 1. The 75 mm (inner diameter) graphite crucible with some Φ8 mm dripping holes on the bottom is used in the tests. 500 g iron- bearing materials (sinter and pellet) with size of around 10-12.5 mm are charged into graphite crucible. Coke is laid at the bottom (size of 5-8 mm) and on the top (size of 5-8 mm) of the iron ore samples to ensure molten materials and gas flow could pass through burden bed easily. The experimental conditions are listed in Table 4.

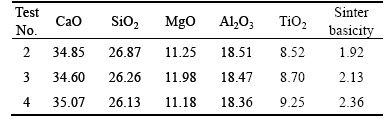

Table 1 Chemical composition of sinter with different basicity (mass fraction, %)

Table 2 Chemical composition of oxidized pellet (mass fraction, %)

Table 3 Structure of mixed burden used in tests

Fig. 1 Structure diagram of softening-melting equipment

Table 4 Experimental conditions for softening-melting experiment

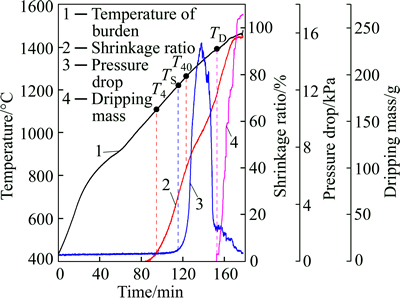

The softening-melting behaviors of iron-bearing materials play a conclusive role in the position and shape of cohesive zone, although BF operations have some effects on cohesive zone [22]. A typical resultant curve of softening-melting test is shown in Fig. 2, in which the temperature of burden, shrinkage ratio, pressure drop and dripping mass are conducted to evaluate the softening- melting behaviors of iron-bearing materials [23]. Simultaneously, it is extremely difficult to observe thebehavior directly since the equipment inner is invisible. So, some indexes are introduced to estimate the softening-melting behaviors of iron-bearing materials. The temperature is defined as the softening start temperature (T4) when shrinkage ratio of iron-bearing materials is 4%. T40 is the softening end temperature with 40% shrinkage ratio of iron-bearing materials. The temperature interval (T40-T4) represents the softening interval of iron-bearing materials. When the pressure drop begins to increase sharply, the corresponding temperature is named as the melting start temperature (TS), which is also the upper temperature of cohesive zone. TD is the dripping temperature at which some molten materials start to drip, namely the bottom temperature of cohesive zone. The temperature interval (TD-TS) is the melting interval or cohesive zone.

Fig. 2 Curve of softening-melting behavior

3 Results and discussion

3.1 Softening behavior of mixed burden

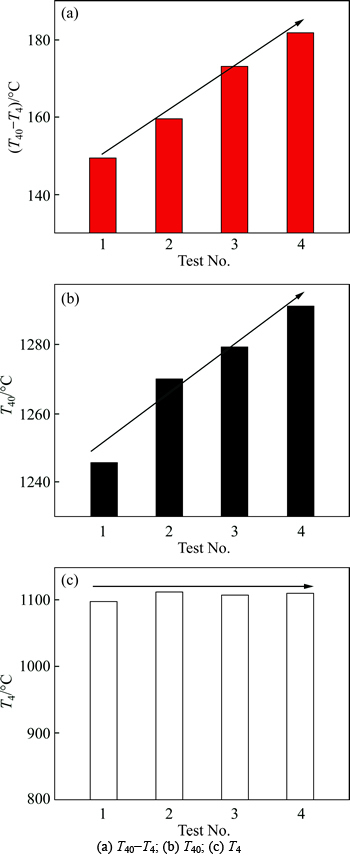

The effect of sinter basicity on the softening behavior of mixed burden is shown in Fig. 3. With increasing sinter basicity, the softening start temperature T4 is mainly kept unchanged at 1104 °C while the softening end temperature T40 is increased from 1245.7 °C to 1291.4 °C. The softening interval (T40-T4) is increased from 149.3 °C to 181.7 °C. Therefore, with increasing sinter basicity, the softening behavior of mixed burden is improved.

With the increase of sinter basicity, the charging ratio of pellet in mixed burden is correspondingly increased, which result in the influence of pellet on the metallurgical property of mixed burden becomes larger since the metallurgical property of mixed burden is greatly influenced by all iron-bearing materials. T40 and (T40-T4) of pellet used in tests is higher than that of sinter since the reducibility of pellet is better. So, T40 and (T40-T4) of mixed burden is increased with pellet charging ratio in mixed burden rising.

Additionally, with the increase of sinter basicity, the softening start temperature and the softening end temperature of sinter are increased while the softening interval of sinter is decreased, which could be attributed to two reasons. One is that with increasing sinter basicity, the reducibility of sinter becomes better. So, more wustite (FeO) are reduced to metallic iron and less wustite are left in slag, which would lead to the melting temperature of slag rising. Another reason is that increasing sinter basicity means CaO content in sinter increasing and more high-melting-point substance, such as perovskite (CaO·TiO2) and schorlomite, would be generated in sinter [9]. As a result, the softening end temperature T40 of mixed burden is increased.

Fig. 3 Effect of sinter basicity on softening behavior of mixed burden:

For smelting Cr-V-Ti magnetite in BF, a higher softening start temperature T4 and an appropriate width of softening interval are favorable to the gas-solid reducing reaction, and the reduction of Cr-V-Ti magnetite would be accelerated [24]. Obviously, with increasing sinter basicity, the softening behavior of the mixed burden tends to be better.

3.2 Melting behavior of mixed burden

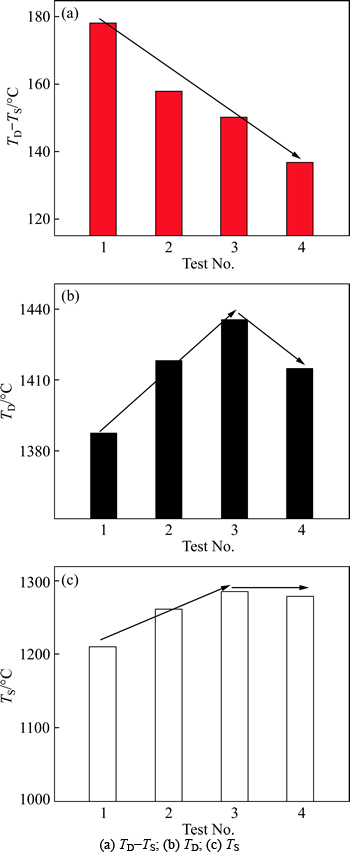

Figure 4 shows the effect of sinter basicity on melting behavior of mixed burden. With increasing sinter basicity, the melting start temperature TS tends to increase from 1209.5 °C to 1285.3 °C but the dripping temperature TD tends to increase firstly and then decrease. When the value of sinter basicity is 2.13 (Test 3), TD acquires the maximum value (1435.4 °C). However, themelting interval (cohesive zone) (TD-TS) tends to decrease from 178.0 °C to 136.7 °C.

Fig. 4 Effect of sinter basicity on melting behavior of mixed burden:

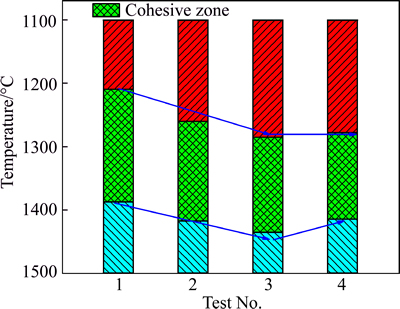

Figure 5 describes the effect of sinter basicity on the location of cohesive zone. With the increase of sinter basicity, the location of cohesive zone significantly moves downwards firstly and then ascends slightly, but the cohesive zone becomes thinner gradually. Therefore, the melting behavior of mixed burden is improved with increasing sinter basicity.

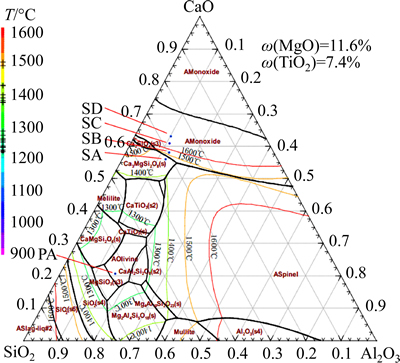

Fig. 5 Effect of sinter basicity on location of cohesive zone

When sinter basicity is less than 2.13, the increase of TS and TD of mixed burden are caused by the increase of slag melting start temperature. However, when sinter basicity is higher than 2.13, as the sinter reducibility becomes better and the ratio of acid pellets increases, TS and TD finally decreases. The phenomenon that the melting start temperature of slag increases with the improvement of sinter basicity can be explained by phase diagram, which is calculated by Factsage 6.4 and shown in Fig. 6. In below phase diagram, the content of MgO and TiO2 is 11.6% and 7.4%, respectively, which is determined by the composition of on-site primary slag and almost kept unchanged in four tests. SA, SB, SC and SD in phase diagram represent slag composition of the above four sinter from low basicity to high basicity respectively and PA means slag composition of pellet. The region of sinter slag phase locates at the early zone between merwinite (Ca3MgSi2O8) and monoxide, and the region of pellet slag phase locates in olivine early zone. The melting start temperature of sinter increases with its basicity rising. The slag melting point of four kinds of sinter is higher than 1400 °C while that of pellet is lower than 1300 °C. Generally, smooth BF operation requires a higher melting start temperature and a narrower melting zone of mixed burden, so the increase of sinter basicity is favorable to improve the melting behavior of mixed burden.

Fig. 6 CaO-SiO2-Al2O3-MgO-TiO2 isotherm-early zone phase diagram

3.3 Dripping behavior of mixed burden

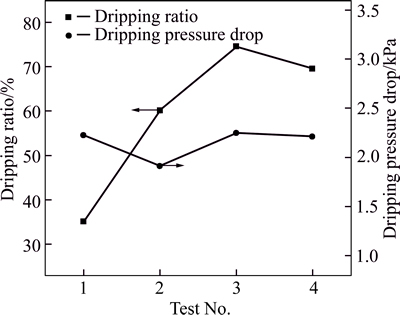

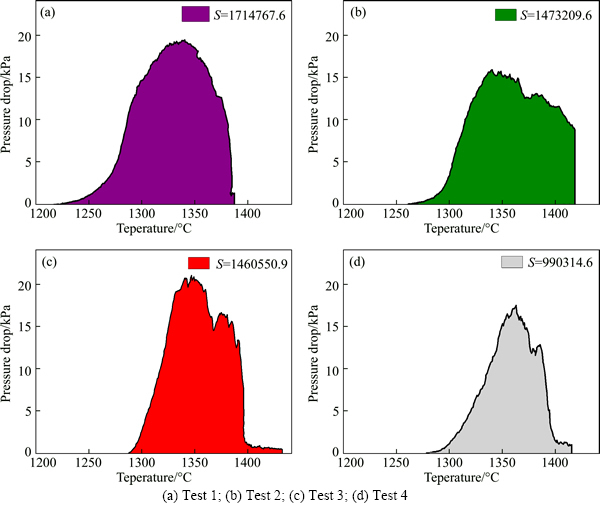

Dripping behavior of mixed burden include dripping temperature, dripping pressure differential and dripping ratio. Figure 7 shows the effect of sinter basicity on dipping behavior of mixed burden. With the increase of sinter basicity, the pressure differential of mixed burden floats between 2.0 kPa and 2.5 kPa and changes little. The dripping ratio of mixed burden increases firstly and then decreases, which reached the maximum value (74.5%) when the sinter basicity is 2.13.

Fig. 7 Effect of sinter basicity on dripping behavior of mixed burden

The dripping ratio is increased by the improvement of the reducibility of mixed burden. But when sinter basicity increases from 2.13 to 2.36, the compounds with high melting point temperature like dicalcium silicate (2CaO·SiO2) and perovskite (CaO·TiO2) tend to be generated nonuniform phase. This nonuniform phase will decreases dripping ratio of mixed burden by affecting the viscosity of slag. Therefore, taking the dripping behavior of mixed burden into consideration, sinter basicity would be not less than 2.13, and the charging ratio of pellet would be not less than 38%.

3.4 Permeability of mixed burden

In order to reasonably evaluate the softening- melting behaviors of mixed burden, softening-melting characteristic value (indexed as S-value) is introduced, which is defined as the integral of pressure drop curve in melting interval (TD-TS), namely the area below the pressure drop curve. Generally speaking, a smaller S-value implies a better permeability of cohesive zone. S-value is calculated by the following formula:

(1)

(1)

where Pm is the pressure drop at any temperature between TS and TD and ΔPS is the pressure drop at the melting start temperature TS.

Figure 8 shows the effect of sinter basicity on the permeability of mixed burden. With sinter basicity increasing, S-value decreases gradually, which indicates that the permeability of burden column is improved. This may be caused by the narrower cohesive zone. Consequently, increasing the sinter basicity and the ratio of pellet are beneficial to the improvement of permeability of mixed burden, which would enhance BF operating smoothly.

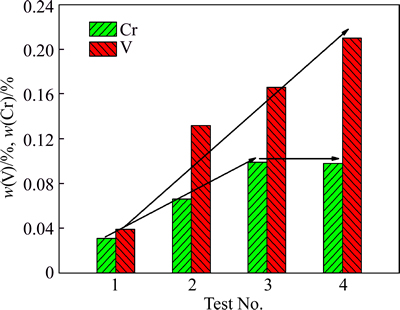

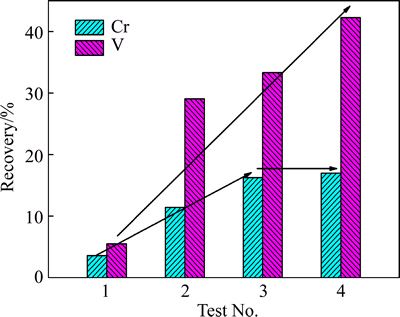

3.5 Migration of V and Cr in primary iron and slag

Figure 9 shows the effect of sinter basicity on the content of V and Cr in dripping iron. Figure 10 shows the effect of sinter basicity on the recovery of V and Cr in dripping iron. With the increase of sinter basicity, both the content of V, Cr and the recovery of V, Cr in dripping iron increase. Therefore, the increase of the sinter basicity and the ratio of pellet are beneficial for the reduction process of V and Cr.

With increasing sinter basicity, the reducibility of mixed burden is improved gradually, which could promote the reduction process of V and Cr. In the process of BF smelting vanadium-titanium magnetite, the reduction of V mainly proceeds in slag-iron interface. And in cohesive zone, the generation of liquid iron accelerates the reduction of V. With increasing sinter basicity, the melting and dripping properties of mixed burden are improved, which promote the reduction process of V. In addition, vanadium oxide reduction reactions can be occurred as follows when Si exists:

(2)

(2)

(3)

(3)

Fig. 8 Effect of sinter basicity on permeability of mixed burden:

Fig. 9 Effect of sinter basicity on content of V and Cr in dripping iron

Fig. 10 Effect of sinter basicity on recovery of V and Cr in dripping iron

(4)

(4)

(5)

(5)

The reduzate of above reactions includes SiO2, which is negative on the reduction of the low valent vanadium oxide. But when CaO exists, the reduction thermodynamics conditions of vanadium oxide changes and the follow reactions will occur:

(6)

(6)

(7)

(7)

(8)

(8)

(9)

(9)

It can be seen from these reactions that the reduction conditions of the vanadium oxide are improved under the exsitence of CaO. Meanwhile, sinter basicity is increased by increasing CaO content and keeping SiO2 content unchanged in sinter. Therefore, the increase of sinter basicity promotes the reduction process of vanadium oxide reduced by silicon.

3.6 Function mechanism of softening-melting process

Both the quality of burden and experimental operating system affect softening-melting behaviors of mixed burden. The quality of burden includes the quantity of slag and wustite, the melting start temperature of slag and wustite, reduction degree and porosity of burden, etc [25]. Experimental operating system consists of gas flow system, heating up system, load system, etc. During the test, the operating system is kept unchanged and the main purpose of the test is to explore the influence of the quality of burden on its softening-melting behaviors.

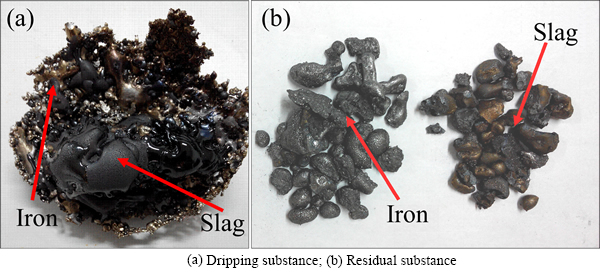

After the reduction, the ferrous burden in graphite crucible becomes two parts: one is dripping substance and the other is the residual substance left in the graphite crucible. The residuum in graphite crucible has two visible different phases: bright phase and dark phase, which are iron and slag respectively by the XRD analysis. Figure 11 shows the appearance of dripping iron, dripping slag, residual iron and residual slag.

Fig. 11 Photos of dripping and residual substance in test:

Tables 5 and 6 give the chemical composition of dripping slag and residual slag, respectively. Note that the composition of Test 1 dripping slag is not given since iron and slag are not dripped. It is can be seen from the tables that, 1) the basicity of dripping slag is increased with the increase of sinter basicity; 2) the compositions of dripping slag and residual slag are almost unchanged but the content of CaO, TiO2 and MgO in residual slag is higher than that in dripping slag, respectively.

For mixed burden, due to the difference of burden structure, there will be a complex interaction between sinter and pellet under the condition of high temperature. And the levels of this interaction have a great influence on the softening-melting behaviors of mixed burden. So, the change of sinter basicity will lead to the changes of interaction level between sinter and pellet, which would affect the softening-melting behaviors of mixed burden.

Table 5 Chemical composition of dripping slag of mixed burden (mass fraction, %)

Table 6 Chemical composition of residual slag of mixed burden (mass fraction, %)

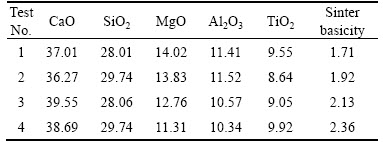

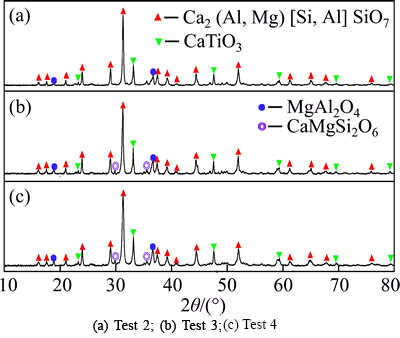

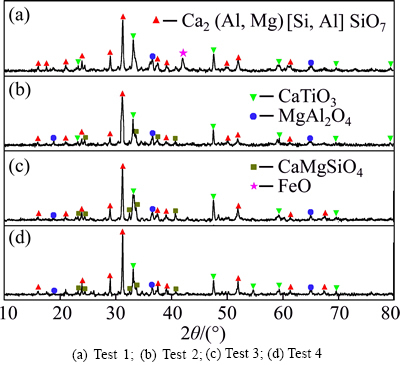

Figures 12 and 13 show the XRD patterns of the dripping slag and residual slag, respectively. The results of X-ray diffraction show that: the main components of residual slag are melilite (Ca2(Al,Mg)[(Si,Al)SiO7], melting point 1300-1400 °C), perovskite (CaTiO3, melting point 1420 °C), magnesium aluminate spinel (MgAl2O4, melting point 2135 °C) and monticellite (CaMgSiO4, melting point >1500 °C). Compared with residual slag, the dripping slag contains some diopside (CaMgSi2O6, melting point 1390 °C) but does not contain monticellite (CaMgSiO4). Besides, there are some FeO existing in residual slag when sinter basicity is 1.71, which means the reducibility of this burden structure is bad. The peak strength of four residual slag is compared and it is found that the content of perovskite tend to decrease with the increase of sinter basicity, which may result in the increase of dripping ratio of mixed burden.

Fig. 12 XRD patterns of dripping slag:

Fig. 13 XRD patterns of residual slag:

4 Conclusions

1) With increasing sinter basicity from 1.71 to 2.36, the softening interval (T40-T4) is increased from 149.3 °C to 181.7 °C, which is conducive to the gas solid reaction for the burden made from Cr-V-Ti magnetite. The melting interval (TD-TS) is narrowed from 178.0 °C to 136.7 °C, which indicates the melting behavior of mixed burden is improved. Meanwhile, the dripping ratio of mixed burden increases and then decreases. The permeability of burden column is improved.

2) With increasing sinter basicity from 1.71 to 2.36, the content and the recovery of V and Cr in dripping iron are all increased. When the sinter basicity is 2.36, the content of V and Cr are 0.210% and 0.198%, respectively. Meanwhile, the recovery of V and Cr are 42.281% and 17.037%, respectively.

3) The higher the sinter basicity is, the fewer components with high melting point are generated, which would improve the permeability of mixed burden.

4) Taking soften-melting behaviors of mixed burden and the yield of valuable elements into account, it is recommend that the proper sinter basicity is no less than 2.13 and the corresponding charging ratio of oxidized pellet should not be less than 38%.

References

[1] DU He-gui. Principle of smelting vanadium-titanium magnetite in the blast furnace [M]. Beijing: Science Press, 1996: 1-2. (in Chinese)

[2] TANG Jue, ZHANG Yong, CHU Man-sheng, XUE Xiang-xin. Preparation of oxidized pellets with high chromium vanadium titanium magnetite [J]. Journal of Northeastern University: Natural Science, 2013, 34(4): 545-550. (in Chinese)

[3] CHEN Xu-ling, HUANG Yun-song, FAN Xiao-hui, GAN Min. Oxidation roasting behavior and concretion properties of vanadium- titanium magnetite pellet [J]. Journal of Central South University: Science and Technology, 2016, 47(2): 359-366. (in Chinese)

[4] FU Wei-guo, XIE Hong-en. Progress in technologies of vanadium-bearing titanomagnetite smelting in PanGang [J]. Steel Research International, 2011, 82(5): 501-504.

[5] LIAO J L, LI J, WANG X D, ZHANG Z T. Influence of TiO2 and basicity on viscosity of Ti bearing slag [J]. Ironmaking & Steelmaking, 2012, 39(2): 133-139.

[6] HAO Zi-guo, FEI Hong-cai, LIU Lian, TURNER S. Comprehensive utilization of vanadium-titanium magnetite deposits in China has come to a new level [J]. Acta Geologica Sinica: English Edition, 2013, 87(1): 286-287.

[7] ZHANG Yuan-bo, ZHOU You-lian, JIANG Tao, HAN Gui-hong, LI Guang-hui, XU Bin. Applications of MHA binder in oxidized pellets preparation from vanadium, titanium-bearing magnetite concentrates [J]. Journal of Central South University: Science and Technology, 2012, 43(7): 2459-2466. (in Chinese)

[8] LIU Shui-shi, GUO Yu-feng, QIU Guan-zhou, JIANG Tao, CHEN Feng. Solid-state reduction kinetics and mechanism of pre-oxidized vanadium-titanium magnetite concentrate [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3372-3377.

[9] ZHANG Yong, LIU Jian-xin, CHENG Gong-jin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Experiment study on sintering process optimization of high chromium vanadium-titanium magnetite [C]// Characterization of Minerals, Metals, and Materials Processing. San Antonio: TMS Publications, 2013: 363-369.

[10] ZHOU Mi, YANG Song-tao, JIANG Tao, XUE XIANG-xin. Influence of MgO in form of magnetite on properties and mineralogy of high chromium, vanadium, titanium magnetite sinters [J]. Ironmaking & Steelmaking, 2015, 42(3): 217-225.

[11] ZHOU Mi, YANG Song-tao, JIANG Tao, XUE Xiang-xin. Influence of basicity on high-chromium vanadium-titanium magnetite sinter properties, productivity, and mineralogy [J]. JOM, 2015, 67(5): 1203-1213.

[12] ZHOU Mi, JIANG Tao, YANG Song-tao, XUE Xiang-xin. Sintering behaviors and consolidation mechanism of high-chromium vanadium and titanium magnetite fines [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(9): 917-925.

[13] TANG Jue, CHU Man-sheng, XUE Xiang-xin. Optimized use of MgO flux in the agglomeration of high-chromium vanadium- titanium magnetite [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(4): 371-380.

[14] CHENG Gong-jin, LIU Jian-xin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Non-isothermal reduction mechanism and kinetics of high chromium vanadium-titanium magnetite pellets [J]. Ironmaking & Steelmaking, 2015, 42(1): 17-26.

[15] LIU Jian-xin, CHENG Gong-jin, LIU Zheng-gen, CHU Man-sheng, XUE Xiang-xin. Reduction process of pellet containing high chromic vanadium-titanium magnetite in cohesive zone [J]. Steel Research International, 2015, 86(7): 808-816.

[16] TANG Jue, CHU Man-sheng, LI Feng, TANG Ya-ting, LIU ZHENG-gen, XUE Xiang-xin. Reduction mechanism of high-chromium vanadium-titanium magnetite pellets by H2-CO-CO2 gas mixtures [J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(6): 562-572.

[17] ZHANG Yong, TANG Jue, CHU Man-sheng, LIU Yang, CHEN Shuang-yin, XUE Xiang-xin. Optimization of BF slag for high Cr2O3 vanadium-titanium magnetite [J]. Journal of Iron and Steel Research International, 2014, 21(2): 144-150.

[18] TOVAROVSKII I G, BOL’SHAKOV V I, TOGOBITSKAYA D N, KHAMKHOT’KO A F. Influence of the softening and melting zone on blast-furnace smelting [J]. Steel in Translation, 2009, 39(1): 34-44.

[19] LIU Xin-liang, WU Sheng-li, HUANG Wei, ZHANG Kai-fa, DU Kai-ping. Influence of high temperature interaction between sinter and lump ores on the formation behavior of primary-slags in blast furnace [J]. ISIJ International, 2014, 54(9): 2089-2096.

[20] LIU Zheng-gen, CHU Man-sheng, WANG Hong-tao, ZHAO Wei, XUE Xiang-xin. Effect of MgO content in sinter on the softening- melting behavior of mixed burden made from chromium-bearing vanadium-titanium magnetite [J]. International Journal of Minerals, Metallurgy and Materials, 2016, 23(1): 25-32.

[21] SUZUKI H, MIZOGUCHI H, HAYASHI S. Influence of ore reducibility on reaction behavior of ore bed mixed with coal composite iron ore hot briquettes [J]. ISIJ International, 2011, 51(8): 1255-1261.

[22] WU Sheng-li, TUO Bi-yang, ZHANG Li-hua, DU Hai-ping, SUN Ying. New evaluation methods discussion of softening-melting and dropping characteristic of BF iron bearing burden [J]. Steel Research International, 2014, 85(2): 233-242.

[23] CHU Man-sheng, LIU Zheng-gen, WANG Zhao-cai, YAGI J I. Fundamental study on carbon composite iron ore hot briquette used as blast furnace burden [J]. Steel Research International, 2011, 85(5): 521-528.

[24] MA Jia-yuan, SU Xi-wen, SHENG Shi-xiong. Intensified smelting of vanadium and titanium magnetite in blast furnace [J]. Iron and Steel, 2000, 35(1): 4-8. (in Chinese)

[25] KAUSHIK P, FRUEHAN R J. Mixed burden softening and melting phenomena in blast furnace operation Part 1-X-ray observation of ferrous burden [J]. Ironmaking & Steelmaking, 2006, 33(6): 507-519.

(Edited by YANG Bing)

Cite this article as: WANG Hong-tao, ZHAO Wei, CHU Man-sheng, WANG Ran, LIU Zheng-gen, XUE Xiang-xin. Effect and function mechanism of sinter basicity on softening-melting behaviors of mixed burden made from chromium-bearing vanadium-titanium magnetite [J]. Journal of Central South University, 2017, 24(1): 39-47. DOI: 10.1007/s11771-017-3406-z.

Foundation item: Project(51574067) supported by the National Natural Science Fundation of China; Projects(2012AA062302, 2012AA062304) supported by the National High Technology Research and Development Program of China; Project(N110202001) supported by the Fundamental Research Funds for the Central Universities of China

Received date: 2015-09-07; Accepted date: 2016-05-11

Corresponding author: CHU Man-sheng, Professor, PhD; Tel: +86-24-83684959; E-mail: chums@smm.neu.edu.cn