文章编号:1004-0609(2013)07-1861-05

BT25钛合金在两相区变形过程中的显微组织定量分析

王 杨1,曾卫东1,马 雄1,周建华2,王晓英2,王 腾1

(1. 西北工业大学 材料学院,西安 710072;

2. 上海市宝钢股份有限公司 特殊钢分公司,上海 200940)

摘 要:对具有片层α相的BT25合金圆饼在两相区进行4种变形程度的等温锻造,用定量金相分析方法研究变形量对显微组织特征参数(α相体积分数、α片层厚度和α相球化率)的影响规律。结果表明:随着变形量增加,α片层不断弯曲破碎,导致α片层长宽比减小而球化率增大,当变形量达到80%时球化率为85.23%,改善了合金组织的均匀性;在变形过程中片层α两端的物质向中间扩散,导致片层厚度增加,变形量从0%增至80%,α片层厚度增加了1.6 μm;α相的体积分数由于等温锻造温度不变而基本维持在60%左右,大变形时有所降低。

关键词:BT25合金; 定量金相; 显微组织参数; 变形量

中图分类号:TG146.2 文献标志码:A

Quantitative metallography analysis of microstructure of BT25 titanium alloy deformed in two-phase field

WANG Yang1, ZENG Wei-dong1, MA Xiong1, ZHOU Jian-hua2, WANG Xiao-ying2, WANG Teng1

(1. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. Special Steel Branch Company, Shanghai Baoshan Iron & Steel Co., Ltd., Shanghai 200940, China)

Abstract: The isothermal compression of BT25 titanium alloy with initial lamellar was carried out with four deformation degrees and the effect of deformation degree on microstructure parameters (volume fraction, thickness and globularization ratio of α phase) was investigated based on quantitative metallography. The results show that the process of α lamellar pinch-off/fragmentation takes place with increasing the deformation degree, which results in the decrease of the Feret ratio of α lamellar and the increase of globularization ratio. It reaches 85.23% when the deformation degree is 80%. The microstructure homogeneity of the alloy is improved. Mass diffusion from both ends of α lamellar to center happens during the deformation process, making the thickness of α phase increase (about 1.6 μm with increasing deformation degree from 0% to 80%). The volume fraction of α phase (about 60%) remains unchanged because of a stable deformation temperature. However, it decreases slightly in the case of high forging strains.

Key words: BT25 titanium alloy; quantitative metallography; microstructure parameter; deformation degree

钛合金因其良好的高温性能逐渐成为制造航空发动机的主要材料,众多科研工作者围绕发动机用钛合金的组织和性能开展了大量工作[1-5],然而对大规格钛合金锻件的研究不多见。由于航空发动机尺寸较大,因此大规格钛合金锻件的组织性能研究更能贴近实际生产应用。此外,在已有的大尺寸钛合金锻件研究中,多数只是对金属显微组织进行了定性的分析,例如于卫敏等[6]采用d160 mm的大尺寸BT25合金棒材研究锻造温度对合金组织和性能的影响。定性分析虽也可以说明材料的性能,然而定量金相分析方法能够更为准确地描述合金组织的显微特征,为建立组织与性能之间的定量关系提供精确的组织依据,因此,采用定量分析方法在描述合金组织演变和获得高质量产品时显得尤为重要[7]。

BT25合金是一种综合性能优良的热强钛合金,适合在500~550 ℃长时间工作,是用于飞机发动机压气机盘的理想候选材料之一[8]。由于压气机盘的叶片部位与轮盘部位对材料性能的要求不同,进而对合金的组织形态要求也不同,因此需要对BT25钛合金的组织演变规律进行研究。本文作者基于生产实践,采用13.5 kg级大规格圆饼,通过定量分析方法来确定变形量对饼坯显微组织(α相体积分数、α片层厚度和α相球化率)演变的影响规律,研究结果对制备压气机盘具有理论和实践指导意义。

1 实验

1.1 试验材料及方法

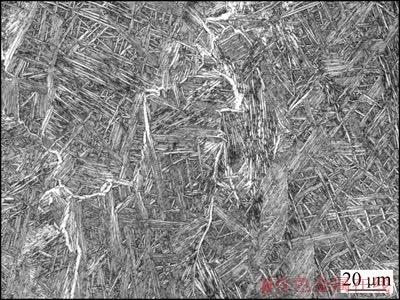

本试验原材料是由宝钢特种材料有限公司提供的β锻BT25合金圆饼,其化学成分(质量分数,%)为6.81Al,2.1Mo,2.25Zr,2.0Sn,0.94W,0.2Si,0.01Cr,0.02Cu,0.05Fe,其余为Ti。采用金相法测得(α+β)/β相变点为1 025~1 030 ℃。初始组织如图1所示:α片层呈针状交错分布在原始β晶粒内,编织成网篮状,组织中仍有大量取向相同的α片层组成的α束域。

图1 BT25合金初始组织

Fig. 1 Initial microstructure of BT25 alloy

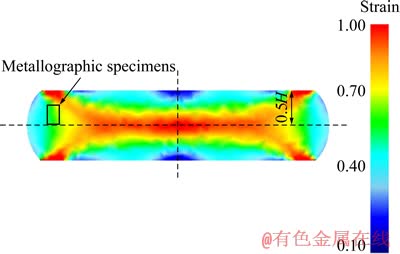

将BT25合金圆饼在(α+β)相区进行不同变形量(0%、30%、50%和80%)的等温锻造获得最终的饼坯,锻造温度为990 ℃,压下速率为2 mm/s。采用有限元软件DEFORM-3D模拟合金的变形过程,计算出合金饼坯的等效应变分布,根据模拟结果在各个变形量的饼坯上选取与理论应变值最接近的位置进行取样和拍摄金相照片。其中变形量为50%的饼坯有限元模拟结果和金相取样位置如图2所示。

图2 BT25饼坯有限元模拟结果和金相取样位置(50%)

Fig. 2 Finite element modeling result of BT25 cake and locations of metallographic specimens(50%)

1.2 BT25合金显微组织参数的定量测量

本试验计算BT25合金组织的α相体积分数、α相球化率和α片层厚度等显微组织参数,每个变形量的合金饼坯取27张照片进行显微组织参数的计算。根据体视学公式[9],利用图像处理软件Image-pro plus 5.0计算单位测试面积中被测相的面积分数AA来得到单位测试体积中被测相的体积分数VV,二者数值上相等。同时,利用Image-pro plus 5.0软件测量参数Feretmax、Feretmin、Width和Length,可以得到BT25合金组织中α相的Feret ratio(Feretmax/Feretmin)比值和片层厚度等参数。SEMIATIN[10]将Ti-6Al-4V合金组 织中α片层的长宽比(Feret ratio)≤2定义为球化,本文作者结合试验BT25合金的微观组织特征将Feret ratio值达到2.5时定为球化阈值,设定球化阈值后可求出α相的球化率。另外,由于α片层在三维空间的取向具有任意性,在金相照片中难以区分片层的宽度与厚度,因此本研究计算出的平均厚度是金相平面上α片层厚度与宽度的统计值。

2 结果分析与讨论

2.1 两相区变形的BT25钛合金显微组织

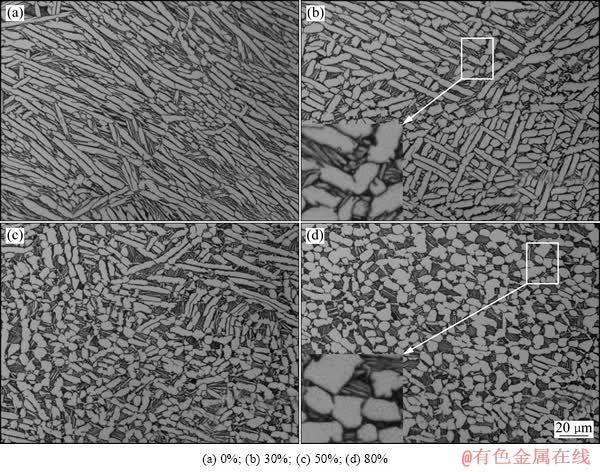

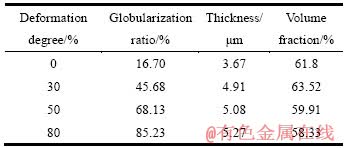

不同变形量BT25合金饼坯的典型组织如图3所示,各项组织参数统计计算结果列于表1。从图3中可以直观地看到,随着变形量的增大,BT25合金的组织形态发生了明显的变化。当变形量为0%,组织以长宽比较大的片状α相为主(见图3(a));变形量增大时,原来大长宽比的片状α开始局部被切断,α相短粗化,小长宽比的α相越来越多(见图3(b)~(c));当变形量达到80%,片状α几乎完全得到细小、均匀的等轴α晶粒,球化率达到80%以上(见图3(d))。变形量从0%增大到80%,BT25合金组织的α片层厚度从3.67 μm增加到5.27 μm,而α相体积分数在大变形时比小变形降低了5%左右。

图3 990 ℃等温锻造、不同变形量下BT25合金的显微组织

Fig. 3 Metallographic images of BT25 alloy isothermal compressed at 990 ℃ with different deformation degrees

表1 不同变形量BT25合金的各项显微组织参数

Table 1 Microstructure parameters of BT25 alloy with different deformation degrees

2.2 变形量与α相球化率的关系

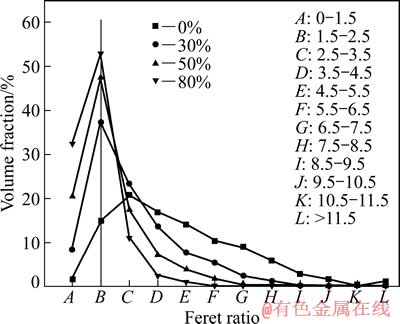

图4所示为不同变形量BT25合金组织中初生α相的球化分布。从图4可以发现:变形量为0%的折线较为平缓,峰值不明显,随着变形程度增加,折线的峰值显著增大,小长宽比的α相含量急剧增加。因为片层组织的球化需要一定的临界应变量,当应变量超过临界值时,球化效果会突然增加,临界变形量可能存在于0%到30%之间。另外,折线的峰值区间越来越窄,说明合金组织的均匀性提高;峰值过后的下降梯度越来越陡,因为变形量的增加使得球化程度逐步增加。

图4 990 ℃等温锻造、不同变形量下BT25合金中α相的球化率分布

Fig. 4 Distribution of Feret ratio of α phase for BT25 alloy isothermal compressed at 990 ℃ with different deformation degrees

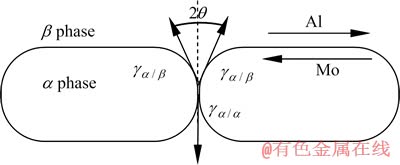

塑性变形能够明显改变BT25合金的片状组织形貌,达到球化目的的原因:当变形量较小时,BT25合金组织中仅有少量具有有利位向的α片层能够在变形力的作用下发生球化,而大多不利位向的α片层将受到金属流动方向和竖直压应力方向两个相互垂直的力的作用,发生弯折断裂(如图3(b)中箭头处),进而在压力作用下逐渐向有利位向转动。α片层断裂及球化是一个复杂的过程,目前对球化机制并没有统一的模型,STEFANSSON[11]提出了晶界分离模型,SESHACHARYULU等[12]提出了动态再结晶模型。根据本文作者观察及研究,当变形量增大时,α片层发生局部剪切变形,若直接形成α/b相界面,则可能完全切断α片层;若剪切变形不完全贯穿,则α片层发生相对错移或扭折,在α/α晶界和α/b相界组成的三方交点处形成热凹槽(三叉点处各界面能之间的平衡关系如图5所示),随后片状组织通过WESS等提出的平直分离机制发生分裂[13]。

图5 三叉点处各界面能之间的平衡图

Fig. 5 Interfacial energy balance of triple junctions

由图5可得出界面能γα/α与α/β相界面能γα/β的关系式为

γα/α = 2γα/β cos θ (1)

一般认为γα/β为恒定值,由式(1)可知,界面能γα/α越高,θ就越小,b相楔入α片层就越深。当α/α界面为小角度晶界时(<15°),界面能γα/α随晶界角的增加而增大,然而,当成为大角度晶界后(>15°),界面能γα/α与晶界角的大小几乎无关,即由晶界角增加导致的界面能升高对b相的楔入作用是非常有限的。因此,随后的α/α界面分离需要靠物质扩散引起的α/β相界面迁移来实现。由于凹槽附近处α/β相界面的曲率半径小于远离凹槽处α/β相界面的曲率半径,前者b相内Al元素(α稳定元素)含量高于后者,而Mo元素(b稳定元素)含量则相反,这种浓度差使Al原子和Mo原子发生扩散,进而导致凹槽附近的α相溶解,其结果促使α/β界面发生迁移。图3(d)中箭头处为α片层在β相楔入后发生平直分离。与此同时,试验结果表明:在变形量增大的过程中,α片层厚度也增加。SHELL等[14]研究发现,细片层的α相动态球化比粗片层的α相要快,β相对α相的穿透作用也相对较强。结合上述讨论可知,变形量越大,有更多的α片层处于有利位向,同时大量应变累积使得不同厚度的α片层能够形成热凹槽,随后α/β相界面迁移而分离,球化率大大增加,组织均匀性提高。

2.3 变形量与α相体积分数的关系

从表1中所列的各变形量BT25合金组织的α相体积分数可以看出:在锻造温度一定的变形过程中,α相体积分数并未随变形量发生明显变化,只是当变形量由30%继续增大时,α相体积分数有略微的下降。

本实验的锻造温度一定,理论上α相含量不会发生变化。因为在相图上若温度改变,α相和β相的含量将按照杠杆定理逐渐变化,也即发生了α/β转变。所以锻造温度确定后,α相的体积分数不会有太大的变化。然而在实际的锻造过程中,钛合金的导热性较差,变形热效应会使合金产生局部温升,根据相图、温度升高将导致α相体积分数降低,并且变形量越大,温升效应越明显,所以在变形量达到30%以后,随着变形量的继续增大,α相体积分数又略微下降。

2.4 变形量与α片层厚度的关系

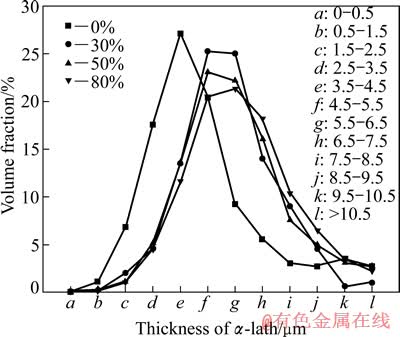

图6所示为不同变形量下BT25合金组织中α相片层厚度的分布情况。从图6可以看出:随着变形量增加,α片层厚度分布的峰值所在区间由e区间(3.5 μm<e≤4.5 μm)移至g区间(5.5 μm<g≤6.5 μm),同时各曲线峰值降低,峰值过后的下降梯度也减小,说明α相总体上在小厚度区间的体积分数减少,而在大厚度区间的体积分数增加。

图6 990 ℃等温锻造、不同变形量下BT25合金中α相片层厚度分布

Fig. 6 Distribution of thickness of α phase for BT25 alloy isothermal compressed at 990 ℃ with different deformation degrees

POTHS等[15]在研究Ti-6Al-4V合金变形时发现α片层有类似的粗化现象。首先,在锻压过程中,α片层不会明显减薄,因为密排六方结构的α相滑移系少,其比体心立方结构的β相具有更高的变形抗力,在压力作用下α相不会发生显著的压扁现象。另外,由2.2节的分析,在变形量增大的过程中α/α晶界和α/β相界交接处形成了热凹槽。由于热凹槽的存在,在邻近和远离凹槽处形成化学势梯度,使物质由片层两端向中间部位迁移,导致片层厚度增加。变形量越大(变形量为50%和80%)且锤头压下速率一定时,合金在高温下停留的时间就越长,有利于物质的充分扩散,因而厚度增加越快。综合以上两方面原因,α片层厚度在整体上表现出增大趋势而非减小趋势。

3 结论

1) 随着变形量增加,α片层通过弯曲断裂,平直分离逐步切断、粗化。长宽比(Feret ratio)小的α片层含量急剧增加,球化率增大,Feret ratio折线的峰值区间越来越小,大变形使合金组织均匀性提高。

2) 在变形量增大的过程中,由于锻造温度一定,α相体积分数基本保持不变;当变形量达到30%以后,合金变形热效应产生的局部温升又使其有所降低。

3) 变形量增加,片层α两端的物质在扩散作用下向中间迁移,所以片层厚度增加,α片层在小厚度区间的比例逐步减少,在大厚度区间的比例增加,α片层厚度整体上表现出增大趋势。

REFERENCES

[1] WU Cheng-bao, YANG He, FAN Xiao-guang, SUN Zhi-chao. Dynamic globularization kinetics during hot working of TA15 titanium alloy with colony microstructure[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(9): 1963-1969.

[2] LUO Jiao, LI Miao-quan. FE-based coupling simulation of Ti60 alloy in isothermal upsetting process[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 849-856.

[3] 李赛毅, 文 浩, 雷力明, 张慧儒. TC11合金两相区退火对微观组织与微观织构的影响[J]. 中国有色金属学报, 2012, 22(11): 3022-3028.

LI Sai-yi, WEN Hao, LEI Li-ming, ZHANG Hui-ru. Effect of annealing in two-phase field on microstructure and microtexture of TC11 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(11): 3022-3028.

[4] HAMOUDA G. Microstructure and fatigue crack growth mechanisms in high temperature titanium alloys[J]. International Journal of Fatigue, 2010, 32(9): 1448-1460.

[5] ZHOU Zhong-bo, FEI Yue, LAI Min-jie, KOU Hong-chao, CHANG Hui, SHANG Guo-qiang, Microstructure and mechanical properties of new metastable β type titanium alloy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(12): 2253-2258.

[6] 于卫敏, 吴跃江, 潘跃进. 锻造温度对BT25钛合金组织和性能的影响[J]. 热处理, 2009, 24(4): 36-40.

YU Wei-min, WU Yue-jiang, PAN Yue-jin. Influence of forging temperature on microstructure and property of BT25 titanium alloy[J]. Heat Treatment, 2009, 24(4): 36-40.

[7] WARCHOMICKA F. Quantitative analysis of the microstructure of near β titanium alloy during compression tests[J]. Journal of Materials Processing Technology, 2006, 177(1/3): 473-477.

[8] 彭新元, 刘元春, 周贤良, 华小珍. 双重退火对BT25钛合金组织与性能的影响[J]. 金属热处理, 2010, 35(4): 42-46.

PENG Xin-yuan, LIU Yuan-chun, ZHOU Xian-liang, HUA Xiao-zhen. Effect of double annealing on microstructure and properties of BT25 titanium alloy[J]. Heat Treatment of Metals, 2010, 35(4): 42-46.

[9] 王凯旋, 曾卫东, 赵永庆, 周义刚. 钛合金显微组织与性能定量关系的模型[J].稀有金属材料与工程, 2011, 40(5): 784-787.

WANG Kai-xuan, ZENG Wei-dong, ZHAO Yong-qing, ZHOU Yi-gang. Modeling the quantitative correlation between the microstructure and mechanical properties in titanium alloys[J]. Rare Metal Materials and Engineering, 2011, 40(5): 784-787.

[10] SEMIATIN S L. Flow behavior and globularization kinetics during hot working of Ti-6Al-4V with a colony alpha microstructure[J]. Materials Science and Engineering A, 1999, 263(2): 257-271.

[11] STEFANSSON N. The kinetics of static globalarization of Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 2002, 33(11): 3527-3534.

[12] SESHACHARYULU T, MEDEIROS S C, FRAZIER W G, PRASAD Y V R K. Microstructural mechanisms during hot working of commercial grade Ti-6Al-4V with lamellar starting structure[J]. Materials Science and Engineering A, 2002, 325(1/2): 112-125.

[13] 王临茹, 赵永庆, 周 廉. 热轧TC21板材中α相形貌的演变[J].中国有色金属学报, 2011, 21(2): 350-355.

WANG Lin-ru, ZHAO Yong-qing, ZHOU Lian. Evolution of α phase morphology in hot-rolling TC21 titanium alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(2): 350-355.

[14] SHELL E B, SEMIATIN S L. Effect of initial microstructure on plastic flow and dynamic globularization during hot working of Ti-6Al-4V[J]. Metallurgical and Materials Transactions A, 1999, 30(12): 3219-3229.

[15] POTHS R M, ANGELLA G, WYNNE B P, RAINFORTH W M, SEMIATIN S L, BEYNON J H. Effect of strain reversal on the dynamic spheroidization of Ti-M-4V during hot deformation[J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2993-3001.

(编辑 何学锋)

基金项目:凝固技术国家重点实验室开放课题(35-TP-2009);教育部博士点基金资助项目(20116102110015)

收稿日期:2012-10-17;修订日期:2013-04-07

通信作者:曾卫东,教授,博士;电话:029-88494298;E-mail:zengwd@nwpu.edu.cn