文章编号:1004-0609(2010)S1-s0967-05

造孔剂法制备多孔生物医用Ti2448合金

王玺涵1,李述军1, 贾明途1, 郝玉琳1, 杨 锐1, 郭正晓2

(1. 中国科学院 金属研究所 沈阳材料科学国家(联合)实验室,沈阳 110016;

2. 英国伦敦大学学院 化学系,伦敦WC1H 0AJ)

摘 要:采用添加造孔剂的粉末冶金方法制备高强度低模量大块多孔医用Ti-24Nb-4Zr-8Sn(质量分数,%,简称Ti2448)合金。采用扫描电镜(SEM)、压缩试验和弹性模量仪对其形貌特征、力学性能进行研究。结果表明:由于造孔剂PMMA(聚甲基丙烯酸甲酯)具有较好的塑性,在冷轧成形过程中能够保持其原始形状,故可以制备出孔隙特征参数和力学性能均可调的多孔Ti2448合金;随着造孔剂粒径的增加,平均孔径增加,压缩强度和弹性模量减小;随着烧结温度的升高,孔隙率和平均孔径略有减小,压缩强度和弹性模量增加。

关键词:医用钛合金;多孔Ti-24Nb-4Zr-8Sn合金;造孔剂;弹性模量

中图分类号:TG146 文献标志码:A

Porous Ti-24Nb-4Zr-8Sn alloy for biomedical applications fabricated by space-holder method

WANG Xi-han1, LI Shu-jun1, JIA Ming-tu1, HAO Yu-lin1, YANG Rui1, GUO Zheng-xiao2

(1. Shenyang National Laboratory for Materials Science, Institute of Metal Research,

Chinese Academy of Sciences, Shenyang 110016, China;

2. Department of Chemistry, University College London, London WC1H 0AJ, England)

Abstract: Porous biomedical Ti-24Nb-4Zr-8Sn (mass fraction, %, Ti2448) alloy with high strength and low modulus was fabricated by powder metallurgy which was called space-holder method. The porous structures and mechanical properties of the porous alloy were examined by scanning electron microscopy (SEM), compressive tests and instrument of elastic modulus. The results show that the good plasticity of space-holder (PMMA) greatly facilitates the fabrication of porous Ti2448 alloys with adjustable pore characteristics and mechanical properties. The average pore size of porous Ti2448 alloy increases correspondingly with the increase of size of space-holder, but compressive strength and elastic modulus take on the trend of decreasing. The effect of sintering temperature is not obvious to the average pore diameter and porosity, but compressive strength and elastic modulus increase with the rising of sintering temperature.

Key words: biomedical titanium alloys; porous Ti-24Nb-4Zr-8Sn alloy; space-holder; elastic modulus

金属生物材料由于具有比陶瓷和聚合物材料更高的强度和断裂韧性,被作为人体植入物而得到广泛的应用[1]。Ti和其合金由于低密度、高的强度-模量比,优良的防腐蚀性能和好的生物相容性等优点而成为尤其重要的生物医用材料[2]。Ti-24Nb-4Zr-8Sn(质量分数,%,简称Ti2448)是一种具有高强度、低模量、耐腐蚀、无生物毒性等优良性能的新型医用β钛合金,在医学领域具有良好的应用前景[3-4]。但其致密体缺乏组织进行内生长的生物环境[5]。多孔金属材料可为骨生长、分化和增殖提供充足的空间,开放的连通孔结构利于水分和养料的传输[6],因此,可以达到更自然的固定。制备多孔钛及其合金的方法很多,包括粉末冶金法、自蔓延燃烧法、快速原型法[7]和冷冻干燥法等。目前,较常用的方法是造孔剂法。

本文作者在常规粉末冶金法基础上通过添加具有较好机械强度和抗破碎能力的聚甲基丙烯酸甲酯(PMMA)作为造孔剂,制备孔隙率可控和孔隙分布均匀的生物医用多孔Ti2448合金。

1 实验

1.1 实验材料

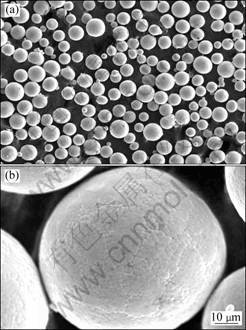

本文所用的Ti2448合金粉末通过感应熔炼气体雾化法(Electrode induction melting gas atomization)喷制而成,并在氩气保护的密封状态下用标准筛将其分级,选取45~70 μm粒径的Ti2448合金粉末作为原料,颗粒主要呈球形,有极少量椭球形等不规格形状和少许黏附在大颗粒上的“卫星球”[8](见图1)。

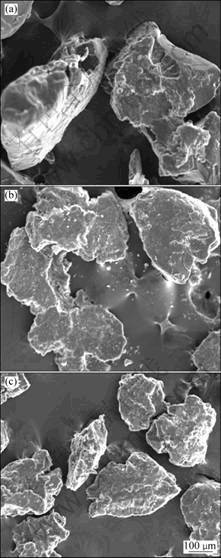

为了研究造孔剂粒径对多孔Ti2448合金的影响,选用3种造孔剂,其粒径分别为250~500 μm, 212~250 μm和150~212 μm(见图2)。

1.2 多孔Ti2448合金的制备

由于Ti2448合金粉末具有优良的冷加工性能,因

图1 雾化法制备的Ti2448合金粉末形貌的SEM像

Fig.1 SEM images of Ti2448 alloy powder fabricated by gas atomization

图2 不同粒径造孔剂(PMMA)的SEM像

Fig.2 SEM images of space-holder powder particles (PMMA) with different sizes: (a) 250-500 μm; (b) 212-250 μm; (c) 150-212 μm

此,采用冷轧成形和真空烧结的方法制备多孔Ti2448合金。首先将造孔剂(30%,体积分数)和Ti2448合金粉末混合均匀,并加入少量黏结剂,使Ti2448合金粉末均匀的附着在PMMA的表面。将混合均匀的粉末封装入包套,对其进行冷轧成形。为了确定最优的烧结温度,对生坯进行1 100~1 300 ℃的真空烧结4 h,随炉冷却。高温烧结前,需要在400 ℃预烧结2 h以彻底去除造孔剂和黏结剂。

1.3 样品表征

孔隙特征参数通过阿基米德方法和定量金相分析(Sisc-Ias8软件)的方法测定。利用S-3400N(HITACHI)型扫描电镜观察多孔Ti2448合金的形貌和组织特征。采用D/MAX2400型X射线衍射仪(Cu靶,40 kV,250 mA,2θ为30?~90?)分析多孔Ti2448合金的相组成。多孔材料压缩力学性能在Instron-5582型电子万能试验机上进行测量,压缩应变速率为10-4 s-1。弹性模量采用JE-RT自由共振弹性模量仪(Nippon Techno-Plus Co., Ltd.)测量,样品尺寸为60 mm×10 mm×2 mm。板状样品测量公式如下:

(1)

(1)

式中:fR为动态频率,Hz;T为试样的厚度;L为试样的长度,mm;E为试样的弹性模量,GPa;ρ为试样的密度,g/cm3。

2 结果与讨论

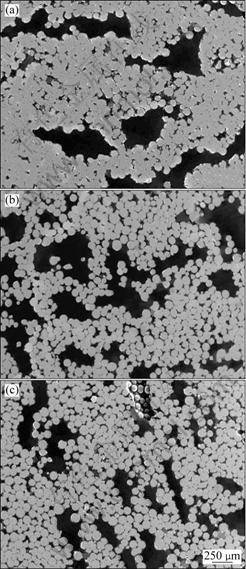

图3所示为采用添加PMMA的造孔剂法制备的大块多孔Ti2448合金的典型宏观照片,图4所示为多孔Ti2448合金的SEM像。造孔剂法制备的多孔钛合金中存在2类孔隙,一类是造孔剂生成的宏观大孔即生成孔,一类是烧结过程中粉末颗粒间形成的间隙小孔。由于实验中选用的造孔剂粒径远大于Ti2448合金粉末的尺寸,故生成孔的等效直径要比间隙孔的大得多。对于多孔Ti2448合金的平均孔径,以生成孔的贡献为主的。由图3和图4可见,随着造孔剂尺寸的增加,即造孔剂粒径的减小,孔隙尺寸明显减小。由于

图3 添加不同尺寸造孔剂(PMMA)制备的多孔Ti2448合金(1 200 ℃/4 h)的宏观照片

Fig.3 Photos of porous Ti2448 alloy prepared with various sizes of PMMA: (a) 250-500 μm; (b) 212-250 μm; (c) 150-212 μm

图4 添加不同尺寸造孔剂(PMMA)制备的多孔Ti2448合金(1 200 ℃/4 h)的SEM像

Fig.4 SEM images of porous Ti2448 alloy prepared with various sizes of PMMA: (a) 250-500 μm; (b) 212-250 μm; (c) 150-212 μm

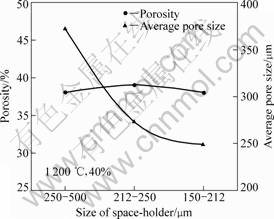

所选用造孔剂已通过球磨的方法处理,其形状不规则,故生成孔大多也为不规则形状。3组多孔样品中,由于冷轧形变量、造孔剂含量和烧结温度都相同,其生坯孔隙率和烧结的收缩程度都相近,故所得多孔材料的孔隙率差别不大,对应的孔隙率依次为38%,39%和38%(见图5)。多孔Ti2448 合金的平均孔径随造孔剂尺寸的减小很明显,依次为372,273和249 μm(见图5),这和形貌照片(见图4)观察到的一致。

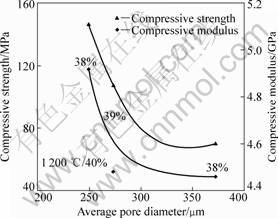

对于多孔钛合金而言,通常用压缩强度和压缩模量来表征其力学性能。由图6可知,压缩强度随着多

图5 造孔剂尺寸与孔隙特征参数的关系

Fig.5 Relationship between size of space-holder and parameter of porous Ti2448 alloy

图6 不同孔隙特征的多孔Ti2448合金的压缩强度

Fig.6 Compressive properties of porous Ti2448 alloy varied with pore characteristics

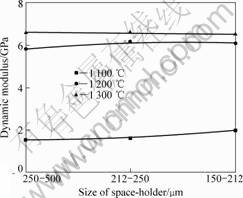

孔Ti2448合金的平均孔径增大而减小,即从146.1 MPa减至70 MPa。弹性模量随着孔径的增加与压缩模量的变化趋势大致相同,依次为4.92,4.48和4.46 GPa。究其原因,孔隙对于材料本身来说是个缺陷,对多孔Ti2448合金的性能影响很大,随着孔径增加,缺陷尺寸增大,多孔材料的强度和刚度降低。人体皮质骨的弹性模量为2.3~20.0 GPa,压缩强度为20~193 MPa[9],故该条件下制备的多孔Ti2448合金与人体皮质骨基本匹配,适用于制备人体植入物。由于受制备条件的限制,多孔钛合金的弹性模量通常采用静态法测得。静态法(拉伸法、压缩法)的相对误差较大,不能准确反映材料内部的性质。加载速度和样品的加工都会很大程度的影响弹性模量。而动态法(共振法)测量时施加应力(应变)很小,加载时间极短,而且频率很高,试样来不及与周围进行热交换,几乎在绝热下测量,其测量的相对误差为0.2%~0.5%,要比静态法测得的结果更接近真实值,更能准确反映材料在微小形变时的物理性质。本研究可以制备大块多孔Ti2448合金,故也通过动态法测定了其弹性模量(见图7)。由图7可知,在同一烧结温度下,随着造孔剂粒径的减小,弹性模量变化不大,略有增加。造孔剂粒径相同时,动态弹性模量随着烧结温度的升高而增大,为1.54~6.61 GPa。这些变化趋势和压缩模量的变化趋势(图6)基本一致,但动态模量比压缩模量略高。对比1200 ℃制备的样品的静态压缩模量和动态模量后发现,当孔径分别为250~500,212~250,150~212 μm时,动态模量比压缩模量分别大30.5%,37.9%和23.8%,压缩弹性模量的误差较大,这与理论相符合。

图7 多孔Ti2448合金的动态弹性模量变化曲线

Fig.7 Dynamic elastic modulus of porous Ti2448 alloy

3 结论

1) 采用造孔剂法制备了孔隙率为35%~43%,平均孔径为244~372 μm,压缩强度为21~260 MPa,动态弹性模量为1.54~6.66 GPa的多孔生物医用Ti2448合金,适用于制备人体植入物。

2) 多孔Ti2448合金的生成孔对孔隙特征参数起重要影响,随着造孔剂PMMA的粒径增加,平均孔径增大,压缩强度和弹性模量则降低,而孔隙率主要由造孔剂的含量决定。

3) 动态模量高于静态压缩模量,其与多孔材料的真实弹性模量更接近。

REFERENCES

[1] LONG M, RACK H J. Titanium alloys in total joint replacement: A materials science perspective[J]. Biomaterials, 1998, 19(18): 1621-1639.

[2] NIINOMI M. Recent metallic materials for biomedical applications[J]. Metallurgical and Materials Transactions A, 2002, 33(3): 477-486.

[3] HAO Y L, LI S J, SUN S S, ZHENG C Y, HU Q M, YANG R. Super-elastic titanium alloy with unstable plastic deformation[J]. Applied Physics Letters, 2005, 87(9): 091916-1-3.

[4] HAO Y L, LI S J, SUN S S, ZHENG CY, YANG R. Elastic deformation behaviour of Ti-24Nb-4Zr-7.9Sn for biomedical applications[J]. Acta Biomaterialia, 2007, 3(2): 277-286.

[5] LI J P, LI S H, GROOT K D. Preparation and characterization of porous titanium[J]. Key Engineering Materials, 2002, 218/220: 51-54.

[6] PILLIAR, R. Porous-surfaced metallic implants for orthopedic applications[J]. Journal of Biomedical Materials Research, 1987, 21(1): 1-33.

[7] LI J P, JOOST R W, CLEMENS A B, KLAAS G. Porous Ti6Al4V scaffold directly fabricating by rapid prototyping: Preparation and in vitro experiment[J]. Biomaterials, 2006, 27(8): 1223-1235.

[8] GERLING R, CLEMENS H, SCHIMANSKY F R. Powder metallurgical processing of intermetallic gamma titanium aluminides[J]. Advanced Engineering Materials, 2004, 6(1/2): 23-28.

[9] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties[M]. 2nd ed. Cambridge: Cambridge University Press, 1997: 176.

(编辑 赵 俊)

基金项目:国家自然科学基金资助项目(50631030,50901080);辽宁省自然科学基金资助项目(20092075)

通信作者:郝玉琳;电话:024-83978841;E-mail:ylhao@imr.ac.cn