预烧温度对用共沉淀法制备的高导锰锌铁氧体

微结构和磁性能的影响

陈带军,胡振光,彭长宏,程晓苏,李景芬,黄虹

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘 要:采用化学共沉淀法由锰锌铁氧体废料制备高导锰锌铁氧体,用X线衍射(XRD)、扫描电镜(SEM)和比表面分析(BET)等表征手段,分析预烧温度对样品微观结构及磁性能的影响。研究结果表明:随着预烧温度的升高,粉料比表面积减小,晶粒逐渐变大,晶形趋于完整;样环的初始磁导率随着预烧温度的升高先增大后减小;共沉淀粉料的最佳预烧温度为850 ℃,此时预烧粉晶形完整,颗粒粒径均匀一致,预烧样品经过气氛烧结后,可获得初始磁导率μi为13 000的铁氧体。

关键词:预烧温度;共沉淀法;锰锌铁氧体;微结构;磁性能

中图分类号:TM271 文献标志码:A 文章编号:1672-7207(2011)01-0017-05

Effects of presintering temperature on microstructure and magnetic properties of high permeability MnZn ferrites prepared by co-precipitation technology

CHEN Dai-jun, HU Zhen-guang, PENG Chang-hong, CHENG Xiao-su, LI Jing-fen, HUANG Hong

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: High permeability Mn-Zn ferrites were prepared from waste Mn-Zn ferrites by co-precipitation technology. The effects of presintering temperature on the sample’s microstructure and magnetic properties were studied using XRD, SEM and BET as characterization method. The results show that with increase of the presintering temperature, the surface area of the powders reduces, the grains gradually become larger and the crystal structure tends to complete. The initial permeability of the ring increases at first then decreases as the presintering temperature increases. The optimal presintering temperature of the co-precipitation powders is 850 ℃, at this point the presintering powders have complete crystal structure and the particle size is uniform. The high permeability μi over 13 000 ferrites are obtained through atmosphere-control sintering.

Key words: presintering temperature; co-precipitation technology; Mn-Zn ferrite; microstructure; magnetic property

锰锌铁氧体材料是现代电子工业及信息产业的基础功能材料。我国锰锌铁氧体的产量为20~30万t/a,约占世界总产量的50%。在锰锌铁氧体产品的制备和加工过程中,产生10%~20%的废器件或抛光废料[1],易造成严重的环境污染和经济损失。实现锰锌铁氧体废料的资源化利用,具有重大经济价值和环保意义。目前,利用矿物原料或工业废渣直接制取铁氧体材料的研究已取得显著进展[2-9]。在前人工作的基础上,彭 长宏等[8-11]采用化学共沉淀法由锰锌软磁废料制备出高导锰锌软磁铁氧体,实现了磁材行业“原材料—产品—废弃物—原材料”的闭路循环。氧化物法制备锰锌铁氧体材料的过程中,预烧温度对铁氧体性能的影响很大[10-11],对湿法制备锰锌铁氧体材料工艺中也有重要影响。预烧温度过低,粉料之间的固相速度很慢,以至很少或根本没有铁氧体形成;预烧温度升高,粉料间的固相反应速度增大,形成的铁氧体含量增大;若预烧温度过高,则会因离解作用失去氧离子,或者某些金属成分挥发,造成组成变动。在此,本文作者就预烧温度对化学共沉淀法制备高导MnZn铁氧体微结构和磁性能的影响开展研究,并确定适宜的预烧温度。

1 实验

1.1 样品的制备

实验采用由锰锌软磁废料制备的锰锌铁氧体前驱体粉料为原料,其铁、锰、锌物质的量比基本符合广东风华高磁导率锰锌铁氧体理论配方,n(铁)?n(锰)?n(锌)=0.682 9?0.165 7?0.151 4。分别在温度为550~950 ℃预烧,每隔50 ℃做1个样品,保温时间为2.0 h。预烧完成后选用合适温度的预烧料,不掺杂,直接进行二次球磨,烘干后加入质量分数为10%的PVA 造粒,并压制成标准样环,然后在1 300 ℃下控制气氛及升温速率烧结,制成烧结样环。

1.2 表征方法

以预烧粉料的烧失率表征预烧温度对粉料质量的影响。用3H-2000(Ⅲ)型比表面测定仪分析粉料比表面积。以S-530扫描电子显微镜(SEM)图像表征不同预烧温度对铁氧体晶体形貌的影响。用Philip s X’Pert Pro MPD X线衍射(XRD)图谱以及半定量分析结果表征不同预烧温度对铁氧体晶体形成的影响。用LCR电桥测量仪测试样环的初始磁导率。

2 预烧过程基本原理

锰锌铁氧体共沉粉料在105 ℃烘干后的主要组成为FeCO3,MnCO3和ZnCO3 3种碳酸盐,以及少量的Fe2O3。用化学共沉淀法制备锰锌铁氧体共沉淀粉料的预烧过程与氧化物法的预烧过程相比,前者在预烧过程中多了一步碳酸盐的分解过程;其中金属碳酸盐首先分解变为金属氧化物,然后发生与氧化物法相同的氧化物间的固相反应;所以,与氧化物法的预烧过程相比,碳酸盐化学共沉淀法的适当预烧更为重要,它要在保证形成适量锰锌铁氧体晶体的同时,还需确保金属碳酸盐全部分解变为金属氧化物。其主要的化学反应如下:

FeCO3→Fe2O3+CO2 (1)

FeCO3+O2→Fe2O3+ CO2 (2)

MnCO3→MnO+ CO2 (3)

MnO+O2→Mn3O4 (4)

ZnCO3→ZnO+CO2 (5)

Fe2O3+MnO→MnFe2O4 (6)

Fe2O3+ZnO→ZnFe2O4 (7)

Mn3O4+ZnFe2O4→Zn1-xMnxFe2O4 (8)

3 实验结果与讨论

3.1 预烧温度对共沉淀粉料烧失率的影响

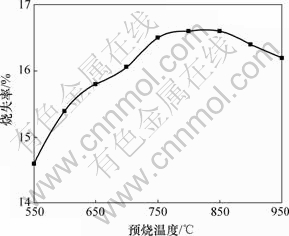

在不同的温度下预烧,粉料的烧失率如图1所示。

图1 烧失率与预烧温度关系

Fig.1 Relationship between loss rate and presintering temperature

图1表明:粉料的烧失率先随温度的升高而增大,在750~850 ℃时达到最大且基本保持恒定值,而后再随温度的升高而减小。这是因为碳酸盐在750 ℃左右分解完毕,且在750~850 ℃范围内,预烧粉料烧失率一致,粉料质量恒定。但是,在900~950 ℃时,烧失率减小,粉料质量增加,这是由于氧化锰和氧化铁与空气中的氧发生反应,吸收氧而使质量增大,导致烧失率降低;所以,预烧温度最低要在750 ℃以上,才能保证碳酸盐完全分解。

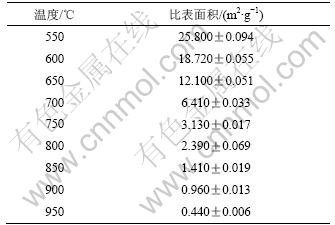

3.2 预烧温度对锰锌铁氧体粉料比表面积的影响

在不同的预烧温度下,预烧粉的比表面积如表1所示。从表1可以看出:随着预烧温度的升高,铁氧体共沉粉料预烧后比表面积越来越小,从800 ℃开始,粉料比表面积开始大幅度递减。主要原因是预烧温度越高,粉料颗粒越容易黏结在一起,使颗粒变大,比表面积变小,这一点从扫描电镜图2中也可以得到 证实。

表1 预烧温度对粉料比表面积的影响

Table 1 Effects of presintering temperature on specific surface area of the powder

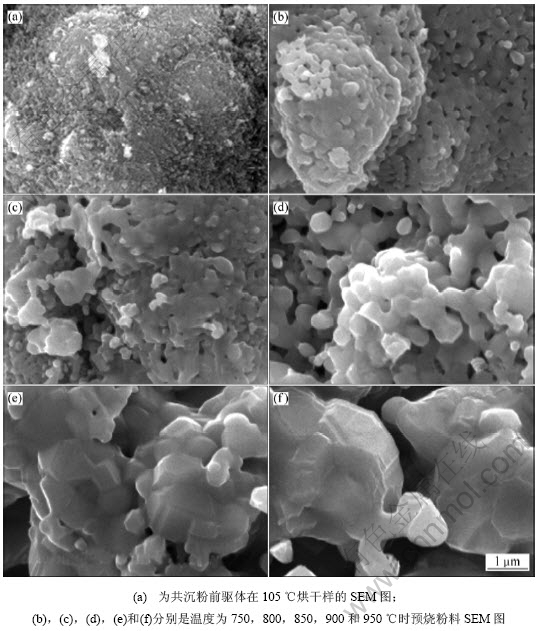

3.3 预烧温度对锰锌铁氧体粉料形貌的影响

图2所示为共沉粉前驱体和不同温度下预烧粉料的SEM图。从图2可以看出:随着预烧温度的升高,晶体颗粒逐渐长大,在温度高达900 ℃和950 ℃时,颗粒分布很不均匀,颗粒形状变得很不规则,颗粒与颗粒之间相互成块。这是由于随着温度升高,小颗粒熔解再结晶,并与其他颗粒相互黏接于一体,使颗粒粒径增大。温度越高,小颗粒熔解越快,再结晶形成的颗粒就越大,所以,随着预烧温度的升高,铁氧体的粒度也增大。只有温度在850 ℃时,晶体颗粒较多且形状均匀。

图2 共沉粉和不同温度下预烧粉的SEM图

Fig.2 SEM pictures of co-precipitation powders and presintering powders at different temperatures

3.4 预烧温度对锰锌铁氧体粉组成的影响

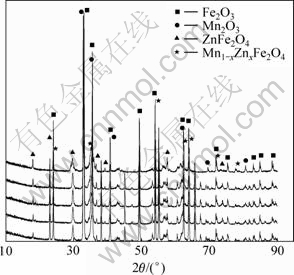

取预烧温度≥750 ℃的锰锌铁氧体粉料进行XRD检测,结果见图3。

图3 不同温度预烧粉料的XRD图谱

Fig.3 XRD picture of different temperature presintering powders

从图3可以看出:随着预烧温度的升高,XRD谱峰越来越尖锐,说明随着预烧温度的提高,铁氧体晶体含量逐渐增多,晶粒中晶胞排列越来越规则。

3.5 预烧温度对样环磁性能的影响

取预烧温度分别为750,800,850和900 ℃的预烧粉料试制样环,随大生产线送钟罩炉烧结。

3.5.1 初始磁导率

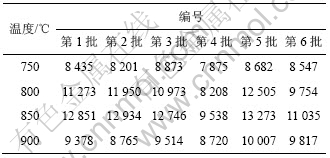

每组预烧料试制6批样环,并对试制的所有铁氧体样环进行初始磁导率检测,结果见表2。

由表2可知,制备的铁氧体样环中,所有样环的初始磁导率μi>7 000,其中预烧温度为800和850 ℃时部分样环μi>12 000,预烧温度为850 ℃的样环磁导率最大。

表2 高磁导率铁氧体的初始磁导率

Table 2 Initial magnetic permeability of high permeability ferrite

3.5.2 温度特性

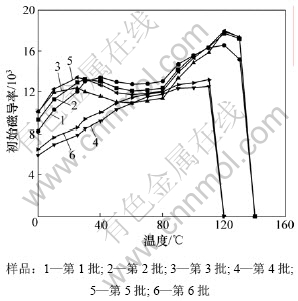

取预烧温度为850 ℃的6个样环,进行温度特性的检测,结果见图4。

图4 高磁导率铁氧体的温度特性曲线

Fig.4 Temperature characteristic graph of high permeability ferrite

从图4可以看出,在温度为0~100 ℃时,铁氧体的磁导率比较稳定,基本上维持在10 000以上;当温度升高到120 ℃左右时,铁氧体样环的磁导率开始 下降。

3.5.3 频率特性

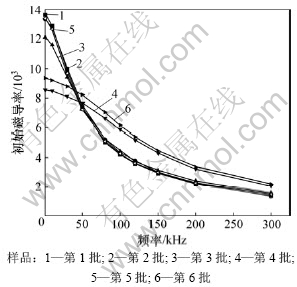

取预烧温度为850 ℃的6个样环,测定不同频率下的磁导率,结果见图5。

图5 高磁导率铁氧体的频率特性曲线

Fig.5 Frequency characteristic graph of high permeability ferrite

从图5可以看出:随着频率的不断升高,铁氧体的初始磁导率不断下降;在频率为1 kHz时,磁导率为10 000左右;当频率升至300 kHz时,磁导率迅速下降到2 000左右。说明铁氧体样环的频率特性并不稳定,有待通过铁氧体工艺进行改善。

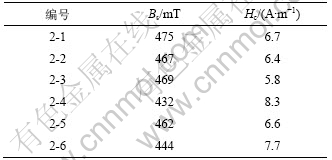

3.5.4 饱和磁感应强度Bs和矫顽力Hc

取预烧温度为850 ℃的6个样环,测定饱和磁感应强度Bs和矫顽力Hc,结果见表3。

表3 高磁导率铁氧体的饱和磁感应强度和矫顽力

Table 3 Bs and Hc of high permeability ferrite

从表3可以看出:所制得样环饱和磁感应强度Bs较高,矫顽力Hc较小,达到了高性能高磁导率铁氧体的要求。

4 结论

(1) 随预烧温度升高,粉料质量先减小后略增加;比表面积减小,晶粒逐渐变大,晶形结构趋于完整。采用合适的预烧温度可以获得形状均匀一致的晶体颗粒。

(2) 样环初始磁导率随预烧温度的升高先增大后减小。

(3) 高磁导率铁氧体与烧结条件相匹配的最佳预烧温度为850 ℃。在此预烧温度下,样环的磁导率最高可达13 000,但其频率特性和温度特性不够好,需要进行进一步实验研究。

参考文献:

[1] 翁兴园. WTO与中国的磁性材料产业[J]. 电子元件与材料, 2002, 4(4): 34-36.

WENG Xing-yuan. WTO and magnetic material industry in China[J]. Electronic Components and Materials, 2002, 4(4): 34-36.

[2] Hage J L T, Schuiling R D, Vriend S P. Production of magnetite sodium jarosite under reducing hydrothermal conditions : the reduction of Fe3+ to Fe2+ with cellulose[J]. Canadian Metallurgical Quarterly, 1999, 36(4): 267-276.

[3] 阳征会, 龚竹青,李宏煦, 等. 用黄钠铁矾渣制备复合镍锌铁氧体[J]. 中南大学学报: 自然科学版, 2006, 37(4): 685-691.

YANG Zheng-hui, GONG Zhu-qing, LI Hong-xu, et al. Preparation of Ni-Zn ferrite from sodium jarosite residue[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 685-691.

[4] Agrawal A, Sahu K K, Pandey B D. Solid waste management in nonferrous industries in India[J]. Resources Conservation and Recycling, 2004, 42(2): 99-120.

[5] Ding M, Schuiling R D, vander Sloot H A. Self-sealing isolation and immobilization: a geochemical approach to solve the environmental problem of waste acidic jarosite[J]. Applied Geochemist, 2002, 17(2): 93-103.

[6] Mauro B, Gaetano B, Pier F M, et al. Recovery of zinc and manganese from spent batteries[J]. Journal of Power Source, 1994, 48(3): 389-392.

[7] 席国喜, 张存芳, 路迈西. 废旧碱性电池共沉淀法制备锰锌铁氧体的研究[J]. 人工晶体学报, 2006, 35(2): 373-377.

XI Guo-xi, ZHANG Cun-fang, LU Mai-xi. Study on preparation of manganese-zinc ferrites by co-precipitation method using spent alkaline Zn-Mn batteries[J]. Journal of Synthetic Crystals, 2006, 35(2): 373-377.

[8] 彭长宏, 李景芬, 李基森. 锰锌铁氧体废料的浸出工艺[J]. 中南大学学报: 自然科学版, 2009, 40(1): 19-24.

PENG Chang-hong, LI Jing-fen, LI Ji-sen. Leaching process of waste Mn-Zn ferrites powder[J]. Journal of Central South University: Science and Technology, 2009, 40(1):19-24.

[9] 彭长宏, 唐谟堂, 黄虹, 等. 一种高性能锰锌铁氧体材料的制备方法: 中国, 200710035816.8 [P]. 2007.

PENG Chang-hong, TANG Mo-tang, HUANG Hong, et al. One method of preparing high permeability MnZn ferrite materials: China, 200710035816.8[P]. 2007.

[10] 荆玉兰, 张怀武. 预烧温度对高磁导率锰锌铁氧体性能的影响[J]. 电子科技大学学报, 2005, 34(6): 836-838.

JING Yu-lan, ZHANG Huai-wu. Effects of anneal temperature on the properties of high permeability MnZn ferrite[J]. Journal of University of Electronical Science and Technology of China, 2005, 34(6): 836-838.

[11] 刘承勇, 兰中文, 蒋晓娜, 等. 预烧温度对LiZn铁氧体微结构和性能的影响[J]. 压电与声光, 2008, 30(5): 604-607.

LIU Cheng-yong, LAN Zhong-wen, JIANG Xiao-na, et al. Effects of calcining temperature on microstructure and properties of lithium-zinc ferrites[J]. Piezoelectectrics & Acoustooptics, 2008, 30(5): 604-607.

(编辑 张曾荣)

收稿日期:2009-09-06;修回日期:2010-01-12

基金项目:广东省科技计划项目(2008A080403007-03)

通信作者:彭长宏(1966-),男,湖南长沙人,教授,从事直接法制备锰锌铁氧体磁性材料及功能性离子液体合成与应用研究;电话:0731-88836940;E-mail: peng9103@163.com