文章编号:1004-0609(2009)03-0469-08

超大直径2219铝合金环轧件的显微组织与力学性能

李红英,王法云,王晓峰,孙 远,赵延阔

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:采用力学性能测试、金相组织观察、透射电镜及扫描电镜观察,研究现代数控轧环机轧制的超大直径2219铝合金环形件的显微组织与力学性能。结果表明:环形件各区域变形比较均匀和充分,其金相组织均匀,θ′ 强化相细小弥散分布;与美国军用标准相比,其力学性能富裕量普遍较大;局部区域的晶粒粗大且大小不均匀、粗大的平衡相、Mn和Fe元素富集而形成的脆性相的存在是造成实验中7个试样力学性能富裕量相对较小的原因。

关键词:2219铝合金;环轧工艺;显微组织;力学性能

中图分类号:TG 146.2 文献标识码:A

Microstructures and mechanical properties of

super large diameter 2219 aluminum alloy ring

LI Hong-ying, WANG Fa-yun, WANG Xiao-feng, SUN Yuan, ZHAO Yan-kuo

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The microstructures and mechanical properties of super large diameter 2219 aluminum alloy ring rolled by the modern radial-axial numerical controlled rolling machine were studied by tensile properties test, optical microscopy (OM), transmission electron microscopy (TEM) and scanning electron microscopy (SEM). The results show that the sufficient plastic deformation is applied uniformly on the work piece. The optical microstructure is homogeneous. In addition, the strengthening phase θ′ is fine and dispersive. As a result, the mechanical properties of the ring are superior to those with a similar diameter in American Military Standard. The existence of coarsening or uneven grains, large equilibrium phases and brittle phases rich in Mn and Fe in local areas are the main reasons leading to the relative poor mechanical properties of seven samples.

Key words: 2219 aluminum alloy; rolling technology; microstructure; mechanical properties

2219铝合金具有比强度高、低温和高温力学性能好、断裂韧性好以及抗应力腐蚀性能、加工性能和焊接性能好等特点,广泛应用于航空航天领域,尤其被用作火箭箱体材料[1]。近20年来,国外研制的大型运载火箭,几乎都采用2219铝合金作为箱体材料[2]。为了减小应力集中,提高运载火箭承载能力,一般将其制成环形件[3],但是,国内生产的铝合金环轧件都是在水压机上采用自由锻工艺锻造,存在精度差、效率低、材料利用率低、外径尺寸受到限制等缺点。目前,我国能制造的环形坯件的最大直径为3 m,而航天工业需要的是最大直径为5 m或更大的高强度精密铝合金环形件。基于需要,国内某厂家已经应用新研制的径?轴向数控轧环机轧制了直径大于5 m的2219铝合金环轧件。关于2219铝合金及其超大直径环形件,目前只有对焊接工艺[4?6]及轧制工艺[7]的研究报导,而对轧制产品的组织及力学性能的研究未见报道。本文作者对采用现代数控轧环机及其相应的环轧工艺轧制成的超大直径2219铝合金环轧件的显微组织及力学性能进行研究,为大型环轧工艺研究提供了依据。

1 实验

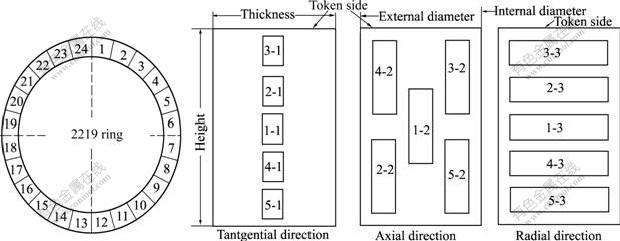

实验材料为2219铝合金环轧件全分析解剖件,其成分(质量分数,%)为:6.8 Cu,0.02 Mg,0.20 Mn,0.10 Zn,0.02 Ti,0.15 V,0.10 Zr,0.30 Fe,0.20 Si,余量为铝。实验材料的处理工艺为:熔铸锭坯、均匀化退火、圆锭镦粗、冲孔、环锻、热环轧成d 5 038 mm×130 mm×345 mm(外径×壁厚×环高)的环轧件、固溶和淬火、冷环轧变形、人工时效。图1所示为轧环机轧制环件示意图[8],主轧辊为驱动辊, 上下锥辊也为驱动辊,芯辊为被动辊, 定心机构的相应运动保证环件的圆度。

图1 轧环机轧制环件的示意图

Fig.1 Sketch map of rolling mill working: 1—King roller; 2—Center fixer; 3—Core roller; 4—Ring; 5—Cone roller

图2所示为取样示意图,将环轧件平均分为24个区段,本实验从奇数段分3个方向取样,切向和径向分别从中心、上下表面、距上下表面1/4处取5个样,轴向从中心、内表面上下和外表面上下取5个样,合计180个试样。文中试样号按照“区段号?位置号?方向号”标示,其中区段标号为1-24,方向号1为切向,方向号2为轴向,方向号3为径向,如17-1-3表示17区段,中心位置,径向。

图2 取样示意图

Fig.2 Sketch map of sampling locations

利用岛津材料试验机进行力学性能试验。采用KYKY?2800型和Sirion200 场发射扫描电镜观察拉伸断口形貌,同时采用能谱分析夹杂物和粗大第二相的成分。利用POLYVAR-MET光学显微镜进行金相组织观察。采用TECNAIG220型透射电镜进行微观组织观察,加速电压为200 kV,试样采用电解双喷减薄,电解液为硝酸与甲醇混合液(体积比为1?3),温度约?20 ℃。

2 结果

2.1 试样的常规拉伸性能

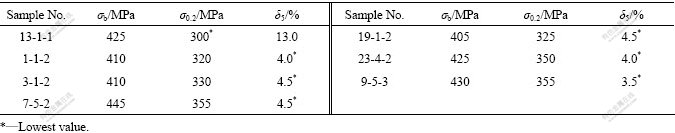

表1所列为所取180个试样的常规拉伸性能实测值范围和美国军用标准2219铝合金同类直径大小的标准值。对照表1中的标准值,所有试样的力学性能都已达标,且大部分富裕量都很大。表2所列为富裕量较小的7个试样及其力学性能(*表示最低值)。

表1 合金的力学性能

Table 1 Mechanical properties of alloy

表2 轧环中富裕量较小的7个试样及其力学性能

Table 2 Seven samples and their special mechanical properties

2.2 试样的金相组织

图3所示为该批测试样中不同区段同一位置(其中表示位置代号的第2个数字均为1,即中心位置)的典型金相组织。图3(a)和(b)所示为切向金相组织,图3(c)和(d)所示为轴向金相组织,图3(e)和(f)所示为径向金相组织。

图3 不同区段中心位置的光学显微组织

Fig.3 Microstructures of central position in different areas: (a) 1-1-1; (b) 19-1-1; (c) 7-1-2; (d) 9-1-2; (e) 3-1-3; (f) 23-1-3

图4所示为第7区段5个不同位置的切向金相组织,其它11个区段不同位置的金相组织与图4所示类似。

图4 区段7不同位置的微观组织

Fig.4 Microstructures of different positions in section seven: (a) 7-1-1; (b) 7-2-1; (c) 7-3-1; (d) 7-4-1; (e) 7-5-1

对表2中的7个试样进行金相组织观察,发现有4个试样出现了非正常组织,其金相组织如图5所示。图5(a)中的晶粒大小不均匀,出现了部分较粗大晶粒,图5(b)~(d)中并未出现细长的纤维状晶粒,且部分晶粒较粗大。

图5 性能最低值试样的光学显微组织

Fig.5 Microstructures of samples with lowest value of property: (a) 13-1-1; (b) 1-1-2; (c) 3-1-2; (d) 9-5-3

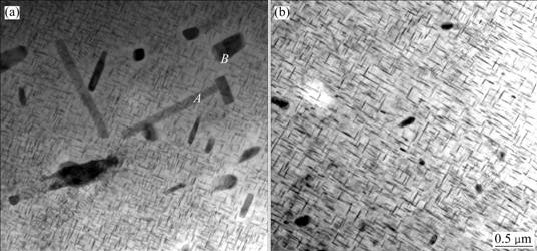

2.3 环轧件的透射显微组织

图6所示为利用透射电子显微镜观察到的环轧件显微组织形貌。由图6可见,合金的主要强化相为相互垂直的θ′相[9?10],且分布较均匀细密。观察表2中7个试样的显微组织发现,除了θ′相外,还有长棒状和近似方形的粗大析出相(如图6(a)),分别对其进行能谱分析,结果如图7所示,分别为Al3Zr和CuMgAl2(S相)[11]析出相。

图6 环轧件的TEM像

Fig.6 TEM images of ring: (a) 1-1-2; (b) 5-4-2

图7 合金第二相的能谱(图6(a)中的A和B)

Fig.7 Energy spectra of second-phase in alloys (points A(a) and B(b) shown in Fig.6 (a))

2.4 试样的拉伸断口形貌

图8所示为典型的拉伸断口形貌。图8(a)和(b)所示为一般试样的拉伸断口形貌(大多数试样形貌),延性断裂特征明显,韧窝多且部分韧窝较深,韧窝中可看到第二相粒子的存在,沿晶断裂程度较小,因而合金的塑性较好。图8(c)、(d)所示为表2中性能较低值(轴向、径向的伸长率)样的断口形貌,断口大部分地方光滑平直,有少量小而浅的韧窝,沿晶断裂特征明显,有些部位可观察到破断的晶界和第二相粒子,合金的塑性低。

图8 轧环拉伸断口的SEM像

Fig.8 SEM images of tensile fracture sections of ring: (a) 7-3-1; (b) 5-4-2; (c) 1-1-2; (d) 9-5-3

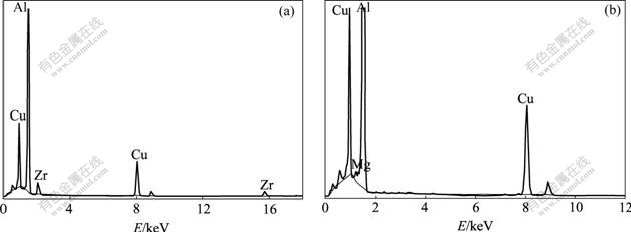

图9所示为断口中第二相粒子的典型能谱。图9(a)所示为对应一般拉伸样的第二相粒子能谱,多为Al2Cu粒子,只有极少数粒子存在Fe、Mn元素的富集。图9(b)所示为伸长率相对较低试样的第二相粒子能谱,粒子多为富集Fe、Mn元素的粗大硬脆相,某些第二相粒子被严重破碎。

图9 典型拉伸断口第二相粒子的SEM像和EDS谱

Fig.9 SEM images and EDS spectra of second-phase on typical tensile fracture sections: (a), (c) 13-1-1; (b), (d) 9-5-3

3 讨论

如图1所示,采用现代数控轧环机轧制环形件时,在主轧辊和芯辊的作用下,环件不断通过辊缝产生连续的局部变形,轧件金属流动沿切线方向延伸,壁厚逐渐减薄,直径不断扩大,在上下锥辊的作用下,轴向宽展受到限制,环件直径扩大时只有少量的轴向宽展(但却能使端面平整)。由图3可以看出,取向不同的金相组织呈现的形式不同,切向多为近似等轴状晶粒,轴向和径向均为纤维组织,且轴向纤维组织比径向更加细长。这说明轧环机轧制时,金属主要沿切线方向延伸,切向变形量最大,而轴向只有少量变形,从而使轴向纤维组织较径向更加细长,这验证了环轧工艺的金属流动和变形特点。由图3还可以看出,取样方向相同时,不同区段同一位置处的晶粒形状相似、尺寸相近,这说明大轧环各个区段的变形基本均匀。从图4可以看出,中心位置、表面位置以及距表面1/4位置处的晶粒的形状基本相似且尺寸基本相同,这说明同一区段不同位置的变形也是基本均匀的,并且变形较充分。

由表1可知,切向取样时其伸长率明显高于轴向和径向取样时的伸长率,这说明切向取样是沿着纤维方向,因而其力学性能好,实际测得的最低值绝大多数为轴向和径向的伸长率。将图5与图3中同一种取样方式所得的组织进行比较可以发现,图5中的晶粒尺寸明显比图3中的大,而且粗细不均匀,这可能是因为这些区域晶粒过分长大,而在随后的冷轧过程中由于变形量不够、破碎不充分所致,与具有细小晶粒的组织相比,晶粒粗大组织变形时晶粒间的协调性变差,产生应力集中的趋势增大,因此会较早出现裂纹和产生断裂,导致塑性相对较差。根据Hall-Petch关系式,多晶体的强度和晶粒的直径呈?1/2次方的关系,晶粒尺寸的增大使合金中晶界区所占的比率减小,消弱晶界强化作用,同时使合金的强度降低[12]。

从图6可以看出,2219环轧件中θ′相尺寸小,密集度很高。这是因为2219铝合金属于高Cu/Mg(>8)比(相对质量比)的Al-Cu-Mg系合金,主要强化相为在{111}α面上半共格析出的θ′相,其典型的时效过程是:α过饱和固溶体→GP区→θ″相→θ′相→θ相[13?14]。θ′相一般优先在位错处形核,由于冷环轧变形引入了大量位错,给θ′相提供了有效的形核位置,从而使θ′相形核数目增加。由于过饱和固溶体中的溶质原子浓度较高,与位错交互作用增强,在位错周围富集形成的气团数目也相继增加,这些富集溶质原子的气团,也是θ′相的核心[15],从而有大量θ′相脱溶析出。由表1可看出,环轧件强度富裕量大,表明强化效果较好,这是因为第二相颗粒体积分数越大,颗粒越小,颗粒数目就越多,颗粒对晶界迁移、位错滑移或攀移所施加的阻力就越大,变形就越困难,强化效果明显提高。同时,脱溶相质点也会阻碍多边化等回复过程的进行,使基体中的亚结构更细,这有利于提高环轧件的强度。由图6(a)可以看出,表2中7个试样的显微组织中除了有θ′相外还有粗大的近似方形的Al3Zr相和板条状的CuMgAl2相。Al3Zr相细小弥散分布时,对位错和晶界具有很强的钉扎作用,可以稳定变形组织的亚结构,阻碍加热时位错重新排列成亚晶界及随后发展成大角度晶界的过程,从而阻碍再结晶形核,抑制再结晶,细化晶粒,有利于提高力学性能[16?17],但在这7个试样中由于以粗大的脆性相形式存在,严重恶化了合金性能,降低了其强度和伸长率。

传统的马架扩孔制出的环件端面是由无数个多边形组成,使用环轧工艺的轧件端面呈圆弧状,且变形均匀、充分,产品精度较高,直径和高度均较大。由表1和表2可以看出,绝大多数试样的性能富裕量很大,仅有7个试样富裕量相对较小,但其力学性能值也高于美国军用标准,这说明采用现代数控轧环机轧制的生产工艺比较合理。2219铝合金铸锭经过锻造和超大变形量的热环轧,使铸造组织中的气孔和疏松等缺陷得到焊合,组织致密性增加,热环轧时反复的形变和再结晶形成了较均匀、细小的变形组织,固溶处理后的冷环轧引入了大量的位错,从而使时效时有大量细小弥散分布的θ′相析出,这种θ′相能随基体一起变形,且位错能以切过粒子的方式移动,因此,环轧件表现出很好的塑性和较高的强度。从图8可看出,绝大多数试样的拉伸断口呈现大量的延性韧窝,且部分韧窝较深,这说明环轧件的塑性较好,可见理论与实验结果吻合得很好。表2列出的7个性能富裕量相对较小的试样多以脆性断裂为主,SEM断口呈现明显的沿晶断裂特征,Fe、Mn元素富集而形成的粗大硬脆相会对基体起割裂作用,在外力作用下,极易产生应力集中而成为裂纹源,导致过早断裂,从而使伸长率和屈服强度降低。如果控制杂质铁和锰含量,可以防止和减少粗大中间相的产生,加入某些微量元素形成高熔点化合物作为异质核心,也可以避免粗大富Fe、Mn的脆性相形成,从而解决大轧环局部区域力学性能富裕量相对较小的问题。

4 结论

1) 相对于传统轧制方法,采用现代数控环轧工艺轧制的2219铝合金大轧环,其组织均匀,强化相θ′相呈细小弥散分布,变形较均匀和充分,力学性能优于美国同类直径大小的军用标准,且富裕量较大。

2) 180个试样中有7个力学性能富裕量相对较小,局部区域变形量不够造成晶粒粗大、大小不均匀,Al3Zr和CuMgAl2以粗大平衡相形式存在以及Mn和Fe元素富集形成的脆性相是实验中7个试样性能较低的原因。

REFERENCES

[1] 陈迎春, 刘会杰, 冯吉才. 2219-0铝合金的搅拌摩擦焊接[J]. 焊接学报, 2006, 27(1): 65?68.

CHENG Ying-chun, LIU Hui-jie, FENG Ji-cai. Frictions stir welding of 2219-0 aluminum alloy[J]. Welding Journal, 2006, 27(1): 65?68.

[2] 刘春辉. 运载贮箱用2219类铝合金的电子束焊[J]. 航天制造技术, 2002, 8(4): 3?9.

LIU Chun-hui. Electron beam welding of 2219 aluminum alloy using in carry boxes[J]. Space Making Technology, 2002, 8(4): 3?9.

[3] 刘 勇, 张海泉, 吴春芳. 非轴对称球锥环轧件有限元分析及优化设计[J]. 船海工程, 2006, 2: 31?34.

LIU Yong, ZHANG Hai-quan, WU Chun-fang. Finite element analysis and optimum design on asymmetric sphere cone with toroidal transition[J]. Navigation Engineering, 2006, 2: 31?34.

[4] VENKITAKRISHNAN P V, SINHA P P, KRISHNAMURTHY R. Study and analysis of effect of various thermal processes in AA 2219 annealed sheet using acoustic emissions[J]. Materials and Design, 2006, 27: 770?775.

[5] SUREKHA K, MURTY B S, RAO K P. Microstructural characterization and corrosion behavior of multipass friction stir processed AA2219 aluminum alloy[J]. Science Direct, 2008, 202(17): 4057?4068.

[6] PAGLIA C S, BUCHHEIT R G. Microstructure, microchemistry and environmental cracking susceptibility of friction stir welded 2219-T87[J]. Mater Sci Eng A, 2006, 429(1/2): 107?114.

[7] 张淑莲, 何养民, 李忠周. 超大直径铝合金环轧件轧制工艺研究[J]. 兵器材料科学与程, 2007, 9: 58?59.

ZHANG Shu-lian, HE Yang-min, LI Zhong-zhou. Super large diameter aluminum alloy ring rolling technology[J]. Ordnance Material Science and Engineering, 2007, 9: 58?59.

[8] 杜学斌, 韩炳涛, 葛东辉, 卫凌云, 周少凡. φ5 000 mm径轴向数控轧环机[J]. 装备, 2007, 3: 34?36.

DU Xue-bin, HAN Bin-tao, GE Hui, WEI Ling-yun, ZHOU Shao-fan. φ5 000 mm radial and axial NC ring rolling mill[J]. Equipment, 2007, 3: 34?36.

[9] 李慧中, 张新明, 陈明安, 周卓平, 龚敏如. 预变形对2519铝合金组织与力学性能的影响[J]. 中国有色金属学报, 2004, 14(12): 1990?1995.

LI Hui-zhong, ZHANG Xin-ming, CHEN Ming-an, ZHOU Zhuo-ping, GONG Ming-ru. Effect of pre-deformation on microstructures and mechanical properties of 2519 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(12): 1990?1995.

[10] 肖代红, 黄伯云, 宋 旼, 陈康华. Al-Cu-Mg-(Ag, La)合金的显微组织与力学性能[J]. 中国有色金属学报, 2008, 18(4): 571?576.

XIAO Dai-hong, HUANG Bai-yun, SONG Min, CHEN Kang-hua. Microstructures and mechanical properties of Al-Cu-Mg-(Ag, La) alloys[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 571?576.

[11] VILLARS P, PRINCE A, OKAMOTO H. Handbook of ternary alloy phase diagrams[M]. Materials Park: ASM International, 1994.

[12] SRIVATSAN T S. An investigation of the cyclic fatigue and fracture behavior of aluminum alloy 7055[J]. Materials and Design, 2002, 23: 141?151.

[13] CORDOVILLA C G, LOUIS E. Characterization of the microstructure of a commercial Al-Cu alloy (2011) by differential scanning calorimetry (DSC)[J]. J Material Science, 1984, 19: 279?290.

[14] MONDOLFO L F. Aluminum alloys: Structure and properties[M]. London: Butterwordths, 1976: 497?504.

[15] YOSHIMURA R, KONNO T J, ABE E, HIRAGA K. Transmission electron microscopy study of the evolution of precipitates in aged Al-Li-Cu alloys: the θ prime and T1 phases[J]. Acta Materialia, 2003, 51(10): 4251?4266.

[16] KAIBYSHEV R, SITDIKOV O, MAZURIN I, LESUER D R. Deformation behavior of a 2219 Al alloy[J]. Mater Sci Eng A, 2002, 334: 104?113.

[17] 李国锋, 张新明, 朱航飞, 李鹏辉. 7B50 高强铝合金的均匀化[J]. 中国有色金属学报, 2008, 18(5): 764?770.

LI Guo-feng, ZHANG Xin-ming, ZHU Hang-fei, LI Peng-hui. Homogenizing treatment of 7B50 high strength aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 764?770.

收稿日期:2008-07-02;修订日期:2008-10-24

通讯作者:李红英,教授,博士;电话:0731-8836328;E-mail: Lhying@mail.csu.edu.cn

(编辑 李向群)