文章编号:1004-0609(2007)04-0617-06

铝/钛异种合金激光熔钎焊接头特性

倪加明, 李俐群, 陈彦宾, 封小松

(哈尔滨工业大学 现代焊接生产技术国家重点实验室, 哈尔滨 150001)

摘 要:以CO2激光为热源,以AlSi 12焊丝为填充材料,对Ti-6Al-4V钛合金和5056铝合金异种材料激光熔钎焊进行研究,采用SEM、EDS、XRD和金相显微镜分析接头的微观结构特征,通过拉伸实验评定接头的力学性能。研究结果表明:所得接头具有熔焊和钎焊双重性质,即铝母材局部熔化,为熔化焊,而钛母材与焊缝金属之间存在金属间化合物层钎焊界面;钎焊界面上部的金属间化合物层组成复杂,可分为2层,即呈针状或芽状的Ti-Al-Si系金属间化合物层和以Ti-Al系金属间化合物为主的连续层;钎焊界面下部的金属间化合物层较薄;拉伸试样断裂倾向于发生在紧邻钎焊界面的焊缝上,平均抗拉强度为298.5 MPa。

关键词:钛合金;铝合金;激光熔钎焊;金属间化合物;接头强度

中图分类号:TG 456.7 文献标识码:A

Characteristics of laser welding-brazing joint of Al/Ti dissimilar alloys

NI Jia-ming, LI Li-qun, CHEN Yan-bin, FENG Xiao-song

(State Key Laboratory of Advanced Welding Production Technology,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: Laser welding-brazing (LWB) of Ti-6Al-4V and 5056Al was conducted using AlSi 12 filler metal. The microstructure characteristics of LWB Al/Ti joints were analyzed by SEM, EDS, XRD and optical microscopy. The joint strength was measured via tensile test. The results show that the joint has dual characteristics and can be divided into a welding part on the aluminium side and a brazing part on the titanium side. An intermetallic compound layer forms at the brazing interface between mixed seam metal and titanium. The intermetallic compound layer at interfacial top includes an acicular Ti-Al-Si intermetallic layer and a continuous Ti-Al intermetallic layer near titanium alloy. The intermetallic compound layer at interfacial bottom is thin and different from that at top. The average tensile strength of joints is 298.5 MPa. Fracture is prone to occur in the seam metal nearby brazing interface.

Key words: titanium alloy; aluminum alloy; laser welding-brazing; intermetallic compound; joint strength

钛合金和铝合金是航空航天工业主要结构材 料[1-2]。由于铝合金的强度及耐热性较低,而钛合金密度较大,价格较高,采用钛和铝连接而成的复合构件可以减小构件质量,降低生产成本以及满足其特殊综合使用性能。然而,钛和铝的熔点、热导率、热膨胀系数以及晶体结构等物理性能差异很大,熔化焊接时2种金属液相混合将生成大量脆性金属间化合物,无法获得满意的焊缝。电弧熔钎焊[3]、固态扩散焊[4-5]、真空钎焊[6-7]、液相扩散焊[8]、激光连接[9]等被用于钛和铝异种材料焊接。

熔钎焊利用2种母材的熔点差异,使低熔点母材熔化,而高熔点母材始终保持固态,避免2种金属液相混合而生成大量脆性金属间化合物。焊接质量的关键是严格控制过程温度范围,而激光热源的加热位置与能量输入精确可控,对实现异种金属熔钎焊具有明显优势。目前,人们针对钢和铝异种金属激光熔钎焊进行较多研究[10-14]。Song等[11]认为激光熔钎焊过程温度决定金属间化合物层厚度,激光功率超过临界值,金属间化合物将急剧生长;Mathieu等[12]通过数值模拟以及实测表面温度来控制金属间化合物的厚度;Ding等[13]研究发现,由于激光熔钎焊的高加热速率和重结晶率,当金属间化合物层厚度为30 μm时仍未观察到显微裂纹。而对于铝与钛异种材料,Kreimeyer等[15]通过直接连接或预沉积铝至钛表面等方式进行激光连接研究。激光熔钎焊过程通过填充材料可以改善焊缝成形,降低工件装配要求。目前,人们对铝/钛异种合金填丝激光熔钎焊较少进行系统研究。在此,本文作者以AlSi 12焊丝为填充材料,对Ti-6Al-4V钛合金和5056铝合金异种材料激光熔钎焊进行研究,分析激光熔钎焊接头宏观、微观结构特征以及金属间化合物组成与形态分布,并采用拉伸实验对接头力学性能进行评定。

1 实验

1.1 实验材料

实验母材是厚度为1.5 mm的Ti-6Al-4V钛合金和5056铝合金板材。采用激光切割,用铣床开出坡口。由于钛和铝均为活性金属,焊前需要严格去除表面氧化膜,并采用丙酮擦拭去除油污。所用填充钎料为AlSi 12焊丝,其熔点范围为575~590 ℃。

1.2 实验方法

实验热源采用散焦CO2激光束,与工件表面成60?夹角倾斜入射,则作用于工件上的加热光斑变为椭圆形,并且其长轴平行于焊接方向,焊丝从激光束前方送入,异种板材对接间隙为0.5 mm,采用氩气同时进行正面和背面保护。激光熔钎焊示意图如图1所示。

图1 激光熔钎焊示意图

Fig.1 Schematic diagram of laser welding-brazing process

采用金相显微镜和扫描电镜(SEM)分析接头组织形貌。采用能谱分析(EDS)以及X射线衍射(XRD)分析金属间化合物的组成。在电子万能材料试验机上测试接头抗拉强度。

2 结果与分析

2.1 激光熔钎焊接头宏观结构特征

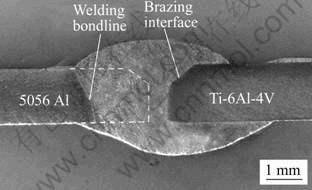

铝/钛激光熔钎焊接头横截面如图2所示。可以看出,接头具有熔焊与钎焊双重性质:低熔点铝母材局部熔化,与熔化焊丝填充金属混合后凝固形成焊缝,且存在明显熔合区;而高熔点钛侧则存在钛母材与焊缝的钎焊界面,表明熔融焊缝金属与固态钛母材发生相互作用而形成钎焊连接。

图2 铝/钛异种合金激光熔钎焊接头横截面

Fig.2 Cross section of Al/Ti joint

2.2 激光熔钎焊接头微观组织特征

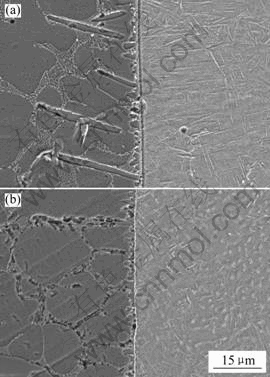

铝母材与焊丝金属熔化混合后凝固形成焊缝,在焊缝金属与铝母材之间存在明显细小等轴晶及网状Al-Si共晶组织的熔合区,如图3(a)所示;靠近熔合区的焊缝组织为垂直熔合区方向生长的粗大枝晶。而在钛合金母材与焊缝金属间存在呈锯齿状向焊缝内部生长的钎焊界面反应层,如图3(b)所示。

图3 铝侧熔合区和钛侧钎焊界面显微组织

Fig.3 Microstructure of Al/Ti joint: (a) Welding bondline; (b) Brazing interface

熔合区的形成是由于紧邻焊缝的母材受焊缝金属的传热而发生局部熔化,同时焊缝的Si元素向铝母材晶界扩散渗透,生成Al-Si共晶组织。由于铝合金具有高热导率,使得靠近熔合区的焊缝柱状枝晶组织沿最大冷却速度反方向迅速生长。钛母材侧出现呈锯齿状形态分布的钎焊界面,主要是在激光熔钎焊过程中,固态钛合金母材与熔融焊缝金属发生相互作用形成金属间化合物层。

2.3 金属间化合物SEM图像

对焊缝金属与钛合金母材之间的钎焊界面进行扫描,其分析结果如图4所示。钎焊界面上部的锯齿状金属间化合物层大体可以分为紧邻钛母材的连续层和呈针状或芽状的非连续层(A) 2部分。连续层又可分为白色絮状层(B)和向白色絮状层内生长的浅灰色芽状层(C),连续层的最大厚度小于10 ?m。

图4 金属间化合物层SEM图像

Fig.4 SEM image of intermetallic compound layer

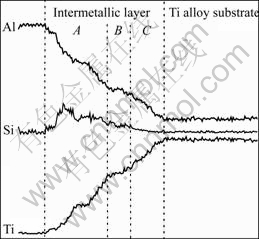

为了分析金属间化合物层组成,进行能谱线扫描分析,所得结果如图5所示。可见,Al和Ti元素在金属间化合物层内各区域质量浓度有所差异,且局部形成台阶分布。需注意的是,Si元素向形成Ti-Al金属间化合物层的钎焊界面扩散和富集。经分析认为,这是由于所形成的新相中的Si元素化学势比熔化焊缝金属的Al-Si液相中Si元素的化学势低,致使发生“上坡扩散”生成Ti-Al-Si金属间化合物。因Si原子扩散时间受限,C层内Si元素质量浓度极低,仍以Ti-Al系金属间化合物为主。各金属间化合物层的能谱分析结果如表1所示。

图5 金属间化合物层能谱线扫描结果

Fig.5 Element line at scanning results of intermetallic compound layer

表1 金属间化合物层的能谱分析结果

Table 1 EDS analysis results of intermetallic compound sublayers in different areas(mole fraction, %)

与扩散焊、钎焊等过程不同,稳定均匀加热所得金属间化合物组成简单[16-18]。激光加热能量集中,加热中心温度高,但热循环迅速,作用时间短,导致原子扩散驱动力很大但扩散时间有限。由于不同区域的各元素浓度存在差异,使得最终形成的金属间化合物组成复杂。

金属间化合物层的X射线衍射分析结果表明,钎焊界面形成的金属间化合物层主要分为2类:一类是Ti3Al、TiAl和TiAl3等Ti-Al系二元金属间化合物;第二类是Ti7Al5Si12等Ti-Al-Si系三元金属间化合物。由于金属间化合物层的物相构成复杂,各层对应的物相及各相含量还有待进一步分析研究。

激光熔钎焊接头界面的金属间化合物层不但组成复杂,而且同一界面不同部位金属间化合物的形态差异也较大。如图6所示,位于接头界面上部处的金属间化合物层较厚,并且有针状化合物向焊缝金属生长;而界面下部金属间化合物层则较薄,且连续层内没有明显分层。

图6 同一界面不同部位金属间化合物层分布形态

Fig.6 SEM images of intermetallic layers of the same brazing interface in different positions: (a) Interfacial top; (b) Interfacial bottom

激光熔钎焊属于局部热源钎焊,通过母材与焊缝金属之间的元素扩散反应,达到连接的目的。其钎焊界面反应过程是由原子扩散控制的,且反应层生长符合抛物线关系,即反应层厚度可表示为[11]

X=k0 tn exp[-Q/(RT)] (1)

式中 X为金属间化合物层厚度;t为反应时间;n为时间因子(通常为0.5);k0为常数;Q为扩散激活能;R为气体常数;T为反应温度。

由式(1)可知,界面反应形成的金属间化合物层厚度由反应时间及反应温度控制。激光加热迅速,因而反应时间短,金属间化合物层厚度总体上较小。然而,界面上部受激光辐照区域温度很高,母材元素向熔融焊缝金属的溶解速率和焊缝金属元素向固态母材扩散速率均很大,受原子扩散控制的金属间化合物成长迅速。反之,激光不能辐照的界面下部,只能靠焊缝金属传递热量,因而温度较低。而且激光熔钎焊是非稳态的快速加热过程,过程温度在空间与时间上的梯度均很大,温度越高,意味着冷却时间延长,导致反应作用时间越长。温度对界面反应的影响是双重的,接头温度梯度导致同一界面上金属间化合物层形态差异很大。

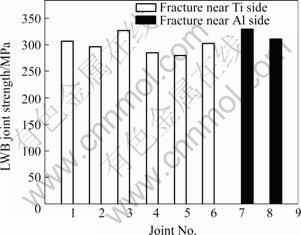

2.4 接头力学性能

对接接头的抗拉强度是反映接头力学性能的重要参数。通过系列拉伸实验获得的接头强度如图7所示。可见,接头易断裂于紧邻钎焊界面的焊缝上,所得平均抗拉强度为298.5 MPa,达到铝母材抗拉强度(5056铝合金抗拉强度约为350 MPa)的85.3%。尤其是裂纹起源于钎焊界面下部,说明钎焊界面下部是熔钎焊接头的薄弱环节。随着线能量增大,接头断裂发生在铝侧熔合区附近的焊缝处,且抗拉强度相对较高,平均强度达到319.6 MPa。但此参数范围较窄,主要是由于线能量增大,易造成钛母材熔化,生成大量脆性金属间化合物,接头性能将急剧下降,甚至无法实现焊接。

图7 接头抗拉强度

Fig.7 Tensile strength of LWB Al/Ti joints

此外,从图8所示的断裂在紧邻钛侧焊缝的断口扫描电镜形貌可以看到典型的撕裂棱,撕裂棱的深度很大,韧窝很小,表明断裂发生在焊缝金属内部,而不是金属间化合物层过厚引起的脆性断裂。至于在界面附近断裂,主要是由于界面处容易造成应力集中,且界面底部反应不充分,金属间化合物层过小,结合不良,受载极易萌生裂纹。随着线能量增大,钎焊界面结合增强,同时铝侧焊缝枝晶过于粗大,断裂从钛侧焊缝转移至铝侧焊缝。因此,不同于散焊等对金属间化合物层厚度的严格要求[19],激光熔钎焊时更要求界面不同部位的金属间化合物层均匀分布。

图8 焊缝断口形貌

Fig.8 Morphology of fractured tensile testing sample

可见,激光热源的加热特点在很大程度上影响金属间化合物的组成、形态及分布。而接头金属间化合物层的组成与分布又在很大程度上决定接头的力学性能。本实验采用长轴沿焊接方向的椭圆形散焦光斑加热,空间上使光斑能量密度分布均匀,延长接头受热时间,有利于接头结合。此外,还可以通过采用合适能量密度分布的激光光斑以及合理的坡口形状进一步提高接头结合。

3 结论

1) 铝/钛激光熔钎焊接头具有熔焊与钎焊双重性质:铝母材局部熔化,与熔化焊丝金属混合后凝固形成焊缝,有明显的熔合区;而另一侧存在钛母材与焊缝金属的钎焊界面,熔融焊缝金属与固态钛母材发生相互作用后形成金属间化合物层。

2) 钎焊界面上部的金属间化合物层组成复杂,大致可分为2层:针状或芽状的Ti-Al-Si系金属间化合物断续层;由Ti-Al系金属间化合物和少量Ti-Al-Si系金属间化合物组成的连续层。同时,钎焊界面下部的金属间化合物层形态与界面上部的形态差异较大。

3) 接头拉伸试样易断裂于紧邻钛侧钎焊界面的焊缝上,裂纹起源于结合不良的钎焊界面底部,其接头平均抗拉强度为298.5 MPa,达到铝母材抗拉强度的85.3%。当界面结合良好时,断裂发生于紧邻铝侧熔合区的焊缝上,且抗拉强度有所提高。

REFERENCE

[1] Leyens C, Peter M. 钛与钛合金[M]. 陈振华, 译. 北京: 化学工业出版社, 2005: 292-305.

Leyens C, Peter M. Titanium and Titanium Alloys[M]. CHEN Zhen-hua, transl. Beijing: Chemical Industry Press, 2005: 292-305.

[2] 陈亚莉. 铝合金在航空领域中的应用[J]. 有色金属加工, 2003, 32(2): 11-17.

CHEN Ya-li. Application of aluminum alloys to aircraft[J]. Nonferrous Metal Processing, 2003, 32(2): 11-17.

[3] Korenyuk Y M. Interaction of liquid aluminium and solid titanium in fusion welding[J]. Welding Production, 1975, 22(6): 3-5.

[4] REN Jiang-wei, LI Ya-jiang, FENG Tao. Microstructure characteristics in the interface zone of Ti/Al diffusion bonding[J]. Materials Letters, 2002, 56(5): 647-652.

[5] Wilden J, Bergmann J P. Manufacturing of titanium/aluminium and titanium/steel joints by means of diffusion welding[J]. Welding and Cutting, 2004, 3(5): 285-290.

[6] Takemoto T, Okamoto I. Intermetallic compounds formed during brazing of titanium with aluminum filler metals[J]. Journal of Material Science, 1988, 23(4): 1301-1308.

[7] 胡 刚, 康 慧, 赵鹏飞, 曲 平. 锡镓对铝钛异种合金真空钎焊的影响[J]. 航空精密制造技术, 2001, 37(4): 15-19.

HU Gang, KANG Hui, ZHAO Peng-fei, QU Ping. Influence of stannum and gallium on vacuum brazing of aluminum and titanium dissimilar alloy[J]. Aviation Precision Manufacture Technology, 2001, 37(4): 15-19.

[8] Sohn W H, Bong H H, Hong S H. Microstructure and bonding mechanism of Al/Ti bonded joint using Al10Si1Mg filler metal[J]. Mater Sci Eng A, 2003, 355(1/2): 231-240.

[9] Kreimeyer M, Wagner F, Vollertsen F. Laser processing of aluminum titanium tailored blanks[J]. Optics and Lasers in Engineering, 2005, 43(9):1021-1035.

[10] Kreimeyer M, Wagner F, Sepold G. Laser welding/brazing for joining tailored blanks[J]. Industrial Laser Solutions, 2002, 17(11): 15-16.

[11] Song W, Saida K, Ando A, Nishimoto K. Brazability of aluminum alloy to steels using aluminum filler metal - dissimilar laser brazing of aluminum alloy and steels (Report Ⅰ)[J]. Quarterly Journal of the Japan Welding Society, 2004, 22(2): 315-322.

[12] Mathieu A, Mattei S, Deschamps A, Martin B, Grevey D. Temperature control in laser brazing of a steel/aluminium assembly using thermographic measurements[J]. NDT and E International, 2006, 39(4): 272-276.

[13] DING Jian-jun, LI Fei-qun, QU Feng, Patrice P, Remy F. Investigation on laser brazing AA6056 Al alloy to XC18 low-carbon steel[J]. Chinese Optics Letters, 2005, 3(1): 31-34.

[14] Laukant H, Wallmann C, Müller M, Korte M, Stirn B, Haldenwanger H G, Glatzel U. Fluxless laser beam joining of aluminium with zinc-coated steel[J]. Science and Technology of Welding and Jioning, 2005, 10(2): 219-226.

[15] Kreimeyer M, Wagner F, Sepold G. Joining aluminium alloys with titanium with the use of a Nd: YAG laser system[J]. Laser Opto, 2001, 33(1): 31-33.

[16] 秦 斌, 盛光敏, 周 波, 黄家伟, 李 聪, 邱绍宇. 钛合金和不锈钢的扩散焊接[J]. 中国有色金属学报, 2004, 14(9): 1545-1550.

QIN Bin, SHENG Guang-min, ZHOU Bo, HUANG Jia-wei, LI Cong, QIU Shao-yu. Diffusion welding of titanium alloy and stainless steel[J]. The Chinese Journal of Nonferrous Metal, 2004, 14(9): 1545-1550.

[17] CAO Jian, FENG Ji-cai, LI Zhuo-ran. Microstructure of TiAl/TiC cermet joint bonded by combustion synthesis[J]. Trans Nonferrous Met Soc China, 2005, 15(3): 323-326.

[18] Shiue R K, Wu S K, Chen S Y. Infrared brazing of TiAl using Al-based braze alloys[J]. Intermetallic, 2003, 11(7): 661-671.

[19] 冯吉才, 李卓然, 何 鹏, 张秉刚. TiAl/40Cr扩散连接接头的界面结构及相成长[J]. 中国有色金属学报, 2003, 13(1): 162-166.

FENG Ji-cai, LI Zhuo-ran, HE Peng, ZHANG Bing-gang. Interface structures and phase growth of TiAl/40Cr diffusion bonded joint[J]. The Chinese Journal of Nonferrous Metal, 2003, 13(1): 162-166.

收稿日期:2006-10-13;修订日期:2006-12-26

通讯作者:李俐群, 副教授, 博士;电话: 0451-86415374, E-mail: liliqun@hit.edu.cn

(编辑 陈灿华)