文章编号:1004-0609(2008)04-0589-06

时效析出对2E12铝合金疲劳断裂行为的影响

李 海1, 2,郑子樵2,魏修宇2,王芝秀1

(1. 江苏工业学院 材料科学与工程学院,常州 213164;

2. 中南大学 材料科学与工程学院,长沙 410083)

摘 要:测试等屈服强度条件下190 ℃,1 h欠时效和190 ℃,46 h过时效状态Al-Cu-Mg系2E12铝合金的疲劳寿命,并分别采用扫描电镜和透射电镜观察了疲劳断口形貌及时效析出特征,并在此基础上解释时效析出对2E12铝合金疲劳断裂行为的影响。结果表明:疲劳裂纹主要萌生于试样表面的粗大残留相位置;由于过时效试样晶内析出大量的S平衡相降低疲劳变形时的位错滑移可逆性,加剧晶界处位错塞积程度;同时晶界上较宽的无析出带和沿晶界析出的粗大针状S相进一步促进晶界集中变形和开裂,从而降低过时效试样的疲劳寿命。

关键词:铝合金;疲劳断裂行为;时效析出

中图分类号:TG 146 文献标识码:A

Effect of ageing precipitation characteristics on fatigue fracture behavior of 2E12 aluminum alloy

LI Hai1, 2, ZHENG Zi-qiao2, WEI Xiu-yu2, WANG Zhi-xiu1

(1. School of Materials Science and Engineering, Jiangsu Polytechnic University, Changzhou 213163, China;

2. School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The fatigue lives of Al-Cu-Mg based 2E12 aluminum alloy under 190 ℃, 1 h and 190 ℃, 46 h were measured. The fractographies and the characteristics of ageing precipitation were investigated using scanning electron microscopy and transmission electron microscopy, respectively. The results show that the fatigue cracks are initiated around the coarse secondary phases on the free surfaces of the specimens. After over-ageing treatment, the equilibrium S phases precipitate the reversible movement of dislocations and further intensify their piles-up on the grain boundaries. On the other hand, the presence of wider PFZs and needle-shaped S phases on grain boundaries accelerate the localized deformation within PFZs and fast cracking along the grain boundary S phases. Therefore, the fatigue properties of the overaged specimens are deteriorated compared with that of the under-ageing specimens.

Key words: aluminum alloy; fatigue fracture behavior; ageing precipitation

Al-Cu-Mg系铝合金因其具有较高的强度和优良的抗疲劳性能,在航空工业中获得广泛应用,其中以2024-T3和2324-T39等为典型代表[1]。近年来,为了进一步提高飞机的安全及寿命,美国Alcoa公司通过降低Fe和Si杂质以及适当调整Cu和Mg主合金元素的含量,开发出了疲劳性能更高的2524铝合金[2-5],并在Boeing777和Airbus380等新型客机上应用[6]。

影响铝合金疲劳性能的组织因素有许多,如晶 粒尺寸、再结晶程度、粗大残留相以及时效析出相 等[7-12]。其中关于时效析出特征对疲劳性能的影 响,较多的实验数据表明欠时效能获得比过时效试样更高的疲劳寿命,这与2X24合金主要以T3状态应用是一致的。但时效析出相对疲劳行为的影响仍缺乏详细研究[8],由于时效析出时并非只有晶内析出相发生改变,晶界析出特征也相应发生变化。因此有必要对时效析出特征对疲劳性能的影响作进一步研究。

本文作者采用成分与2524合金相近的国产2E12合金经495 ℃,1 h固溶处理后,在190 ℃时效不同时间以获得屈服强度相同的欠时效和过时效两种状态,从而排除因强度不同而导致裂纹塑性闭合效应差异对疲劳寿命的影响,并在此基础上研究了时效析出特征对2E12铝合金疲劳断裂行为的影响。

1 实验

实验材料为包覆铝的2E12冷轧薄板,其厚度约为2 mm,化学成分为4.0Cu,1.4Mg,0.6Mn,0.06Fe,0.06Si,余量为Al(质量分数,%)。

首先截取硬度试样,经495 ℃,1 h固溶处理,室温水淬后立即进行190 ℃下人工时效,在HXD-1000TMC显微硬度计上进行硬度测试,获得时效硬化曲线,然后根据硬化曲线选取硬度相近的欠时效和过时效工艺参数再对拉伸试样进行热处理,在AGS-10KND电子拉伸试验机上测试其拉伸性能,经过适当调整热处理参数,最终找出工艺合适且屈服强度相近的欠时效和过时效状态,分别为190 ℃,1 h和190 ℃,46 h。

根据这两种工艺参数对板材进行热处理,并按GB3075—82加工成光滑疲劳试样,在EHF-EG250KN-40L液压伺服疲劳试验机上进行应力控制疲劳寿命测试。实验采用正弦波加载,频率为10 Hz,应力比为0.1(25 MPa/250 MPa)。每种时效状态取5个平行试样。

截取疲劳试样断口,在JSM-6360LA扫描电镜上观察疲劳断口形貌,研究裂纹萌生和扩展情况。截取试样,先用金相砂纸预减薄至100 mm左右,再经离子减薄后制成薄膜试样,在Tecnai G12 透射电镜上观察析出相特征。

2 结果与讨论

2.1 力学性能

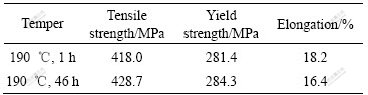

表1所列为2E12合金经190 ℃,1 h欠时效和190 ℃,46 h过时效两种状态的拉伸性能数据。由表1可看出,通过这两种时效处理,合金能够获得相近的屈服强度,分别为281.4和284.3 MPa。

表1 实验合金拉伸性能

Table 1 Static tensile properties of examined alloy

表2所列为190 ℃,1 h和190 ℃,46 h两种时效状态下5个平行试样的疲劳寿命值。由表2中可看出,尽管两种时效状态下合金拉伸屈服强度相近,但疲劳寿命存在显著差别,190 ℃,46 h过时效试样的疲劳寿命约为190 ℃,1 h欠时效试样的1/2。

表2 实验合金疲劳寿命数据

Table 2 Fatigue lives of samples

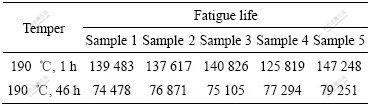

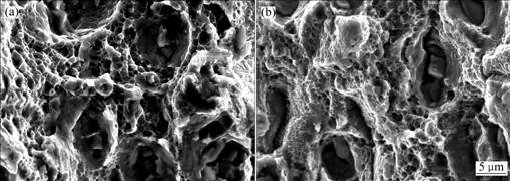

2.2 疲劳裂纹萌生

图1所示为合金在190 ℃,1 h和190 ℃,46 h两种时效状态下疲劳断口的SEM像。由图1可看出,从疲劳裂纹扩展方向可看出,疲劳裂纹主要从试样表面上的粗大残留相位置萌生,在循环载荷的作用下,位错滑移至粗大残留相附近塞积形成应力集中,导致粗大残留相与基体之间的结合面受拉伸应力作用而脱开或脆性夹杂物自身破裂而形成裂纹。在图1(a)和(b)中都可清楚发现,粗大残留相与基体之间的界面分离和自身破裂情况。能谱分析表明:这些粗大残留相主要是固溶处理时未充分溶解的Al2CuMg可溶相和难溶的Al7Cu2(Fe, Mn)杂质相,尺寸一般在几微米至几十微米之间。

图1 试样疲劳裂纹萌生位置的SEM像

Fig.1 SEM images of fatigue crack formation sites of samples: (a) 190 ℃, 1h; (b) 190 ℃, 46h

2.3 疲劳裂纹扩展

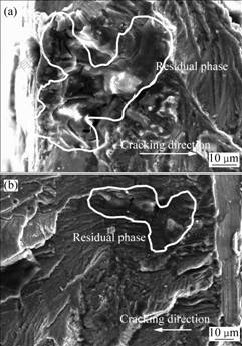

Forsyth将疲劳裂纹扩展过程分为两个阶段[13]。当裂纹萌生后,沿着主滑移系方向以纯剪切方式扩展,称为疲劳裂纹扩展第Ⅰ阶段,此时裂纹扩展路径呈锯齿型。而当应力强度范围较高时,裂纹顶端塑性区跨越多个晶粒,此时裂纹扩展沿两个滑移系统同时或者交替进行,断口上通常形成疲劳辉纹,这一过程称为疲劳裂纹扩展第Ⅱ阶段。

图2所示为两种时效状态试样的疲劳裂纹扩展第Ⅰ和Ⅱ阶段的SEM像。在图上沿平行于试样表面作长300 mm、间距为50 mm的5条平行线,测得与直线相交的平均台阶数分别为11.8和8.5,也就是说,在疲劳裂纹扩展第Ⅰ阶段,190 ℃, 1 h欠时效试样上形成的疲劳裂纹台阶数比190 ℃,46 h过时效试样的更多,这表明在疲劳裂纹扩展第Ⅰ阶段,欠时效试样断口的粗糙程度更高些。

图2 试样疲劳裂纹扩展的SEM像

Fig.2 SEM images of fatigue crack propagation of samples: (a) 190 ℃, 1 h, Stage Ⅰ; (b) 190 ℃, 46 h, Stage Ⅰ; (c) 190 ℃, 1 h, Stage Ⅱ; (d) 190 ℃, 46 h, Stage Ⅱ

通过比较图2(c)和(d)可看出,图2(c)中的相邻疲劳辉纹间距比图2(d)的更细小些,表明190 ℃,1 h欠时效试样所经历的循环次数比190℃,46 h过时效试样的更多。另外,从图2(d)还可看出,过时效试样断口上存在较多的二次裂纹,且二次裂纹中含有较多的析出相,如图2(d)中箭头所示。

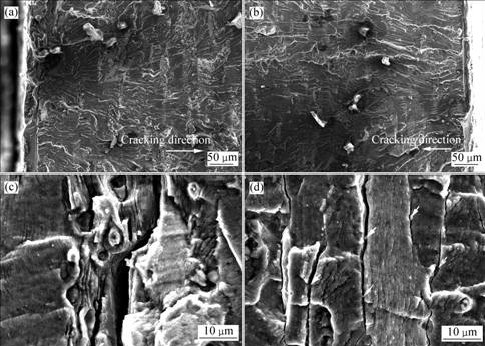

2.4 瞬时断裂区

图3所示分别为190 ℃,1 h欠时效和190 ℃,46 h过时效试样的瞬时断裂区的SEM像。由图3可见,试样断口上存在两种尺寸分布的韧窝。相比之下,190 ℃,46 h过时效试样断口上的小尺寸韧窝数量更多、尺寸也更小些,而大尺寸韧窝特征相似。

图3 瞬时断裂区的SEM像

Fig.3 SEM images of fast fracture zone: (a) 190 ℃, 1 h; (b) 190 ℃, 46 h

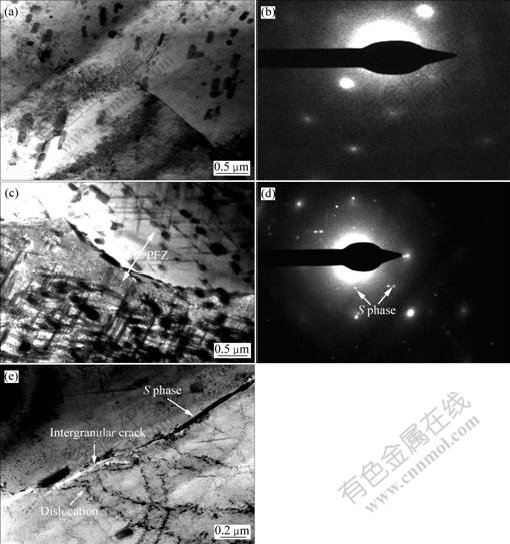

2.5 时效析出特征

图4(a)所示为经190 ℃,1 h欠时效试样的TEM像。由图4(a)可看出,基体中只有短棒状的Al20CuMn3弥散相,晶界附近既无明显的PFZ,也无析出相存 在。然而时效硬化曲线测试表明,经190 ℃,1 h欠时效处理,试样硬度要比固溶淬火态高出HV20左右,而[100]选区电子衍射花样中却只含有基体斑点(见图4(b)),这说明此时基体中析出的强化相应为共格GPB区。而在190 ℃,46 h过时效条件下,基体中除了Al20CuMn3相,还析出了数量较多的针状相,此时晶界附近出现较宽的PFZ(见图4(c)),对应的[100]选区电子衍射花样表明针状相为S平衡相(Al2CuMg),如图4(d)中箭头所指的衍射斑点。图4(e)所示为190 ℃,46 h过时效试样的晶界区域TEM像。由图4(e)可看出,位错塞积在晶界附近,晶界上析出长针状S相,且S相尖端出现裂纹。

图4 试样的时效析出特征

Fig.4 Ageing precipitation characteristics of samples: (a) 190 ℃, 1 h; (b) SAED patterns of (a); (c) 190 ℃, 46 h; (d) SAED patterns of (c); (e) TEM image around grain boundary

3 分析与讨论

光滑试样的疲劳总寿命为萌生主裂纹的疲劳循环数和使这一主裂纹扩展到发生突然破坏的疲劳循环数之和。因此,要研究时效析出特征对疲劳寿命的影响必须排除其它因素的干扰。对于本研究合金来说,其热处理工艺区别主要在于495 ℃,1 h固溶处理后的时效制度不同,而由固溶处理工艺参数所决定的残留相数量及大小、晶粒尺寸和再结晶程度等微观组织特征对合金疲劳性能的影响,从统计意义上来说应该是相同的。随后的时效处理对微观组织的影响,主要体现在固溶处理形成的过饱和溶质原子随时效时间的变化,造成晶内和晶界时效析出特征显著不同。对于Al-Cu-Mg基的2E12铝合金来说,经495 ℃,1 h固溶处理后再进行190 ℃人工时效,随着时效时间的延长,晶内过饱和溶质原子主要按SSSS-共格GPB区/共格S″相-半共格S′-非共格S相序列进行析出[14]。另外在时效过程中,晶界附近的溶质原子向晶界扩散,并与晶界上偏聚的溶质原子一起析出平衡相。从图4(a)~(d)可以看出,经190 ℃,1 h欠时效和190 ℃,46 h过时效处理,晶内分别析出共格GPB区和S平衡相;而晶界附近则由欠时效状态的无PFZ和析出相转变成过时效状态的较宽PFZ和析出粗大针状S相。

随着时效时间的不同,晶内析出相性质发生改变,导致其对疲劳变形时的位错运动阻碍作用也不同。试样经190 ℃,1 h时效,合金处于欠时效状态,滑移位错能剪切与基体共格的GPB区,并继续向前滑移至障碍物处形成位错塞积。当从最大载荷卸载时,由于作用在塞积位错上的应力平衡被打破,部分塞积位错将发生逆向滑移。另外,由于位错按原晶面逆向滑移时,将使共格析出相被剪切面愈合,这一过程属于能量降低过程,其阻碍作用要比位错正向滑移时小,因而位错易在晶内往复滑移,所造成的疲劳损伤较小。而对于190 ℃,46 h过时效试样,晶内析出大量与基体不共格的S相,位错只能以绕过机制穿过析出相,并围绕S相留下位错环,这一过程实际上相当于减小了粒子间距,因而增加了载荷减小时位错逆向滑移时反向绕过粒子的阻力,因此对于过时效试样来说,位错更容易滑移至晶界或试样表面,造成的变形损伤更大。

另外,由于过时效处理导致晶界PFZ较宽,其强度要低于晶内强度,使得位错容易在较软的晶界PFZ处发生优先滑移,这一作用与晶内滑移至晶界的塞积位错共同作用,增大了晶界上应力集中强度,同时晶界上析出的粗大针状S相也削弱晶粒间的结合强度,导致过时效试样具有更强的沿晶界开裂倾向,图2(d)中较多的二次裂纹和图4(e)中的沿晶裂纹即说明了这一点。而对于190 ℃,1 h欠时效试样来说,没有明显的晶界PFZ,因而晶内和晶界强度相近,这使得晶界处集中变形难以进行,同时晶内析出相的共格性质,使得晶内位错容易发生可逆滑移,因此欠时效试样由于晶界开裂所造成的损伤要低于过时效试样的。

另外,裂纹闭合效应也会对合金疲劳寿命产生影响,主要有塑性闭合、氧化物闭合和裂纹面粗糙闭合等机制[15]。对本研究来说,由于试样屈服强度和实验环境等相同,由此造成的塑性闭合和氧化物闭合所产生的疲劳裂纹扩展阻滞作用也应相同。但从图2(a)和(b)可看出,190 ℃,1 h欠时效试样的断裂面更为粗糙,因而由断裂面粗糙度诱发的裂纹扩展阻滞作用应更强,这也使得欠时效试样具有更高的疲劳寿命。

4 结论

1) 2E12铝合金疲劳裂纹主要萌生于试样表面的粗大残留相位置。

2) 在等屈服强度条件下,欠时效试样能获得比过时效试样更高的疲劳寿命。这主要是由于过时效状态下晶内非共格S相的大量析出降低了位错滑移可逆性,以及较宽的晶界PFZ和晶界针状S相的存在促进了晶界附近集中变形和开裂倾向的共同作用。

REFERENCES

[1] 杨守杰, 戴圣龙. 航空铝合金的发展回顾与展望[J]. 材料导报, 2005, 19(2): 76-80.

YANG Shou-jie, DAI Sheng-long. A glimpse at the development and application of aluminum alloys in aviation industry[J]. Materials Review, 2005, 19(2): 76-80.

[2] SRIVATSAN T S, KOLAR D, MAGNUSEN P. The cyclic fatigue and final fracture behavior of aluminum alloy 2524[J]. Materials Design, 2002, 23(2): 129-139.

[3] SRIVATSAN T S, KOLAR D, MAGNUSEN P. Influence of temperature on cyclic stress response, strain resistance and fracture behavior of aluminum alloy 2524[J]. Mater Sci Eng A, 2001, 314(1/2): 118-130.

[4] De BARTOLO E A, HILLBERRY B M. A model of initial flaw sizes in aluminum alloys[J]. International Journal of Fatigue, 2001, 23(S1): 79-86.

[5] GOLDEN P J, GRANDT A F, BRAY G H. A comparison of fatigue crack formation at holes in 2024-T3 and 2524-T3 aluminum alloy specimens[J]. International Journal of Fatigue, 1999, 21(S1): 211-219.

[6] 陈 文. 先进铝合金在A380上的应用[J]. 航空维修与工程, 2005(2): 41-42.

CHEN Wen. Application of advanced aluminum alloys in A380 structures[J]. Aviation Maintenance and Engineering, 2005(2): 41-42.

[7] HOPPEL H W, KAUTZ M, XU C, MURASHKIN M, LANGDON T G, VALIV R Z, MUGHRABI H. An review: fatigue behavior of ultrafine-grained metals and alloys[J]. Int J Fatigue, 2006, 28: 1001-1010.

[8] BARY G H, GLAZOV M, RIOJA R J, LI D, GANGLOFF R P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys[J]. Int J Fatigue, 2001, 23: s265-s276.

[9] GURBUZ R, SARIOGLU F. Fatigue crack growth behavior in aluminum alloy 7075 under different aging conditions[J]. Mater Sci Tech, 2001, 17: 1539-1543.

[10] LUMLEY R N, O’DONNELL R G, POLMEAR I J, GRIFFITHS J R. Enhanced fatigue resistance by underaged an Al-Cu-Mg-Ag alloy[J]. Materials Forum, 2005, 29: 256-261.

[11] VRATNICA M, CUROVIC J, BURZIC Z. Fatigue properties of high strength Al-Zn-Mg-Cu alloys with different levels impurity[J]. Materiali in Technologije, 2002, 36(1/2): 11-14.

[12] RODRIGES E M, MATIAS A, GODERFROID L B, BASTIAN F L, AL-RUBAIE K. Fatigue crack growth resistance and crack closure behavior in two aluminum alloys for aeronautical applications[J]. Materials Research, 2005, 8(3): 287-291.

[13] FORSYTH P J E. A two stage process of fatigue crack growth[C]//Proceedings of crack propagation symposium. Cranfield: The College of Aeronautics, 1961: 76-94.

[14] WANG S C, STARINK M J. Precipitates and intermetallic phase in precipitation hardening Al-Cu-Mg-(Li) based alloys[J]. Int Mater Rev, 2005, 50: 193-215.

[15] SURESH S. 材料的疲劳[M]. 王中光, 译. 北京: 国防工业出版社, 1999.

SURESH S. Fatigue of materials[M]. WANG Zhong-guang, transl. Beijing: National Defense Industry Press, 1999.

基金项目:国家重点基础研究发展规划资助项目(2005CB623705)

收稿日期:2007-09-14;修订日期:2007-12-28

通讯作者:李 海,副教授,博士;电话:0519-86330099;E-mail: lehigh_73@163.com

(编辑 李艳红)