文章编号:1004-0609(2013)S1-s0761-04

铸态Ti-46.5Al-2Cr-2Nb-0.15B合金650 ℃的持久性能

林博超,刘仁慈,贾 清,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:研究了Ti-46.5Al-2Cr-2Nb-0.15B合金铸锭不同位置的显微组织及其650 ℃持久性能。结果表明:铸锭不同部位显微组织与凝固速率有关,其中凝固速率较大的边缘形成了片层界面与铸锭轴向平行的晶粒,而凝固速率较小的芯部则形成了片层界面取向杂乱的晶粒。相应组织在相同试验条件下的持久性能差异明显,其中边缘试样持久寿命长且断后伸长率大;而芯部试样持久寿命短且断后伸长率小,这与不同方向加载应力下的两相片层变形协调性有关。

关键词:γ-TiAl基合金;铸态组织;持久性能;片层取向

中图分类号:TG 146.2 文献标志码:A

Creep rupture properties of cast Ti-46.5Al-2Cr-2Nb-0.15B alloy at 650 ℃

LIN Bo-chao, LIU Ren-ci, JIA Qing, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The microstructures of different parts of a cast Ti-46.5Al-2Cr-2Nb-0.15B ingot as well as the influence of microstructure on creep rupture properties were investigated. The results suggest that the microstructure is closely related to solidification rate, grains with lamellae parallel to the ingot’s axis are found near the edge of the ingot where solidification is fast, while grains near the inner part of the ingot have scattered lamellar orientation on account of the slower solidification rate. Different microstructures result in different creep rupture properties, specimens near the edge of the ingot exhibit better creep rupture properties including creep rupture life and elongation, while specimens near the center of the ingot have lower creep rupture life and elongation. This is due to the deformation of the two phases under different loading direction.

Key words: γ-TiAl-based alloy; cast structure; creep rupture property; lamellar orientation

γ-TiAl基合金具有优异的比强度和比模量、较好的阻燃性和抗氧化能力,与高温合金相比质量更轻、效率更高,已在汽车和航空航天等领域得到应用[1-2]。作为高温结构材料,γ-TiAl基合金的高温力学性能是关注的焦点[3-4][2]。影响γ-TiAl基合金力学性能的主要因素有:合金组成、晶粒尺寸、片层间距、晶界形貌等[5-8]。其中,片层取向对γ-TiAl基合金的拉伸性能[9]、断裂韧性[10-11]以及疲劳裂纹扩展方向[12]等性能有着重要影响。本文研究了Ti-46.5Al-2Cr-2Nb-0.15B合金铸锭不同位置的显微组织及其650℃持久性能。

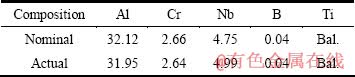

1 实验

实验所用的Ti-46.5Al-2Cr-2Nb-0.15B合金锭采用两次真空自耗熔炼和一次冷壁铜坩埚感应熔炼浇铸而成,其尺寸(直径×长度)为70 mm×650 mm,铸锭名义成分与实际成分(质量分数)如表1所示,换算得到铸锭实际成分为Ti-46.4Al-2Cr-2.1Nb-0.15B;铸锭经热等静压(1 260 ℃,200 MPa,4 h)和热处理(1 280 ℃保温2 h后炉冷)后,沿其内外圆周取直径×长度为13 mm×66 mm的圆棒,取样位置如图1(a)虚线框所示,而后机加工成平行段直径×长度为5 mm×25 mm的标准持久试样。持久试验在RDJ系列杠杆式高温持久试验机上进行,试验温度为650 ℃,加载应力分别为460,470和490 MPa,样品持续加载直至断裂,记录持久寿命并测量断后伸长率;利用KEYENCE VHX-1000型体式显微镜和SSX-550型扫描电子显微镜观察持久试样断口形貌和表面形貌;采用Zeiss-AXiovert200型金相显微镜观察拉断试样纵向显微组织。

表1 Ti-46.5Al-2Cr-2Nb-0.15B合金铸锭化学成分

Table 1 Chemical compositions of Ti-46.5Al-2Cr-2Nb-0.15B alloy cast ingot (mass fraction, %)

2 结果与讨论

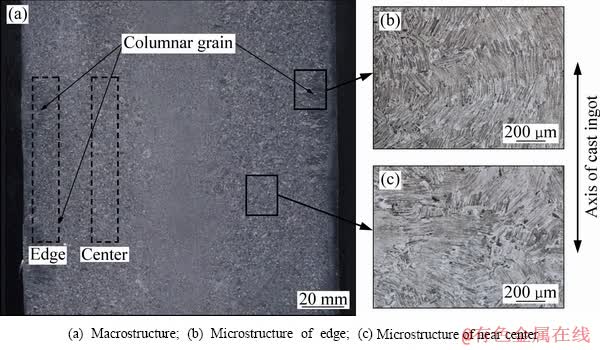

图1(a)所示为热等静压后铸锭纵截面的低倍组织,可见铸锭边缘存在柱状晶,如箭头所示,其片层界面迹线平行于铸锭轴向(见图1(b));而铸锭芯部晶粒细小,片层取向杂乱无序(见图1(c))。SU等[13]的研究表明,Ti-46Al合金在凝固速率较大时发生α相平面生长,而在凝固速率较小时发生β胞状生长或β枝晶生长。金属凝固过程中,由于钢模的激冷作用,边缘凝固速率大,α相沿着<0001>方向平面生长,在冷却过程中按照Blackburn取向关系形成α2+γ两相片层组织,片层界面与生长方向垂直,即平行于铸锭轴向;而芯部凝固速率较小,金属发生β凝固,但在后续凝固过程中由于Al在枝晶间的偏析而导致包晶相α相领先生长,并且偏离其择优取向<0001>[14],从而形成片层界面迹线取向杂乱的组织。

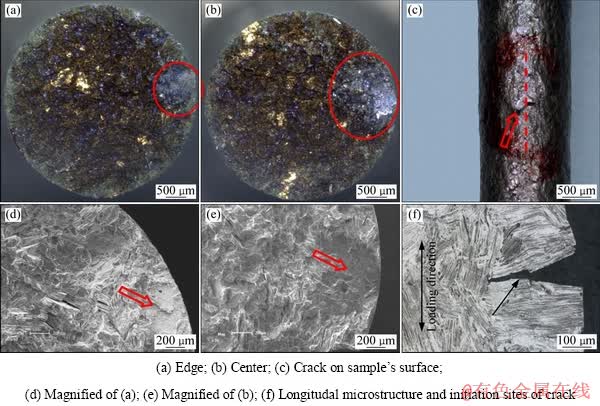

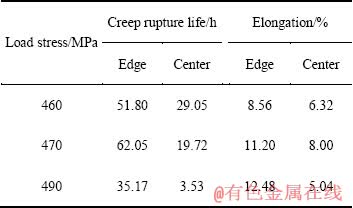

持久强度试验结果如表2所示。可见:随着加载应力增加,材料持久寿命减小;相同应力条件下,铸锭边缘试样的持久寿命和断后伸长率均优于靠近铸锭芯部的试样。对比二者宏观断口形貌(见图2(a)~(b),加载应力为470 MPa)可见:二者断口边缘均存在深色区域,这与持久试样表面开裂但未迅速断裂(见图2(c)箭头处)而经历长时间的高温氧化有关。从图2可看出,边缘试样的氧化面积比芯部试样的小,相应的持久寿命较长、断后伸长率较大,这说明较难萌生裂纹的试样具有更好的持久性能,并在断裂前已发生充分塑性变形。采用扫描电镜观察裂纹形核位置可观察到界面平直且片层与加载方向接近垂直的晶粒,如图2(d)~(e)箭头所示。观察持久试样表面开裂处(见图2(c)虚线处)纵向组织可发现,开裂晶粒的片层界面与加载方向几乎垂直(见图2(f))。

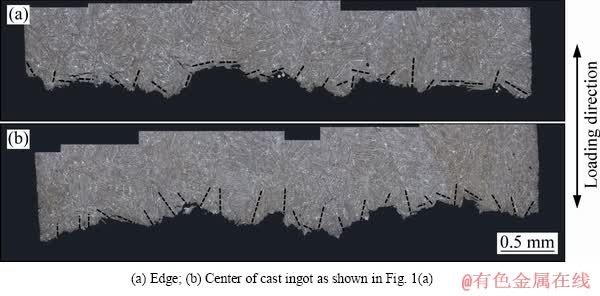

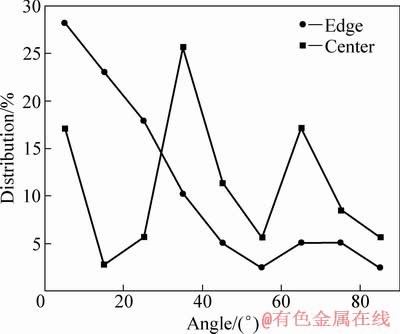

持久试样断口处纵向显微组织见图3,其中,虚线为片层界面迹线,加载应力为490 MPa。可见:持久寿命较长的试样断口处大多数晶粒的片层界面迹线与加载方向夹角较小(见图3(a));而持久寿命较短的试样断口处大多数晶粒的片层界面迹线(即图中虚线)与加载方向夹角较大,甚至接近90°(见图3(b))。

图1 铸锭的宏观组织及不同取样位置的微观组织

Fig. 1 Macrostructure and microstructures of different parts of ingot

图2 不同试样的断口形貌和纵向表面裂纹及显微组织

Fig. 2 Fracture morphologies, cracks, and microstructures of different samples

图3 拉断试样断口纵向显微组织

Fig. 3 Longitudinal microstructures of creep rupture specimens

表2 650 ℃不同加载应力下的持久性能

Table 2 Creep rupture life and elongation of samples tested under different load stress at 650 ℃

以上试验结果表明,晶粒片层界面取向与加载方向夹角较大时,片层界面更容易发生裂纹形核,从而导致较低的持久寿命和断后伸长率,这与两相片层间的变形传递受阻而应力集中导致片层开裂有关。已有研究表明,片层界面与加载方向平行时,α2相棱柱面滑移所需临界剪切应力较小,γ+α2两相片层更易发生协调变形,从而表现出较好的断后伸长率;而与加载方向垂直时,α2相较难发生临界分切应力较大的锥面滑移,从而导致两相片层界面处应力集中并最终开裂,相应断后伸长率较低[8, 15]。因此,边缘试样由于大部分晶粒的两相片层界面与加载方向接近平行,两相片层较难发生裂纹形核且变形充分,从而表现出较高的持久寿命和断后伸长率;而芯部试样由于存在较多片层界面与加载方向垂直的片层晶粒,两相片层易发生裂纹形核,从而表现出较低的持久寿命和断后伸长率。

图4 持久试样断口附近晶粒片层界面迹线与加载方向间夹角的分布

Fig. 4 Distributions of angle between trace line of lamellar boundary and loading direction near fracture surface of test samples corresponding to Fig. 3

3 结论

1) Ti-46.4Al-2Cr-2.1Nb-0.1B合金铸锭边缘多为片层界面与铸锭轴向平行的晶粒,而芯部为片层取向杂乱的晶粒,这与相应区域凝固速率不同导致的领先相不同有关。

2) 全片层组织的高温持久性能与片层界面和加载方向之间夹角有关,角度较大时两相片层较难协调变形而在片层界面产生应力集中,最终导致两相片层开裂,从而表现出较低的持久寿命和断后伸长率。

REFERENCES

[1] KOTHARI K, RADHAKRISHNAN R, WERELEY N W. Advances in gamma titanium aluminides and their manufacturing techniques[J]. Progress in Aerospace Sciences, 2012, 55: 1-16.

[2] APPEL F, BROSSMANN U, CHRISTOPH U, EGGERT S, JANSCHEK P, LORENZ U. Recent progress in the development of gamma titanium aluminide alloys[J]. Advanced Engineering Materials, 2000, 2(11): 699-720.

[3] APPEL F. Mechanistic understanding of creep in gamma-base titanium aluminide alloys[J]. Intermetallics, 2001, 9(10/11): 907-914.

[4] DLOUH A,  K, and ORLOV A. Long-term creep and creep rupture characteristics of TiAl-base intermetallics[J]. Materials Science and Engineering A, 2009, 510/511: 350-355.

K, and ORLOV A. Long-term creep and creep rupture characteristics of TiAl-base intermetallics[J]. Materials Science and Engineering A, 2009, 510/511: 350-355.

[5] 董利民, 崔玉友, 杨 锐. 微量B和C对铸造 TiAl 合金高温性能的影响[J]. 金属学报, 2002, 38(z1): 66-69.

DONG Li-min, CUI Yu-you, YANG Rui. The effects of minor alloying elements B and C on high temperature properties of a cast TiAl based alloy[J]. ActaMetallurgica Sinica, 2002, 38(z1): 66-69.

[6] 李臻熙, 曹春晓. 添加微量硼对TiAl 合金持久性能的影响[J]. 中国有色金属学报, 2005, 15(6): 836-841.

LI Zhen-xi, CAO Chun-xiao. Effect of minor boron addition on creep rupture property of TiAlalloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(6): 836-841.

[7] CHEN W R, TRIANTAFILLOU J, BEDDOES J, ZHAO L. Effect of fully lamellar morphology on creep of a near γ-TiAl intermetallic[J]. Intermetallics, 1999, 7(2): 171-178.

[8] UMAKOSHI Y, NAKANO T. The role of ordered domains and slip mode of α2 phase in the plastic behaviour of TiAl crystals containing oriented lamellae[J]. Acta Metallurgica et Materialia, 1993, 41(4): 1155-1161.

[9] INUI H, OH MH, NAKAMURA A, YAMAGUCHI M. Room-temperature tensile deformation of polysynthetically twinned (PST) crystals of TiAl[J]. Acta metallurgica et materialia, 1992, 40(11): 3095-3104.

[10] DAVIDSON D L and CAMPBELL J B. Fatigue crack growth through the lamellar microstructure of an alloy based on TiAI at 25 ℃ and 800 ℃[J]. Metallurgical Transactions A, 1993, 24(7): 1555-1574.

[11] GNANAMOORTHY R, MUTOH Y, HAYASHI K, MIZUHARA Y. Influence of lamellar lath orientation on the fatigue crack growth behavior of gamma base titanium aluminides[J]. Scripta Metallurgica et Materialia, 1995, 33(6): 907-912.

[12] MITAO S, ISAWA T, TSUYAMA S. Lamellar orientation dependent anisotropy of fracture toughness in γ-base titanium aluminide[J]. Scripta Metallurgica et Materialia, 1992, 26(9): 1405-1410.

[13] SU Yan-qing, LIU Chang, LI Xin-zhong, GUO Jing-jie, LI Bang-sheng, JIA Jun. Microstructure selection during the directionally peritectic solidification of Ti-Al binary system[J]. Intermetallics, 2005, 13(3/4): 267-274.

[14] 张 元, 李新中, 刘国怀, 苏彦庆, 郭景杰, 傅恒志. 定向凝固Ti-46Al-2Cr-2Nb 合金领先相及其生长取向与凝固进程的相关性[J]. 金属学报, 2013, 49(9): 1061-1068.

ZHANG Yuan, LI Xin-zhong, LIU Guo-huai, SU Yan-qing, GUO Jing-jie, FU Heng-zhi. Dependence of primary phase and its growth direction on solidification process in directionally solidified Ti-46Al-2Cr-2Nb alloy[J]. ActaMetallurgica Sinica, 2013, 49(9): 1061-1068.

[15] 刘仁慈. Ti-47Al-2Cr-2Nb-0.15B 合金挤压变形组织演变及其力学性能研究[D]. 沈阳: 中国科学院金属研究所, 2013: 70-71.

LIU Ren-ci.Microstructure evolution and mechanical properties of Ti-47Al-2Cr-2Nb-0.15B alloy processed by hot extrusion[D]. Shenyang: Institute of Metal Research, 2013: 70-71.

(编辑 赵 俊)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:刘仁慈,助理研究员,博士;电话:024-83970951;E-mail:rcliu@imr.ac.cn