Morphological evolutions of cast and melt-spun Mg97Zn1Y2 alloys during deformation and heat-treating

WANG Bai-shu(王柏树)1, 2, LIU Yong-bing(刘勇兵)1, AN Jian(安 健)1,

LI Rong-guang(李荣广)1, SU Zhen-guo(苏振国)1, CAO Zhan-yi(曹占义)1

1. Key Laboratory of Automobile Materials, Ministry of Education, Department of Materials Science and Engineering, Jilin University, Changchun 130025, China;

2. Department of Materials Science and Engineering, Changchun University of Technology, Changchun 130012, China

Received 12 June 2008; accepted 5 September 2008

Abstract: Mg97Zn1Y2 alloy has been studied as an elevated temperature creep resistant Mg-based alloy for nearly ten years. While, the strength of the cast Mg97Zn1Y2 alloy with long-period stacking(LPS) structure is lower than that of the commercial AZ91 alloy at room temperature. The microstructure evolutions in Mg97Zn1Y2 (molar fraction, %) alloys with LPS phase, processed by rolling and annealing the as-cast alloy and rapidly solidifying/melt-spinning and age treating at different temperatures respectively, were investigated by differential thermal analysis(DTA), X-ray diffraction(XRD), and laser optical microscopy(LOM), scanning electron microscopy (SEM), and transmission electron microscopy(TEM). The evolutionary direction of microstructure prescribed by thermodynamics in the Mg97Zn1Y2 alloy is reflected from experimental data of the as-cast alloy; and the actual evolution paths selected by kinetics are depicted in detail in the as-spun alloy and rolled alloy. The strong influences of thermodynamic non- equilibrium mechanism, which entails the factual complexity of microstructures typically during rapid solidification and deformation processing for strengthening the creep resistant magnesium alloy, are presented.

Key words: Mg-Zn-Y alloy; rolling; annealing; ageing; microstructure

1 Introduction

Due to the strong demand for weight reduction of transportation vehicles, for better fuel efficiency, magnesium alloys have recently received much research interest for applications to various structural components of automobile and aircraft[1]. Intermetallic phases can be found in almost every magnesium alloy and play a very important role in optimizing the microstructure and mechanical properties[2]. PADEZHNOVA et al[3] found three ternary equilibrium phases, i.e. W-Mg3Zn3Y2, Z-Mg3Zn6Y and X-Mg12YZn phases. They reported that the W-Mg3Zn3Y2 phase belongs to an isostructure of AlMnCu2. The Mg-Zn-RE-Zr system is regarded as high strength magnesium alloy because of the evident strengthening effect of rare earth(RE) addition on magnesium alloys. In recent years, LUO and ZHANG[4] identified the Z-Mg3Zn6Y as a stable icosahedral quasi-crystalline phase, and determined the X-Mg12YZn phase as an 18R LPS structure by an electron diffraction technique [5-6]. INOUE et al[7-9] fabricated a high strength Mg-based Mg97Zn1Y2 alloy with a novel LPS structure by rapid solidification(RS) techniques such as powder metallurgy and melt-spinning, and later the variation and formation process of LPS structures were reported [10-12]. While the strength of a conventionally cast Mg97Zn1Y2 (molar fraction, %) alloy is lower than that of commercial AZ91 at room temperature. Currently, the investigation to improve the mechanical property of the elevated temperature creep resistant Mg alloys with LPS structures has been advanced toward refining LPS structures as the second phases or deformation treatment[13-14]. The microstructure evolutions of the Mg97Zn1Y2 alloy with LPS structure, processed by rolling and annealing conventionally cast alloy and by RS/melt-spinning and aging the ribbon, which have been not introduced by other papers systematically, will be generally illustrated in this work.

2 Experimental

The nominal composition of the alloy in this work is Mg97Zn1Y2 (molar fraction, %). The ingot was prepared by melting intermediate alloy Mg-19.9%Y (mass fraction) and pure magnesium in a graphite crucible at 775 ℃ with protecting of SF6+CO2 atmosphere, and adding pure zinc particles and holding at 775 ℃ for 30 min, and then casting the alloy melt into a steel mould of 190 mm× 95 mm×20 mm. The as-cast alloy specimen and plate type of samples for rolling were cut from the ingot.

The samples for deformation were preheat treated at 400 ℃ for 30 min before rolling. The plates were reduced by 12.3% and 45.0% and 74.8% respectively through one pass and four and nine passes by 12%-17% rolled deformation strain per pass. The samples with 74.8% rolling reduction were annealed at different temperatures with protection of CO2+SF6 atmosphere and cooled out of furnace at room temperature. The RS ribbon was processed by a melt-spinning apparatus at a speed of 34 m/s, and its size is about 7 mm in width and 60 ?m in thickness. Then the ribbon was divided into ten groups. Eight groups were aged with protection of CO2+SF6 atmosphere and cooled out of furnace at room temperature. Another two were kept as spun.

The rolled alloys and one sample from an as-spun ribbon were prepared by insetting in polyester. The as-cast specimen and one inset sample from an as-spun ribbon were etched with a solution of 4% (volume ratio) nitric acid alcohol. And all rolled specimens were etched with acetic-picric acid solution (5.5 mL CH3COOH, 2.1 g picric acid, 5 mL water, 2 mL nitric acid and 90 mL alcohol). The microstructures of the alloy were characterized by optical microscope, laser optical microscope and scanning electron microscope (JSM5600, JEOL) and transmission electron microscope (JEM- 2000EX, JEOL), and phase constitutions of these specimens were identified using an X-ray diffractometer (D/MAX 2000/PC, Rigaku). The differential thermal analysis of the as-cast specimen was conducted with Ar atmosphere protecting.

3 Results and discussion

3.1 Microstructure characteristics of Mg97Zn1Y2 alloy

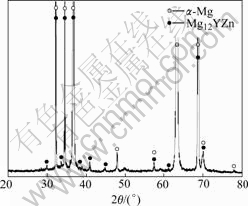

The phase constitution of the as-cast alloy was identified as α-Mg (2H-Mg) and the ternary X-Mg12YZn (18R type hexagonal super-lattice) secondary phase, as shown in Fig.1. The α-Mg dendrites as matrix in Fig.2(a) and the X-Mg12YZn phase in Fig.2(b), distributing on the

Fig.1 XRD pattern of as-cast Mg97Zn1Y2 alloy

grain boundaries, make up of the microstructure of the as-cast alloy. The acicular X-Mg12YZn intermetallic compound in different dendrites is furthermore shown in Fig.2(c); the different orientation of X-Mg12YZn can be distinguished according to the orientation relationship with the α-Mg provided by Ref.[6].

The DTA heating curve of the as-cast alloy is shown in Fig.3, and it can be interpreted as follows. After the alloy was heated to between point A and B, a eutectic including α-Mg and X-Mg12YZn, was melted. The single solid solution phase was heated between point B and C; the solid solution started to change into the liquid from point C and furthermore heating toward higher temperature after point D resulted in a single liquid phase. Thus the X-Mg12YZn phase of the alloy will dissolve partially and the alloy will be homogenized when it is heated to elevated temperature under about 522 ℃ as designated by point A and the alloy containing the secondary phase transformed during solidification will partially melt when it is heated at 550 ℃ for short period.

According to the analysis of microstructure, phase constitution and DTA heating curve of the as-cast Mg97Zn1Y2 alloy, Zn segregation to grain boundaries occurs during the non-equilibrium solidification with a great tendency and the eutectic is obtained due to a micro-segregation during non- equilibrium solidification of the alloy. Thus, the evolutionary direction prescribed by thermodynamics in Mg97Zn1Y2 alloy is generalized as follows. The alloy from a single liquid phase region, above approximate 645 ℃, will enter the two phase region including liquid phase and pre-eutectic α-Mg solid solution, in the temperature range from about 645 ℃ to 589 ℃. Further, it will transform into a single α-Mg solid solution in a small temperature range below 589 ℃. LPS phase will precipitate out of supersaturated α-Mg during thermodynamic equilibrium phase transformation if slowly enough cooling is conducted upon the Mg97Zn1Y2 melt.

Fig.2 Micrographs of as-cast Mg97Zn1Y2 alloy: (a) OM image; (b) SEM image; (c) Magnified SEM image

Fig.3 DTA curve of as-cast Mg97Zn1Y2 alloy

3.2 Microstructure evolution of bulk Mg97Zn1Y2 alloy upon rolling and annealing

Compared with the spectrum of the as-cast alloy, the phase constitution was not altered during rolling and further annealing.

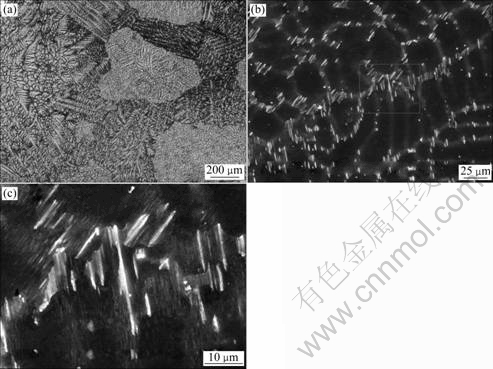

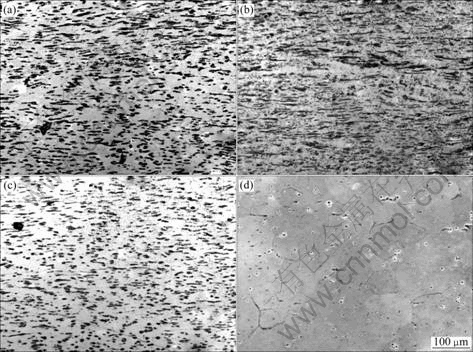

The microstructures of th deformed Mg97Zn1Y2 alloy with rolling reduction of 12.3%, 45.0% and 74.8% are shown by the LOM micrographs in Fig.4(a) and 4(b) and 4(c), respectively. The intensified deformation texture and gradually refined microstructures can be looked through. When the Mg97Zn1Y2 alloy was heated to 400 ℃ and hold for 30 min before rolling, the flow stress can be lowered during deformation. The dendrite morphology disappeared to a greater extent with increasing rolling pass and the X-Mg12YZn secondary phase shrank and distributed along the rolling direction in Fig.4(c). Through magnifying the LOM image of Fig.4(c), besides the dark X-Mg12YZn compound, the different contrast grains can be seen. Thus a conclusion, that the partial recr ystallization behavior occurred in the α-Mg matrix during cooling after rolling, can be ascertained. With increasing rolling reduction, the plastic flow strain was increased and the microstructures including both the α-Mg matrix and X-Mg12YZn phase evolved along the rolling direction. The deformation twins are not found in Fig.4 and the deformation bands can nearly be visible after the hot working. Plastic deformation at the elevated temperature of 400 ℃ increases the number of slip systems in the 2H-Mg phase in principle. The basal plane slip is retarded in 2H-Mg with Y solid solution, and the c+a dislocation was observed in the TEM images of the annealed specimen in Ref.[15]. So a non-basal slip is the main deformation mechanism of the Mg97Zn1Y2 alloy during rolling after heating up to 400 ℃. Moreover, the c+a dislocation as a main non-equilibrium lattice defect exists in the deformed alloy. The LPS structure in the rolled alloy was fragmented fundamentally by non-basal slip, and its shrinking resulted basically from Zn and Y diffusion into dislocation, which developed into cottrell atmosphere.

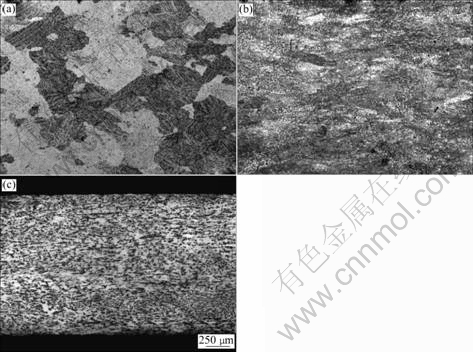

The microstructures of the annealed Mg97Zn1Y2 alloy with rolling 74.8% reduction at 200 ℃, 400 ℃, 450 ℃ and 500 ℃ for 30 min are shown in Fig.5. Upon annealing at 200 ℃, there are some grains, whose boundaries are more sharp-cut in the rolled Mg97Zn1Y2 alloy in Fig.5(a) compared with the as-rolled alloy.

Fig.4 Micrographs of as-deformed alloy with different rolling reduction: (a) 12.3%; (b) 45.0%; (c) 74.8%

Fig.5 Micrographs of annealed alloys at different temperatures: (a) 200 ℃; (b) 400 ℃; (c) 450 ℃; (d) 500 ℃

The recovery and partial recrystallization occurred in the rolled Mg97Zn1Y2 alloy, and the recrystallization furthermore proceeded upon annealing at 200 ℃ for 30 min. The recrystallized grains are difficult to be discerned because of small orientation difference between them and the distribution of the secondary phase in the microstructure. From Fig.4(b), a great amount of precipitates exist in the microstructure of the rolled alloy after annealing at 400 ℃. The structure of the fine precipitates has not been confirmed till a furthermore study though there is not new transformed phase from the XRD examining. The density of precipitated particles was decreased as shown in Fig.5(c) when the deformed alloy was annealed at higher temperature of 450 ℃. When being annealed at 500 ℃, the alloy has only a small quantity of remnant particles (shown in Fig.5(d)). Because the coarse particles and fine precipitated X-Mg12YZn phase were dissolved and ripped during annealing at 500 ℃, a small quantity of X-Mg12YZn phase was remained as sphericial particles. At the same time an equiaxed grain of 2H-Mg came into being. This indicated that grain growth proceeded and the final grain size was almost equal to the dendritic grain size of the as-cast alloy during annealing at 500 ℃. Through X-ray analysis of the peak intensity of (002) and (101) and (110) of α-Mg in the annealed alloy at different temperatures and equiaxed grains of 2H-Mg obtained during annealing upon the rolled alloy at 500 ℃, the grain growth started at 350 ℃ and seemed to finish as shown in Fig.5(d) when the anneal treatment was carried through at 500 ℃ for 30 min. When the annealing time was extended to 2 h, grain growth did not proceed and the annealing texture was proceeded. The grain size is also similar to the size of the dendritic grain in the as-cast alloy. This can be deduced from the fact that the different deformation mechanism, between LPS structure and 2H-Mg, results in the increased atom mismatch among dendritic grains and X-Mg12YZn phase on grain boundaries, and compounds on the grain boundary retard growth of grains.

3.3 Microstructure evolution in RS/melt-spun Mg97Zn1Y2 alloy upon aging

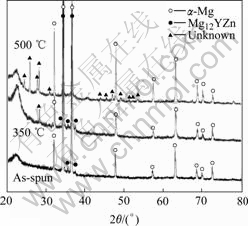

A same phase constitution, which consists of only 2H-Mg and the X-Mg12YZn LPS structure in the as-spun Mg97Zn1Y2 alloy, is presented from XRD analysis in Fig.6 in comparison with as-cast one in Fig.1. The as- spun alloy has a solidification texture, and the melt is solidified by the prior [002] orientation. This results from that the directional solidification process occurs with greatly increased temperature gradient from the interface with the wheel of the apparatus to the free surface of the ribbon by the rapid solidification technique[16]. When the ribbon age treated up to 350 ℃. A peak of unknown structure appeared at 28.343?, and more peaks appear at 500 ℃ (shown in Fig.6). This indicates that a solid phase transformation of some new precipitates is developed during ageing from 350 ℃ to 500 ℃.

The morphology of the transverse section of the ribbon is characterized in Fig.7(a). The upside is the

Fig.6 XRD patterns of alloy as-spun and aged at 350 ℃ and 500 ℃

Fig.7 Micrographs of melt-spun alloy: (a) General OM image of transverse section of ribbon; (b) TEM image of dendritic arrays in Fig.7 (a); (c) TEM image of cellular arrays in Fig.7(a)

interface with the wheel of the melt-spinning apparatus and the downside is the free surface of the ribbon. TEM morphologies of dendritic and cellular arrays are shown in Figs.7(b) and (c). It can be seen that, dendritic arrays are near the interface and cellular arrays are near the free surface. A cellular/dendritic transition or distribution exists according to the ratio of thermal gradient to solidification rate in the as-spun alloy[17]. The size of dendritic arrays is about 15 ?m and the second dendrite arm spacing or the size of dendritic grains in the arrays is about 500 nm. The cellular spacing in the cellular arrays is about 320 nm. The secondary phase distributes on the boundaries of grains, cells and their arrays, and mainly along boundary edges.

Upon ageing at 300 ℃, the acicular secondary phase which is like a group of ordered lines distributes within the dendritic arrays of the ribbon as shown in Fig.8(a), and there are small quantities of short columns distributing on boundary edges and at corners. This is confirmed by the fact that the higher cooling rate resulted in the more homogenized Zn and Y atom to a greater extent in dendritic arrays than in the cellular arrays. While the short columnar secondary phase grows at expense of the phase on the cell boundaries and distributes in the cellular arrays, and the compound at boundary edges of cell are long column like. Their circular and square sections are visible universally. The size of short columnar precipitates is about 100 nm in Fig.8(b). Upon ageing at 400 ℃, the circular and square sections of short columnar secondary phase are visible explicitly in cellular arrays, and the prior extending orientation perpendicular to c axis of HCP structure can

Fig.8 TEM micrographs of aged ribbons and corresponding respective SAED spectra: (a), (b) LPS phase in region of dendritic and cellular arrays in ribbon aged at 300 ℃; (c) General microstructure morphology of ribbon aged at 500 ℃; (d) LPS phase in grains of ribbon aged at 500 ℃; (e) New precipitated phase on boundaries of array in ribbon aged at 500 ℃; (f) Compound on boundaries of arrays in ribbon aged at 550 ℃

be discerned clearly. The blurred morphologies of dendritic and cellular arrays can be distinguished in the ribbon aged at 400 ℃. Fig.8(c) shows the morphology of the Mg97Zn1Y2 alloy aged at 500 ℃. The precipitates ripped and grew into many acicular clusters which have same metallographic orientation between each other in a dendritic or cellular array. The size of some precipitates at longitude direction is similar to that of the arrays; and the size at latitude direction is much smaller than the array size which includes cLPS axial direction. From Fig.8(d) including an inset SAED spectrum, a LPS phase and 2H-Mg distribute in a grain, which is an array in the alloy before ageing. The LPS phase had ripen according to Ostwald’s step rule. The new cells on the array boundaries have a different structure (shown in Fig.8(e)), which is similar to the L-phase among the approximates in the Zn-Mg-rare earth alloys reported in Ref.[18]. When the ribbon was heated at 550 ℃ and held for 20 min, a very small quantity of LPS phase remained, and the eutectic structures appeared on boundary edges or corners (shown in Fig.8(f)). From the evolution as designated by the inset SAED spectrum shown in Fig.8(e), the phase can be vindicated to be a quasi-crystal one.

4 Conclusions

1) The Mg97Zn1Y2 alloy exists by single phase solid solution in a small temperature range below 589 ℃, and LPS phase precipitates out of supersaturated α-Mg during thermodynamic equilibrium phase transformation by cooling slowly enough.

2) With increasing rolling reduction, the LPS structure of X-Mg12YZn phase in the rolled alloy shrank and distributed along rolling direction. Many fine particles precipitated in the alloy when age temperature was up to 400 ℃. Upon annealing from 450 ℃ to 500 ℃ the amount of precipitates was gradually reduced. Second recrystallized grains of 2H-Mg were obtained during annealing the rolled alloy at 500 ℃, and the grain size was also similar to the size of the dendritic grains in the as-cast alloy.

3) The RS/melt-spun alloy has a cellular/dendritic transition. Upon ageing at 300 ℃, the acicular secondary phase distributes within dendritic arrays of the ribbon. While in cellular arrays, the short columnar secondary phase with circular and square sections distributes in type of dispersion. When being aged at 500 ℃, the precipitates ripped and grew into many acicular clusters in a grain which is the original array in the as-spun alloy. New cells on new grain boundaries have a different structure similar to the hexagonal L-phase, which is an approximate of icosahedral quasicrystalline phase Zn6Mg3Y1.

References

[1] Mordike B L, Ebert T. Magnesium: Properties—applications—potential [J]. Materials Science Engineering A, 2001, 302(1): 37-45.

[2] Hort N, Huang Y D, Kainer K U. Intermetallics in magnesium alloys [J]. Advanced Engineering Materials, 2006, 8(4): 235-240.

[3] Padezhnova E M, Melnik E V, Miliyevskiy R A, Dobatkina T V, Kinzhibalo V V. Investigation of the Mg- Zn-Y system [J]. Russian Metallurgy (Metally) (Engl. Transl.), 1982, 4(9): 185-188.

[4] Luo Zhi-ping, Zhang Shao-qing. Comments on the so-called Z-phase in magnesium alloys containing zinc and rare-earth elements [J]. Journal of Materials Science Letters, 1993, 12(19): 1490-1492.

[5] Luo Zhi-ping, Zhang Shao-qing, Tang Ya-li, Zhao Dong-shan. Microstructures of Mg-Zn-Zr-RE alloys with high RE and low Zn contents variation of long-period stacking order strucutres in rapidly solidified Mg97Zn1Y2 alloy [J]. Journal of Alloys and Compounds, 1994, 209: 275-278.

[6] Luo Zhi-ping, Zhang Shao-qing. High-resolution electron microscopy on the X-Mg12ZnY phase in a high-strength Mg-Zn-Zr-Y magnesium alloy [J]. Journal of Materials Science Letters, 2000, 19(9): 813-815.

[7] Inoue A, Kawamura Y, Matsushita M, Hayashi K, Koike J. Novel hexagonal structure and ultrahigh strength of magnesium solid solution in the Mg-Zn-Y system [J]. Journal of Materials Research, 2001, 16(7): 1894-1900.

[8] Kawamura Y, Hayashi K, Inoue A, Masumoto T. Rapidly solidified powder metallurgy Mg97Zn1Y2 alloys with excellent tensile yield strength above 600 MPa [J]. Materials Transactions, 2001, 42(7): 1172-1176.

[9] Inoue A, Matsushita M, Kawamura Y, Amiya K, Hayashi K, Koike J. Novel hexagonal structure of ultra-high strength magnesium-based alloys [J]. Materials Transactions, 2002, 43(3): 580-584.

[10] Amiya K, Ohsuna T, Inoue A. Long-period hexagonal structures in melt-spun Mg97Ln2Zn1 (Ln=Lanthanide metal) alloys [J]. Materials Transactions, 2003, 44(10): 2151-2156.

[11] Nishida M, Kawamura Y, Yamamuro T. Formation process of unique microstructure in rapidly solidified Mg97Zn1Y2 alloy [J]. Materials Science Engineering A, 2004, 375/377: 1217-1223.

[12] Matsuda M, Ii S, Kawamura Y, Ikuhara Y, Nishida M. Variation of long-period stacking order structures in rapidly solidified [J]. Materials Science Engineering A, 2005, 393(1/2): 269-274.

[13] Zhu Y M, Morton A J, Nie J F. Improvement in the age-hardening response of Mg-Y-Zn alloys by Ag additions [J]. Script Materialia, 2008, 58(7): 525-528.

[14] Watanabe H, Somekawa H, Higashi K. Fine-grain processing by equal channel angular extrusion of rapidly quenched bulk Mg-Y-Zn alloy [J]. Journal of Materials Research, 2005, 20(1): 93-101.

[15] Matsuda M, Ando S, Nishida M. Dislocation structure in rapidly solidified alloy with period stacking order phase [J]. Materials Transactions, 2005, 46(2): 361-364.

[16] Xu Chang-lin, Wang Hui-yuan, Qiu Feng, Yang Ya-feng, Jiang Qi-chuan. Cooling rate and microstructure of rapidly solidified Al-20% Si alloy [J]. Materials Science Engineering A, 2006, 417(1/2): 275-280.

[17] Hu Han-qi. Fundamentals of solidification [M]. Beijing: China Machine Press, 2000: 128-151. (in Chinese)

[18] Abe E, Takakura H, Singh A, Tsai A P. Hexagonal superstructures in the Zn–Mg–rare-earth alloys [J]. Journal of Alloys and Compounds, 1999, 283(1/2): 169-172.

(Edited by YANG You-ping)

Foundation item: Projects(2006BA104B04-1; 2006BAE04B07-3) supported by the National Science and Technology Supporting Program of China; Project (2007KZ05) supported by the Science and Technology Supporting Project of Changchun City, China; Project supported by the “985 Project” of Jilin University, China

Corresponding author: WANG Bai-shu; Tel: +86-431-85095874; Fax: +86-431-85095876; E-mail: baishu6933@163.com