文章编号:1004-0609(2014)11-2784-05

690合金在含Pb高温高压水中的腐蚀产物膜

李成涛1,费克勋1,宋利君1,任 爱1,李晓刚2

(1. 苏州热工研究院 寿命管理技术中心,苏州 215004;

2. 北京科技大学 新材料技术研究院,北京 100083)

摘 要:将690合金样品在高压釜内进行4400 h含高温高压水腐蚀试验,采用扫描电子显微镜(SEM)、X射线衍射分析(XRD)、俄歇电子能谱(AES)和拉曼光谱(Raman)等研究690合金在含Pb高温高压水中形成的腐蚀产物膜,研究690合金在含Pb溶液中腐蚀产物膜的生长规模。结果表明:690合金在晶界处腐蚀较快,腐蚀形貌呈晶格网状;腐蚀产物膜中含有Pb,呈外层富镍内层富铬的双层结构;腐蚀产物膜主要由Cr2O3、NiFe2O4、NiO等氧化物和Ni2Cr相组成;Pb掺杂于腐蚀产物膜,降低了腐蚀产物膜的保护性,增加了690合金的腐蚀速度。

关键词:690合金;高温高压;铅;腐蚀产物膜

中图分类号:TG172 文献标志码:A

Corrosion production film of alloy 690 in high temperature and high pressure water containing Pb

LI Cheng-tao1, FEI Ke-xun1, SONG Li-jun1, REN Ai1, LI Xiao-gang2

(1. Life Management Technology Center, Suzhou Nuclear Power Research Institute, Suzhou 215004, China;

2. Advanced Material and Technology Institute, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Alloy 690 were put in autoclave to carry out corrosion test in high temperature and high pressure water containing Pb for 4400 h to study the corrosion film growth rule of alloy 690 in the solution containing Pb. The corrosion production film of alloy 690 in high temperature and high pressure water containing Pb was investigated by SEM, XRD, AES and Raman technique. The results show that the corrosion morphology is grain grid for the high corrosion rate of grain boundaries. The corrosion production film is the double layer, the outer layer is rich in Ni and the inner layer is rich in Cr. The corrosion production film is consisted of Cr2O3, NiFe2O4, NiO and other oxides. The new phase of Ni2Cr is found in the passive film formed in Pb-containing solution. Pb in the surface corrosion product leads to the decrease of protectiveness of the passive film and increase of stress corrosion sensitivity.

Key words: alloy 690; high temperature; high pressure; lead; corrosion production film

核电作为一种极具潜力的清洁能源,近年来在我国得到了快速发展。目前,国内核电站大多为压水堆核电站,并且未来建造的核电站也以安全性更高的三代压水堆核电站为主。蒸汽发生器作为连接压水堆核电站一回路和二回路关键设备,其主要结构部件传热管多采用690合金。690合金不仅在氢氧化钠溶液中具有比Inconel 600、Incoloy 800、304L不锈钢更优异的抗应力腐蚀开裂能力,还具有较高的强度、良好的冶金稳定性和优良的加工特性[1]。

核电站运行经验表明:蒸汽发生器传热管的失效形式主要是应力腐蚀开裂,而Pb在传热管失效的原因中具有重要作用。1987年,St.Lucie核电站传热管应力腐蚀开裂失效和1992年Doel核电站的传热管失效,都被认为是蒸汽发生器中的铅导致的。研究发现,Pb可以显著降低应力腐蚀的门槛值,极少量的Pb就可以造成Pb致应力腐蚀[2]。透射电镜对裂纹尖端进行分析发现,裂纹路径上有Pb存在[3-4]。Pb是蒸汽发生器二回路的重要污染元素,来源主要有化学原料和系统材料。Pb在二回路腐蚀产物堆积区的含量通常会达到1×10-4~1×10-3。应力腐蚀开裂等局部腐蚀的发生往往是由于金属表面形成腐蚀产物膜的不均匀性造成的,因此,腐蚀产物膜是影响镍基合金等耐蚀材料应力腐蚀敏感性的重要因素[5-7]。国内外研究者对690合金在含Pb环境中的腐蚀产物膜进行了较为深入的研究[8-10],但对Pb在腐蚀产物生长中的作用仍然未形成统一的认识。随着我国核电站运行时间的延长,690合金传热管发生失效的几率越来越高,研究Pb对690合金在高温高压环境中腐蚀产物膜的影响,对确保蒸汽发生器传热管的安全可靠运行具有重要意义。

因此,本文作者通过690合金在Pb的高温高压核电模拟环境下的浸泡腐蚀实验,利用SEM、EDS、XRD、AES和Raman等分析手段研究690合金在含Pb高温高压水环境中的腐蚀产物膜,探讨Pb对690合金腐蚀行为的影响。

1 实验

实验材料为壁厚1.09 mm,外径19.05 mm的690合金管,化学成分(质量分数,%)C 0.023、Si 0.07、Mn 0.23、P 0.006、S 0.002、N 0.020、Cr 30.39、Fe 8.88、Ni余量。实验设备为体积5L的镍基合金高压釜,试验溶液以纯水和分析纯黄色PbO配制,Pb浓度为1 g/L,实验温度为320 ℃,时间为4400 h,压力为10 MPa。线切割截取10 mm长690合金管,利用水砂纸将切割面逐级打磨至2000号,表面抛光,用丙酮清洗干净,吹干待用。将试样放入试验釜中,充5 MPa氮气至高压釜,待稳定5 min后放气,重复3次。第三次放气至1 MPa,关闭阀门,升温到104 ℃时,打开放气阀,冷凝放气,保证溶液中的含氧量小于0.2 mg/kg。待实验结束后,取出试样,冷风吹干,然后采用SEM、XRD、AES和Raman等物理分析方法对表面腐蚀产物膜进行表征。

2 结果与讨论

2.1 腐蚀产物膜的SEM和能谱分析

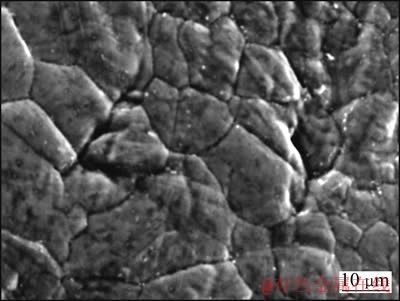

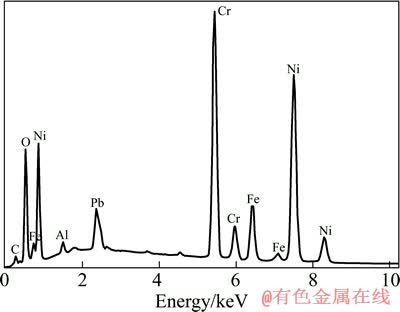

图1所示为690合金试样在含Pb高温高压水环境中浸泡4400 h后的SEM像。由于晶界处腐蚀和晶粒内腐蚀不同造成晶界处腐蚀明显,呈晶格网状[11]。690合金作为一种耐蚀性能非常好的镍基合金,高温高压水能够形成对基体保护作用优异的钝化膜,溶液中O元素与金属的扩散是反应的控制步骤,晶界扩散比晶粒扩散相对容易得多,导致晶界处腐蚀氧化较为严重,从而形成晶格网状的腐蚀形貌。腐蚀产物膜表面还分布着一些白色颗粒,这可能是NiO和Ni(OH)2[12]。图2所示为表面腐蚀产物的能谱分析结果。结果表明:腐蚀产物主要由Fe、Ni和Cr的氧化物组成。此外,还可以发现腐蚀产物膜中有Pb存在,这说明PbO参与反应,并保留在腐蚀产物中。

图1 690合金在含Pb高温高压水中浸泡后的SEM像

Fig. 1 SEM image of alloy 690 surface after immersion in high temperature and high pressure water containing Pb

图2 690合金在含Pb高温高压水中腐蚀产物膜的EDS谱

Fig. 2 EDS spectrum of corrosion product film of alloy 690 in high temperature and high pressure water containing Pb

2.2 腐蚀产物膜的截面分析

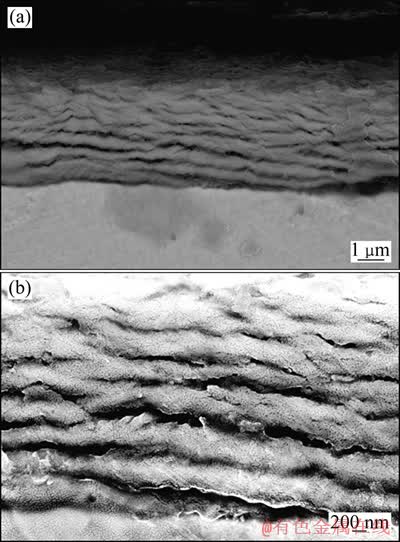

图3所示为690合金在含Pb高温高压水中腐蚀产物膜的截面形貌。腐蚀产物膜厚度约为4 μm,呈明显的分层现象,且腐蚀产物膜金属与基体出现分离。这是由于690合金在含Pb溶液中腐蚀速率较快,所形成的腐蚀产物膜与基体因膨胀系数相差较大,当形成一定厚度后因应力较大,而与基体分离,此时,水会直接到达金属基体与之反应生成新的氧化膜。循环往复,就形成690合金在含Pb高温高压水中的多层腐蚀产物膜。研究表明:690合金在高温高压纯水的形成腐蚀产物膜与金属基体结合紧密[13]。相比而言,690合金在含Pb高温高压水中形成的腐蚀产物膜与基体的结合差,对基体的保护性差,因此,Pb的存在降低了表面腐蚀产物膜与金属基体的结合强度。

图3 690合金在含Pb高温高压水中浸泡后的截面形貌

Fig. 3 Cross-section morphologies of alloy 690 after immersion in high temperature and high pressure water containing Pb

2.3 腐蚀产物膜的AES分析

图4所示为690合金在含Pb高温高压水中腐蚀产物膜的AES分析结果。由图4可以看出,钝化膜分成两层,最外层镍含量较高,内层镍含量较低,铬含量较高。690合金在实验环境下最先生成Cr(OH)3,随后转变成Cr2O3,生成的Cr2O3腐蚀层会阻碍Cr的扩散;而Fe和Ni的扩散比较容易,Fe转变生成Fe2O3,Ni转变生成NiO,并且Fe扩散析出与NiO反应生成NiFe2O4,因此,外表面最易生成Fe和Ni的化合物。NiO极易与内层的Cr2O3发生反应生成NiCr2O4,此尖晶石氧化物构成的钝化膜可以作为一个很好的屏障,有效降低离子的传输速率,抑制金属元素发生进一步的阳极溶解[8]。当溶液中含Pb时,Cr2O3生成加快。能谱结果表明:膜中存有Pb,Pb的存在增大了腐蚀产物膜的电导率,且腐蚀产物膜与基体结合较差,使得膜的隔绝作用降低,基体的腐蚀速率很高,因此,690合金在含Pb高温高压水中的腐蚀速率较快,形成较厚的腐蚀产物膜。

图4 690合金在含Pb高温高压水中腐蚀产物膜的AES分析结果

Fig. 4 AES analysis results of corrosion product film of alloy 690 in high temperature and high pressure water containing Pb

2.4 腐蚀产物膜的XRD分析

图5 690合金在含Pb高温高压水中腐蚀产物膜的XRD分析结果

Fig. 5 XRD analysis results of corrosion product film of alloy 690 in high temperature and high pressure water containing Pb

图5所示为690合金在含Pb高温高压水溶液中腐蚀表面膜的XRD分析结果。根据不同的峰强,并对照PDF卡片,可以得出,690合金在长时间的高温高压二回路水环境中表面形成的腐蚀产物主要由NiFe2O4、(Fe、Ni)Cr2O4、NiO、Ni(OH)2、Cr2O3等物质组成,这与已有的研究结果相一致[5,14]。在690合金基体峰右侧出现了新峰,通过比对可以知道,出现的相为Ni2Cr相。由Ni-Cr合金的二元相图可以发现,当温度为300 ℃时,有Ni2Cr新相生成。说明690合金在实验温度下生成Ni2Cr新相,但是此生成相尺寸较小,一般为纳米级。含Pb溶液出现了此新相的原因,应该与Pb离子的存在加快了金属离子的脱溶过程,从而在靠近生成氧化物的区域形成富Ni区,这使得Ni2Cr相生成更容易。表面处生成的Ni2Cr相对690合金力学性能等方面影响较大,可以为应力腐蚀的发生提供更有利的条件。

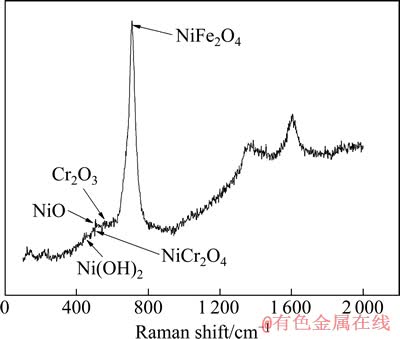

2.5 腐蚀产物膜的Raman分析

图6所示为690合金在含Pb高温高压水中腐蚀产物的激光拉曼谱。由图6可以看出,705、655、592、570、488和457 cm-1处是NiFe2O4的特征峰值,609、551、530、397、357和303 cm-1处是Cr2O3的特征峰值,516、449、376和314 cm-1处是β-Ni(OH)2的特征峰值,685、616、585、554、514和430 cm-1处是NiCr2O4的特征峰值[15-16]。此外,该谱线还含有很少量的对应峰值525和497 cm-1的NiO。拉曼谱显示:NiFe2O4的特征峰值最为明显,说明钝化膜中最主要的成分是NiFe2O4。

图6 690合金在含Pb高温高压水中腐蚀产物膜的Raman分析结果

Fig. 6 Raman analysis results of corrosion product film of alloy 690 in high temperature and high pressure water containing Pb

3 结论

1) Pb的加入导致晶界腐蚀与晶内腐蚀差异增大,690合金表面的晶格网状腐蚀形貌明显。腐蚀产物膜中有Pb存在,并且呈多层分布,腐蚀产物膜外层富Ni,内层富Cr。

2) 腐蚀产物膜由Ni、Cr和Fe的氧化物组成,主要有NiFe2O4、Cr2O3、NiO、Ni(OH)2和NiCr2O4等相,析出相中含Ni2Cr。

3) 由于Pb存在使得Cr2O3生成加快,并掺杂在腐蚀产物膜中,达到一定厚度后从表面剥离,该过程重复进行形成多层结构,对基体的保护性较差,使腐蚀始终保持较快速率。

REFERENCES

[1] ANGELIU T M, WAS G S, Behavior of grain boundary chemistry and precipitates upon thermal treatment of controlled purity alloy 690[J]. Metallurgical Transactions A, 1990, 21(8): 2097-2107.

[2] KIM S W, KIM H P. Electrochemical noise analysis of PbSCC of Alloy 600 SG tube in caustic environments at high temperature[J]. Corrosion Science, 2009, 51(1): 191-196.

[3] STAEHLE R W. Clues and issues in the SCC of high nickel alloys associated with dissolved lead[C]//Proceeding of 12th International Conference on Environmental Degradation of Materials in Nuclear Power System-Water Reactors, 2005: 1163-1210.

[4] 孟凡江, 王俭秋, 韩恩厚, 庄子哲雄, 柯 伟, 690TT合金划痕微观组织及划伤诱发的应力腐蚀[J]. 金属学报, 2011, 47(7): 839-846.

MENG Fan-jiang, WANG Jian-qiu, HAN En-hou, SHOI Testuo, KE Wei. Microstructure near scratch on alloy 690TT and stress corrosion induced by scratching[J]. Acta Metallurgica Sinica, 2011, 47(7): 839-946.

[5] HUANG J B, WU X Q, HAN E H. Electrochemical properties and growth mechanism of passive films on alloy 690 in high-temperature alkaline environments[J]. Corrosion Science, 2010, 52 (10): 3444-3452.

[6] LU B T, LUO J L, LU Y C. Correlation between film rupture ductility and PbSCC of Alloy 800[J]. Electrochim Acta, 2008, 53 (12): 4122-4136.

[7] KIM D J, KWON H C, KIM H W, HWANG S S, KIM H P. Oxide properties and stress corrosion cracking behaviour for alloy 600 in leaded caustic solutions at high temperature[J]. Corrosion Science, 2011, 53(4): 1247-1253.

[8] AHN S J, RAO V S, KON H S, KIM U C. Effects of PbO on the repassivation kinetics of alloy 690[J]. Corrosion Science, 2006, 48(5): 1137-1153.

[9] PENG B, LU B T, LUO J L, MA H H. Investigation of passive films on nickel alloy 690 in lead-containing environments[J]. Journal of Nuclear Materials, 2008, 378(3): 333-340.

[10] 刘飞华, 李成涛, 张 新, 李 岩, 任 爱. 690 合金的Pb 致应力腐蚀行为[J]. 北京科技大学学报, 2013, 35(8): 1034-1039.

LIU Fei-hua, LI Cheng-tao, ZHANG Xin, LI Yan, REN Ai. Lead-induced stress corrosion behavior of alloy 690[J]. Journal of University of Science and Technology Beijing, 2013, 35(8): 1034-1039.

[11] SUN M C, WU X Q, ZHANG Z E, HAN E H. Analyses of oxide films grown on alloy 625 in oxidizing supercritical water[J]. The Journal of Supercritical Fluids, 2008, 47(2): 309-317.

[12] HUANG J B, WU X Q, HAN E H. Influence of pH on electrochemical properties of passive films formed on alloy 690 in high aqueous environments[J]. Corrosion Science, 2009, 51: 2976-2982.

[13] 任 爱, 李成涛, 刘飞华, 李 岩, 李晓刚. Cl-对690合金在高温高压水中腐蚀行为的影响[J]. 中国有色金属学报, 2012, 22(4): 1082-1087.

REN Ai, LI Cheng-tao, LIU Fei-hua, LI Yan, LI Xiao-gang. Effect of Cl- on corrosion behavior of alloy 690 in high temperature and high pressure water solution[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(4): 1082-1087.

[14] BOJINOV M, GALTAYRIES A, KINNUNEN P, MACHET A, MARCUS P. Estimation of parameters of oxide film growth on nickel-based alloys in high-temperature water electrolytes[J]. Electrochimica Acta, 2007, 52: 7475-7483.

[15] OBLONSKY L J, DEVINE T M. A surface enhanced Raman spectroscopic study of the passive films formed in borate buffer on iron, nickel, chromium and stainless steel[J]. Corrosion Science, 1995, 37(1): 17-41.

[16] KIM J H, HWANG I S. Development of an in situ Raman spectroscopic system for surface oxide films on metals and alloys in high temperature water[J]. Nuclear Engineering and Design, 2005, 235(9): 1029-1040.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(钢铁联合研究基金)(U1260201)

收稿日期:2014-03-10;修订日期:2014-08-06

通信作者:李成涛,高级工程师,博士;电话:0512-68601473;E-mail:lct1980@163.com