DOI:10.19476/j.ysxb.1004.0609.2018.08.10

Rene104镍基高温合金选区激光熔化成形及开裂行为

段然曦,黄伯云,刘祖铭,彭 凯,吕学谦

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:采用选区激光熔化技术,结合旋转+填充扫描策略制备Rene104镍基高温合金,研究了成形参数对显微组织和开裂行为的影响。结果表明:线能量密度和扫描间距是影响Rene104镍基高温合金致密度及开裂的主要参数。当线能量密度为250 J/m,扫描间距为0.08mm时,Rene104镍基高温合金成形件的致密度达98.37%。选区激光熔化成形Rene104合金主要由横截面尺寸为0.5 μm、轴向尺寸为3~5 μm或30 μm的柱状晶组织组成,晶粒沿建造方向的(200)晶面择优取向生长,同时,在晶界存在碳化物和Laves相,出现了裂纹、孔洞及残留粉末颗粒等缺陷。高线能量密度产生的大温度梯度导致残余应力,从而在晶界析出相周围形成应力集中,在熔池和层间搭接处的熔池尖端萌生裂纹,且沿建造方向扩展。残留孔洞主要来自粉末空心缺陷,残留粉末颗粒则由粉末飞溅产生。

关键词:Rene104合金;选区激光熔化;致密度;显微组织;裂纹;碳化物

文章编号:1004-0609(2018)-08-1568-11 中图分类号:TF124;TG146 文献标志码:A

镍基粉末高温合金具有优异的高温力学性能,是航空发动机及燃气轮机涡轮盘件等高温热端部件的关键材料[1-2]。当前,主要采用热等静压(HIP)、热挤压(HEX)、等温锻造[3-4]等工艺成形,这些传统粉末冶金成形工艺难以满足复杂结构的一体化构件的成形需求。选区激光熔化技术(SLM)[5]是一种新型粉末成形技术,可将金属粉末完全熔化,制造出高性能复杂结构金属零件[6],已经在多种镍基高温合金获得应用,并制备出近全致密的SLM成形件,如Inconel 718[7-8]、Inconel 625[9-10]、Waspaloy[11] 和Hastelloy X[12-13]。

Rene104镍基高温合金(ME3高温合金)是美国NASA设计的第三代镍基高温合金,具有优异的高温力学性能(拉伸、蠕变和疲劳等),以及抗氧化性能[14-15]。在Rene104合金基体中,均匀分布高密度的γ′析出相(Ni3(Al,Ti)面心立方L12结构),以及由高浓度难熔金属组成的碳化物相,因而加工难度大、热加工性能较差,极易产生焊接开裂,给激光成形制备高致密度样件带来了挑战[16-18]。本文作者以气雾化Rene104合金粉末为原料,系统研究了选区激光熔化成形参数对致密度及微观结构的影响,观察和分析了高能量密度参数成形件的微观结构及开裂行为,研究结果可为高性能Rene104镍基高温合金构件的制备提供参考。

1 实验

采用英国PSI紧耦合气雾化设备制备、并经真空震动筛分和气流分级的镍基高温合金粉末作为选区激光熔化(SLM)成形原料粉末(粉末粒径≤53 μm),采用湖南华曙高科Farsoon FS271m型选区激光熔化成形设备进行粉末成形,光斑直径为90 μm,设置层厚为30 μm,通入惰性气体氩气控制腔内氧含量低于0.1%。在单层单道实验的基础上,设置激光输入功率为180、200、210、210 W以及扫描速度分别为900、800、700、600 mm/s,定义线能量输入密度η为:

(1)

(1)

式中:η为线能量密度;P为激光输入功率;v为激光扫描速度。线能量密度η分别设置为200、250、300、350 J/m,扫描间距分别设置为0.07、0.08、0.09、0.10、0.11以及0.12 mm。激光成形过程中,每成形一层粉末之后,下一层的激光扫描方向顺时针旋转67.5°,每层成形采用激光优先扫描轮廓,后扫描填充的方式进行成形。

使用Mastersizer 3000型激光粒度分析仪进行粉末粒径分析。采用IRIS Advantage 1000等离子发射光谱仪对粉末进行成分分析,采用TC-436氧氮测定仪测定粉末N、O的含量。使用Sartorius MSA324S-000-DU型电子天平结合阿基米德原理测量成形件的致密度。采用TESCAN VEGA3扫描电镜、Quanta FEG 250场发射扫描电子显微镜观察粉末形貌、显微组织和SLM样品显微组织及微观结构。采用FEI F20透射电子显微镜观察SLM样品的显微组织。采用日本理学D/max 2550全自动(18 kW)转靶X射线衍射仪进行物相分析。

2 实验结果

2.1 雾化Rene104合金粉末形貌和显微组织

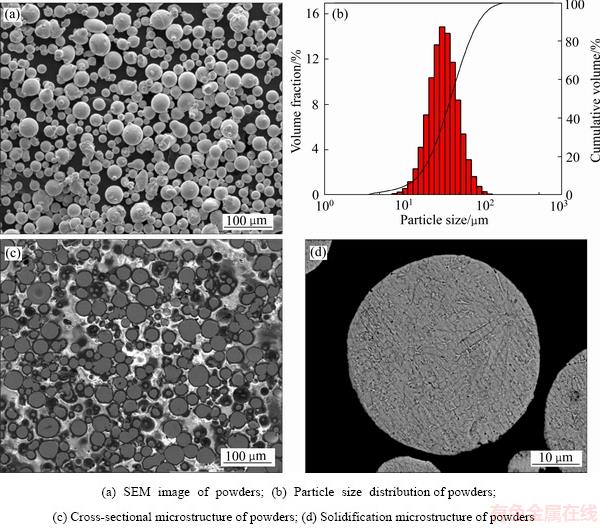

图1所示为本研究所采用的氩气雾化Rene104合金粉末形貌及显微组织。其中,图1(a)所示为粉末形貌,经过45 μm孔径网筛筛分的粉末球形度高、卫星粉少。粉末的粒径分布见图1(b),其D10、D50和D90粒径分别为17.13、29.23和 49.83 μm,分布较为集中,有利于选区激光熔化成形过程中粉末均匀摊铺。图1(c)所示为粉末的微观结构,仅有少量粉末出现空心现象,由图1(d)观察到粉末内部组织主要为胞状组织,以及少量树枝状组织。表1所列为雾化粉末成分分析结果,粉末主要成分在气雾化前后无明显变化,N、O含量较低,分别为0.0073%和0.011%(质量分数)。

图1 Rene104合金雾化粉末形貌及显微组织

Fig. 1 Morphologies and microstructures of as-atomized Rene104 powders

表1 Rene104合金雾化粉末成分分析结果

Table 1 Composition of as-atomized Rene104 superalloy powders (mass fraction, %)

2.2 选区激光熔化成形Rene104合金的致密度及微观组织

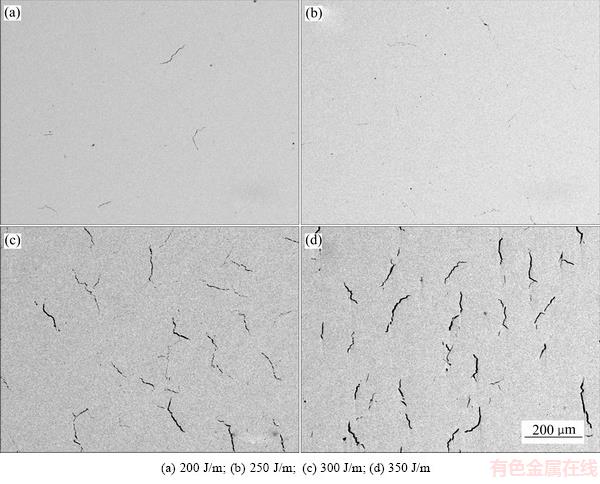

SLM成形线能量密度和熔池搭接参数是影响成形件致密度的主要因素,本实验分别对此进行了系统的研究。图2所示为SLM成形线能量密度对Rene104成形件致密度的影响。在控制扫描间距等其他工艺参数不变的情况下,当线能量密度为200 J/m时,致密度为98.25%;当线能量密度上升至250 J/m,样品致密度达到了98.32%;进一步提高线能量密度,致密度骤然降低;当线能量密度达到350J/m时,致密度降至最低(97.48%)。图3所示为对Rene104合金SLM成形件微观结构的观察结果。其中,采用200 J/m成形制备的Rene104合金的微观结构明显观察到了少量裂纹(见图3(a))。将线能量密度提高到250 J/m,裂纹的数量明显减少(见图3(b))。进一步将线能量密度提高到250 J/m及以上时,裂纹数量骤增,分布密集,尺寸明显增大(见图3(c)和(d))。这一结果与图2致密度结果一致。由此可见,SLM成形线能量密度对致密度具有重要影响,本实验的最佳激光线能量密度为250 J/m。

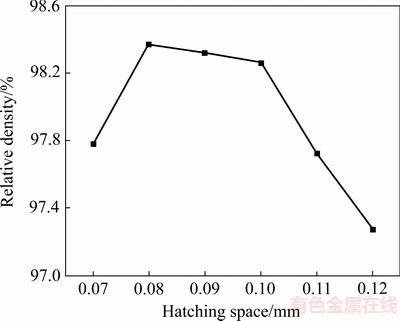

图4所示为 SLM扫描间距参数对Rene104成形件致密度的影响。在控制激光线能量密度等条件不变的情况下,当扫描间距为0.07 mm时,致密度为97.78%;当扫描间距参数增大至0.08 mm,样品致密度达到98.37%;进一步提高扫描间距,致密度降低;当扫描间距达到0.1 mm之后,致密度骤然降低;当扫描间距为0.12 mm时,致密度仅为97.27%。图5所示为对Rene104合金SLM成形件微观结构的观察结果。图5(a)所示为采用0.07 mm扫描间距制备的Rene104合金的微观结构,同样观察到了细长的裂纹。

图2 Rene104合金SLM成形件致密度随线能量密度(η)的变化

Fig. 2 Variation of relative density of SLM-processed Rene104 samples with linear energy input (η)

图3 不同线能量密度制备的Rene104合金SLM成形件X-Y面微观结构

Fig. 3 Microstructures in X-Y plane of SLM-processed Rene104 samples at various linear energy input

当扫描间距增加到0.08 mm时,熔池道之间的搭接达到了合适的比例,明显消除了裂纹,仅出现少量细小的孔隙,其致密度达到98.37%(见图5(b))。进一步提高扫描间距,出现了长度较短且宽度较小的裂纹(见图5(c)),使得致密度降低。扫描间距进一步增加,裂纹数量和尺寸增加,如图5(d)~图5(f)所示,与图4致密度结果一致。因此,最适合的扫描间距参数为0.08 mm。

2.3 选区激光熔化成形Rene104镍基高温合金的裂纹

图4 Rene104合金SLM成形件致密度随扫描间距的变化

Fig. 4 Variation of relative density of SLM-processed Rene104 samples with hatching space

图5 不同扫描间距制备的Rene104合金SLM成形件X-Y面微观结构

Fig. 5 Microstructures of X-Y planes in SLM-processed Rene104 samples at various hatching space

由于选区激光熔化成形工艺参数优化的过程中,线能量密度对成形件中裂纹形成的影响尚不明确,本实验研究了350 J/m高线能量密度成形件中不同成形面裂纹及缺陷的形貌(见图6)。从图6(a)和(b)(其中白线标注为熔池搭接处)可以发现,在X-Y成形面(垂直于建造方向),裂纹尖端于熔池搭接处萌生,并沿熔池的法向方向扩展,有部分裂纹连贯在一起;图6(c)和(d)所示X-Z平面(平行于建造方向)的SEM观察结果表明,所有的裂纹都在熔池尖端萌生,且均为沿建造方向(BD)开裂。同时,可以观察到各成形面裂纹均沿晶界开裂,裂纹呈现出锯齿形和长直形两种形貌。除了裂纹以外,在成形件中还观察到了残留孔洞和疑似残留粉末(见图6(c)),孔洞大小约为25 μm,裂纹贯穿残留粉末。同时,还观察到了空心粉末残留孔洞,在孔洞内部可以清楚观察到粉末颗粒内部的胞状及树枝晶组织,以及裂纹(见图6(e))。图6(f)所示为未完全熔化的残留粉末颗粒,可以从图6(f)清晰的观察到残留的原始粉末颗粒组织特征以及原始粉末颗粒边界。

2.4 选区激光熔化成形Rene104镍基高温合金的显微组织

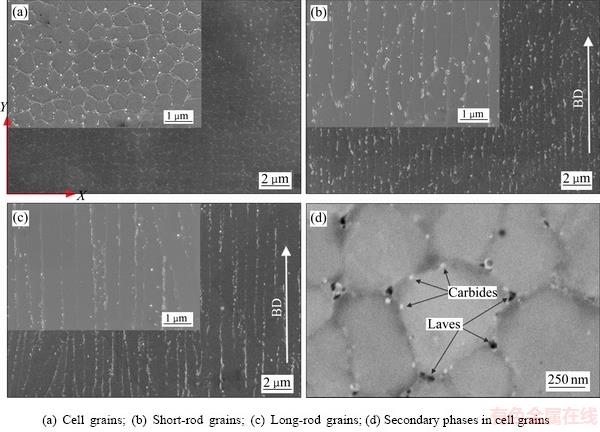

图7所示为经过腐蚀后的选区激光熔化成形样品显微组织形貌。由图7可以发现,在X-Y平面主要为规则的胞状晶组织(见图7(a)),尺寸约为0.5 μm;在X-Z以及Y-Z平面存在沿建造方向生长的短棒状柱状晶组织(见图7(b)),长度约3~5 μm;以及连续生长的长条状的柱状晶组织(见图7(c)),长度超过30 μm。综合图7三维方向的观察结果,SLM成形Rene104合金的晶粒主要为横截面尺寸为0.5 μm、轴向尺寸为3~5 μm或30 μm的柱状晶组织。对图7(a)显微组织的深入观察(见图7(d)),发现在晶界出现了均匀分布的细小碳化物以及Laves相,在晶内也发现了少量碳化物。这些碳化物主要为MC和M23C6型,Laves相是由于凝固过程中Nb元素偏析形成的一种不稳定的脆性相,为密排六方结构。通过EDS能谱分析,发现在晶界出现了Nb元素和C元素的偏析,进一步证明了这一现象。

图6 Rene104合金SLM成形缺陷形貌(图中所标白线为熔池道)

Fig. 6 Morphologies of defects in SLM-processed Rene104 samples

图8所示为选区激光熔化成形Rene104样品显微组织的透射电镜观察结果。从图8(a)的X-Y面和图8(b)的X-Z面显微组织中,均观察到了高密度的位错。由于晶内碳化物的存在,位错运动遇到阻碍,形成了位错塞积。如图8(c)所示,在晶界处发现了大量的位错缠结,以及碳化物钉扎位错现象,晶内较大的碳化物为立方块体形状(见图8(d)),主要为MC型碳化物,它具有面心立方密堆结构,析出温度较高,是一种非常稳定的强化相。

图7 Rene104合金SLM样品腐蚀后显微组织

Fig. 7 Microstructures of etched SLM-processed Rene104 samples

图8 Rene104合金SLM样品显微组织(透射电镜明场相)

Fig. 8 TEM bright field images of SLM-processed Rene104 samples

2.5 物相组成与晶粒取向

图9所示为Rene104镍基高温合金雾化粉末和选区激光熔化不同成形面XRD分析结果,以及不同线能量密度成形件的XRD衍射峰位置的变化。在Rene104雾化粉末和选区激光熔化成形件中均发现了面心立方γ基体相(Ni-Cr-Co-Mo)和L12面心立方结构γ′析出相(Ni3(Al,Ti))。如图9(a)所示,在Rene104合金粉末中呈现出(111)晶面的择优取向,这和AMATO等[7]选区激光熔化成形制备的Inconel718合金一致。然而,激光成形致密化导致Rene104合金在X-Y面(见图 9(b))呈现出(200)晶面的择优取向,随线能量密度的提高,晶粒的择优取向逐渐变为(111)晶面。在SLM成形件侧面,即X-Z面(见图9(c)),大部分样品在(111)晶面呈现出择优取向,但是在线能量密度为250 J/m,即致密度达到最高时,呈现出(200)晶面的择优取向。可见,在致密度最高时,在(200)晶面出现择优取向,随着线能量密度进一步升高,晶粒择优取向转为(111)晶面。如图9(d)和表2所示,可以发现,衍射峰位置随着能量密度升高向高角度偏移,在300 J/m达到最高,之后降低。

图9 Rene104合金SLM成形件的XRD谱

Fig. 9 XRD patterns of SLM-processed Rene104 sample

表2 Rene104成形件XRD衍射峰位置变化

Table 2 XRD data showing displacement of identified peaks for Rene104

3 分析与讨论

3.1 SLM成形参数对Rene104合金显微组织的影响

在SLM成形过程中,粉末颗粒沿着激光扫描线熔化并形成熔池,熔池凝固实现粉末的冶金结合与致密化,因此SLM成形组织主要受熔池控制,晶粒的生长过程主要取决于SLM凝固过程。晶粒在成形层重熔过程中发生了沿建造方向择优取向生长的现象,有一部分晶粒在旋转扫描中得到反复重熔,从而形成长条柱状晶组织,而另一部分晶粒仅在层内发生了生长,呈现短棒状,表现为图7所示在X-Y平面主要为规则的胞状晶组织,在X-Z和Y-Z平面沿建造方向生长的短棒状柱状晶组织,或长条状的柱状晶组织。通过成形件不同成形面的物相分析和能量密度参数对晶粒择优取向生长的影响规律分析(见图9),在Rene104合金粉末和选区激光熔化成形件中均发现了面心立方γ基体相(Ni-Cr-Co-Mo)和L12面心立方结构γ′析出相(Ni3(Al,Ti))的存在,在快速凝固过程中,γ′析出相固溶于γ基体,在极短的冷却过程中γ′析出相来不及长大,在扫描电镜中并未观察到γ′析出相。晶粒在X-Y平面的择优取向主要为(200)晶面,在X-Z平面主要为(111)晶面。随着线能量密度的提升,不论在X-Y平面或X-Z平面(111)晶面的择优取向不断增强,但是在线能量密度为250 J/m,即致密度达到最高时,Rene104镍基高温合金在不同成形面晶粒的(200)晶面均呈现出择优取向,可见随着线能量密度升高,晶粒的择优取向发生了转变。如表3所列,可以发现峰位置随着能量密度升高而向高角度偏移,在300 J/m达到最高,之后降低,这种现象主要是由于在快速凝固过程中产生的晶格畸变造成的[11-12, 19]。

另一方面,在这几种不同形貌晶粒的晶界处发现了均匀分布的细小碳化物以及Laves相,在晶内也发现了少量碳化物,这些碳化物主要为MC和M23C6型,而Laves相是在快速凝固过程中形成的一种不稳定的脆性相,为密排六方结构,根据PROBSTLE等[20]的研究,这种晶间形成的Laves相,是由于Nb元素在晶界枝晶偏析而形成的一种共晶产物,这种脆性的、不稳定的Laves相大大降低了合金的塑形。由于高能量密度产生的大温度梯度导致残余应力,并产生局部变形,因而在图8的TEM明场相中观察到高密度的位错,晶内碳化物对位错运动形成了阻碍,使得位错在碳化物相及晶界处形成位错塞积,当位错塞积到一定程度便会使得位错源开动,萌生裂纹,因而在晶界处发现了大量的位错缠结以及碳化物相钉扎位错现象。

3.2 SLM成形参数对Rene104合金开裂行为的影响

在选区激光熔化成形过程中,为了降低表面能,熔池倾向于形成一连串弥散的熔滴,从而产生“球化”[21-22],而激光参数(如线能量密度、扫描间距等)的设定极大地影响了这种现象的形成。当线能量密度为250 J/m时,熔池得到了充分的摊铺,凝固组织变得连续,获得了良好的冶金结合,成形件致密度最高。进一步提高激光线能量密度,受表面张力的影响,使得熔池发生皱缩,而不再连续。当扫描间距为0.08 mm时,熔池道之间的搭接达到了合适的比例,使得熔池均匀摊铺,明显消除了裂纹的产生,仅残留少量细小的孔隙,其致密度达到98.37%。当扫描间距小于0.08 mm时,熔池道之间的搭接为层内搭接,熔池获得了较大的搭接率,由于熔池搭接过多,在前一熔池道的热量尚未均匀扩散出去之时,下一道熔池便开始了重熔,温度场的过度叠加,形成较大的温度梯度,产生较高的热应力,从而导致形成较长且细密的裂纹,致密度较低。当扫描间距大于0.08 mm时,熔池道之间的搭接变为层间搭接,结合比较困难,裂纹数量进一步增加,裂纹宽度进一步增加,使得致密度降低。

可见,裂纹是影响成形件致密度的主要因素。Rene104镍基高温合金选区激光熔化成形过程中,成形件中由于线能量密度过大而引发裂纹形成的具体原因尚不明确。为了进一步消除裂纹以提高Rene104- SLM成形件致密度,本实验研究了高能量密度对Rene104合金SLM成形开裂行为的影响。发现在高能量密度下,由于高温度梯度、频繁的热循环和镍基高温合金的低热导率,在熔池的线与线搭接,层与层之间重熔的过程中,熔池边界以及层间熔池尖端产生了较大的残余应力,促使晶界迁移,位错源开动[23-24],在碳化物以及脆性Laves相周围产生严重的应力集中,从而在熔池搭接处以及层间熔池尖端萌生裂纹,产生沿晶开裂。由于不同成形面的晶粒组织结构的特点,在X-Y面的胞状结构使得裂纹主要呈现为锯齿状,在X-Z平面则存在锯齿状和长直状两种裂纹,基于晶粒沿建造方向生长的特性,裂纹也沿建造方向扩展。这种裂纹与焊接过程中常常出现的失延裂纹(Ductility-dip cracking)非常相似,COLLINS等[25-27]对DDC裂纹的研究发现,镍基高温合金处于中间温度时延性降低,从而产生DDC裂纹的情况,YOUNG[28]的研究认为DDC开裂是由于晶界边缘碳化物的存在而产生。因此,可以降低原材料碳化物含量,或者通过降低温度梯度、更改扫描策略、增加激光重熔来降低熔池间的残余应力来消除裂纹,提高选区激光熔化成形Rene104镍基高温合金致密度。

成形件中出现的残留孔洞中观察到了明显的粉末显微组织,而且孔洞直径普遍在25 μm左右,可见其主要来自粉末空心缺陷,在成形过程中,粉末空心缺陷中封闭的气体产生热膨胀从而导致裂纹。残留粉末颗粒主要是由于成形过程中,粉末飞溅落入熔池而形成的,尽管其对致密度的影响有限,但是当构件在高温服役时,这些残余粉末容易成为裂纹源,降低成形件寿命,因此需要进一步调节工艺参数以控制粉末飞溅,或改进设备内气体循环装置以减小影响。

4 结论

1) SLM成形线能量密度和扫描间距是影响Rene104镍基高温合金致密度及缺陷的主要参数。过高的线能量密度或不恰当的熔池搭接均会导致在成形件中形成大量的裂纹缺陷,优化采用250 J/m线能量密度,0.08 mm扫描间距,制备得到了致密度达98.37%的Rene104合金。

2) SLM成形Rene104合金X-Y平面主要为规则的胞状晶组织,X-Z或Y-Z平面存在短棒状或长柱状晶组织,且沿建造方向的(200)晶面择优取向生长,进一步提高线能量密度可以控制晶粒取向转为(111)晶面。

3) 当线能量密度过高时,会形成较大的温度梯度,产生较高的残余应力,从而在晶界碳化物相以及脆性Laves相处产生应力集中导致开裂,裂纹在X-Y平面沿熔池搭接处萌生且沿熔池法向扩展,在X-Z平面于层间交界处熔池尖端开裂,且沿建造方向扩展。

4) 选区激光熔化成形Rene104合金出现了裂纹、孔洞及残留粉末颗粒等3种缺陷,裂纹是影响致密度的主要因素。粉末空心缺陷是导致残留孔洞的主要原因,残留粉末颗粒则是成形过程中粉末飞溅落入熔池形成的。

REFERENCES

[1] 王 恺, 王 俊, 康茂东, 董安平, 孙宝德. 热等静压对K4169高温合金组织与性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1224-1231.

WANG Kai, WANG Jun, KANG Mao-dong, DONG An-ping, SUN Bao-de.Effect of hot isostatic pressing on microstructures and properties of superalloy K4169[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1224-1231.

[2] 刘小涛, 丁晗晖, 杨 川, 刘 锋, 黄 岚, 江 亮. 热挤压态FGH96粉末冶金高温合金的显微组织与力学性能[J]. 中国有色金属学报, 2016, 26(2): 354-364.

LIU Xiao-tao, DING Han-hui, YANG Chuan, LIU Feng, HUANG Lan, JIANG Liang. Microstructure and mechanical properties of hot extruded FGH96 powder metallurgy superalloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 354-364.

[3] SUDBRACK C K, DRAPER S L, GORMAN T T, TELESMAN J, GABB T P. Oxidation and the effects of high temperature exposures on notched fatigue life of an advanced powder metallurgy disk superalloy[J]. Superalloys, 2012,82: 863-872.

[4] 贾 建, 陶 宇, 张义文, 张 莹, 刘建涛. 第三代粉末冶金高温合金 的研究进展[J]. 粉末冶金工业, 2007, 17(3): 36-43.

的研究进展[J]. 粉末冶金工业, 2007, 17(3): 36-43.

JIA Jian, TAO Yu, ZHANG Yi-wen, ZHANG Ying, LIU Jian-tao. Recent development of third generation P/M superalloy  [J]. Powder Metallurgy Industry, 2007, 17(3): 36-43.

[J]. Powder Metallurgy Industry, 2007, 17(3): 36-43.

[5] ABE F, OSAKADA K, SHIOMI M. The manufacturing of hard tools from metallic powders by selective laser melting[J]. Journal of Materials Processing Technology, 2001, 111(1/3): 210-213.

[6] KRUTH J P, FROYEN L, VAERENBERGH J V, MERCELIS P, ROMBOUTS M. Selective laser melting of iron-based powder[J]. Journal of Materials Processing Technology, 2004, 149(1/3): 616-622.

[7] AMATO K N, GAYTAN S M, MURR L E, MARTINEZ E, SHINDO P W. Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting[J]. Acta Materialia, 2012, 60(5): 2229-2239.

[8] JIA Q B, GU D D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties[J]. Journal of Alloys and Compounds, 2014, 585: 713-721.

[9] LI S, WEI Q, SHI Y, ZHU Z, ZHANG D. Microstructure characteristics of Inconel 625 superalloy manufactured by selective laser melting[J]. Journal of Materials Science & Technology, 2015, 31(9): 946- 952.

[10] WITKIN D B, ADAMS P, ALBRIGHT T. Microstructural evolution and mechanical behavior of nickel-based superalloy 625 made by selective laser melting[C]// HELVAJIAN H, PIQUE A, WEGENER M, GU B. Laser 3d Manufacturing Ii. San Francisco: CA SPIE, 2015: 9-30.

[11] MUMTAZ K A, ERASENTHIRAN P, HOPKINSON N. High density selective laser melting of Waspaloy (R)[J]. Journal of Materials Processing Technology, 2008, 195(1/3): 77-87.

[12] WANG F D. Mechanical property study on rapid additive layer manufacture Hastelloy (R) X alloy by selective laser melting technology[J]. International Journal of Advanced Manufacturing Technology, 2012, 58(5/8): 545-551.

[13] TOMUS D, TIAN Y, ROMETSCH P A, HEILMAIER M, WU X. Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting[J]. Materials Science and Engineering A, 2016, 667: 42-53.

[14] YANG J J, LI F Z, WANG Z M, ZENG X. Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication[J]. Journal of Materials Processing Technology, 2015, 225: 229-239.

[15] UNOCIC R R, ZHOU N, KOVARIK L, SHEN C, WANG Y. Dislocation decorrelation and relationship to deformation microtwins during creep of a γ′ precipitate strengthened Ni-based superalloy[J]. Acta Materialia, 2011, 59(19): 7325-7339.

[16] KITAGUCHI H. Microstructure-property relationship in advanced Ni-based superalloys[M]. Cambridge: Cambridge University Press, 2012: 18-42.

[17] REED R C. The superalloys: Fundamentals and applications[J]. Aeronautical Journal, 2006, 5: 54-62.

[18] CARTER L N, ATTALLAH M M, REED R C. Laser powder bed fabrication of nickel-base superalloys: Influence of parameters, characterisation, quantification and mitigation of cracking[J]. Superalloys, 2012, 76(9): 577-586.

[19] GU D D, HAGEDORN Y C, MEINERS W, MENG G, RUI JSB. Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium[J]. Acta Materialia, 2012, 60(9): 3849-3860.

[20] PROBSTLE M, NEUMEIER S, HOPFENMULLER J, FREUND L P, NIENDORF T. Superior creep strength of a nickel-based superalloy produced by selective laser melting[J]. Materials Science and Engineering A, 2016, 674: 299-307.

[21] SIMCHI A, POHL H. Effects of laser sintering processing parameters on the microstructure and densification of iron powder[J]. Materials Science and Engineering A, 2003, 359(1/2): 119-128.

[22] NIU H J, CHANG I T H. Liquid phase sintering of M3/2 high speed steel by selective laser sintering[J]. Scripta Materialia, 1998, 39(1): 67-72.

[23] VILARO T, COLIN C, BARTOUT J D, NAZE L, SENNOUR M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy[J]. Materials Science and Engineering A, 2012, 534: 446-451.

[24] KANAGARAJAH P, BRENNE F, NIENDORF T, MAIER H J. Inconel 939 processed by selective laser melting: Effect of microstructure and temperature on the mechanical properties under static and cyclic loading[J]. Materials Science and Engineering A, 2013, 588: 188-195.

[25] COLLINS M G, LIPPOLD J C. An investigation of ductility dip cracking in nickel-based filler materials-Part Ⅰ [J]. Welding Journal, 2003, 82(10): 288-295.

[26] COLLINS M G, RAMIREZ A J, LIPPOLD J C. An investigation of ductility dip cracking in nickel-based weld metals - Part II[J]. Welding Journal, 2003, 82(12): 348-354.

[27] COLLINS M G, RAMIREZ A J, LIPPOLD J C. An investigation of ductility-dip cracking in nickel-based weld metals-Part Ⅲ[J]. Welding Journal, 2004, 83(2): 39-49.

[28] YOUNG G A. The mechanism of ductility dip cracking in nickel-chromium alloys[J]. Welding Journal, 2008, 2(2): 31-43.

Selective laser melting fabrication and cracking behavior of Rene104 nickel-based superalloy

DUAN Ran-xi, HUANG Bai-yun, LIU Zu-ming, PENG Kai, Lü Xue-qian

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The Rene104 nickel-based superalloy was fabricated by selective laser melting technology with the scan strategy of rotation plus filling, and the impacts of process parameters on the microstructure and cracking behavior were investigated. The results show the linear energy density and hatch spacing are the main parameters that affect the density and cracking behavior of Rene104 nickel-based superalloy. When the energy density is 250 J/m, and the hatch spacing is 0.08 mm, the relative density of Rene104 nickel-based superalloy samples reaches 98.37%. The Rene104 alloy is mainly composed of columnar grains with the cross-sectional dimension of 0.5 μm and the axial dimension of 3-5 μm or 30 μm. The grain grows along the build direction with the strong (200) texture, while the carbides and Laves phases exist along the grain boundaries. The defects, including cracks, pores and remained powders, are also be found. The high linear energy density can cause the large temperature gradient and residual stress, which results in the stress concentration around precipitates. Therefore, the cracks initiate at the pool tip and interlayer junctions, then extend along the build direction. The remained pores are mainly caused by the powder hollow, and the remained powders are generated by the powder splash phenomenon.

Key words: Rene104 superalloy; selective laser melting; relative density; microstructure; crack; carbide

Foundation item: Project(2009AA03Z526) supported by the National High-Tech Research and Development Program of China; Project(2016ZZTS272) supported by the Fundamental Research Funds for the Central Universities of Central South University, China; Project(2015CX004) supported by Innovation- Driven Plan of Central South University, China; Project(2016YFB0301300) supported by National Key Research and Development Program, China

Received date: 2017-04-18; Accepted date: 2017-07-26

Corresponding author: LIU Zu-ming; Tel: +86-731-88836355; E-mail: lzm@csu.edu.cn

(编辑 王 超)

基金项目:国家高技术研究发展计划资助项目(2009AA03Z526);中南大学中央高校基本科研业务费专项资助(2016ZZTS272);中南大学创新驱动计划资助项目(2015CX004);国家重点研发计划资助项目(2016YFB0301300)

收稿日期:2017-04-18;修订日期:2017-07-26

通信作者:刘祖铭,博士,教授;电话:0731-88836355;E-mail: lzm@csu.edu.cn