Enhancement of ductility in high strength Mg-Gd-Y-Zr alloy

来源期刊:中国有色金属学报(英文版)2011年第4期

论文作者:高磊 陈荣石 韩恩厚

文章页码:863 - 868

关键词:Mg-Gd-Y合金; 塑性; 多向锻造;组织; 动态析出

Key words:Mg-Gd-Y alloy; ductility; multiaxial forging; microstructure; dynamic precipitate

摘 要:采用多向锻造及人工时效制备高强度高塑性GW94合金。该合金具有完全再结晶组织和亚微米级超细等轴晶,其抗拉强度、屈服强度及伸长率分别为377 MPa,295 MPa和21.7%。与传统挤压工艺相比,多向锻造显著提高材料的塑性。在573 K下拉伸时,该合金表现出超塑性,其最大伸长率为450%。GW94合金的高强度和高塑性是由完全再结晶晶粒和在晶界处动态析出Mg5(Gd,Y) 纳米颗粒的共同作用。

Abstract: A high strength GW94 alloy with fully recrystallized microstructure and equiaxed ultrafine grains of submicron size was produced by multiaxial forging and ageing. The alloy exhibits an ultimate tensile strength of 377 MPa, proof stress of 295 MPa and elongation to failure of 21.7%. The ductility is improved in comparison with that of the conventional extrusion processing. Superplastic ductility is achieved in tensile testing at 573 K with a maximum elongation of 450%. These high ductility and high strength are attributed to the coexistence of fully recrystallized grains and nanoscale Mg5(Gd, Y) particles dynamically precipitated at grain boundaries.

GAO Lei1, 2, CHEN Rong-shi1, HAN En-hou1

1. State Key Laboratory for Corrosion and Protection, Institute of Metal Research,

Chinese Academy of Sciences, Shenyang 110016, China;

2. Graduate School of the Chinese Academy of Sciences, Beijing 100039, China

Received 23 September 2010; accepted 25 December 2010

Abstract: A high strength GW94 alloy with fully recrystallized microstructure and equiaxed ultrafine grains of submicron size was produced by multiaxial forging and ageing. The alloy exhibits an ultimate tensile strength of 377 MPa, proof stress of 295 MPa and elongation to failure of 21.7%. The ductility is improved in comparison with that of the conventional extrusion processing. Superplastic ductility is achieved in tensile testing at 573 K with a maximum elongation of 450%. These high ductility and high strength are attributed to the coexistence of fully recrystallized grains and nanoscale Mg5(Gd, Y) particles dynamically precipitated at grain boundaries.

Key words: Mg-Gd-Y alloy; ductility; multiaxial forging; microstructure; dynamic precipitate

1 Introduction

There is increasing scientific and industrial interest in the development of bulk ultrafine-grained (UFG) alloys produced by severe plastic deformation (SPD)[1-2]. A good combination of high strength and high ductility can be achieved in UFG metals[1-3]. They also exhibit superplastic properties at elevated temperatures[4]. Many novel approaches are often used to obtain UFG materials, including equal channel angular pressing (ECAP)[5-6], high-pressure torsion (HPT)[7], accumulative roll bonding (ARB)[8] and multiaxial forging (MAF)[9-10], etc. Metals processed by MAF are free forged repeatedly in three orthogonal directions, sequentially[2].

Recently, the Mg-Gd-Y system alloys have been extensively studied by a number of researchers[11-12], because they exhibit high tensile strength and excellent creep resistance at a temperature up to 250 °C, which makes them promising for applications in aerospace, aircraft and automotive industries. However, these types of Mg alloys also suffer from the challenge in meeting the requirements of ductility[12-13]. On the other hand, it is well established in recent work that the ductility of metallic alloys may be significantly enhanced, often to a superplastic range, by processing the alloys through the introduction of SPD[14-15]. However, to our knowledge, little work has been performed on the SPD of the Mg-Gd-Y system alloys.

Therefore, MAF was applied in the present study to a heat resistant GW94 alloy[16] in order to improve both the strength and ductility of magnesium alloy. Relationships between the microstructures and the corresponding mechanical properties were investigated.

2 Experimental

The material used in the present study was GW94 alloy rod (Mg-8.57Gd-3.72Y-0.54Zr, mass fraction, %) with a diameter of 29 mm prepared by hot extrusion. Columnar samples were machined parallelly to the extrusion direction from the as-extruded rod to dimensions of d29 mm × 60 mm. These samples were preheated at 773 K for 10 min, and then deformed to a true strain of about 0.4 between hot anvils with surface temperature of 573 K. Samples were repeatedly deformed up to cumulative strain of about 3.2 with changing loading direction from pass to pass under decreasing temperature conditions from 773 to 573 K. The forged samples were subsequently aged at 498 K for 24 h (T5).

The hardness values were determined by the Vickers hardness test with a load of 50 N. The tensile specimens with gauge length of 5 mm were cut along planes normal to the final compression direction for the forged samples and parallel to the extrusion direction for the extruded samples. Tensile tests were carried out at room temperature and 573 K and at a strain rate of 1×10-3 s-1.

The microstructures of the specimens were observed using optical microscope (OM), scanning electron microscope (SEM) and transmission electron microscope (TEM). The etching solution was 5% nitric acid in ethanol. Compositions of phases were analyzed by energy dispersive X-ray spectrometry (EDS) in the TEM mode. Foils for TEM observations were mechanically polished to a thickness about 0.1 mm, and then thinned to perforation by ion milling. The thinned foils were examined using a FEI TECNAL 20 transmission electron microscope operating at 200 kV and with a double-tilt stage. X-ray diffraction (XRD) was performed with a Rigaku D/max 2400 X-ray diffractometer using Cu Kα radiation.

3 Results and discussion

3.1 Mechanical properties of forged alloy

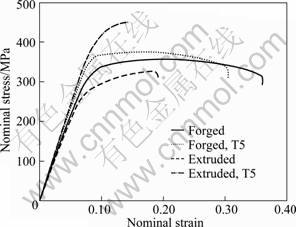

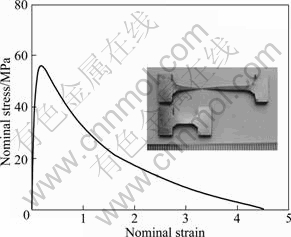

The tensile stress—strain curves of the as-forged and T5-treated GW94 alloy are shown in Fig.1, and the ultimate tensile strength (σb), tensile yield strength (σ0.2) and elongation to failure (δ) of the alloy are summarized in Table 1. Data of the samples before being forged, i.e. the extruded GW94 alloy, are also included for comparison. As listed in Table 1, the strength obtained in the as-forged alloy is comparable of or higher than that in the as-extruded counterpart. The Vickers hardness also indicates a significant increase in hardness after MAF.

Fig.1 Tensile test results of conventionally extruded and forged samples in different conditions

The age-hardening response of the forged alloy is relatively small. A significant increase in strength is obtained in the extruded alloy after ageing. Specifically, the extruded-T5 alloy exhibits the highest strength and the σb and σ0.2 are 441 and 338 MPa, respectively. Unfortunately, it displays a considerable decrease in ductility to 3.5%. This strengthening effect and loss in ductility are believed to be due to the precipitation of β′, phase, as previously demonstrated by TEM observation[16]. It is clear that the forged alloys exhibit tensile elongations higher than 20% which are substantially larger than those of the conventional extruded alloy.

Table 1 Mechanical properties of as-deformed and T5 aged GW94 alloys

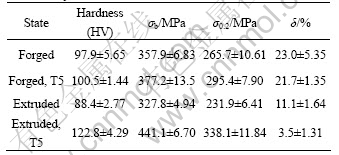

As a matter of fact, further good combination of high strength and high ductility of the forged samples can be obtained under optimized process conditions, as shown in Fig.2. It can be seen that a high strength of more than 411 MPa and a corresponding high elongation of over 16% are obtained simultaneously. Therefore, the optimization of the forging procedures and the corresponding evolution of the microstructure are essentially necessary to be investigated and will be published in another paper.

Fig.2 Tensile mechanical properties of as-forged samples with optimized processing procedures

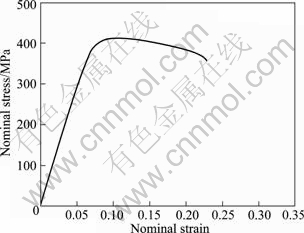

Figure 3 shows the tensile stress—strain curve of the as-forged alloy tested at 573 K with an initial strain rate of 1×10-3 s-1. The inset shows the photo of samples before and after tensile test. It is obvious that superplastic ductility is achieved with a maximum measured elongation of 450%.

Fig.3 Stress—strain curves of as-forged GW94 alloy tested at 573 K. Inset shows specimens before and after tensile tests

3.2 Microstructure of forged alloy

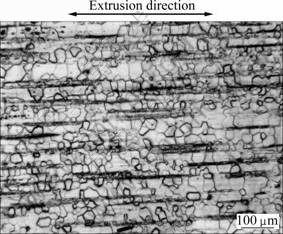

Figure 4 shows the microstructure of the as-extruded alloy[17-18] prior to the forging stage. The microstructure consists of fine equiaxed grains with well-defined grain boundaries, suggesting that dynamic recrystallization took place during the extrusion processing. Some extrusion strips can be observed. The second-phase particles (the black particles in Fig.4) are oriented approximately parallel to the extrusion direction. The average grain size of the as-extruded alloy is about 40 μm.

Fig.4 Optical microstructure of as-extruded GW94 alloy prior to forging stage

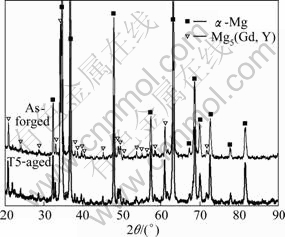

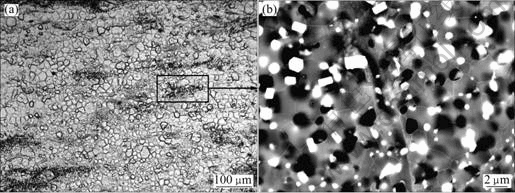

Figure 5(a) shows the optical microstructure of the as-forged sample etched by 5% nitric acid in ethanol. The phases and grain boundaries are illegible. The microstructure without prior acid etching is observed in high-magnification backscattered electron micrograph as shown in Fig.5(b). It can be seen that a high number density of fine particles (the bright particles) uniformly distributed in the matrix. The mean diameter of the particles varies between nanoscale and 1-2 μm. Figure 6 shows the XRD patterns of the forged GW94 alloy in the as-forged and T5-aged conditions. Two phases are identified, namely α-Mg and Mg5(Gd,Y) in which Y probably substitutes for Gd.

Fig.5 Optical (a) and SEM (b) images of as-forged GW94 alloy

Fig.6 XRD patterns of forged GW94 alloy in as-forged and T5-aged conditions

To obtain clear grain boundaries, the forged samples were annealed at 430 °C for 30 min. The resulting microstructure of the annealed sample is shown in Fig.7(a). A homogeneous distribution of equiaxed grains is obtained in most regions. The grains appear fairly equiaxed and do not show elongation in any preferred direction, which appears the result of multiaxial straining characteristic of the MAF process employed in this work. The average grain size in these regions, determined using linear intercept method, is about 2 μm. However, in a few regions, the microstructure is still illegible, as indicated by the rectangle in Fig.7(a). The corresponding magnified SEM image is shown in Fig.7(b). It can be seen that the secondary phase particles are mainly distributed at the grain boundaries.

3.3 Dynamic precipitates at grain boundaries

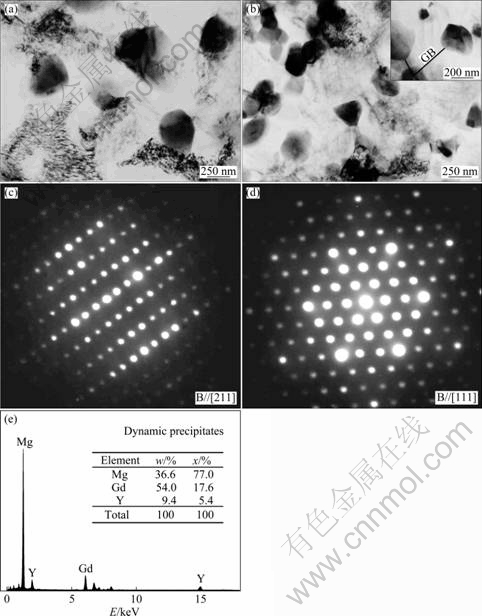

The microstructures of the forged samples were examined by TEM and are shown in Figs.8(a) and (b) in as-forged and T5-aged conditions, respectively. A high density of dislocations can be observed in the as-forged condition due to previous plastic deformation during forging, as shown in Fig.8(a). Inside the grains, the dislocation density is lower and the grain boundaries are associated with high dislocation density. Further ageing leads to the recovery process associated with the absorption of dislocations (Fig.8(b)). The inset in Fig.8(b) shows equiaxed ultrafine grains of submicron size. Some of the grain boundaries are poorly delineated. This suggests that the dynamic recrystallization occurred during MAF.

Fig.7 Optical (a) and SEM (b) images of forged sample annealed at 430 °C for 30 min

Fig.8 Typical TEM bright-field images of forged GW94 alloy in as-forged (a) and T5-aged (b) conditions with corresponding SAED patterns (c, d) and EDS analysis (e) of dynamic precipitates. Inset in (b) shows grain boundaries of magnesium matrix

Similar to the results obtained in SEM images shown in Figs.5(b) and 7(b), TEM images also show the presence of dynamic precipitates at grain boundaries in the MAF processed material. The corresponding selected-area electron diffraction (SAED) patterns of [211] and [111] zone axis are shown in Figs.8(c) and (d), respectively. It is confirmed that the precipitates in the forged samples are mostly the equilibrium β-Mg5(Gd,Y) (space group: F-43m) phase, which is an FCC structured crystal with a=2.23 nm. The table in Fig.8(e) lists the average composition of the dynamic precipitates, as determined by EDS analysis. The fine Mg5(Gd,Y) phases distributed at the grain boundaries and greatly restricted the growth of the dynamic recrystallized (DRXed) grains during the MAF processing, resulting in the remarkable grain refinement.

The dynamically recrystallized grains are fine in the forged samples, regardless of the aging treatment, which may lead to high proof stresses according to the Hall-Petch relationship. Furthermore, the forging process promotes a high density of nanoscale Mg5(Gd,Y) dynamic precipitates at the grain boundaries during processing. These precipitates enhance both the strength and ductility of the alloy through increasing dislocation density and work hardening rate due to the interactions between nanoprecipitates and dislocations[3]. Because of their high thermal stability, Mg5(Gd,Y) precipitates are also believed to stabilize the UFG structure produced by MAF through grain boundary pinning[19-20] and hence contribute to the superplastic ductility at elevated temperature.

3.4 Fractographs

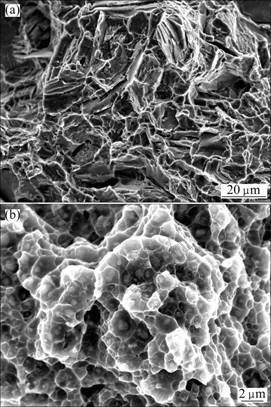

The SEM fractographs of tensile samples of the as-extruded and the as-forged GW94 alloy are shown in Figs.9(a) and (b), respectively. The fracture surface of the as-extruded alloy (Fig.9(a)) is mainly composed of large cleavages. At a few locations (where the broken secondary particles exist), however, a weak dimple pattern is visible. This is consistent with the observed lower ductility value of elongation to failure. The fracture surface of the MAF processed sample was examined and a distinctly different fracture mode compared with that of the as-extruded counterpart is observed. As shown in Fig.9(b), the fracture surface of the as-forged alloy is full of dimples and grain boundaries which can be ascribed to its high ductility of 23%. Furthermore, Mg5(Gd,Y) particles are embedded in the magnesium matrix and are visible at the bottom of the large dimples.

Fig.9 Fractographs of fractured tensile specimens: (a) As-extruded; (b) As-forged

4 Conclusions

1) GW94 alloy with high strength and high ductility could be fabricated by using MAF. The ductility of the forged GW94 alloy is enhanced dramatically over that of conventional extrusion processing. Samples in T5 condition exhibit a high strength of 377 MPa and tensile elongation of 22%. The MAF processed alloy exhibits superplastic behavior at 573 K with a maximum elongation of 450%.

2) The microstructure of the MAF processed alloy consists of equiaxed ultrafine grains in submicron size and dynamic Mg5(Gd,Y) nano precipitates at grain boundaries. The fine secondary phases restrict the dynamic recrystallized grain growth during the MAF processing, resulting in a remarkable grain refinement. The UFG microstructure and the fine dispersion of nanoscale Mg5(Gd,Y) particles are responsible for the high strength and high ductility of this alloy.

References

[1] KIM W J, JEONG H G, JEONG H T. Achieving high strength and high ductility in magnesium alloys using severe plastic deformation combined with low-temperature aging [J]. Scripta Mater, 2009, 61(11): 1040-1043.

[2] PADAP A K, CHAUDHARI G P, NATH S K, PANCHOLI V. Ultrafine-grained steel fabricated using warm multiaxial forging: Microstructure and mechanical properties [J]. Mater Sci Eng A, 2009, 527(1-2): 110-117.

[3] WANG T S, LI Z, ZHANG B, ZHANG X J, DENG J M, ZHANG F C. High tensile ductility and high strength in ultrafine-grained low-carbon steel [J]. Mater Sci Eng A, 2010, 527(10-11): 2798-2801.

[4] DESRAYAUD C, RINGEVAL S, GIRARD S, DRIVER J H. A novel high straining process for bulk materials—The development of a multipass forging system by compression along three axes [J]. J Mater Proc Technol, 2006, 172(1): 152-158.

[5] TONG L B, ZHENG M Y, CHANG H, HUA X S, WU K, XU S W, KAMADO S, KOJIMA Y. Microstructure and mechanical properties of Mg-Zn-Ca alloy processed by equal channel angular pressing [J]. Mater Sci Eng A, 2009, 523(1-2): 289-294.

[6] LI B, JOSHI S, AZEVEDO K, MA E, RAMESH K T, FIGUEIREDO R B, LANGDON T G. Dynamic testing at high strain rates of an ultrafine-grained magnesium alloy processed by ECAP [J]. Mater Sci Eng A, 2009, 517(1-2): 24-29.

[7] KAI M, HORITA Z, LANGDON T G. Developing grain refinement and superplasticity in a magnesium alloy processed by high-pressure torsion [J]. Mater Sci Eng A, 2008, 488: 117-124.

[8] PASEBANI S, TOROGHINEJAD M R. Nano-grained 70/30 brass strip produced by accumulative roll-bonding (ARB) process [J]. Mater Sci Eng A, 2010, 527(3): 491-497.

[9] GUO Q, YAN H G, CHEN Z H, ZHANG H. Grain refinement in as-cast AZ80 Mg alloy under large strain deformation [J]. Mater Charact, 2007, 58(2): 162-167.

[10] YANG X Y, XING J, MIURA H, SAKAI T. Strain-induced grain refinement in magnesium alloy AZ31 during hot forging [J]. Mater Sci Forum, 2006, 503-504: 521-526.

[11] HONMA T, OHKUBO T, HONO K, KAMADO S. Chemistry of nanoscale precipitates in Mg-2.1Gd-0.6Y-0.2Zr (at.%) alloy investigated by the atom probe technique [J]. Mater Sci Eng A, 2005, 395(1-2): 301-306.

[12] HE S M, ZENG X Q, PENG L M, GAO X, NIE J F, DING W J. Microstructure and strengthening mechanism of high strength Mg-10Gd-2Y-0.5Zr alloy [J]. J Alloys Compd, 2007, 427(1-2): 316-323.

[13] WANG J, MENG J, ZHANG D P, TANG D X. Effect of Y for enhanced age hardening response and mechanical properties of Mg-Gd-Y-Zr alloys [J]. Mater Sci Eng A, 2007, 456(1-2): 78-84.

[14] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nanostructured materials from severe plastic deformation [J]. Progress in Material Science, 2000, 45(2): 103-189.

[15] MATSUBARA K, MIYAHARA Y, HORITA Z, LANGDON T G. Achieving enhanced ductility in a dilute magnesium alloy through severe plastic deformation [J]. Metall Mater Trans A, 2004, 35(6): 1735-1744.

[16] GAO L, CHEN R S, HAN E H. Microstructure and strengthening mechanisms of a cast Mg-1.48Gd-1.13Y-0.16Zr (at.%) alloy [J]. J Mater Sci, 2009, 44(16): 4443-4454.

[17] GAO L, LIANG S M, CHEN R S, HAN E H. Microstructure evolution during reheating of extruded Mg-Gd-Y-Zr alloy into semisolid state [J]. Transactions of Nonferrous Metal Society of China, 2010, 20(9): 1585-1590.

[18] GAO L, CHEN R S, HAN E H. Thixoformability of Mg-Gd-Y magnesium alloy and its mechanical properties [J]. Mater Sci Technol, doi: 10.1179/026708309X12578491814834,

[19] TELLKAMP V L, MELMED A, LAVERNIA E J. Mechanical behavior and microstructure of a thermally stable bulk nanostructured Al alloy [J]. Metall Mater Trans A, 2001, 32(9): 2335-2343.

[20] CAO B, JOSHI S P, RAMESH K T. Strengthening mechanisms in cryomilled ultrafine-grained aluminum alloy at quasi-static and dynamic rates of loading [J]. Scripta Mater, 2009, 60(8): 619-622.

高 磊1, 2, 陈荣石1, 韩恩厚1

1. 中国科学院 金属研究所 金属腐蚀与防护国家重点实验室, 沈阳 110016;

2. 中国科学院研究生院, 北京 100039

摘 要:采用多向锻造及人工时效制备高强度高塑性GW94合金。该合金具有完全再结晶组织和亚微米级超细等轴晶,其抗拉强度、屈服强度及伸长率分别为377 MPa,295 MPa和21.7%。与传统挤压工艺相比,多向锻造显著提高材料的塑性。在573 K下拉伸时,该合金表现出超塑性,其最大伸长率为450%。GW94合金的高强度和高塑性是由完全再结晶晶粒和在晶界处动态析出Mg5(Gd,Y) 纳米颗粒的共同作用。

关键词:Mg-Gd-Y合金; 塑性; 多向锻造;组织; 动态析出

(Edited by FANG Jing-hua)

Foundation item: Project (2007CB613704) supported by the National Basic Research Program of China

Corresponding author: CHEN Rong-shi; Tel: +86-24-23926646; Fax: +86-24-23894149; E-mail: rongshichen@yahoo.com

DOI: 10.1016/S1003-6326(11)60794-2