文章编号:1004-0609(2015)-11-3229-08

Ida2--H2O体系中氧化锌矿的循环浸出低品位

窦爱春1,杨天足2,刘云建1,苏明如1

(1. 江苏大学 材料科学与工程学院,镇江 212013;

2. 中南大学 冶金与环境学院,长沙 410083)

摘 要:采用亚氨基二乙酸盐体系循环浸出处理低品位氧化锌矿,浸出剂溶液经浸出-沉锌-沉钙处理后可实现浸出剂再生,再生后的浸出剂溶液按浸出-沉锌-沉钙批处理循环5次,综合考察各过程对再生浸出剂溶液浸锌效果的影响。结果表明:沉锌和沉钙过程可分别将溶液体系中与Ida2-配合的大量Zn2+和Ca2+脱除,达到恢复配体Ida2-活性的目的,再生后浸出剂溶液的浸锌效果与新鲜浸出剂溶液的相当;在循环浸出过程中,锌的平均浸出率为76.90%,理论可溶性锌的平均浸出率为93.8%。

关键词:氧化锌矿;循环浸出;亚氨基二乙酸;锌冶金

中图分类号:TF813 文献标志码:A

Cycle leaching of low grade zinc oxide ores in Ida2--H2O system

DOU Ai-chun1, YANG Tian-zu2, LIU Yun-jian1, SU Ming-ru1

(1. School of Material Science and Engineering, Jiangsu University, Zhengjiang 212013, China;

2. School of Metallurgy and Environment, Central South University, Changsha 410083, China)

Abstract: Low grade zinc oxide ores were treated by cycle leaching in Ida2--H2O system (iminodiacetate aqueous solution). The lixiviant solution was regenerated under a batch process containing the following stages of leaching, Zn precipitation and Ca precipitation. The regenerated lixiviant solution was treated by leaching, Zn precipitaling and Ca precipitating five cycles. And the influences of each process on Zn leaching behavior in the regenerated lixiviant solution were investigated at each stage of all the batch cycles. The results show that the main ions Zn2+ and Ca2+ combined with Ida2- are removed efficiently from leaching liquor with the treatment of Zn precipitation and Ca precipitation, respectively. After two stages precipitation, the activity of Ida2- is recovered in the solution. The resulting of zinc-leaching in the regenerated lixiviant solution are reappeared results in the freshly prepared lixiviant solution. The results of the zinc leaching rates for raw ores and theoretical soluble zinc in raw ores are 76.90% and 93.8% on average.

Key words: zinc oxide ore; cycle leaching; iminodiacetic acid; zinc metallurgy

随着易选冶硫化锌矿的逐渐枯竭,氧化锌矿的开发利用势在必行。我国氧化锌矿的储量极其丰富,但大部分为含锌品位低于10%的高脉石型低品位矿[1-3],不适于采用回转窑挥发富集工艺处理。

低品位氧化锌矿由于脉石(CaO、MgO及SiO2)含量高,采用传统酸浸方法[4-6]处理时,酸性体系对脉石类杂质及Fe不具有选择性,吨锌耗酸可达数吨乃至数十吨,且固液分离困难,浸出液杂质多,后续处理复杂。采用碱浸工艺[7-10]处理时,体系对酸性脉石SiO2不具有选择性,且碱浸工艺需要在强碱性条件下进行,碱耗较高,对设备防腐有一定要求。采用氨浸工艺[11-14]处理时,体系对脉石类杂质及Fe均具有较好的选择性,试剂消耗小,该方法具有一定的工业应用前景。唐默堂等[15-16]进行了实验室及半工业规模氨浸工艺循环浸出试验:在一定的开路系数条件下,浸出液中锌浓度可富集到30 g/L以上,净化后进行电沉积,可得国标1#电锌。但氨浸工艺有其不可回避的问题,即氨的挥发问题,氨气对操作现场的环境和人体危害较大。近年来随着研究的深入,出现了一些改进型酸浸和碱浸工艺:1) 硫酸铵焙烧-水浸法[17-20],即利用硫酸铵焙烧分解产物硫酸将矿物中锌转化为可溶锌硫酸锌再进行水浸,该方法最大的优点在于避免了矿物中酸性脉石SiO2的溶出,改善了传统酸浸过程固液分离困难的状况,但其本质上仍是酸浸工艺,焙烧过程中杂质Fe和Al也形成相应硫酸盐,在水浸过程随锌进入溶液,因而后续硫酸锌溶液净化复杂[19-20];2) 烧碱焙烧-水浸法[21-22],即在一定焙烧温度下,利用氢氧化钠使矿物中锌、铅转化为可溶性锌酸盐和铅酸盐进行水浸,该方法改进之处在于水浸时游离碱浓度较常规碱浸工艺大幅将低,但其本质上仍是碱浸工艺,无法挣脱碱浸工艺对酸性脉石SiO2不具选择性的缺点。另外,上述两种改进型工艺存在一个共同的不足之处,即处理含锌小于10%的低品位氧化锌矿时能耗高,试剂消耗大。鉴于以上方法的一些不足之处,本文作者开发了一种更加环保的、新的配合物选择性浸出体系处理低品位氧化锌矿[23-25]。

亚氨基二乙酸盐体系以Ida2-(亚氨基二乙酸根离子)为配体,可在弱碱性条件下,选择性浸出低品位氧化锌矿中有价金属。同时,体系对脉石类杂质Ca、Mg、Si及Fe均具有较强的选择性,且体系操作条件温和,对人体和环境危害小,可实现清洁生产。但所用试剂IDA(亚氨基二乙酸)价格较高,为降低工艺成本,本文作者在条件实验的基础上,采用循环浸出工艺,将浸出剂溶液按浸出-沉锌-沉钙批处理循环,综合考察批处理循环中各过程对再生浸出剂溶液浸锌效果的影响。

1 实验

1.1 实验原料

实验所用原料低品位氧化锌矿取自云南南坪铅锌矿,矿石经破碎、球磨和筛分处理后,95%以上矿物粒度小于150 μm。原料主要化学成分和锌物相组成分别列于表1和表2。

由表1和表2可见,原矿中锌品位较低,总锌含量仅为7.72%,其中,理论可溶锌含量(非硫化锌)为6.37%,占总锌含量的82.51%,说明原矿中锌氧化程度较高;另外,原矿中脉石含量(w(CaO)+w(MgO)+ w(SiO2)=54.65%)较高,原矿属高脉石型低品位氧化锌矿。

表1 低品位氧化锌矿的化学成分

Table 1 Chemical composition of low grade zinc oxide ores (mass fraction, %)

表2 低品位氧化锌矿中锌物相组成

Table 2 Phase composition of Zn in low grade zinc oxide ores (mass fraction, %)

1.2 实验条件及原理

循环浸出各过程实验条件均经过相关条件因素考察优化后得出[23-24],具体实验条件及原理如下。

1.2.1 浸出过程

浸出过程原矿投料200 g/次,实验条件如下:液固比(L/S)5:1、配体亚氨基二乙酸根总浓度([Ida2-]T)为1.0 mol/L、反应温度70 ℃、pH值8、反应时间4 h。浸出时,锌矿物中除ZnS外,其他氧化锌矿物均可形成Zn(Ⅱ)-Ida2-配离子而溶解,浸出液中锌主要以Zn(Ida)22-配离子形式存在;伴生有价金属Cu、Ni、Pb及Cd可部分随主金属Zn溶解进入浸出液;脉石类杂质Ca、Mg、Si和杂质Fe基本不溶解,留在渣中。相关反应如下:

(1)

(1)

(2)

(2)

式中:Me表示Cu、Ni、Pb及Cd;j表示配位数。

1.2.2 沉锌过程

沉锌过程的主要目的是回收浸出液中锌,并尽可能地降低溶液中残留锌浓度,避免残留的锌对原矿中锌溶出形成抑制。

实验规模为浸出液1 L/次,沉锌实验条件如下:温度85 ℃、终点pH值10、反应陈化时间0.5 h。沉锌过程利用Zn2+-Ida2--CO32--H2O体系平衡固相转变时锌溶解度差异进行[24],在较高pH值时,Zn2+-Ida2--CO32--H2O体系中锌以ZnO形式存在。沉锌时,用CaO调节体系pH值,可将浸出液pH值调节至ZnO沉淀条件,同时,可达到脱除浸出过程中由ZnCO3溶解引入的CO32-的目的,避免了CO32-的积累对循环浸出过程的影响。相关反应如下:

(3)

(3)

(4)

(4)

(5)

(5)

在碱性条件下,Ida2--H2O体系对CaCO3具有较强的选择性[23],不具有溶解CaCO3的能力,如式(5)所示,沉锌过程中(沉锌后液中)积累的Ca2+为Ida2--H2O体系溶解Ca(OH)2所致[24]。

1.2.3 沉钙过程

沉钙过程的主要目的是脱除沉锌过程中引入的大量Ca2+,并使游离Ida2-得到释放,恢复配体Ida2-的活性。

实验规模为沉锌后液每次1 L,沉钙实验条件如下:温度70 ℃、终点pH值8、CO2气体流量为0.2 L/min。沉钙时,用CO2气体脱除沉锌过程中积累的Ca2+,由于CaCO3析出和H+生成,体系中Ca(Ida)22-可释放出大量游离Ida2-,配体Ida2-活性得以恢复,且体系pH值恢复至适宜浸出的弱碱性条件,此时浸出剂得以再生,可直接返回进行循环浸出。相关反应如下:

(6)

(6)

用CO2气体调酸沉钙,可使浸出剂溶液再生,且不会造成溶液中CO32-或CO2的积累,避免其对原矿中ZnCO3溶出产生抑制。

1.3 实验流程及步骤

亚氨基二乙酸盐体系循环浸出低品位氧化锌矿的原则流程如图1所示,该流程的特点是再生后的浸出剂溶液可直接返回浸矿,无需额外添加新鲜浸出剂和调整pH值,显著降低工艺成本。

实验共进行6个批次,合计处理原矿1200 g。浸出剂溶液按浸出-沉锌-沉钙处理一次为一个批次进行实验,编号分别为C-0~C-5,其中:C-0批次实验为新配制的新鲜浸出剂溶液;C-1~C-5批次实验为再生后的浸出剂溶液。

新鲜浸出剂溶液按浸出-沉锌-沉钙进行处理后实现浸出剂再生,再生后的浸出剂溶液直接返回浸矿,再按浸出-沉锌-沉钙处理为一次循环,再次实现浸出剂再生,如此往复,进行总计5批次的循环浸出实验。

每批次中浸出-沉锌-沉钙各过程完成后固液分离,用去离子水洗涤固相3次,各过程洗水单独合并存放,用以补偿各过程损失的水分;各过程固相烘干后分析;各过程液相取25 mL用于分析,并用25 mL同类型溶液(条件实验中所得浸出液、沉锌后液、沉钙后液)补足此部分体积,最后再用相应洗水补充,使得各过程液相体积在进入下一过程时为1 L,实验中所有液相中元素含量均换算成1 L的体积含量。

图1 Ida2--H2O体系循环浸出低品位氧化锌矿工艺流程

Fig. 1 Flowsheet of cycle leaching of low grade zinc oxide ore in Ida2--H2O system

1.4 分析方法

液相中高浓度锌采用EDTA容量法分析,低浓度锌及其他杂质元素含量采用ICP-AES分析;固相中元素含量采用X射线荧光分析(XRF)。在浸出过程中,锌浸出率以液计为准,液计锌浸出率R计算公式如下:

(7)

(7)

式中:wl(Zn)为浸出液中锌含量(g);wa(Zn)为上一个批次沉钙后液中锌含量(g);wt(Zn)为投入的原矿中总锌含量(g)。沉锌过程中,锌沉淀率以液计P1和渣计P2分别计算如下:

(8)

(8)

(9)

(9)

式中:ws(Zn)、wr(Zn)分别表示沉锌后溶液和粗氧化锌中锌含量(g)。沉钙过程中,钙沉淀率以液计P表示如下:

(10)

(10)

式中:wa(Ca)、wl(Ca)分别表示沉钙后液及沉锌后液中钙含量(g)。

2 结果与讨论

2.1 循环浸出过程

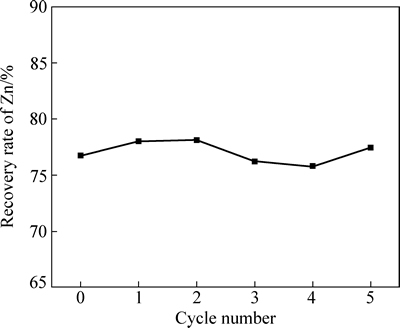

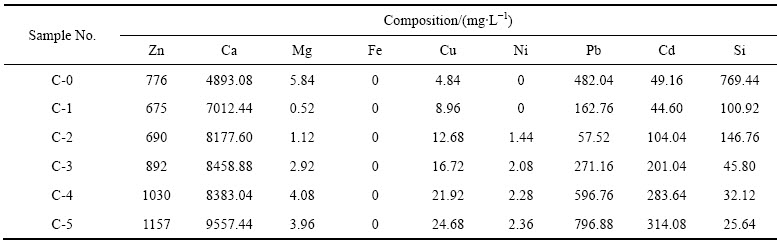

新鲜浸出剂溶液经浸出-沉锌-沉钙处理实现浸出剂再生后,循环浸出5批次,循环浸出过程锌浸出率结果见图2,浸出液中主要元素含量见表3。

由图2可看出,再生后的浸出剂溶液循环浸锌结果较为理想,在实验规模放大10倍后,浸出剂溶液再生循环浸出5批次,锌的平均浸出率为76.90%,非硫化锌(理论可溶锌)浸出率达93.8%。以上结果表明,再生后的浸出剂溶液浸锌效果可与新鲜浸出剂溶液相当。

图2 循环过程中锌浸出率变化曲线

Fig. 2 Changing curves of leaching recovery rate of Zn in circulatory precess

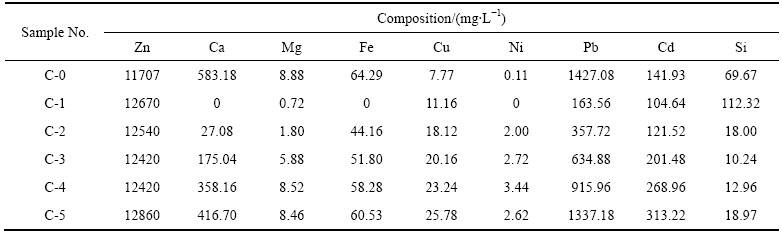

由表3可知,杂质元素Ca、Mg和Fe循环浸出过程中有一定的积累现象,杂质Si未出现明显的积累现象,但Ca、Mg、Fe和Si并未出现大量溶出的情况,其在浸出液中浓度并未超出预期范围[23](如Ca浓度最高仅为583.18 mg/L),这是因为碱性Ida2--H2O体系对上述杂质具有较强的选择性,即使存在着积累现象也不会超出体系本身溶解极限,且如此低浓度的杂质含量尚不足以抑制主金属锌的溶出;伴生有价金属Cu、Ni、Pb、Cd部分溶出,且呈现一定的积累现象。这是由于原矿中上述伴生金属含量低(Ni甚至不能检测出来),因而其在浸出液中浓度低,从溶液中沉淀析出动力不足,在各批次循环的沉锌和沉钙过程不能很好地沉淀析出,造成循环浸出过程中积累。这种积累现象于伴生有价金属的富集和综合回收有利,且不会抑制主金属锌的溶出。

2.2 沉锌过程

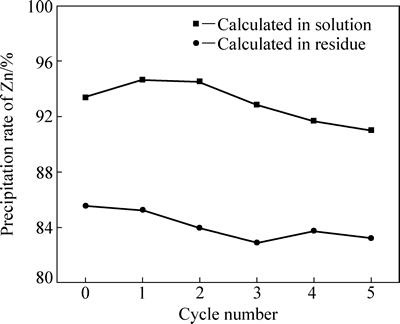

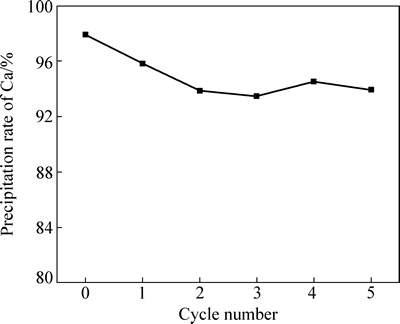

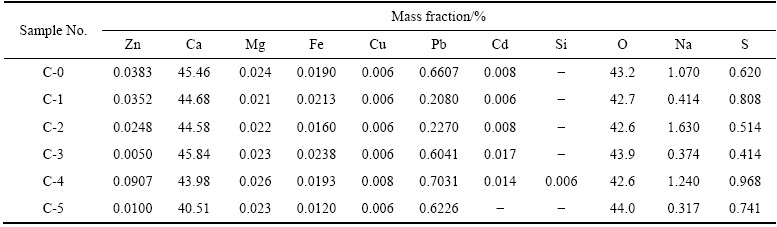

浸出过程所得浸出液补足体积后用CaO进行调碱沉锌,沉锌过程中锌沉淀率变化结果见图3,沉锌后液中相关元素含量列于表4,所得粗氧化锌中相关元素含量见表5。

沉锌过程中分别以液计和渣计计算沉锌率,如图3所示,液计和渣计沉锌率结果有明显差距,但整体变化趋势相似,随循环次数增加,锌沉淀率略有下降,但液计沉锌率仍保持在91%以上,说明浸出液中锌回收效果较好,如此,方可保证残留于溶液中的锌不至于抑制原矿中锌溶出。

表3 浸出液中相关元素含量

Table 3 Elemental composition of leaching liquor

图3 循环过程中浸出液中沉锌率的变化曲线

Fig. 3 Changing curves of Zn precipitation rate from leaching liquor in circulatory process

由图3可以看出,平均液计沉锌率为93.01%,平均渣计沉锌率为84.12%。渣计锌沉淀率普遍低于液计锌沉淀率,主要原因是渣中部分ZnO损失于洗水中。在沉淀过程中,式(3)生成的Ca(OH)2包裹少量新生成的ZnO,此部分被包裹的ZnO晶核难以长大;渣洗涤时,Ca(OH)2被淋洗进入洗水中,暴露出被包裹的细颗粒ZnO,此部分细颗粒ZnO可穿透滤纸进入洗水中,致使渣计沉锌率偏小。另外,随循环次数增加,锌沉淀率呈现一定的下降趋势,其原因可能是由于部分杂质金属离子随ZnO沉淀时消耗Ca(OH)2,导致沉锌pH值偏低,沉锌效果变差;随循环次数的增加,杂质金属元素又出现一定的积累(见表3),将加剧Ca(OH)2的消耗(见表4中Ca浓度数据),造成沉锌pH值更加偏低。实验中发现,陈化反应0.5 h后,溶液pH值有所降低,但降低幅度不大,从图3和表4可以看出,循环次数未对锌沉淀造成严重后果。

对比表3和表4中数据可知,沉锌前后溶液中Ca、Si浓度升高,其中Ca浓度升高为沉锌过程中的必然结果,而Si浓度的升高是由所用沉淀剂CaO引入所致;主金属Zn浓度急剧下降,说明溶液的沉锌效果明显;杂质及伴生有价金属Mg、Fe、Cu、Ni、Cd可部分或全部随ZnO沉淀析出。

由表5可见,所得粗氧化锌中锌品位较高,锌平均品位为60.07%,铅平均品位为3.84%,主要杂质Ca在粗氧化锌中以CaCO3形式存在[24]。所得高品位ZnO可用于生产金属Zn及相关锌深加工产品。

2.3 沉钙过程

表4 沉锌后液中相关元素含量

Table 4 Elemental composition of solution after Zn precipitation

表5 粗氧化锌中主要元素含量

Table 5 Elemental composition of crude ZnO

图4 循环过程中钙沉淀率变化曲线

Fig. 4 Changing curves of precipitation rate of Ca from solution after Zn precipitation in circulatory process

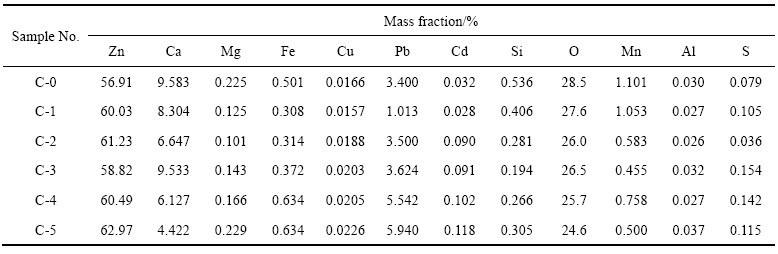

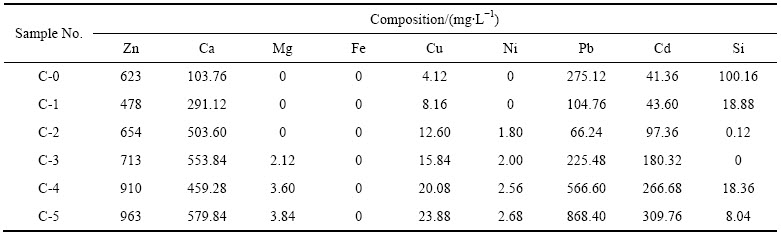

沉锌后液采用CO2进行调酸沉钙,并实现浸出剂溶液的再生。沉钙过程钙沉淀结果见图4,沉钙后液中相关元素含量数据如表6所列,所得CaCO3渣中主要元素成分如表7所列。

如式(6)所示,钙脱除效果直接影响溶液中配体Ida2-的存在形态。由图4可见,各批次循环中钙沉淀率变化基本稳定,钙沉淀率平均为94.91%,钙脱除效果较为理想,由此表明,沉钙后液中Ida2-绝大部分以游离态存在,Ida2-活性得以恢复。

对比表4和表6沉钙前后溶液中元素含量变化可见,在沉钙过程中,各元素包括Zn均出现浓度降低情况,其原因应该是CaCO3从溶液中大量析出时吸附所引起; 此时,CaCO3沉淀过程亦存在吸附配体Ida2-的可能,导致一次次循环过程中配体浓度降低,但结合表3循环浸出的结果来看,5次循环后,再生浸出剂溶液仍保持较好的浸锌能力。由此说明,即使存在配体Ida2-损失,但损失量不大,不至于影响锌浸出,当然,这也与实验过程中洗水返回各相应过程使用有关。

另外,对比表3和6中数据可见,再生后的浸出剂溶液返回浸矿时,溶液中Ca浓度在浸出后均出现不升反降的现象,这是由于原矿中ZnCO3溶解引入的CO32-再次与上批残留的Ca2+形成沉淀,由此说明,沉钙后液中并未有CO32-或CO2积累。

表7所列为碳酸钙渣中主要元素含量。由表7可知,以渣中杂质元素含量计算CaCO3纯度均在97%以上。另外,CaCO3渣中确实存在着一些金属的富集,如Pb和Zn,说明CaCO3沉淀析出过程中确实能吸附一定量的金属。若能以图1中流程实现CaCO3在体系中的循环利用,则CaCO3渣中所含金属Pb、Zn最终应富集于沉锌过程所得粗ZnO中,避免原矿中有价金属在工艺过程中的分散。

表6 沉钙后液中相关元素含量

Table 6 Elemental composition of solution after Ca precipitation

表7 碳酸钙渣中主要元素含量

Table 7 Elemental composition of crude CaCO3

3 结论

1) 采用亚氨基二乙酸盐体系循环浸出处理低品位氧化锌矿,浸出剂溶液经浸出-沉锌-沉钙处理后可实浸出剂再生,再生后的浸出剂溶液可直接返回浸矿,循环利用,显著降低工艺成本。

2) 在浸出过程中,杂质Ca、Mg、Fe、Si未出现大量溶出,锌的平均浸出率为76.90%,再生后的浸出剂溶液循环利用5次后,浸锌效果仍可与新鲜浸出剂溶液相媲美。

3) 在沉锌过程中,伴生金属Cu、Ni、Pb、Cd部分随锌沉淀于粗氧化锌中,液计沉锌率平均为93.01%,粗氧化锌中平均锌品位的60.07%,平均铅品位3.84%。

4) 沉钙过程中,钙的平均沉淀率为94.91%,沉钙过程可有效恢复配体Ida2-的活性,实现浸出剂再生,且过程中无CO32-或CO2积累,避免了其对原矿中ZnCO3矿物的溶出抑制。

REFERENCES

[1] 夏志美, 陈艺峰, 王宇菲, 王 超, 李 丽. 低品位氧化锌矿的湿法冶金研究进展[J]. 湖南工业大学学报(自然科学版), 2010(6): 9-13.

XIA Zhi-mei, CHEN Yi-feng, WANG Yu-fei, WANG Chao, LI Li. Development of treating low-grade zinc oxide ore by hydrometallurgy[J]. Journal of Hunan University of Technology (Nature Science), 2010(6): 9-13.

[2] 赵春虎. 低品位氧化锌矿的氨法浸出剂离子膜电解制锌[D]. 长沙: 中南大学, 2012.

ZHAO Chun-hu. Ammonia leaching of low-grade zinc oxide ore and zinc ion-exchange membrane electrolysis[D]. Changsha: Central South University, 2012.

[3] 张家靓. MACA法循环浸出低品位氧化锌矿制取电解锌新工艺研究[D]. 长沙: 中南大学, 2010.

ZHANG Jia-liang. Study on cycle leaching of low grade zinc oxide ores and electrolyzing zinc in MACA system[D]. Changsha: Central South University, 2010.

[4] SOUZA A D, PINA P S, SANTOS F M F, DA SILVA C A,  V A. Effect of iron in zinc silicate concentrate on leaching with sulphuric acid[J]. Hydrometallurgy, 2009, 95(3/4): 207-214.

V A. Effect of iron in zinc silicate concentrate on leaching with sulphuric acid[J]. Hydrometallurgy, 2009, 95(3/4): 207-214.

[5] QIN Wen-qing, LI Wei-zhong, LAN Zhuo-yue. Simulated small-scale pilot plant heap leaching of low-grade oxide zinc ore with integrated selective extraction of zinc[J]. Minerals Engineering, 2007, 20(7): 694-700.

[6] LI Cun-xiong, XU Hong-sheng, DENG Zhi-gan, LI Xing-bin, LI Ming-tin, WEI Chang. Pressure leaching of zinc silicate ore in sulfuric acid medium[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(5): 918-923.

[7] YUAN Tie-chui, CAO Qin-yuan, LI Jie. Effects of mechanical activation on physicochemical properties and alkaline leaching of hemimorphite[J]. Hydrometallurgy, 2010, 104(2): 136-141.

[8] ZHANG Yu-cheng, DENG Jin-xia, CHEN Jun, YU Ran-bo, XING Xian-ran. Leaching of zinc from calcined smithsonite using sodium hydroxide[J]. Hydrometallurgy, 2013, 131/132(1): 89-92.

[9] CHEN Ai-liang, ZHAO Zhong-wei, XU Dong, LIU Xu-heng, CHEN Xing-yu. Effect of sodium silicate on the solubility of zinc oxide of the Na2O-ZnO-H2O equilibrium system[J]. Hydrometallurgy, 2013, 136(4): 46-50.

[10] CHEN Ai-liang, ZHAO Zhong-wei, JIA Xi-jun, LONG Shuang, HUOL Guang-sheng, CHENG Xing-yu. Alkaline leaching Zn and its concomitant metals from refractory hemimorphite zinc oxide ore[J]. Hydrometallurgy, 2009, 97(3/4): 228-232.

[11] JU Shao-hua, TANG Mo-tang, YANG Sheng-hai. Dissolution kinetics of smithsonite ore in ammonium chloride solution[J]. Hydrometallurgy, 2005, 80(1/2): 67-74.

[12] YIN Zhou-lan, DING Zhi-ying, HU Hui-ping, LIU Kui, CHEN Qi-yuan. Dissolution of zinc silicate (hemimorphite) with ammonia-ammonium chloride solution[J]. Hydrometallurgy, 2010, 103(1/4): 215-220.

[13] YIN Zhou-lan, DING Zhi-ying, HU Hui-ping, CHEN Qi-yuan. Dissolution kinetics of zinc silicate (hemimorphite) in ammoniacal solution[J]. Hydrometallurgy, 2010, 104(2): 201-206.

[14] WANG Rui-xiang, TANG Mo-tang, YANG Sheng-hai, ZHANG Wen-hai, TANG Chao-bo, HE Jing, YANG Jian-guang. Leaching kinetics of low grade zinc oxide ore in NH3-NH4Cl-H2O system[J]. J Cent South Univ Technol, 2008, 15(5): 679-683.

[15] 夏志美, 杨声海, 唐谟堂, 杨天足, 刘志宏, 唐朝波, 何 静, 邓小林. MACA体系中循环浸出低品位氧化锌矿制备电解锌[J]. 中国有色金属学报, 2013, 23(12): 3455-3461.

XIA Zhi-mei, YANG Sheng-hai, TANG Mo-tang, YANG Tian-zu, LIU Zhi-hong, TANG Chao-bo, HE Jing, DENG Xiao-ling. Cycle leaching of low grade zinc oxide ores in MACA system for preparing zinc[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(12): 3455-3461.

[16] 唐谟堂, 张家靓, 王 博, 杨声海, 何 静, 唐朝波, 杨建广. 低品位氧化锌矿在MACA体系中的循环浸出[J]. 中国有色金属学报, 2011, 21(1): 214-219.

TANG Mo-tang, ZHANG Jia-liang, WANG Bo, YANG Sheng-hai, HE Jing, TANG Chao-bo, YANG Jian-guang. Cycle leaching of low grade zinc oxide ores in MACA system[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(1): 214-219.

[17] SUN Yi, SHENG Xiao-yi, ZHAI Yu-chun. Thermodynamics and kinetics of extracting zinc from zinc oxide ore by the ammonium sulfate roasting method[J]. International Journal of Minerals, Metallurgy and Materials, 2015, 22(5): 467-474.

[18] 申晓毅, 孙 毅, 宋继强, 翟玉春. 硫酸铵低温焙烧中低品位氧化锌矿[J]. 材料研究学报, 2012, 26(4): 396-401.

SHENG Xiao-yi, SUN Yi, SONG Ji-qiang, ZHAI Yu-chun. Low grade zinc ore by low temperature roasting using (NH4)2SO4[J]. Chinese Journal of Materials Research, 2012, 26(4): 396-401.

[19] 邵鸿媚, 申晓毅, 张彬彬, 翟玉春. 氧化锌矿溶出液的净化[J]. 东北大学学报(自然科学版), 2015, 36(6): 811-813.

SHAO Hong-mei, SHEN Xiao-yi, ZHANG Bin-bin, ZHAI Yu-chun. Purification of the digestion solution of zinc oxide ores[J]. Journal of Northeasten University (Natural Science), 2015, 36(6): 811-813.

[20] 孙 毅, 申晓毅, 翟玉春. 氧化锌矿浸出液的除铁工艺研究[J]. 中国稀土学报, 2012, 30(增刊): 761-763.

SUN Yi, SHEN Xiao-yi, ZHAI Yu-chun. Technical study on iron removal from leaching solution of zinc oxide ore[J]. Journal of Chinese Society of Rare Earths, 2012, 30(Special Issue):761-763.

[21] ZHANG Yu-cheng, DENG Jin-xia, CHEN Jun, YU Ran-bo, XING Xian-ran. A low-cost and large-scale synthesis of nano-zinc oxide from smithsonite[J]. Inorganic Chemistry Communication, 2014, 43(5): 138-141.

[22] 陈 兵, 申晓毅, 顾惠敏, 孙 毅, 李德官, 翟玉春, 马培华. 碱法焙烧法由氧化锌矿提取ZnO[J]. 化工学报, 2012, 63(2): 658-661.

CHEN Bing, SHEN Xiao-yi, GU Hui-min, SUN Yi, LI De-guan, ZHAI Yu-chun, MA Pei-hua. Extraction of ZnO from zinc oxide ore by alkali roasting method[J]. Journal of Chemical Industry and Engineering, 2012, 63(2): 658-661.

[23] DOU Ai-chun, YANG Tian-zu, YANG Ji-xing, WU Jiang-hua, WANG An. Leaching of low grade zinc oxide ores in Ida2--H2O system[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(11): 2548-2553.

[24] 窦爱春, 杨天足, 吴江华, 张杜超, 杨际幸, 王 安. Zn2+-Ida2--CO32--H2O体系浸出液中锌的回收及浸出剂再生[J]. 中国有色金属学报, 2011, 21(12): 3218-3225.

DOU Ai-chun, YANG Tian-zu, WU Jiang-hua, ZHANG Du-chao, YANG Ji-xing, WANG An. Recovery of zinc and regeneration of lixiviant from Zn2+-Ida2--CO32--H2O system[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(12): 3218-3225.

[25] YANG Tian-zu, DOU Ai-chun, LEI Cun-mao, REN Jin, LIU Zhen-zhen. Ligand selection for complex-leaching valuable metals in hydrometallurgy[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(6): 1148-1153.

(编辑 龙怀中)

基金项目:江苏省自然科学基金资助项目(BK20140558);江苏大学高级人才基金资助项目(13JDG097)

收稿日期:2015-05-06;修订日期:2015-07-20

通信作者:窦爱春,讲师,博士;电话:15806100120;E-mail:aichund@163.com