烧结温度对BN/Ni(Cr)自润滑材料组织与性能的影响

蒋冰玉,王日初,彭超群

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:以Ni-20%Cr(质量分数)合金粉末作为基体材料,添加体积分数为31.4%的六方BN(h-BN)作为固体润滑剂,采用粉末冶金法制备BN/Ni(Cr)自润滑复合材料。研究不同烧结温度对该复合材料硬度、弯曲强度和孔隙率以及显微组织的影响。研究结果表明:BN/Ni(Cr)自润滑材料的硬度和抗弯强度与Ni-Cr颗粒烧结颈的形成、长大以及孔隙率的变化有关;当烧结温度不超过1 180 ℃时,随着温度的升高,BN/Ni(Cr)复合材料的孔隙率下降,硬度和弯曲强度均呈上升趋势。

关键词:BN/Ni(Cr)复合材料;烧结温度;显微组织;力学性能

中图分类号:TG135+.6 文献标志码:A 文章编号:1672-7207(2012)01-0093-07

Influence of sintering temperature on structure and properties of BN/Ni(Cr) self-lubricating composites

JIANG Bing-yu, WANG Ri-chu, PENG Chao-qun

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: BN/Ni(Cr) self-lubricating composites were fabricated by powder metallurgy, where the Ni-Cr solid solution powder was used as matrix material, with a hexagonal BN(h-BN) powder added as solid lubricant. Effects of sintering temperature on the density, porosity, hardness and three-point bending strength were studied. Meanwhile, the microstructural evolution of BN/Ni(Cr) composites was observed. It is found that the hardness and three-point bending strength of BN/Ni(Cr) self-lubricating composites are related to the formation, growth of the sintered necks and variance of the porosity. Besides, when the temperature is no higher than 1 180 ℃, the porosity of BN/Ni(Cr) composites decreases with the increase of temperature, while the hardness and three-point bending strength of them increase.

Key words: BN/Ni(Cr) composites; sintering temperature; microtructure; mechanical properties

在现代科技和国防建设中,为了发展热动力机械等先进技术,需要研制能够在高温下使用的自润滑复合材料[1]。在高温自润滑材料的摩擦过程中,基体材料的主要作用是承担载荷和抵抗磨损,必须具有优异的高温力学性能、抗氧化性能和抗腐蚀性能[2]。迄今为止,可以用作高温自润滑材料基体的有镍基、铁基、铜基、银基、轻金属基和难熔金属基等[3]。有着“发动机心脏”之称的镍基高温合金在650~1 000 ℃高温下仍具有优良的力学性能,能在高温和高应力条件下工作,是高温合金中应用最广、高温强度最高的一类合金[4]。含15%~22%铬(质量分数)的镍基固溶合金既具有抗高温氧化性及耐腐蚀性能,又能保持优异的高温力学性能[5-6],逐渐成为高温自润滑复合材料的主要基体材料。常用的固体润滑剂有石墨、MoS2和六方BN(h-BN)等。h-BN、石墨和MoS2都属于层状六方晶系,因而具有极易滑动的解理面和较低的摩擦因数。但h-BN热稳定性比石墨和MoS2的更强,在900 ℃下性能仍然稳定,表现出良好的可磨耗性能和润滑性能,是高温自润滑材料的优良添加剂,已被用作航空航天发动机的高温可磨耗密封材料[7-8]。采用Ni-Cr合金为基体材料,添加h-BN形成的BN/Ni(Cr)复合材料有着独特的性能,是一种理想的燃气轮机中密封减摩用的高温自润滑材料。研究表明[9-10]:提高固体润滑剂含量有利于镍基自润滑材料的增滑和减摩作用;当固体润滑剂含量增加到一定程度时就会阻碍烧结的进 行。魏圣明等[11]研究了BN对镍基可磨耗密封材料烧结性能的影响,发现当h-BN的体积分数超过16.3%时,烧结严重受阻,几乎不形成烧结颈,BN/Ni(Cr)复合材料性能较差。采用热压烧结方法制备BN/Ni(Cr)复合材料,当BN的体积分数达到31.4%时,其弯曲强度只有41.1 MPa[12]。因此,研究具有优异综合性能的BN/Ni(Cr)复合材料是该复合材料研究的重点。本文选用Ni-20%Cr(质量分数)固溶合金作为基体材料,添加高体积分数为31.4%的预处理后的h-BN粉末,通过粉末冶金工艺制备BN/Ni(Cr)可磨耗密封材料,探讨烧结温度对该复合材料的力学性能和组织特征的影响。

1 实验过程

1.1 材料制备

在真空熔炼炉中熔炼Ni-20%Cr(质量分数)固溶体合金锭坯,利用HERMIGA高能气体雾化系统,在氩气保护下采用雾化法制备出Ni-Cr固溶体合金粉末,筛取平均粒度为D≤38 μm的Ni-Cr合金粉末,粉末形貌如图1(a)所示,主要呈球形颗粒;六方晶型BN(h-BN) 由丹东日进科技有限公司生产,其平均粒度D≤2 μm,颗粒形貌如图1(b)所示,呈鳞片状。

按BN质量分数为11%配料,使BN/Ni(Cr)复合材料中BN的体积分数达到31.4%(如表1所示)。将BN粉末预处理,当2种粉末混合均匀后,在300 MPa压力下冷压成形,试样尺寸为50 mm×10 mm×3 mm (长×宽×高), 然后在真空碳管炉中烧结,真空度为0.5 Pa。烧结温度为:1 050,1 100,1 150,1 180和 1 200 ℃,保温时间为1 h,随炉冷却。

1.2 性能测试

在不同烧结温度下BN/Ni(Cr)合金试样的3点弯曲实验参照GB 2038—91标准,在CMT-7205电子万能试验机上测定,样品弯曲跨度为30 mm,弯曲速率为1 mm/min。在德国NETZSCH STA449C综合热分析仪上进行差热分析(DSC)和热重分析(TG)测试。在HW187.5 型布洛维硬度计上进行布氏硬度测试,选用直径为5 mm 钢球、62.5 N 载荷和30 s保压时间。利用阿基米德排水法测量密度。试样的物相分析在Rigaku D-MAX2000型X线衍射仪上进行,在Sirion200场发射扫描电镜上观察材料弯曲断口形貌。

图1 Ni-Cr合金粉末和BN粉末的扫描电镜照片

Fig.1 SEM images of Ni-Cr alloy powders and BN alloy powders

表1 BN/Ni(Cr)复合材料的质量配比和体积分数

Table 1 Mass fraction and volume fraction of BN/Ni(Cr) composites

2 结果与分析

2.1 BN/Ni(Cr)试验合金烧结温度的确定

烧结温度对烧结制品的组织性能至关重要。一般认为,温度越高,烧结制品的致密化和合金化过程进行得越好,具体表现在:(1) 烧结体致密度逐渐提 高;(2) 粉末颗粒结合部位增多,并逐渐形成冶金结合;(3) 孔隙逐步减少,但也伴随有晶粒尺寸变大。若烧结温度低, 烧结过程所发生的各种致密化行为无法充分进行,则烧结制品的性能达不到使用要求。因此,合适烧结温度的确定十分重要。

图2所示为BN/Ni(Cr)试验合金在1 000~1 400 ℃的DSC和TG曲线。由图2可知:该合金在1 097.2~ 1 162.0 ℃之间有1个较大的吸热峰,峰值约为1 138.8 ℃;当烧结温度1 200 ℃时,BN/Ni(Cr)合金质量损失明显。

图2 BN/Ni(Cr)合金粉末的TG和DSC曲线

Fig.2 TG and DSC graph of BN/Ni(Cr) alloy powders

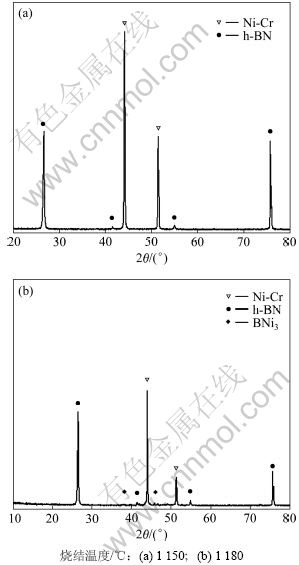

BN/Ni(Cr)试验合金在1 150 ℃和1 180 ℃烧结温度下的X线衍射(XRD)分析如图3所示。由图3可见:BN/Ni(Cr)试验合金在1 050 ℃和1 100 ℃烧结温度下的XRD与1 150 ℃相似,固溶相Ni-Cr成为BN/Ni(Cr)材料中X线强度最大的物相,烧结试样主要由h-BN和Ni-Cr固溶体相组成;而BN/Ni(Cr)试验合金在 1 180 ℃烧结温度下的X线衍射图谱中发现除了有Ni-Cr固溶体相和BN相外,还有少量的BNi3相生成。这是由于在1 180 ℃烧结温度下,BN与Ni-Cr固溶体中的Ni发生反应生成硼镍化合物,而少量的硼镍化合物对BN/Ni(Cr)材料能起到活化烧结作用。在实验过程中,当烧结温度为1 200 ℃时,保温1 h后取出的BN/Ni(Cr)合金试样已发生严重的歪曲和变形的“过烧”现象。因此,实验中尝试选择的烧结温度分别为1 050,1 100,1 150和1 180 ℃,保温时间为1 h。

2.2 断口形貌分析

在不同温度下烧结后BN/Ni(Cr)复合材料中Ni-Cr颗粒烧结的弯曲断面形貌如图4所示。从图4(a)可知:于1 050 ℃烧结后试样处于烧结的初期阶段,Ni-Cr颗粒间的原始接触点或面转变成线接触或部分面接触,并开始形成烧结颈,因此,烧结强度较低。于1 100 ℃烧结试样的断口形貌见图4(b),可以看到Ni-Cr颗粒间距离缩小,黏结面扩大,致使烧结颈长大。于1 150 ℃烧结后试样断口形貌如图4(c)所示,可见烧结颈进一步长大,Ni-Cr颗粒并合形成粗大的晶粒。于1 180 ℃烧结后试样断口形貌如图4(d)所示,可见大量Ni-Cr颗粒并合长大形成连续的Ni-Cr合金基体,BN/Ni(Cr)复合材料孔隙减少,Ni-Cr基体结合的更紧密。

图3 BN/Ni(Cr)试样的XRD分析

Fig.3 XRD patterns of BN/Ni(Cr) sample

影响BN/Ni(Cr)复合材料的断裂强度主要有3个因素,即BN颗粒间的结合强度、BN与Ni-Cr颗粒间的结合强度以及Ni-Cr颗粒间的结合强度。图5所示为1 150 ℃烧结试样的弯曲断口形貌。图5中A所示区域为片状BN颗粒的断裂情况,由于陶瓷化合物BN颗粒在一般温度下很难烧结,需要在1 600~1 800 ℃温度下采取热压烧结才能烧结成形,故本文采用常压烧结且烧结温度低于1 200 ℃,该温度远达不到1 600~1 800℃的要求,因而,BN颗粒间结合强度十分弱小。图5中B区域可见类似蜂窝状的凹坑,这是由于压制过程中形成的Ni-Cr颗粒与BN的接触面,在弯曲过程中接触面断开而形成凹坑面。由于Ni-Cr和BN在烧结温度范围内不发生烧结扩散和冶金结合,只是简单的机械结合,因此,这部分的结合强度也是十分弱小。图5中C区域为Ni-Cr颗粒间弯曲断裂留下的撕裂面。Ni-Cr颗粒间因为发生扩散烧结,从而形成烧结颈,烧结颈的形成和长大使基体材料的结合强度提高,因而Ni-Cr颗粒间的结合强度是BN/Ni(Cr)复合材料强度的主要来源。

图4 不同温度烧结的BN/Ni(Cr)合金试样的弯曲断口形貌

Fig.4 Three-point bending fracture morphologies of BN/Ni(Cr) specimens sintered at different sintering temperatures

图5 1 150 ℃烧结BN/Ni(Cr)试样的弯曲断口形貌

Fig.5 Morphology of the bending fracture of BN/Ni(Cr) specimen sintered at 1 150 ℃

2.3 烧结温度对BN/Ni(Cr) 3点抗弯强度的影响

不同温度烧结下BN/Ni(Cr)复合材料的抗弯强度曲线如图6所示。从图6可以看出:材料的抗弯强度随温度升高而增加;在1 050 ℃烧结样品的最大抗弯强度为32.9 MPa,而在1 180 ℃的最大抗弯强度达到182.4 MPa。随着烧结温度高,断裂前的弯曲挠度也不断增加。1 050 ℃烧结试样的断裂挠度约为0.5 mm,而1 180 ℃烧结样品的断裂挠度超过5 mm。这说明烧结温度不但提高BN/Ni(Cr)复合材料的弯曲强度,而且使其韧性大幅度提高。

图6 不同温度烧结BN/Ni(Cr)合金试样的弯曲强度变化曲线

Fig.6 Variation of bending strength of BN/Ni(Cr) specimens sintered at different temperatures

由于Ni-Cr颗粒烧结颈的长大和粗化,材料在外力作用下的实际承力面积增大,发生断裂时需要克服的Ni-Cr颗粒间的塑性变形增多,需要更高的变形抗力和变形量。因此,随着烧结温度升高,Ni-Cr颗粒间烧结颈长大更充分,材料致密化程度提高,Ni-Cr基体的结合强度增加,因而BN/Ni(Cr)复合材料的抗弯强度得以提高,并且弯曲挠度也大幅度增加。抗弯强度是与材料整体性质有关的物理量,体现了材料整体的结合强度。由此可见,升高烧结温度有助于提高材料的结合强度。

2.4 烧结温度对密度和硬度的影响

烧结温度对BN/Ni(Cr)复合材料密度和硬度的影响如图7所示。从图7可以看出:当合金试样的烧结温度从1 050 ℃上升到1 180 ℃时,密度从4.78 g/cm3上升5.36 g/cm3,硬度从15.4提高到22.8。因此,提高烧结温度有利于BN/Ni(Cr)复合材料密度和硬度的增加。

图7 烧结温度对BN/Ni(Cr)复合材料密度和硬度的影响

Fig.7 Effect of sintering temperatures on density and hardness of BN/Ni(Cr) composites

随着烧结温度升高,具有可以克服能垒扩散激活能Q的质点浓度将显著增加,从而使质点的扩散系数增大。扩散系数D与烧结温度T的实验关系式[13]可以表示为:

(1)

(1)

式中:D0为扩散常数;Q为扩散激活能;R为气体常数。

烧结温度升高时,原子扩散系数增大,借助于热起伏使扩散原子获得超越势垒的能量增加,烧结驱动力增强使原子在驱动力下发生扩散的速度逐渐增加,使Ni-Cr颗粒相互靠近并进一步增大颗粒的接触面积,烧结颈长大使烧结进行得更充分,BN/Ni(Cr)材料的孔隙减少,使得材料产生少量收缩,因此,BN/Ni(Cr)复合材料的密度增大。

硬度是材料抵抗局部塑性变形能力的表征。随着温度升高,原子扩散增强,使基体组织中的孔洞和缺陷减少,材料的致密度提高,相界面增多,对位错的阻碍作用增大,塑性变形抗力增大,材料的硬度 提 高[14]。

2.5 不同烧结温度下孔隙率对强度和硬度的影响

不同温度烧结BN/Ni(Cr)合金试样的孔隙率、硬度和强度变化曲线如图8所示。从图8可看出:随着烧结温度的提高,材料的密度从4.78 g/cm3上升到 5.36 g/cm3,说明材料中的孔隙率随着烧结温度的提高而下降。孔隙率θ是烧结材料的基本特性参数,粉末冶金材料的孔隙率可以用下式计算:

(2)

(2)

式中: 为孔隙材料密度;

为孔隙材料密度; 为全致密化材料密度。对于BN/Ni(Cr)复合材料全致密化密度可用加和公式来计算,即:

为全致密化材料密度。对于BN/Ni(Cr)复合材料全致密化密度可用加和公式来计算,即:

(g/cm3) (3)

(g/cm3) (3)

式中:w1和 分别为Ni-Cr合金的质量分数和全致密化密度,w1为89%,

分别为Ni-Cr合金的质量分数和全致密化密度,w1为89%, 为8.482 g/cm3;w2和

为8.482 g/cm3;w2和 分别为h-BN的质量分数和全致密化密度,w2为11%,

分别为h-BN的质量分数和全致密化密度,w2为11%, 为2.29 g/cm3。

为2.29 g/cm3。

孔隙率θ为

(4)

(4)

由图7所得烧结试样的密度代入式(4)可以计算孔隙率。图8所示为BN/Ni(Cr)复合材料的孔隙率、强度和硬度与烧结温度的关系曲线。

从图8可以看出:随着烧结温度升高,合金试样孔隙率显著下降。BN/Ni(Cr)复合材料在1 050 ℃的孔隙率为26.89%,而在1 180 ℃的孔隙率降低到18.02%。这是由于随着烧结温度升高,原子扩散速度逐渐增大,必然引起烧结颈长大,材料致密度提高,从而使得孔隙率降低[15]。

孔隙是材料微裂纹产生和破坏的应力集中地,是导致材料力学性能(如强度、硬度等)降低的主要因素。孔隙率的减少使孔隙的作用由强减弱,材料的强度和硬度提高。由图4所示断口扫描形貌可以看出:温度升高,孔隙明显减少,Ni-Cr颗粒黏结面扩大,烧结颈长大;颗粒之间由分子间力转变为较强的晶体结合键力,颗粒之间的结合力大大提高,孔隙率降低进而使材料的致密化程度提高,烧结体的强度增加。材料基体中的孔隙率对硬度也有较大影响,孔隙越少越小,Ni-Cr颗粒结合得更加紧密,基体结合强度提高,材料致密度提高则硬度越高。

图8 不同温度烧结BN/Ni(Cr)合金试样的孔隙率、硬度和强度变化曲线

Fig.8 Variation of sintered porosity, hardness and bending strength versus sintering temperatures

孔隙度θ与抗弯强度σbb间的关系[16]为

(6)

(6)

式中: 为当孔隙度趋于0时材料的抗弯强度,当近似计算时, 可用致密材料的抗弯强度代替;

为当孔隙度趋于0时材料的抗弯强度,当近似计算时, 可用致密材料的抗弯强度代替; 为与孔隙形状有关的常数。由式(6)可知:孔隙率降低会引起抗弯强度显著提高,这与图8所示结果相吻合。

为与孔隙形状有关的常数。由式(6)可知:孔隙率降低会引起抗弯强度显著提高,这与图8所示结果相吻合。

3 结论

(1) 随着烧结温度的提高,Ni-Cr颗粒烧结颈不断长大,出现颗粒并合现象。Ni-Cr颗粒烧结颈的直径影响BN/Ni(Cr)自润滑材料硬度和抗弯强度。

(2) 在1 050 ℃至1 180 ℃范围内,随烧结温度升高,BN/Ni(Cr)复合材料的孔隙率降低,密度和硬度增加,材料的抗弯强度和弯曲挠度显著提高。

(3) 在1 180 ℃/1 h的条件下,BN/Ni(Cr)复合材料获得优异的综合性能:材料的孔隙率、密度、布氏硬度和弯曲强度分别达到18.0%,5.36 g/cm3,22.8和182.3 MPa;在1 200 ℃温度烧结,保温1 h后取出的合金试样发生了歪曲和变形的“过烧”现象。

参考文献:

[1] 魏圣明, 王日初, 李庆勇, 等. BN对镍基可磨耗密封材料烧结性能的影响[J]. 稀有金属材料与工程, 2006, 35(1): 127-130.

WEI Sheng-ming, WANG Ri-chu, LI Qin-yong, et al. Effect of BN on sintering properties of Ni-based abradable seal alloy[J]. Rare Metal Material and Engineering, 2006, 35(1): 127-130.

[2] 余琨, 阳震, 王日初, 等. 活化烧结工艺制备Ni-Cr/BN自润滑复合材料[J]. 中南大学学报: 自然科学版, 2008, 39(3): 538-542.

YU Kun, YANG Zhen, WANG Ri-chu, et al. Preparation of Ni-Cr/BN self-lubricating composites by active sintering process[J]. Journal of Central South University: Science and Technology, 2008, 39(3): 538-542.

[3] Wang A H, Zhang X L, Zhang X F, et al. Ni-based alloy/ submicron WS2 self-lubricating composite coating synthesized by Nd:YAG laser cladding[J]. Materials Science and Engineering,2008, 475(1/2): 312-318.

[4] Choudhury I A, El-Baradie M A. Machinability of nickel-base super alloys: a general review[J]. Journal of Materials Processing Technology, 1998, 77(1/3): 278-284.

[5] 刘如铁, 李溪滨, 程时和. Ni-Cr-Mo-S合金的自润滑机理[J]. 中国有色金属学报, 2003, 13(2): 469-473.

LIU Ru-tie, LI Xi-bin, CHENG Shi-he. Self-lubrication mechanism of Ni-Cr-Mo2S alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 469-473.

[6] Lin Hsinyi, Bowers Bonnie, Wolan J T, et al. Metallurgical, surface, and corrosion analysis of Ni-Cr dental casting alloys before and after porcelain firing[J]. Dental Materials,2008, 24(3): 378-385.

[7] ZHANG Shi-tang, ZHOU Jian-song, GUO Bao-gang, et al. Friction and wear behavior of laser cladding Ni/h-BN self- lubricating composite coating[J]. Materials Science and Engineering, 2008, 491(1/2): 47-54.

[8] 孔晓丽, 刘勇兵, 陆有, 等. 粉末冶金高温金属基固体自润滑材料[J]. 粉末冶金技术, 2001, 19(2): 86-92.

KONG Xiao-li, LIU Yong-bing, LU You, et al. P/M metal- matrix high-temperature solid self-lubricating materials[J]. Powder Metallurgy Technology, 2001, 19(2): 86-92.

[9] LU Jin-jun, YANG Sheng-rong, WANG Jing-bo, et al. Mechanical and tribological properties of Ni-based alloy/CeF3/ graphite high temperature self-lubricating composites[J]. Wear,2001, 249(12): 1070-1076.

[10] LI Jian-liang, XIONG Dang-sheng, HUO Ming-feng. Friction and wear properties of Ni-Cr-W-Al-Ti-MoS2 at elevated temperatures and self-consumption phenomena[J]. Wear,2008, 265(3/4): 566-575.

[11] 魏圣明, 王日初, 李庆勇, 等. BN对镍基可磨耗密封材料烧结性能的影响[J]. 稀有金属材料与工程, 2006, 35(1): 127-130.

WEI Sheng-ming, WANG Ri-chu, LI Qin-yong, et al. Effect of BN on sintering properties of Ni-based abradable seal alloy[J]. Rare Metal Material and Engineering, 2006, 35(1): 127-130.

[12] 冯艳, 王日初, 余琨. Ni-Cr/BN自润滑材料摩擦磨损机理分析[J]. 稀有金属材料与工程, 2007, 36(10): 1820-1823.

FENG Yan, WANG Ri-chu, YU Kun. Analyses of frictional wear mechanics of Ni-Cr/BN self-lubricating composites[J]. Rare Metal Material and Engineering, 2007, 36(10): 1820-1823.

[13] 崔国文. 缺陷、扩散与烧结[M]. 北京: 清华大学出版社, 1990: 54.

CUI Guo-wen. Deficiency, diffusion and sintering[M]. Beijing: Tsinghua University Press, 1990: 54.

[14] 尹延国, 杜春宽, 郑治祥, 等. 镀镍石墨粉对铜基石墨复合材料力学性能的影响[J]. 中国有色金属学报, 2006, 16(11): 1895-1901.

YIN Yan-guo, DU Chun-kuan, ZHENG Zhi-xiang, et al. Effect of graphite coated with nickel on mechanical properties of copper-matrix/graphite composite materials[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(11): 1895-1901.

[15] 姚萍屏, 张忠义, 汪琳, 等. 烧结温度对铁基粉末冶金航空刹车材料组织的影响[J]. 粉末冶金材料科学与工程, 2007, 12(3): 160-166.

YAO Ping-ping, ZHANG Zhong-yi, WANG Lin, et al. Effect of sintering temperature on contexture and performance of iron-based P/M aircraft brake materials[J]. Materials Science and Engineering of Powder Metallurgy, 2007, 12(3): 160-166.

[16] 丁华东, 李雅文, 浩宏奇, 等. 铜石墨材料抗弯强度与孔隙的关系[J]. 中国有色金属学报, 1996, 6(4): 123-126.

DING Hua-dong, LI Ya-wen, HAO Hong-qi, et al. Grey equation between bending strength and porosity of copper graphite material[J ]. The Chinese Journal of Nonferrous Metals, 1996, 6(4): 123-126.

(编辑 邓履翔)

收稿日期:2011-01-02;修回日期:2011-03-28

基金项目:国家民口配套科研项目(MKPT-03-182)

通信作者:王日初(1965-),男,广东和平人,教授,博士,从事有色金属材料研究;电话:0731-8836638;E-mail: wrc910103@163.com