热模模压制取铝电解阳极炭块

来源期刊:中国有色金属学报(英文版)2013年第10期

论文作者:王耀武 彭建平 狄跃忠 冯乃祥

文章页码:3119 - 3124

关键词:炭阳极;热模压;高密度;铝电解

Key words:carbon anodes; high temperature mould pressing; aluminum electrolysis; high bulk density

摘 要:采用热模模压法制备铝电解阳极炭块,并对制取的阳极炭块的物理化学性能进行测试。研究模压工艺和沥青添加量对预焙阳极炭块体积密度、抗压强度和抗氧化性的影响。采用扫描电镜对炭块的微观结构进行分析,对热模模压生产阳极炭块的机理进行探讨。结果表明:采用热模模压法生产炭阳极可使沥青进入石油焦颗粒的内部,并填充石油焦颗粒内部的气孔,从而减少预焙阳极炭块的气孔率,提高其密度。采用热模模压生产的预焙阳极炭块的体积密度为1.64~1.66 g/cm3,比工业阳极炭块的体积密度增加0.08~0.12 g/cm3,同时其抗氧化性能也获得较大的提高。

Abstract: Laboratory-scale carbon anodes were produced by a new method of high temperature mould pressing, and their physico-chemical properties were studied. The influence of mould pressing conditions and coal pitch addition on the bulk density, crushing strength, and oxidation resistance was analyzed. The microstructure of carbon anodes was investigated by scanning electron microscopy (SEM), and the mechanism of producing carbon anodes by high-temperature mould pressing was analyzed. The results show that when the anodes are produced by high-temperature mould pressing, coal pitch can expand into the coke particles and fill the pores inside the particles, which is beneficial for improving the quality of prebaked anodes. The bulk density of carbon anodes is 1.64-1.66 g/cm3, which is 0.08-0.12 g/cm3 higher than that of industrial anodes, and the oxidation resistance of carbon anodes is also significantly improved.

Trans. Nonferrous Met. Soc. China 23(2013) 3119-3124

Yao-wu WANG, Jian-ping PENG, Yue-zhong DI, Nai-xiang FENG

School of Materials and Metallurgy, Northeastern University, Shenyang 110819, China

Received 22 October 2012; accepted 8 May 2013

Abstract: Laboratory-scale carbon anodes were produced by a new method of high temperature mould pressing, and their physico-chemical properties were studied. The influence of mould pressing conditions and coal pitch addition on the bulk density, crushing strength, and oxidation resistance was analyzed. The microstructure of carbon anodes was investigated by scanning electron microscopy (SEM), and the mechanism of producing carbon anodes by high-temperature mould pressing was analyzed. The results show that when the anodes are produced by high-temperature mould pressing, coal pitch can expand into the coke particles and fill the pores inside the particles, which is beneficial for improving the quality of prebaked anodes. The bulk density of carbon anodes is 1.64-1.66 g/cm3, which is 0.08-0.12 g/cm3 higher than that of industrial anodes, and the oxidation resistance of carbon anodes is also significantly improved.

Key words: carbon anodes; high temperature mould pressing; aluminum electrolysis; high bulk density

1 Introduction

Anodes are called the heart of aluminum electrolysis cells, and their quality directly influences the operation conditions and techno-economic data of the aluminum electrolysis cells. The commercial operation shows that about 70% of cell malfunction is caused by low quality anodes [1,2]. The basic requirements of anodes for aluminum electrolysis are as follows: 1) High density, low resistivity and high mechanical strength; 2) Low susceptibility to thermal impact or good heat-break resisting ability; 3) Low air permeability; 4) Low air and CO2 reactivity [3,4].

Based on the existing practice, it is difficult to improve anode quality by increasing the real density and electrical conductivity of calcined petroleum coke, improving adhesion and carbonization abilities of coal pitch, and raising calcination temperature of anodes [5-7]. Outcomes of these data depend on raising calcination temperatures to improve the performance of calcined petroleum coke and coal pitch, but it is very difficult with the present equipment. This would require making a substantial improvement on the equipments and materials of calciner and the roaster system, which is less economically viable [8,9].

An important way to improve anode quality is by increasing anode bulk density. The anode bulk density, which has a close relation with porosity, oxidation resistance, resistivity, thermal conductivity and mechanical property, is an important index. The increasing of anode bulk density can decrease the porosity and permeability, and improve thermal conductivity and oxidation resistance. It also can prolong the lifetime of anodes in the condition of constant size, lessen the effect of artificial action, keep the balance of the electric field and magnet field, and keep a reliable and efficient operation of aluminum electrolysis cell production [10,11].

In the 1980s, American Union Carbide Corporation started to use a new method to produce blast furnace carbon brick. In the new method, the mould pressing and baking of carbon brick were completed in one step. The carbon brick had a very good quality with high density, low porosity and permeability, high thermal conductivity and excellent mechanical property [12]. In the 1990s and 2000s, FENG et al [13] used the same method to produce carbon anodes. The density of the carbon anodes which were composed of calcined coke, green petroleum coke and coal pitch was up to 1.71 g/cm3, the specific electrical resistance was about 50 Ω·mm2/m and the crushing strength was above 40 MPa. Although the quality of carbon anode which was produced by the method of pressing and baking completed in one step was very good, it consumed more energy since it was baked by electricity, which led to inventory cost added, so it failed to use in industry.

In order to save energy, a new anode production technology called high-temperature mould pressing was developed [14]. When using this method to produce anodes, a lower current run through the two sides of the mould and the materials were heated by themselves, then a green anode was produced at a given temperature (lower than 250 °C) with high pressure, finally a prebaked anode was obtained after the green carbon anode calcined in the baking furnace. In this work, laboratory-scale carbon anodes are produced by high temperature mould pressing, and their physico-chemical properties are studied.

2 Experimental

2.1 Experimental materials

In the present work, the materials used were calcined petroleum coke, spent anodes and off-grade green anodes fragments. Coal pitch with softening point of 105 °C was used as adhesive. The materials consisted of four grain sizes (5-8 mm, 2-5 mm, 1-2 mm and powder) and the batch formula was identical with the industrial anodes.

2.2 Experimental apparatus

The high temperature mould pressing apparatus consisted of a pressure mould and an electrically heated pressurization apparatus. A drawing of the experimental arrangement is shown in Fig. 1. The pressure mould consisted of a core and a mould jacket which had an inside diameter of 110 mm and a height of 250 mm. There was a steel tube with an inside diameter of 260 mm, and an outside diameter of 268 mm and a height of 250 mm at the outer wall of the mould jacket. Heat-resistant concrete was filled between the tube and the core. The mould core was made of heat-resistant steel. The pressurization apparatus was a hydraulic jack with 100 MPa pressure. The electrical equipment consisted of an electric heater and a transformer of 15 kW. The electric heater was the carbon anode itself. The output voltage of the transformer was controlled by a voltage regulator.

2.3 Experimental method

The mixture of materials for producing carbon anode was prepared by weighing the components in the desired proportions and preheating to given temperature in a resistance furnace. Then the mixture was put into a malaxator preheated to the same temperature (the kneading temperature). At the same time, coal pitch was melted at the kneading temperature, and then kneaded with the other materials. After kneading for a given time, the mixture was put into the mould and pressed under 20 MPa. Then the electric current was turned on and the mixture was heated. The temperature and the pressure were monitored by a thermocouple and a pressure gauge, respectively. The pressure increased with the increasing of electric current. The pressure and temperature reached a given value, and kept for several seconds, and then the pressure was cut off and electric current was turned off. Green carbon anodes could be obtained after the sample was demoulded, and prebaked anodes for aluminum electrolysis cell could be obtained after the green carbon anode was baked in industrial baking furnace.

After each experiment, a sample of the baked carbon anode was taken for analysis. The bulk density, specific electrical resistance, crushing strength, remains of CO2 and air reaction were determined.

Fig. 1 Apparatus of high temperature mould pressing

3 Results and discussion

The compression moulding process is the key to produce high quality green anode. The major factors influencing the chemical and physical properties of anodes are moulding pressure and moulding temperature. A optimal moulding process of suitable pressure and temperature is important.

It is better to remain for a few minutes before demoulding in order to cool down the temperature of green anodes. If the demoulding temperature is too high, the green anodes break easily and the crushing strength of the prebaked anodes is low. If the demoulding temperature is too low, the green anode will glue on the mould and is difficult to demould. A green anode which has smooth surface and compact interior structure with outside diameter of 110 mm, height of 70-100 mm and mass of 1.2-1.5 kg can be produced under proper conditions (Fig. 2). The density testing showed that the bulk density of green anodes are all over 1.70 g/cm3.

Fig. 2 Photo of laboratory-scale green carbon anodes

It should be noted that since the temperature tested by thermocouple is the surface temperature of green carbon, there may be a deviation from 10 to 40 °C. The present temperature is the actual temperature tested by thermocouple.

3.1 Effect of moulding pressure and moulding temperature on bulk density of prebaked anodes

Moulding pressure and moulding temperature are important factors influencing the quality of prebaked anodes. The higher the moulding pressure is, the tighter the solid particles contacting and the lower the porosity is. But if the moulding pressure is too high, it may make solid particles brittle fracture, which deteriorates anode crushing strength and resistivity. Moulding temperature mainly has an impact on the viscosity of coal pitch. When moulding temperature is low, coal pitch has high viscosity and poor flowability, and its bond property is poor. But if moulding temperature is too high, the low viscosity and good flowability of coal pitch will make it distribute inhomogeneously. Besides that, raising the moulding temperature properly is beneficial to improving bulk density and decreasing the porosity of prebaked anodes [14]. Figure 3 shows the effect of moulding pressure and moulding temperature on the bulk density of prebaked anodes.

The bulk density of prebaked carbon anode increases with the increasing of moulding pressure and moulding temperature when the moulding temperature is lower than 150 °C and the moulding pressure is lower than 70 MPa.

Fig. 3 Effect of moulding pressure and moulding temperature on bulk density of prebaked anodes

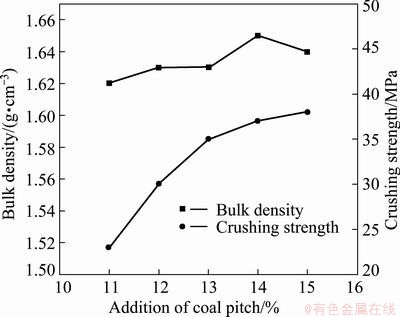

3.2 Effect of coal pitch addition on bulk density and crushing strength of prebaked anodes

The addition of coal pitch is another major factor influencing the quality of prebaked anodes. Too little coal pitch addition results in incomplete filling between coke particles, which leads to low bulk density, high porosity and low crushing strength. But on the other hand, since 40% of coal pitch is volatile in the process of anode calcination [15], the more the coal pitch addition, the lower the bulk density is. Besides, if the addition of coal pitch is too much, some will spread out of green anodes in the moulding process, which causes a loss of pitch. The effect of coal pitch addition on the bulk density and crushing strength is shown in Fig. 4.

Fig. 4 Effect of coal pitch addition on bulk density and crushing strength of prebaked anodes

As shown in Fig. 4, the bulk density is not significantly influenced by coal pitch addition, but the crushing strength is obviously influenced. The crushing strength increases with the increasing of coal pitch addition, but the bulk density of prebaked anode increases firstly, and then decreases. The optimal addition of coal pitch is 14%.

3.3 Effect of moulding pressure and moulding temperature on air and CO2 reactivity of prebaked anodes

During the process of aluminum electrolysis, CO2 producing from anode bottom and air will corrode carbon anodes due to high bath temperature. The corrosion leads to extra consumption of anodes and produces a lot of carbon residue in the bottom of aluminum cell, which decreases the current efficiency and deteriorates the technical and economic performances [16]. So an excellent oxidation resistance of anode is a basic requirement for modern aluminum electrolysis cells. The oxidation resistance is always characterized by remains of CO2 reaction and remains of air reaction. Figures 5 and 6 show the effect of moulding pressure and moulding temperature on the remains of air and CO2 reaction of prebaked anodes.

Fig. 5 Effect of moulding pressure and moulding temperature on remains of air reaction

Fig. 6 Effect of moulding pressure and moulding temperature on remains of CO2 reaction

As shown in Figs. 5 and 6, when the moulding pressure and moulding temperature are low, the remains of air and CO2 reaction of prebaked anodes are low. They increase with the increasing of moulding pressure and moulding temperature, but change little while the moulding pressure is over 70 MPa and moulding temperature is over 150 °C. The remains of air and CO2 reaction closely correlate with the bulk density and the porosity of prebaked anodes, and their changing with moulding pressure and moulding temperature is similar to the changing of bulk density.

3.4 Mechanism of quality improving by high temperature mould pressing

Anodes mainly use calcined petroleum coke as materials. There are a lot of pores in some petroleum coke particles. In the kneading process, coal pitch will be uniformly distributed on the surface of petroleum coke particles, but can not expand into the particles. Figure 7 shows the SEM image of industrial prebaked anodes. As shown in Fig. 7, in the process of traditional vibration moulding, coal pitch can only fill the void spaces between coke particles and can not expand inside the particles either. So most of the pores inside the coke particles remain in the prebaked anodes, and the pores have a very adverse effect on the quality of prebaked anodes for increasing the porosity, decreasing the bulk density and deteriorating the oxidation resistance [17].

Fig. 7 SEM images of pores of industrial prebaked anodes

Figure 8 shows the SEM image of prebaked anode produced by high temperature mould pressing. As shown in Fig. 8, when the anode is produced by high temperature mould pressing, any pores can not be found inside the prebaked anodes that are not similar to the anodes produced by traditional vibration moulding, except for some vents which are the escape passages of coal pitch volatile. This indicates that most of pores inside the coke particles may be filled when the anodes are produced by high temperature mould pressing. The filling of pores can decrease the porosity and increase the bulk density of anodes. It can decrease the possibility of air and CO2 diffusing into the inside of carbon anodes and reduce the contact area between anodes and the air and CO2, which are very beneficial to slowing the oxidation reaction. It can also increase the cohesiveness around the pores, which decreases the possibility of carbon debris broke off from the anodes to prevent extra consumption of anodes. This is the major cause of the bulk density increasing and oxidation resistance improving.

Fig. 8 SEM image of prebaked anode produced by high temperature mould pressing

The result of filling of pores will get better with the decreasing of the viscosity of the coal pitch and the increasing of moulding pressure. But if the viscosity of coal pitch is too low, the coal pitch has a good flowability and it is difficulty to remain in its place.

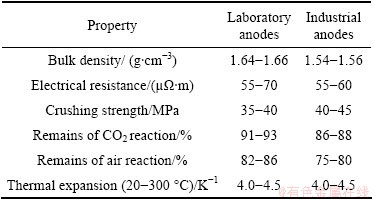

The physical properties such as bulk density, electrical resistance, crushing strength, remains of CO2 and air reaction of the prebaked anodes produced in the conditions of moulding pressure of 70 MPa, moulding temperature of 150 °C and coal pitch addition of 14%, were determined. The results and the physical properties of industrial prebaked carbon anodes produced by the same materials are listed in Table 1.

Table 1 Physical properties of laboratory and industrial prebaked carbon anodes

As shown in Table 1, the bulk density of carbon anodes produced by high temperature mould pressing is 0.08-0.12 g/cm3 higher than that of industrial anodes, which means that the utilization time of the carbon anodes produced by high temperature mould pressing will prolong about two days in comparison with traditional anodes whose utilization time is about 30 d. On the other hand, the increasing of bulk density leads to lower porosity and more excellent oxidation resistance, which indicates lower anode consumption. All of these are beneficial to improving the operation conditions and the techno-economic data of the aluminum electrolysis cell.

However, compared to industrial anodes, the electrical resistance of laboratory-scale carbon anodes is higher and the crushing strength is lower. There may be two reasons for the disadvantage. Firstly, the laboratory-scale anodes are overfired when baked with industrial anode (Length is 1500 mm, height is 600 mm and width is 660 mm) together, and the overfiring have adverse influence on electrical resistance and crushing strength. Secondly, the moulding pressure of 70 MPa is too high which makes the bigger coke particles crack.

4 Conclusions

1) High bulk density and low porosity of carbon anodes can be obtained by high temperature mould pressing. The bulk density of carbon anodes produced by high temperature mould pressing is 0.08-0.12 g/cm3 higher than that of industrial anodes.

2) Producing carbon anodes by high temperature mould pressing can make coal pitch expand into the coke particles and fill the pores inside the coke particles. The filling of pores reduces the contact area between anodes and the air and CO2, and increases the cohesiveness around the pores, which slows the oxidation reaction and decreases the extra consumption of anodes. Compared to the present industrial anodes, the oxidation resistance of carbon anodes produced by high-temperature mould pressing is significantly improved.

References

[1] VLASOV A, SIZYAKOV V M, SEREGIN D A, MOLIN M V, IDIYATULIN R N. Reducing the incidence of anode effects at the Krasnoyarsk aluminum plant [J]. Metallurgist, 2011, 55(8): 601-606.

[2] YE Shao-long, XIAO Jin, DING Feng-qi, LI Jie, ZOU Zhong, LIU Ye-xiang. Comprehension properties of carbon anode for aluminium electrolysis [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 490-495. (in Chinese)

[3] VOGT H. On the mechanism of the anode effect in aluminum electrolysis [J]. Metallurgical and Materials Transactions, 2000, 31(2): 1225-1231.

[4] ANDERSEN D H, ZHANG Z L. Study on the anode-to-cathode distance in an aluminum reduction cell [J]. Metallurgical and Materials Transactions B, 2011, 42(2): 424-433.

[5] YE Shao-long, XIAO Jin, YANG Jian-hong, LAI Yai-qing, ZOU Zhong, LIU Ye-xiang. Laboratory study of modified prebaked carbon anodes for aluminum electrolysis [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(1): 245-249. (in Chinese)

[6] KUANG Z, THONSTAD J, ROLSET S, SORLIE M. Effect of baking temperature and anode current density on anode carbon consumption [J]. Metallurgical and Materials Transactions B, 1996, 27: 178-181.

[7] LIU Feng-qin, LIU Ye-xiang, MANNWEIEL U, PERRUCHOUD R. Effect of coke properties and its blending recipe on performances of carbon anode for aluminium electrolysis [J]. Journal of Central South University of Technology, 2006, 13(6): 647-652.

[8] XIAO Jin, LI Jie, YE Shao-long, LAI Yan-qing, LIU Ye-xiang. Laboratory study of property-modified prebaked carbon anode and application in large aluminum electrolysis cells [J]. Journal of Central South University of Technology, 2005, 12(1): 68-71.

[9] FENG Nai-xiang. Aluminum electrolysis [M]. Beijing: Chemical Industry Press, 2006: 252-253. (in Chinese)

[10] LAI Yan-qing, LIU Ye-xiang. Research review of carbon anode consumption in aluminum electrolysis [J]. Light Metals, 2002(8): 3-6. (in Chinese)

[11] ZORIC J, THONSTAD J, HAAEBERG T. The Influence of the initial shape and position of an anode and the curvature of the aluminum on the current distribution in prebaked aluminum cells [J]. Metallurgical and Materials Transactions B, 1999, 3(7): 341-347.

[12] WANG Ping-fu, GONG Zhen. Production and application of carbon anode in aluminium electrolysis [M]. Beijing: Metallurgical Industry Press, 2005: 40-45, 78-79. (in Chinese)

[13] FENG Nai-xiang, QIU Zhu-xian, LIU Lian-shun, ZHANG Shi-cheng. Electrical baking of laboratory-scale carbon anode under high pressure [C]//Ligh Tmetals. 1992: 505-508.

[14] FENG Nai-xiang, WANG Yao-wu. A method and device of producing high density aluminum electrolytic anode: CN101748441A [P]. 2010. (in Chinese)

[15] ZHANG Tian-xing. The study and practice in optimizing anode production and increasing prebaked anode quality [J]. Gansu Metallurgy, 2012, 34(2): 35-38. (in Chinese)

[16] JI Yan-xin, JIA Lu-ning, YU Yi-ru, WEI Xin-wei, WANG Ping-fu. Analysis of improving oxidation resistance of aluminium anode [J]. Light Metals, 2009(11): 37-40. (in Chinese)

[17] MEIER M W. Cracking behaviour of anodes [D]. Switzerland: R&D Carbon Ltd, 1996: 30-36.

王耀武,彭建平,狄跃忠,冯乃祥

东北大学 材料与冶金学院,沈阳 110819

摘 要:采用热模模压法制备铝电解阳极炭块,并对制取的阳极炭块的物理化学性能进行测试。研究模压工艺和沥青添加量对预焙阳极炭块体积密度、抗压强度和抗氧化性的影响。采用扫描电镜对炭块的微观结构进行分析,对热模模压生产阳极炭块的机理进行探讨。结果表明:采用热模模压法生产炭阳极可使沥青进入石油焦颗粒的内部,并填充石油焦颗粒内部的气孔,从而减少预焙阳极炭块的气孔率,提高其密度。采用热模模压生产的预焙阳极炭块的体积密度为1.64~1.66 g/cm3,比工业阳极炭块的体积密度增加0.08~0.12 g/cm3,同时其抗氧化性能也获得较大的提高。

关键词:炭阳极;热模压;高密度;铝电解

(Edited by Chao WANG)

Foundation item: Project (090302012) supported by the Fundamental Research Funds for the Central Universities, China; Project (50934005) supported by the National Natural Science Foundation of China

Corresponding author: Yao-wu WANG; Tel: +86-24-83680508; E-mail: wangyw113@163.com

DOI: 10.1016/S1003-6326(13)62842-3