ZrB2陶瓷的制备和烧结

方 舟, 傅正义, 王 皓, 王为民, 张清杰

(武汉理工大学 材料复合新技术国家重点实验室, 武汉 430070)

摘 要: 采用自蔓延高温合成(Self-propagating high-temperature synthesis, SHS)技术和热压烧结(Hot pressing, HP)方法分别研究了Zr-B2O3-Mg和ZrO2-B4C-C体系反应原料的粒度和配比以及烧结温度对产物的影响规律, 并烧结得到ZrB2陶瓷。 采用X射线衍射和化学分析方法分析了材料的相组成, 利用SEM和TEM观察了显微结构; 并用阿基米德排水法测定了相对密度。 结果表明: 在Zr-B2O3-Mg体系中, 50μm Zr粉和Mg过量15%(摩尔分数)的体系是最理想的SHS反应体系; SHS产物粒径、 酸洗产物粒径和烧结体粒径分别为2~5μm、 0.5~2.0μm和2~10μm; 酸洗产物组成为94.59%ZrB2、 3.87%ZrO2和1.54%H3BO3(质量分数); 烧结体为单相ZrB2陶瓷, 相对密度为95.4%。 在ZrO2-B4C-C体系中, B4C过量15%和C过量10%(摩尔分数)的体系是最理想的反应体系; 烧结体相对密度为94%; 烧结体组成为95.44%ZrB2、 3.87%ZrO2、 0.32%B4C和0.37%C(质量分数)。

关键词: 二硼化锆; 自蔓延高温合成; 热压烧结 中图分类号: TQ174.75

文献标识码: A

Preparation and sintering of ZrB2 ceramics

FANG Zhou, FU Zheng-yi, WANG Hao, WANG Wei-min, ZHANG Qing-jie

(State Key Laboratory of Advanced Technology for Materials Synthesis and Processing,Wuhan University of Technology, Wuhan 430070, China)

Abstract: ZrB2 ceramics were prepared by self-propagating high-temperature synthesis (SHS) and hot pressing (HP). The effects of granularities and dosages of raw materials in Zr-B2O3-Mg system on SHS process and product, as well as sintering temperature in ZrO2-B4C-C system on sintered product, were investigated. The phase constituent was analyzed by X-ray diffraction and chemical analysis. The microstructure of samples was observed by SEM and TEM. The density was measured based on Archimedes drainage method. The results indicate that, in Zr-B2O3-Mg system, the ideal SHS reactants are 50μm Zr powder and 15% (molar fraction) excessive Mg powder; the particle sizes of SHS product, acid-leached product and sintered product are 2-5μm, 0.5-2μm and 2-10μm respectively; the acid-leached product consists of 94.59%ZrB2, 3.87%ZrO2 and 1.54%H3BO3 (mass fraction); and the relative density of sintered product is 95.4%. In ZrO2-B4C-C system, the reaction system of excessive 15%B4C and excessive 10%C (molar fraction) are the best; for the sintered product, the relative density is 94%; and it is a mixture of 95.44%ZrB2, 3.87%ZrO2, 0.32%B4C and 0.37%C (mass fraction).

Key words: zirconium diboride ; self-propagating high-temperature synthesis; hot pressing

二硼化锆陶瓷因为具有高熔点、 高强度、 高硬度、 导电导热性好、 良好的阻燃性、 耐热性、 抗氧化性、 耐腐蚀性、 捕集中子[1]等特点, 而在高温结构陶瓷材料[2]、 复合材料[3, 4]、 电极材料[5]、 薄膜材料[6, 7]、 耐火材料[8]、 核控制材料等领域中得到广泛开发和应用[9-11]。

自蔓延高温合成(Self-propagating high-temperature synthesis, SHS)技术是利用原料在初始点燃条件下化学反应所产生的高温高热, 使燃烧反应自发地进行, 从而得到指定成分和结构的产物。 SHS技术因为合成速度快、 温度高、 能耗少等特点, 已成为现代科学和工业技术领域广泛重视的一种新型材料制备技术[12,13]。 采用SHS技术制备ZrB2陶瓷可克服工业合成方法[1,14]时间长、 能耗大、 产物可烧结性能差等缺点。 为此, 作者分别采用SHS技术和热压烧结方法, 以Zr-B2O3-Mg和ZrO2-B4C-C为反应体系, 研究ZrB2陶瓷粉末的制备和烧结。

1 实验

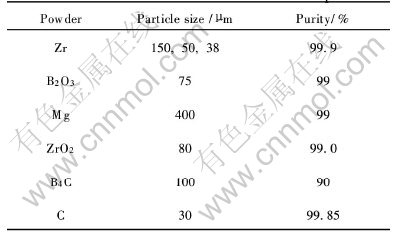

实验原料的物理特性见表1。

表1 实验原料的物理特性

Table 1 Characteristics of raw material powders

Zr-B2O3-Mg体系的SHS反应方程式为

Zr+B2O3+3Mg→ZrB2+3MgO(1)

配料时分别取Mg不过量、 过量10%、 15%、 20%和30%(摩尔分数)5种剂量, 用玛瑙球以球料质量比2∶1混料4h后压成d25mm试样, 在自行研制的SHS装置中进行SHS反应。 用钨-铼热电偶(最高测量温度2300℃)测量试样底端的燃烧温度, 反应条件参见文献[15]。 由于SHS产物中含有杂质MgO和ZrO2, 故先采用盐酸和硝酸的混合酸酸洗去除MgO, 然后在酸洗产物中加入适量的B4C和C, 利用固相反应:

2ZrO2+B4C+3C→2ZrB2+4CO(2)

去除杂质产物ZrO2, 1800℃热压烧结1h得到ZrB2陶瓷。

ZrO2-B4C-C体系反应见方程式(2)。 配料时B4C粉和C粉取不过量、 过量10%、 15%、 20%和30%(摩尔分数)5种剂量, 用玛瑙球以球料质量比2∶1混料2h。 采用热压炉在流动氮气中固相反应合成ZrB2粉末和热压烧结ZrB2陶瓷, 升温速率为30℃/s。 固相反应时升温到1600℃或1700℃后保温1h, 再随炉自然冷却到室温。 烧结时先升温到1800℃, 不加压固相反应1h后再施加30MPa压力, 保温保压1h, 最后以梯度降温方式冷却(从1800℃降至800℃, 每降低200℃保温20min)。

用HZG4-PC UNIVERSAL X射线衍射仪分析材料的物相组成, X射线源为Co靶; 实验样品为固相反应产物或烧结体经磨细后过筛的粉末, 颗粒尺寸小于75μm。 用日本产Rigaku D/max-rB型转靶X射线仪测定衍射数据, CuKα1, λ=0.15406nm, 2θ=15°~90°, 加速电压为40kV, 电流为100mA, 最大计数为2000counts/s, 步长为0.02°, 每步计数为2s。 用SX-40型SEM和JEM-2010型TEM观察材料的显微结构。 用阿基米德排水法测定烧结体的密度。

2 结果与讨论

2.1 Zr-B2O3-Mg体系SHS产物

2.1.1 XRD分析

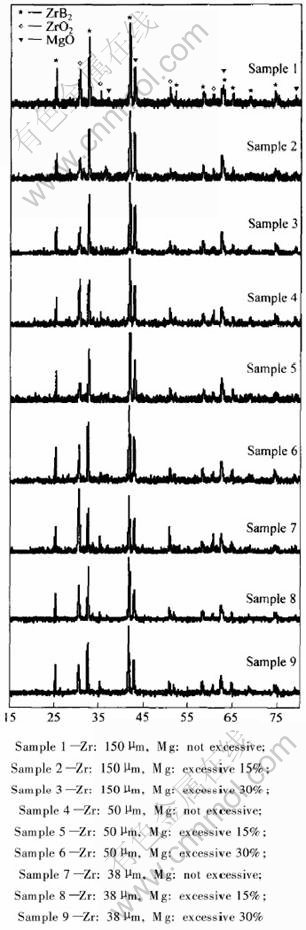

Zr-B2O3-Mg体系SHS产物的XRD谱见图1。 从图1可以看出, 在粒度为150μm、 50μm 和38μm Zr粉的反应体系中, Mg分别过量15%、 15%和30%时, SHS产物中杂质ZrO2的含量较少。 比较这3个体系可以看出, 采用50μm Zr粉和Mg过量15%时, SHS产物中ZrO2含量最少, 因此是最理想的反应体系。

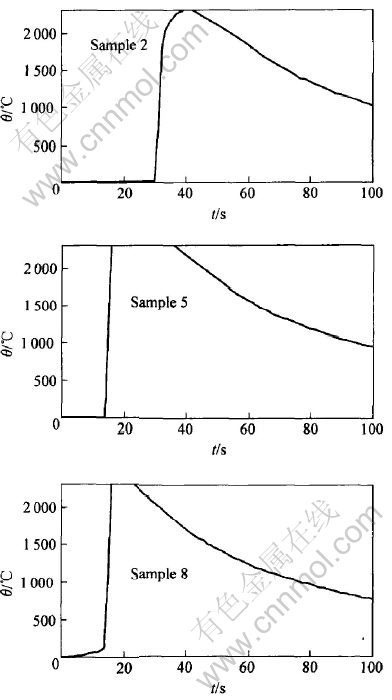

2.1.2 燃烧温度

150μm、 50μm、 38μm Zr粉和Mg过量15%这3个体系(对应于样品2、 5和8)的SHS反应燃烧温度曲线见图2。 从图2中各曲线上升趋势和高温区滞留时间可估算燃烧温度高低关系为: θ5>θ8>θ2。 正因为5号样品的燃烧温度最高, 且在高温区滞留时间最长, 所以SHS反应进行得最完全, 转化率也最高。 这从另一方面证明了5号样品, 即50μm Zr粉和Mg过量15%的反应体系是最理想的反应体系。

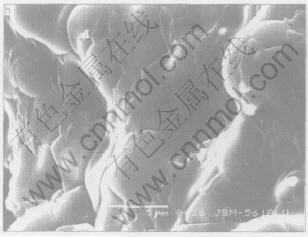

2.1.3 显微结构

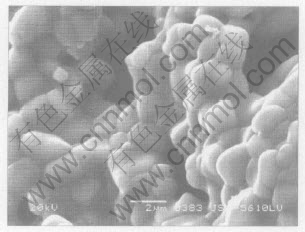

Zr-B2O3-Mg体系中5号样品的SHS产物的SEM形貌像见图3。 从图3可以看出, 产物晶粒形状和尺寸都很不规则, 粒径为2~5μm。

图1 Zr-B2O3-Mg体系SHS产物的XRD谱

Fig.1 XRD patterns for SHS products of Zr-B2O3-Mg system

图2 Zr-B2O3-Mg体系燃烧温度曲线

Fig.2 Combustion temperature curves of Zr-B2O3-Mg system

图3 Zr-B2O3-Mg体系SHS产物的SEM像

Fig.3 SEM image for SHS product of Zr-B2O3-Mg system (Sample 5)

2.2 Zr-B2O3-Mg体系酸洗产物

2.2.1 显微结构

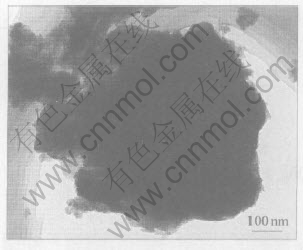

5号样品的酸洗产物的SEM像和TEM像分别见图4和图5。 从图4可以发现, 产物颗粒基本上为圆形或椭圆形, 颗粒大小比较均匀, 粒径为0.5~2μm。 从图5可以看到, 颗粒表面比较疏松, 缺陷较多, 说明活性很高, 这和文献[16]得到的结果相似。

图4 Zr-B2O3-Mg体系酸洗产物的SEM像

Fig.4 SEM image for acid-leached product of Zr-B2O3-Mg system (Sample 5)

图5 Zr-B2O3-Mg体系酸洗产物的TEM像

Fig.5 TEM image for acid-leached product of Zr-B2O3-Mg system (Sample 5)

2.2.2 化学分析

为精确测定酸洗产物的相组成, 对酸洗产物进行了化学分析。 分析结果表明: 酸洗产物组成为94.59%ZrB2、 3.87%ZrO2和1.54%H3BO3(质量分数)。

2.3 Zr-B2O3-Mg体系酸洗产物烧结体

2.3.1 XRD分析

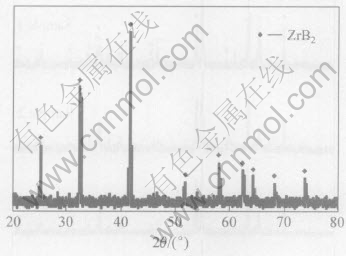

在Zr-B2O3-Mg体系酸洗产物中添加适量B4C和C后烧结得到的烧结体的XRD谱见图6。 从图6中可以看出烧结体为单相的ZrB2陶瓷。

图6 添加适量B4C和C后Zr-B2O3-Mg体系烧结体的XRD谱

Fig.6 XRD pattern for sintered product of Zr-B2O3-Mg system added with B4C and C

2.3.2 显微结构

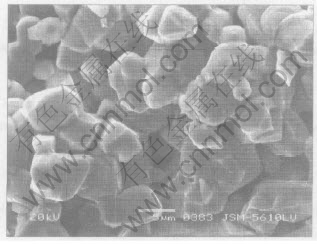

烧结体的SEM像如图7所示。 从图7可以看出, 烧结体颗粒外形较规则, 基本上为近圆形或菱形, 颗粒尺寸不很均匀, 颗粒粒径为2~10μm。

图7 SHS酸洗产物热压烧结体的SEM像

Fig.7 SEM image for hot-pressed product

2.3.3 密度分析

为分析烧结体的密实度, 用阿基米德排水法测定烧结体的密度为5.53g/cm3, 相对密度为95.4%。

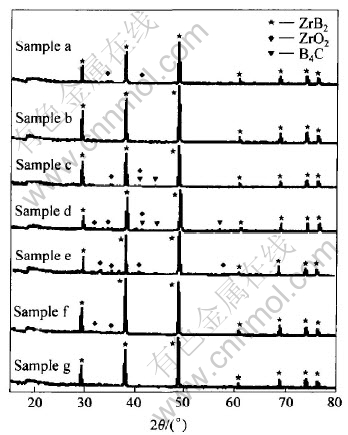

2.4 ZrO2-B4C-C体系固相反应产物

ZrO2-B4C-C体系固相反应产物的XRD谱见图8。 表2为反应条件和实验体系的对应关系。 从图8可以看出, 样品b和g的XRD结果比较理想, 只存在单相产物ZrB2。 在C不过量的条件下, 发现B4C过量15%时最为理想, 因为B4C过量15%以上的产物中出现过量的B4C。 B4C过量10%时, 发现C过量30%最为理想。 XRD结果说明了以ZrO2-B4C-C体系为反应体系制备高纯度ZrB2陶瓷时B4C和C都需要过量, 这与文献[1]结论一致。

图8 ZrO2-B4C-C体系固相反应产物的XRD谱

Fig.8 XRD patterns of solid reaction product in ZrO2-B4C-C system

表2 实验条件和体系的对应关系

Table 2 Corresponding relationship between system and experimental condition

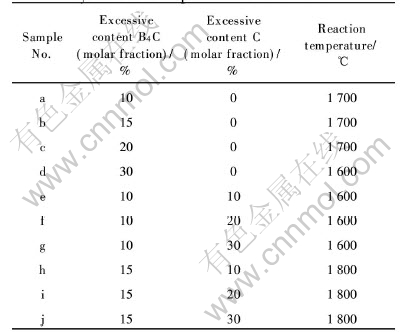

2.5 ZrO2-B4C-C体系热压烧结体

2.5.1 XRD分析

B4C过量15%时, C含量取过量10%, 20%, 30% 3种剂量, 充分混合后进行热压烧结, 烧结体粉末的XRD谱如图9所示。 从图9可知, 样品h(即B4C过量15%和C过量10%时)的烧结体为单相ZrB2陶瓷, 为最理想的反应体系。

图9 ZrO2-B4C-C体系烧结体的XRD谱

Fig.9 XRD patterns of sintered product in ZrO2-B4C-C system

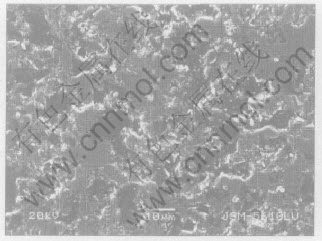

2.5.2 显微结构分析

为了解烧结体的显微结构, 对样品h进行了SEM分析, 见图10。 从图10可以看出, ZrB2陶瓷烧结较完全, 部分晶粒间存在孔隙。 烧结体的晶粒形状很不规则, 晶粒大小也很不均匀, 小的晶粒约为1~2μm, 大的晶粒约为13μm以上。

图10 ZrO2-B4C-C体系烧结体的SEM像

Fig.10 SEM image of ZrO2-B4C-C sintered sample

2.5.3 相对密度分析

为分析烧结体的密实度, 用阿基米德排水法测定烧结体的密度为5.45g/cm3, 相对密度为94%。

2.5.4 化学分析

为精确测定烧结体的相组成, 对烧结体进行了化学分析。 分析结果表明: 烧结体组成为95.44%ZrB2、 3.87%ZrO2、 0.32%B4C和0.37%C。

3 结论

1) 在Zr-B2O3-Mg体系中, 50μm Zr粉和Mg过量15%(摩尔分数)的体系是最理想的SHS反应体系, SHS产物粒径、 酸洗产物粒径和烧结体粒径分别为2~5μm、 0.5~2μm和2~10μm; 酸洗产物组成为ZrB2(94.59%)、 ZrO2(3.87%)和H3BO3(1.54%)(质量分数)。 烧结体为单相ZrB2陶瓷; 相对密度为95.4%。

2) 在ZrO2-B4C-C体系中, B4C过量15%和C过量10%(摩尔分数)的体系是最理想的反应体系; 烧结体相对密度为94%; 烧结体组成为ZrB2(95.44%)、 ZrO2(3.87%)、 B4C(0.32%)和C(0.37%)(质量分数)。

REFERENCES

[1]王零森. 特种陶瓷[M]. 长沙: 中南工业大学出版社, 1994. 210-211.

WANG Ling-sen. Special Ceramics[M]. Changsha: Central South University of Technology Press, 1994. 210-211. (in Chinese)

[2]Radev D D, Marinov M. Properties of titanium and zirconium diborides obtained by self-propagated high-temperature synthesis[J]. Journal of Alloys and Compounds, 1996, 224: 48-51.

[3]Kenji M, Keiko N, Yasuhiro Y. Preparation and microstructure of spherical composites in the system carbon-zirconium diboride[J]. Journal of the Ceramic Society of Japan (Int. Edition), 1994, 103: 287-291.

[4]Berthon S, Male G. Infiltration of zirconium diboride by ICVI in porous materials[J]. Composites Science and Technology, 1997, 57: 217-227.

[5]Norasetthekul S, Eubank P T, Bradley W L, et al. Use of zirconium diboride-copper as an electrode in plasma applications[J]. Journal of Materials Science, 1999, 34: 1261-1270.

[6]Mitterer C, Ubleis A, Ebner R. Sputter deposition of wear-resistant coatings within the system Zr-B-N[J]. Material Science and Engineering A, 1991, 140: 670-675.

[7]Brandstetter E, Mitterer C, Ebner R. A transmission electron microscopy study on sputtered Zr-B and Zr-B-N Films[J]. Thin Solid Films, 1991, 201: 123-135.

[8]Mishra S K, Das S, Das S K, et al. Sintering studies on ultrafine ZrB2 powder produces by a self-propagating high-temperature synthesis process[J]. J Mater Res, 2000, 15(11): 2499-2504.

[9]方舟, 王皓, 傅正义. Zr-B2O3-Mg体系自蔓延高温合成ZrB2陶瓷粉末[J]. 硅酸盐学报, 2004, 32(6): 755-758.

FANG Zhou, WANG Hao, FU Zheng-yi. ZrB2 ceramics powder in Zr-B2O3-Mg system prepared by self-propagating high-temperature synthesis[J]. J Chin Ceram Soc, 2004, 32(6): 755-758. (in Chinese)

[10]方舟, 王皓, 傅正义. Zr-B体系自蔓延高温合成ZrB2陶瓷粉末[J]. 硅酸盐学报, 2004, 32(8): 1016-1018.

FANG Zhou, WANG Hao, FU Zheng-yi. Preparation of ZrB2 ceramics powder in Zr-B system by self-propagating high-temperature synthesis[J]. J Chin Ceram Soc, 2004, 32(8): 1016-1018. (in Chinese)

[11]方舟, 傅正义, 王皓, 等. ZrB2陶瓷的自蔓延高温合成和热压烧结[J]. 中国有色金属学报, 2004, 14(S3): 106-109.

FANG Zhou, FU Zheng-yi, WANG Hao, et al. ZrB2 ceramics prepared by self-propagating high-temperature synthesis and hot-pressing[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(S3): 106-109. (in Chinese)

[12]Bowen C R, Derby B. Self-propagating high-temperature synthesis of ceramics materials[J]. British Ceramic Transactions, 1997, 96(1): 25-31.

[13]Merzhanov A G. History and new developments in SHS[J]. Ceramic Transactions, 1995, 56: 3-25.

[14]ZHAO Hong, HE Yu, JIN Zong-zhe. Preparation of zirconium boride powder[J]. J Am Ceram Soc, 1995, 78(9): 2534-2536.

[15]FU Zheng-yi. Metal liquid in SHS reaction for TiB2 ceramics[J]. Key Engineering Materials, 2002, 217: 41-49.

[16]Mishra S K, Das S, Pathak L C, et al. Defect structures in zirconium diboride powder prepared by self-propagating high-temperature synthesis[J]. Materials Science and Engineering A, 2004, 364: 249-255.

(编辑杨兵)

基金项目: 国防科技重点实验室基金资助项目(003985.3.6)

收稿日期: 2005-07-15; 修订日期: 2005-08-20

作者简介: 方 舟(1978-), 男, 博士研究生

通讯作者: 方 舟, 博士; 电话: 027-66044799; 传真:027-87215421; E-mail: wutfz@163.com