文章编号:1004-0609(2007)09-1417-06

2197铝锂合金的耐热性能

魏修宇,郑子樵,李世晨,陈秋妮

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:研究了2197铝锂合金的高温拉伸性能以及长时间热暴露后的室温力学性能,同时对合金热暴露前后的显微组织进行透射电镜观察。结果表明:2197合金的高温拉伸强度随拉伸温度的升高而逐渐降低,在200 ℃下的高温拉伸性能优于传统高温用铝合金;在低于150 ℃的温度下热暴露100 h后,2197合金的强度略有上升,这与T1相具有较强的抗粗化能力及θ′相的二次析出有关;但在200 ℃和250 ℃热暴露条件下,合金的力学性能快速下降,这与在此温度下θ′相的溶解和T1相的快速粗化有关。

关键词:2197铝锂合金;热暴露;耐热性能;T1相

中图分类号:TG 146.21 文献标识码:A

Heat resistant properties of 2197 Al-Li alloy

WEI Xiu-yu, ZHENG Zi-qiao, LI Shi-chen, CHEN Qiu-ni

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The tensile properties at elevated temperatures and the room-temperature properties after long time thermal exposure of 2197 alloy were studied. Microstructures of 2197 alloy after long time thermal exposure at different temperatures were observed by TEM. The results show that the tensile strength at elevated temperatures decreases with increasing test temperature, and the tensile properties at 200 ℃ are higher than those of traditional aluminum alloy used at elevated temperature. After exposure at temperatures below 150 ℃ for 100 h, the mechanical properties of 2197 alloy increase slightly. This is related to the high coarsening resistance of T1 phase and secondary precipitation of θ′ phase at these temperatures. However, after exposure at 200 ℃ and 250 ℃ for 100 h, the mechanical properties of 2197 alloy decrease rapidly due to the dissolution of θ′ phase and rapid coarsening of T1 phase at these temperatures.

Key words: 2197 Al-Li alloy; thermal exposure; heat resistant properties; T1 phase

铝锂合金由于具有低密度、高比强度和比刚度以及良好的耐腐蚀性和卓越的超塑成型性能[1?2],用其取代常规铝合金,可使构件质量减轻10%~15%,刚度提高15%~20%,特别是它的价格比先进的复合材料便宜很多,因此被认为是21世纪航空航天工业领域中最理想的轻质高强结构材料。2197合金是一种新型的第三代铝锂合金,该合金已成功取代2124合金用于F-16战斗机的后隔框,满足了8 000 h使用寿命的要求,而且该合金相对减重5%,断裂韧性提高7%[3?4]。

一般来说,航空工业对材料往往有一定的使用温度要求。当飞机航速为2.0~2.4马赫时,机体与空气摩擦会使机身蒙皮温度达90~190 ℃[5]。铝锂合金属于时效强化型铝合金,在一定温度下长时间热暴露后,由于强化相的粗化会导致合金强度水平的快速下降,因此合金显微组织和性能的稳定性是判断合金能否在这些温度下使用的有效依据[6]。然而,目前国内对铝锂合金的耐热性能研究较少,仅有少量报道[7?8]。为此,本文作者研究了2197铝锂合金的高温拉伸性能以及不同温度、不同时间热暴露对合金常温力学性能及显微组织的影响,以期了解2197铝锂合金的耐热特性,为改善合金热稳定性和开拓新的应用领域提供基础数据和理论参考。

1 实验

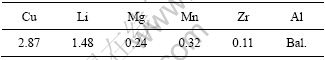

实验用料为西南铝加工厂提供的2197铝锂合金热轧板材。该合金的化学成分分析结果见表1。

表1 2197合金化学成分分析结果(质量分数,%)

Table 1 Measured chemical composition of 2197 alloy (mass fraction, %)

合金板材经510 ℃、1 h固溶处理后水淬,并经过冷轧预变形6%后,在 160 ℃时效16 h达到峰值强度。将经T8峰时效处理后的试样分别在70、100、150、200和250 ℃下进行高温拉伸实验以及在这些温度下长时间热暴露后测量其室温拉伸性能。高温拉伸实验在Instron8032型电子拉伸机上进行,试样在测试温度下保温20 min后进行拉伸,拉伸应变速率为2×10?4 s?1。热暴露后的试样拉伸实验在CSS?44100万能电子拉伸机上进行,名义拉伸速度为2 mm/min,所有样品都平行轧向截取。

透射电镜观察试样经打磨和双喷电解减薄制取,电解溶液为1/4硝酸和3/4甲醇混合溶液(体积分数),采用液氮冷却到?20~?35 ℃,工作电压为15~20 V,电流控制在80~95 mA。电镜观察在TecnaiG220上进行,加速电压为200 kV。

2 实验结果

2.1 高温拉伸性能

表2所列为2197合金在不同测试温度下的拉伸性能测试结果。从表2可以看出,随着温度的升高,合金强度逐渐降低。变形温度高于150 ℃以后,合金强度下降速度加快。尽管如此,由实验结果可知,2197合金在经过T8态峰值时效后,具有良好的高温性能,250 ℃下的强度可达到常温时的55%,而200 ℃下的强度可达常温时的72%。合金的伸长率随变形温度的升高而逐渐升高,在200 ℃和250 ℃高温拉伸,合金的伸长率分别比常温下提高了55%和89%。总体来说,从高温拉伸性能来看,2197合金优于2618、2219等传统耐热铝合金[9]。

表2 2197合金不同温度下的拉伸性能

Table 2 Tensile properties of 2197 alloy tested at different temperatures

2.2 热暴露后的室温拉伸性能

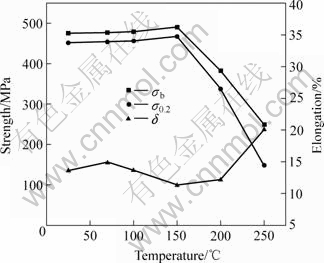

图1所示为2197合金经不同温度热暴露100 h后的室温拉伸性能。可以看出,2197合金在150 ℃以下的温度下热暴露100 h后,与未热暴露的合金相比,其强度没有降低,反而略有上升。当热暴露温度高于200 ℃时,热暴露使合金的强度降低。经200 ℃热暴露后,合金的抗拉强度降低了19.5%;而经250 ℃热暴露后,合金的抗拉强度降低了47.7%。在200 ℃以下温度热暴露100 h,合金的伸长率变化不大,而经250 ℃热暴露100 h后,合金的伸长率明显升高。

图1 2197合金经不同温度热暴露100 h后的室温拉伸性能

Fig.1 Tensile properties of 2197 alloy after 100 h exposure at different temperatures

图2所示为2197合金在150 ℃热暴露不同时间后的室温拉伸性能。可以看出,随着150 ℃热暴露时间的延长,合金的强度呈现出先上升后下降的趋势。热暴露100 h后,合金的强度提高15 MPa左右,随后合金的强度就逐渐降低,但降低的幅度并不大;热暴露500 h后,合金的强度比未热暴露时降低了16 MPa。至于伸长率,随着热暴露时间的延长,它呈现出逐渐下降的趋势,但仍维持在较高水平,经热暴露500 h后,合金的伸长率仍保持在9%以上。

图2 2197合金150 ℃热暴露不同时间后的室温拉伸性能

Fig.2 Tensile properties of 2197 alloy exposured at 150 ℃ for different times

2.3 显微组织

图3(a)和(b)所示分别为2197合金热暴露前电子束从<110>α、<100>α方向入射的透射电镜照片。可以看出,在T8状态下,2197合金的主要析出相为大量弥散分布的片状T1相(图3(a))和少量的θ′相(图3(b))。

图3 2197合金热暴露前的TEM组织

Fig.3 TEM micrographs of 2197 alloy before thermal exposure: (a) T1, <110>α; (b) θ′, <100>α

合金在低于150 ℃的温度下热暴露100 h,合金中主要析出相T1相的尺寸及分布没有发现明显的变化(图4(a)),这说明T1相在150 ℃以下的温度具有良好的热稳定性,有利于合金保持稳定的力学性能。同时,低于150 ℃温度热暴露的合金中θ′相数量有所增多,尺寸有所增大,并且这种趋势随热暴露温度的提高而更加明显(图4(b)、(c)、(d))。当合金在200 ℃热暴露时,TEM组织中观察到析出相主要是T1相,θ′相的数量很少,说明在此温度下,合金中的θ′相已经发生溶解,同时T1相已经开始长大粗化且数量减少(图4(e))。进一步升高热暴露温度到250 ℃,T1相密度显著减小,且尺寸更加粗大(图4(f))。

图4 2197合金经不同温度热暴露100 h后的TEM组织

Fig.4 TEM micrographs of 2197 alloy after 100 h exposure at different temperatures: (a) 70 ℃, <110>α; (b) 70 ℃, <100>α; (c) 100 ℃, <100>α; (d) 150 ℃, <110>α; (e) 200 ℃, <110>α; (f) 250 ℃, <110>α

图5所示为2197合金在150 ℃热暴露不同时间后的TEM组织。可以看出,150 ℃热暴露300 h后,合金中的T1相和θ′相逐渐发生长大粗化,因此其强度有所降低。热暴露500 h后,合金中的T1相和θ′相进一步粗化,且T1相的数量有所减少。

图5 2197合金在150 ℃热暴露不同时间后的TEM组织

Fig.5 TEM micrographs of 2197 alloy exposured at 150 ℃ for different times: (a) 300 h, <110>α; (b) 500 h, <110>α

3 分析与讨论

2197合金属中等Cu/Li比的铝锂合金,在T8状态下,其主要强化相为大量细小、弥散分布的T1 (Al2CuLi)相和少量的θ′相。T1相为密排六方结构,其惯析面为{111}[10]。在{111}面上析出的片状相引起的临界分切应力增量大于在其它面所析出粒子引起的临界分切应力增量[11],因此以T1相为主要强化相的2197合金的室温及高温拉伸强度,高于以在{100}面析出的θ′相 (如2219)或在{210}面析出的S?相(如2618)为主要强化相的传统耐热铝合金。

本文的实验结果表明,2197合金在150 ℃以下具有较好的耐热性能,这主要与T1相有较高的抗粗化能力有关。片状相的长大粗化受台阶机制的长程扩散控制[12?14]。T1相与基体之间产生的错配较小,为0.12%[15],因此T1相与Al基体具有良好的匹配性,这种与基体良好的共格关系使得提供T1相粗化所需的台阶数量有限,T1相粗化驱动力较小,因此T1相在一定的温度下粗化倾向较小,从而起到稳定合金力学性能的作用。

另一方面,由于2197合金经160 ℃时效16 h后,合金基体中仍残留有部分的过剩溶质原子,当合金在150℃以下的温度长时间热暴露时,会在合金中二次析出细小弥散的强化相[16?17]。Gao等[17]的研究表明,2090合金在90~150 ℃温度范围内热暴露时,视热暴露温度的高低分别有GP区、θ″相和θ′相析出。而在本实验中仅发现有θ′相数量的增多,θ′相的二次析出可能是2197合金在150 ℃以下温度热暴露后,强度有所提高的主要原因。

当合金在200 ℃和250 ℃热暴露时,合金中Cu、Li原子的扩散速度加快,从而加快溶质原子向台阶迁移的速率;同时,在200 ℃和250 ℃下长时间热暴露,T1相与基体逐渐失去共格关系,台阶的形核阻力变 小[18?19],提供T1相粗化的台阶数目增加,因此T1相显著长大粗化,合金的强度降低。另一方面,高温下热激活过程进一步降低合金抵抗变形的能力。此外,在200 ℃和250 ℃长时间热暴露,合金可能出现表面脱Li现象,进一步导致合金力学性能的下降。

4 结论

1) 2197合金的高温拉伸强度随拉伸温度的升高而逐渐降低,在200℃下的高温拉伸性能优于传统高温用铝合金,这与{111}面析出的T1相的强化效果 有关。

2) 在低于150 ℃的温度下热暴露100 h,合金的强度未见明显下降。这是由于T1相在低于150 ℃的温度下具有较好的热稳定性,同时θ′相的二次析出可能是合金强度略有上升的主要原因。

3) 在200 ℃和250 ℃下热暴露100 h,合金的强度显著下降。这与θ′相的溶解和T1相的显著粗化有关。

REFERENCES

[1] Grimes R, Cornish A J, Miller W S, Reynolds M A. Aluminium-lithium based alloys for aerospace application[J]. Metals and Materials, 1985, 1(6): 357?363.

[2] Lavernia E J, Grand N J. Aluminum-lithium alloys[J]. Journal of Materials Science, 1987, 22(5): 1521?1529.

[3] Balmuth E S, Chellman D J. Alloy design for overcoming the limitations of Al-Li alloy plate[C]//Proceedings of the 4th International Conference on Aluminum Alloys. USA: School of Mater Sci and Eng, The Georgia Institute of Technology, 1994: 282?289.

[4] 黄兰萍, 郑子樵, 黄永平. 2197铝-锂合金的组织与性能[J]. 中国有色金属学报, 2004, 14(12): 2066?2072.

HUANG Lan-ping, ZHENG Zi-qiao, HUANG Yong-ping. Microstructure and properties of 2197 Al-Li alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 2066?2072.

[5] Polmear I J, Pons G, Barbaux Y, Octor H, Sanchez C. After Concorde: evaluation of creep resistant Al-Cu-Mg-Ag alloys[J]. Materails Science and Technology, 1996, 15: 861?868.

[6] Ortiz D, Brown J, Abdelshehid M, DeLeon P. The effects of prolonged thermal exposure on the mechanical properties and fracture toughness of C458 aluminum-lithium alloy[J]. Engineering Failure Analysis, 2006, 13: 170?180.

[7] 陆 政, 强 俊, 吴一雷, 李永伟, 刘波操. 热暴露对铝锂8090合金挤压型材性能的影响[J]. 兵器材料科学与工程, 1996, 19(4): 25?29.

LU Zheng, QIANG Jun, WU Yi-lei, LI Yong-wei, LIU Bo-cao. Effects of thermal exposure on properties of Al-Li 8090 extrudates[J]. Ordnance Material Science and Engineering, 1996, 19(4): 25?29.

[8] Zheng Z Q, Chen X Z, Chen Z G, Li S C, Wei X Y. Trace element effects on microstructure and mechanical properties in Al-Cu-Li alloy after thermal exposure[J]. Materials Science Forum, 2006, 519/521: 1931?1936.

[9] Plomear I J, Couper M J. Design and development of an experimental wrought aluminum alloy for use at elevated temperatures[J]. Metallurgical Transactions A, 1988, A19(4): 1027?1035.

[10] Flower H M, Gregson P J. Solid state phase transformations in aluminium alloys containing lithium[J]. Materials Science and Technology, 1987, 3(2): 81?90.

[11] Nie J F, Muddle B C, Polmear I J. Effect of precipitate shape and orientation on dispersion strengthening in high strength aluminium alloys[J]. Materials Science Forum, 1996, 217/222: 1257?1262.

[12] Gable B M, Pana M A, Shiflet G J, Starke E A Jr. The role of trace additions on the T1 coarsening behavior in Al-Li-Cu-X alloys[J]. Materials Science Forum, 2002, 396/402: 699?704.

[13] Shiflet G J, Mangan M A, Meng W G. Growth by ledges[J]. Interface Science, 1998, 6(1/2): 133?154.

[14] ?nl? N, Gable B M, Shiflet G J, Starke E A Jr. The effect of cold work on the precipitation of Ω and θ parallel in a ternary Al-Cu-Mg alloy[J]. Metallurgical and Materials Transaction A, 2003, 34(12): 2757?2769.

[15] Hutchinson C R, Fan X, Pennycook S J, Shiflet G J. On the origin of the high coarsening resistance of Ω plates in Al-Cu-Mg-Ag alloys[J]. Acta Materialia, 2001, 49(14): 2827?2841.

[16] Kerr M J, Sweet E D, Bennett C G, Muddle B C. Effect of alkali metal impurities on the low temperature thermal stability of 2090 Al-Cu-Li alloys[J]. Materials Science Forum, 1996, 217/222: 1079?1084.

[17] Gao X, Nie J F, Muddle B C. Secondary hardening in 2090(Al-Cu-Li) alloy[C]//Proceeding of the 6th International Conference on Aluminum Alloys. Toyohashi: The Japan Institute of Light Metals, 1998: 651?656.

[18] Huang J C, Ardell A J. Crystal structure and stability of T1 precipitates in aged Al-Li-Cu alloys[J]. Materials Science and Technology, 1987, 3(3): 176?188.

[19] Gable B M, Pana M A, Shiflet G J, Starke E A Jr. The role of trace addition on the T1 coarsening behavior in Al-Li-Cu-X alloys[J]. Materials Science Forum, 2002, 396/402: 699?704.

基金项目:国防科工委“十五”重点资助项目(MKPT-2004-19ZD)

收稿日期:2006-12-28;修订日期:2007-06-19

通讯作者:魏修宇,博士研究生;电话:0731-8830270;E-mail: s-maloy@mail.csu.edu.cn

(编辑 袁赛前)