DOI: 10.11817/j.ysxb.1004.0609.2021-36550

钒铬渣锰盐焙烧酸浸过程中钒、铬的分离行为

温 婧,姜 涛,余唐霞,孙红艳,周 密

(东北大学 冶金学院,沈阳 110819)

摘 要:本文针对目前钒铬渣中钒铬组元难以实现高效环保分离的研究现状,以钒铬渣为研究对象,碳酸锰为焙烧添加剂,通过钒铬渣碳酸锰焙烧-酸浸工艺实现了钒铬的高效分离。通过正交试验设计研究碳酸锰加入量、焙烧温度、恒温时间和升温速率对钒铬浸出行为的影响。结果表明:焙烧过程中钒尖晶石与碳酸锰的分解产物Mn2O3结合生成酸溶性的焦钒酸锰Mn2V2O7,随后在浸出过程中进入液相。而铬与铁结合生成稳定的固溶体(Fe0.6Cr0.4)2O3,浸出后转移入渣相。当碳酸锰加入量(以n(MnO)/n(V2O5)计)为2.0,焙烧温度为850 ℃,恒温时间为2 h,升温速率为5 ℃/min时,钒浸出率达到最大值89.37%,铬浸出率仅为0.10%,实现钒的高效提取与钒铬分离。

关键词:钒铬渣;锰盐焙烧;酸浸;分离

文章编号:1004-0609(2021)-04-0977-07 中图分类号:TF11.31 文献标志码:A

引文格式:温 婧, 姜 涛, 余唐霞, 等. 钒铬渣锰盐焙烧酸浸过程中钒、铬的分离行为[J]. 中国有色金属学报, 2021, 31(4): 977-983. DOI: 10.11817/j.ysxb.1004.0609.2021-36550

WEN Jing, JIANG Tao, YU Tang-xia, et al. Experimental study on separation of vanadium and chromium from vanadium-chromium slag by manganese salt roasting[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(4): 977-983. DOI: 10.11817/j.ysxb.1004.0609.2021-36550

钒、铬是我国重要的战略性金属元素,广泛应用于冶金、化工、航空航天等领域[1-3]。钒铬渣作为一种富含钒铬的原料可用于钒和铬的提取[4-5]。在高铬型钒钛磁铁矿冶炼过程中,由于钒和铬化学性质相似,因此,在高炉炼铁时同时进入铁水,并在转炉中吹氧得到钒铬渣[6]。目前,铬含量较低的普通钒渣已广泛应用于钒工业生产,而铬含量较高的钒铬渣尚未实现大规模工业化利用。一方面是由于缺乏高分离效率、低成本消耗且环保的钒铬分离技术[7],另一方面是有毒的高价态钒铬对环境存在潜在的威胁。随着普通钒钛磁铁矿资源的日益消耗,高铬型钒钛磁铁矿和钒铬渣的资源化利用已迫在眉睫,而钒铬渣的利用必须符合环保要求。

目前,对于普通钒渣的提钒工艺有钠化焙烧-水浸、钙化焙烧-酸浸、亚熔盐等方法[4, 6, 8-10]。钠化焙烧-水浸工艺流程简单,提钒效率高,但面临物料易烧结,提钒尾渣含钠盐无法回用,提钒废水含铬污染环境等问题。钙化焙烧-酸浸工艺有效避免了钠化焙烧工艺的诸多问题,但钒回收率偏低,难以达到钠化焙烧工艺的水平[11]。浸出过程生成的副产物硫酸钙包裹含钒物相阻碍钒进一步浸出,且浸出后硫酸钙继续留在渣中导致尾渣难以资源化利用。亚熔盐是一种具有高化学活性和高活度富氧离子的碱金属高浓度离子化介质,采用亚熔盐法提钒后钒的回收率由传统钠化焙烧提钒工艺的80%提高到95%以上,铬由基本不回收提高到85%以上,但该工艺的经济性和环保性仍需进一步评价。对于钒铬渣的钒铬提取工艺,目前研究表明,以钒铬渣为原料的钠化焙烧工艺需要消耗数倍于理论值的钠盐[5],尾渣和废水中存在大量有毒的六价铬,对环境压力极大[12-13]。以钒铬渣为原料的钙化焙烧工艺虽能实现钒与铬的有效分离,但钒回收率略低,尾渣中含大量的硫,难以资源化利用。因此,亟需寻找一种更适合于钒铬渣资源化利用的工艺。

值得注意的是,除钠盐和钙盐外,锰盐与钒同样具有较强的结合能力[14-15]。锰盐在焙烧过程中与钒结合生成钒酸锰,浸出时锰离子不被硫酸根沉淀,不会干扰钒浸出且尾渣基本不含硫。后续锰离子还可被沉淀并继续投入焙烧工序,实现工艺闭路循环。因此,本文作者以钒铬渣为原料,通过正交试验设计初步探索了不同焙烧条件对钒铬浸出和分离行为的影响,并对焙烧-浸出过程中的物相演变规律做了进一步探讨。

1 实验

1.1 原料

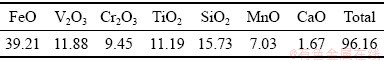

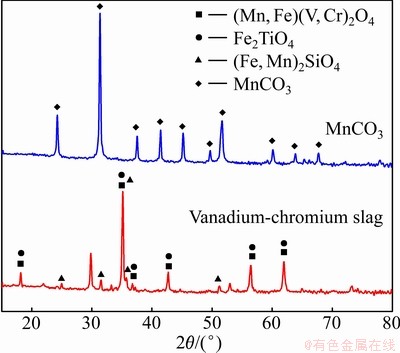

试验采用的钒铬渣来自承德建龙钢铁有限公司,其主要化学成分和物相分布如表1和图1所示。钒铬渣中铬含量几乎与钒含量处于同一水平,钒、铬以类质同象形式赋存于钒铬尖晶石中,钛以钛铁尖晶石相存在,硅以铁锰橄榄石形式存在,并将尖晶石相包裹。焙烧添加剂为分析纯碳酸锰(MnCO3),其物相如图1所示。浸出实验中所用试剂为体积分数98%的浓硫酸。

1.2 试验方法

锰盐焙烧实验在箱式炉(KSL-1200X,沈阳科晶自动化设备有限公司)中进行。通过正交试验合理设计焙烧实验方案,按锰钒摩尔比n(MnO)/ n(V2O5)称取一定量粒度<74 μm的钒铬渣,并与碳酸锰混合均匀。将混合物料放入箱式炉中,按照一定升温速率将物料从室温升到预设焙烧温度,并恒温一段时间。待焙烧结束后,熟料随炉冷却并磨细至粒度<74 μm。取一定量的熟料酸浸,浸出设备为集热式恒温加热磁力搅拌器(DF-101S,巩义市予华仪器有限责任公司)。浸出过程中加入体积分数为10%的稀硫酸溶液,使浸出体系pH值始终保持在2.5左右,pH值监控设备为酸度计(雷磁PHS-3E,上海仪电科学仪器有限公司)。此外,浸出温度为60 ℃,浸出时间为1 h。浸出结束后通过真空抽滤分离固液,得到含钒浸出液和提钒尾渣用于后续分析。

表1 钒铬渣主要化学成分

Table 1 Chemical compositions of vanadium-chromium slag (mass fraction, %)

图1 钒铬渣和碳酸锰的XRD谱

Fig. 1 XRD patterns of vanadium-chromium slag and MnCO3

1.3 分析方法

原料、焙烧熟料和提钒尾渣的物相由多晶X射线衍射仪(X'Pert Pro,荷兰帕纳科公司)表征,以确定钒铬渣锰盐焙烧-酸浸过程中主要物相的演变规律。浸出后浸出液中钒的含量用硫酸亚铁铵滴定法测定,铬的含量用原子火焰吸收法测定,并进一步计算钒、铬浸出率。浸出率( )的计算公式如下:

)的计算公式如下:

(1)

(1)

式中:mL表示浸出液中钒或铬的质量,g;m0表示焙烧熟料中钒或铬的质量,g。

2 结果与分析

2.1 正交试验

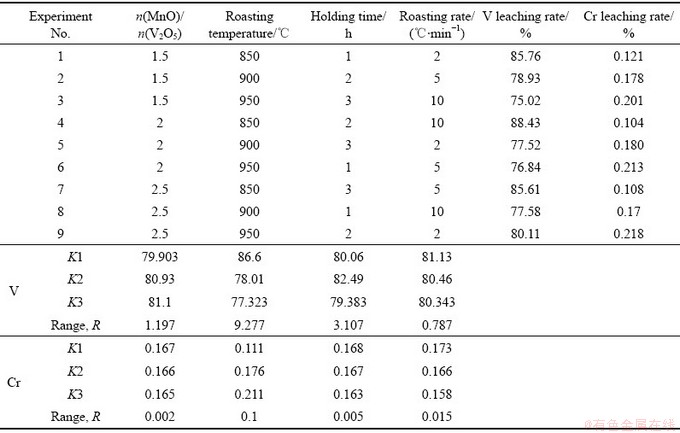

在焙烧过程中,选取锰钒比n(MnO)/n(V2O5)、焙烧温度、恒温时间、升温速率四个焙烧因素作为正交试验因素,每个因素选取三个水平进行如表2所示的四因素三水平正交试验。水平选择:n(MnO)/n(V2O5),1.5~2.5;焙烧温度,850~950 ℃;恒温时间,1~3 h;升温速率,2~10 ℃/min。考察不同焙烧条件对钒铬浸出和分离行为的影响。

表2列出了不同焙烧条件下钒铬的浸出率、均值和极差。根据极差(R)的大小可以判断各因素对钒铬浸出率影响的主次顺序。由表2可知,对钒浸出率而言,R(焙烧温度)>R(恒温时间)>R(锰钒比)>R(升温速率)。因此,焙烧温度对钒浸出率影响最大,其次是恒温时间和锰钒比,升温速率对钒浸出率影响最小。对铬浸出率而言,R(焙烧温度)>R(升温速率)>R(恒温时间)>R(锰钒比),因此焙烧温度对铬浸出率影响最大。此外,钒铬渣经锰盐焙烧-酸浸后,铬浸出率均小于0.3%,这说明锰盐焙烧过程中碳酸锰将钒铬渣中的钒转化为酸溶性的钒酸盐并在浸出过程中溶解,而铬仍留在尾渣中,实现了钒与铬的高效分离。

2.2 锰盐焙烧条件对钒浸出率的影响

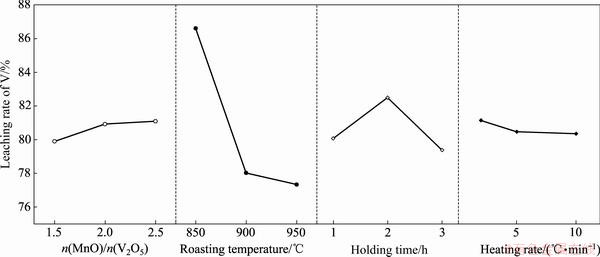

图2所示为各个焙烧因素对钒浸出率的影响。由图2可知,随着碳酸锰的逐渐加入,钒浸出率逐渐提高。n(MnO)/n(V2O5)=2.0是生成锰盐焙烧目标产物焦钒酸锰Mn2V2O7的理论锰盐添加量。低于该值时,部分钒可能未与锰反应生成Mn2V2O7,导致浸出率略低。n(MnO)/n(V2O5)=2.5与n(MnO)/ n(V2O5)=2.0相比,钒浸出率无明显提高,这是因为锰盐添加量高于理论值时,过量的锰盐不会再进一步与钒作用,钒浸出率基本不再增加,且会造成成本消耗。焙烧温度对钒浸出率影响最大,且钒浸出率随温度的升高显著降低,这说明850 ℃即是最优焙烧条件。继续升高焙烧温度,会生成其他副产物将含钒物相包裹,进而影响钒浸出率。同时较高的焙烧温度会造成能量消耗,增加成本。

钒浸出率随恒温时间的升高呈现先升高后降低的趋势,这是因为恒温时间较短时,目标产物Mn2V2O7生成量较少,导致钒浸出率略低。而恒温时间较长时,副产物增多进而影响钒浸出率,因此,恒温时间2 h是较优的条件。钒浸出率随升温速率的提高略有降低,这是因为升温速率越小,焙烧过程中各反应进行得越充分,钒浸出率越大。但升温速率较小会导致焙烧时间延长,进而导致整个提钒流程延长。因此综合考虑钒浸出率和成本消耗,5 ℃/min为较优的升温速率。

表2 锰盐焙烧条件对钒铬浸出率影响正交试验

Table 2 Orthogonal test on effect of manganese salt roasting conditions on leaching rates of vanadium and chromium

2.3 锰盐焙烧条件对铬浸出率的影响

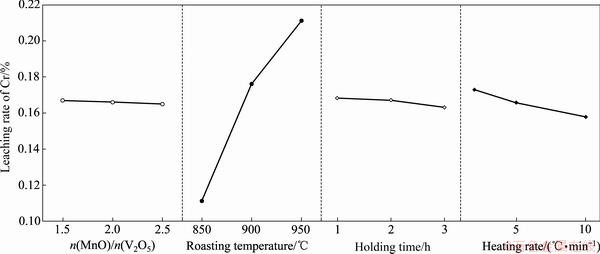

图3所示为各个焙烧因素对铬浸出率的影响。由图3可知,铬浸出率始终低于0.3%,说明绝大多数铬仍留在提钒尾渣中。由于锰盐在此焙烧条件下几乎不能与铬发生反应,因此,浸出液中的铬可能是由于钒铬渣本身存在少量钙,在焙烧过程中与铬结合生成铬酸钙并在酸浸过程中转移入浸出液。铬浸出率随温度变化影响很大,且随着焙烧温度升高铬浸出率逐渐升高。因此,为保证较低的铬浸出率和较高的钒铬分离效率,应在850 ℃下焙烧。配钙量、恒温时间和升温速率对铬浸出率影响较小。

通过正交试验设计,综合考虑钒铬浸出率及成本问题,确定最优焙烧条件为n(MnO)/n(V2O5) 2.0、焙烧温度850 ℃、恒温时间2 h、升温速率5 ℃/min。在此焙烧条件下进行焙烧试验,钒铬浸出率分别为89.37%和0.10%,实现了钒与铬的高效分离。

2.4 焙烧-浸出过程物相变化

图2 焙烧因素对钒浸出率的影响

Fig. 2 Effects of roasting factors on vanadium leaching rate

图3 焙烧因素对铬浸出率的影响

Fig. 3 Effects of roasting factors on chromium leaching rate

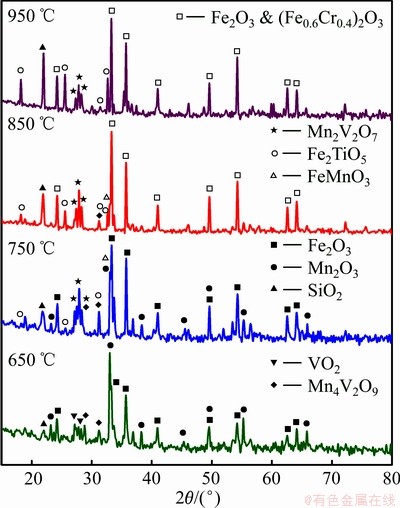

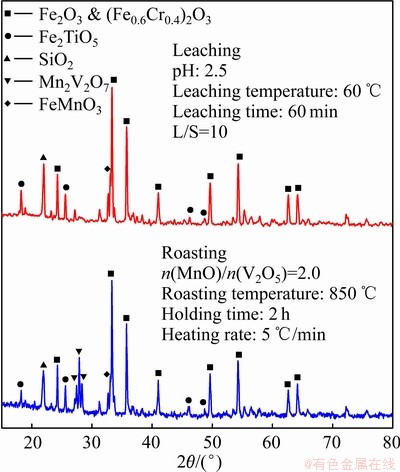

图4所示为不同焙烧温度下钒铬渣锰盐焙烧过程中主要物相的演变规律。由图4可看出,当焙烧温度为650℃时,添加剂MnCO3分解生成Mn2O3,这与单独焙烧MnCO3的实验结果一致。钒铬渣中的钒尖晶石氧化为Fe2O3和低价钒氧化物,部分钒氧化物与锰结合生成Mn4V2O9。钒铬渣中的铁锰橄榄石相(Fe,Mn)2SiO4氧化分解生成Fe2O3、Mn2O3和SiO2。继续升高焙烧温度到750 ℃时,钒铬渣中的钛铁尖晶石Fe2TiO4氧化成钛酸铁Fe2TiO5。同时,由于钒铬渣中本身存在一部分锰,这部分锰与添加剂MnCO3的分解产物Mn2O3共同与钒氧化物结合生成稳定的焦钒酸锰Mn2V2O7,反应剩余的Mn2O3与Fe2O3结合生成FeMnO3。此外,钒铬渣中的铬铁尖晶石转化成稳定的固溶体(Fe0.6Cr0.4)2O3。当焙烧温度为850 ℃时,Mn2O3的衍射峰消失,说明Mn2O3已被完全消耗,Fe2O3、Mn2V2O7、SiO2、Fe2TiO5和FeMnO3仍存在于850 ℃焙烧熟料中。当焙烧温度为950 ℃时,主要物相与850 ℃焙烧熟料相同,说明继续升高温度不会有新物相产生。但焦钒酸锰Mn2V2O7的衍射峰强度明显降低,可能是由于低熔点物相熔化后将含钒物相包裹,导致在浸出过程中这部分钒酸盐难与浸出介质接触从而降低了钒浸出率。反应方程式如式(2)~(11)所示。图5比较了酸浸反应前后焙烧熟料和提钒尾渣的XRD谱,结果显示,酸浸反应结束后,仅焦钒酸锰Mn2V2O7的衍射峰消失,说明只有钒酸锰是酸溶性的,反应方程式如式(12)所示。Fe2O3、SiO2、Fe2TiO5和FeMnO3均留在提钒尾渣中,实现了钒的高效分离与提取。

图4 不同焙烧温度下焙烧熟料的XRD谱

Fig. 4 XRD patterns of roasted samples at different roasting temperatures

图5 焙烧-浸出过程物相演变规律

Fig. 5 Phase evolution during roasting-leaching process

4MnCO3+O2=2Mn2O3+4CO2 (2)

4FeV2O4+O2=2Fe2O3+4V2O3 (3)

2V2O3+O2=4VO2 (4)

V2O3+Mn2O3=Mn4V2O9 (5)

2Fe2SiO4+O2=2SiO2+2Fe2O3 (6)

2Mn2SiO4+O2=2SiO2+2Mn2O3 (7)

2Fe2TiO4+O2=2Fe2TiO5 (8)

2VO2+Mn2O3=Mn2V2O7 (9)

Mn2O3+Fe2O3=2FeMnO3 (10)

FeCr2O4+Fe2O3→(Fe0.6Cr0.4)2O3 (11)

Mn2V2O7+3H2SO4=(VO2)2SO4+2MnSO4+3H2O (12)

3 结论

1) 以钒铬渣为原料,通过锰盐焙烧-酸浸工艺实现了钒与铬的高效分离。

2) 焙烧温度对钒铬浸出率影响最大。焙烧过程中钒尖晶石与碳酸锰的分解产物Mn2O3结合生成酸溶性的焦钒酸锰Mn2V2O7,随后在浸出过程中进入液相。而铬与铁结合生成稳定的固溶体(Fe0.6Cr0.4)2O3,浸出后转移入渣相。

3) 碳酸锰加入量(以n(MnO)/n(V2O5)计)为2.0,焙烧温度为850 ℃,恒温时间为120 min,升温速率为5 ℃/min时,钒浸出率达到最大值89.37%,铬浸出率仅为0.10%,实现了钒的高效提取。

REFERENCES

[1] ZHANG Y M, BAO S X, LIU T, et al. The technology of extracting vanadium from stone coal in China: History, current status and future prospects[J]. Hydrometallurgy, 2011, 109: 116-124.

[2] DHAL B, THATOI H N, DAS N N, et al. Chemical and microbial remediation of hexavalent chromium from contaminated soil and mining/metallurgical solid waste: A review[J]. J Hazard Mater, 2013, 250/251: 272-291.

[3] MIRETZKY P, CIRELLI A F. Cr(Ⅵ) and Cr(Ⅲ) removal from aqueous solution by raw and modified lignocellulosic materials: A review[J]. J Hazard Mater, 2010, 180(1/3): 1-19.

[4] WEN J, JIANG T, ZHOU M, et al. Roasting and leaching behaviors of vanadium and chromium in calcification roasting–acid leaching of high-chromium vanadium slag[J]. International Journal of Minerals, Metallurgy, and Materials, 2018, 25(5): 515-526.

[5] WEN J, JIANG T, XU Y Z, et al. Efficient extraction and separation of vanadium and chromium in high chromium vanadium slag by sodium salt roasting-(NH4)2SO4 leaching[J]. J Ind Eng Chem, 2019, 71: 327-335.

[6] LIU B, DU H, WANG S N, et al. A novel method to extract vanadium and chromium from vanadium slag using molten NaOH-NaNO3 binary system[J]. AICHE Journal, 2013, 59(2): 541-552.

[7] WEN J, JIANG T, ZHOU W Y, et al. A cleaner and efficient process for extraction of vanadium from high chromium vanadium slag: Leaching in (NH4)2SO4-H2SO4 synergistic system and NH4+ recycle[J]. Sep Purif Technol, 2019, 216: 126-135.

[8] LI X S, XIE B, WANG G E, et al. Oxidation process of low-grade vanadium slag in presence of Na2CO3[J]. Transaction of Nonferrous Metals Society of China, 2011, 21(8): 1860-1867.

[9] CAO P. Research on vanadium slag roasted with calcium salt[J]. Iron Steel Vanadium Titanium, 2012, 33(1): 30-34.

[10] CHEN H S. Study on extraction of V2O5 from vanadium slag by lime roasting[J]. Iron Steel Vanadium Titanium, 1992, 13(6): 1-9.

[11] WEN J, JIANG T, LIU Y, et al. Extraction behavior of vanadium and chromium by calcification roasting-acid leaching from high chromium vanadium slag: Optimization using response surface methodology[J]. Miner Process Extr Metall Rev, 2018, 40(1): 56-66.

[12] LI M, XIAO L, LIU J J, et al. Effective extraction of vanadium and chromium from high chromium content vanadium slag by sodium roasting and water leaching[J]. Mater Sci Forum, 2016, 863: 144-148.

[13] WANG H G, WANG M Y, WANG X W. Leaching behaviour of chromium during vanadium extraction from vanadium slag[J]. Miner Process Extr Metall Rev, 2015, 124(3): 127-131.

[14] 向俊一. 转炉钒渣钙化提钒工艺优化及提钒尾渣综合利用基础研究[D]. 重庆: 重庆大学, 2018.

XIANG Jun-yi. Process optimization of vanadium extraction from coverter slag by calcification and basic research on comprehensive utilization of vanadium extraction tailing[D]. Chongqing: Chongqing University, 2018.

[15] 曹 鹏. 钒渣钙化焙烧试验研究[J]. 钢铁钒钛, 2012, 33(1): 30-34.

CAO Peng. Research on vanadium slag roasted with calcium salt[J]. Iron Steel Vanadium Titanium, 2012, 33(1): 30-34.

Separation of vanadium and chromium from vanadium-chromium slag by manganese salt roasting

WEN Jing, JIANG Tao, YU Tang-xia, SU Hong-yan, ZHOU Mi

(School of Metallurgy, Northeastern University, Shenyang 110819, China)

Abstract: In view of the current research status that it is difficult to separate vanadium and chromium from vanadium chromium slag with high efficiency and environmental protection, vanadium-chromium slag was taken as the research object, and manganese carbonate was used as the roasting additive to achieve the high-efficiency separation of vanadium and chromium by manganese carbonate roasting-acid leaching process. The effects of manganese carbonate content, roasting temperature, holding time and heating rate on the leaching behaviors of vanadium and chromium were studied by orthogonal test design. The results show that, in the roasting process, vanadium spinel combines with the decomposition product of manganese carbonate, Mn2O3, to form the acid soluble Mn2V2O7, and then enter the liquid phase after leaching. The stable solid solution (Fe0.6Cr0.4)2O3 is formed by the combination of chromium and iron, which is transferred into the slag phase after leaching. The leaching rate of vanadium reaches the maximum of 89.37% when the addition amount of manganese carbonate (n(MnO)/n(V2O5) is 2.0, the roasting temperature is 850 ℃, the holding time is 2 h and the heating rate is 5 ℃/min. At the same time, the leaching rate of chromium is only 0.10%, realizing the efficient extraction of vanadium and separation of vanadium and chromium.

Key words: vanadium-chromium slag; manganese salt roasting; acid leaching; separation

Foundation item: Projects(51574082, 51604065) supported by the National Natural Science Foundation of China

Received date: 2020-03-02; Accepted date: 2021-01-25

Corresponding author: TAO Jiang; Tel: +86-13998229100; E-mail: jiangt@smm.neu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51574082,51604065)

收稿日期:2020-03-02;修订日期:2021-01-25

通信作者:姜 涛,教授,博士;电话:13998229100;E-mail:jiangt@smm.neu.edu.cn