经不同熔体处理的易拉罐用铝材的热压缩变形组织

陈永禄1, 傅高升1, 陈文哲1, 2, 王火生2, 王沁峰1

(1. 福州大学 材料科学与工程学院, 福州 350002;

2. 福建工程学院 机电与自动化工程系, 福州 350014)

摘 要: 采用动态热/力模拟实验技术对经不同熔体处理的易拉罐用铝材进行高温压缩变形实验, 并用光学显微镜、 透射电镜分析探讨其热变形组织特征。 结果表明: 冶金质量影响易拉罐用铝材的动态再结晶组织特征, 在未处理或常规熔体处理状态下存在枝晶网胞结构, 晶粒组织不均匀; 高效熔体处理使易拉罐用铝材在较低的温度下即可通过亚晶合并方式发生动态再结晶, 并在变形温度573~673K、 应变速率0.1~1.0s-1、 变形量约0.7的较宽的热变形工艺条件下可获得细小且分布较均匀的再结晶晶粒组织。

关键词: 易拉罐用铝材; 熔体处理; 热压缩变形; 微观组织; 动态再结晶 中图分类号: TG113.1, TG243

文献标识码: A

Hot deformation microstructure of aluminum sheets prepared by different melt-treatments used for easy-open can

CHEN Yong-lu1, FU Gao-sheng1, CHEN Wen-zhe1, 2, WANG Huo-sheng2, WANG Qin-feng1

(1. College of Materials Science and Engineering, Fuzhou University, Fuzhou 350002, China;

2. Department of Electromechanical and Automation Engineering,Fujian University of Technology, Fuzhou 350014, China)

Abstract: Compression test at elevated-temperature of aluminum sheets used for easy-open can prepared by different melt-treatment were carried out with dynamic thermal/mechanical simulation experimental technique. And the feature of hot deformation microstructure of the sheets was studied preliminarily by opitical microscope, transmission electron microscope. The results show that the metallurgical quality of the sheets influences dynamic recrystallization. Dendrite net-cells exist in the sheets prepared without melt-treatment or by routine melt-treatment and the distribution of grain size is non-uniform; dynamic recrystallization occurs easily by means of subgrain merging at the lower temperature in the sheet prepared by high-efficiency melt-treatment, and the tiny and evenly distributed grains can be obtained under the wider hot deformation condition. It is the ideal hot deformation condition that the sheet prepared by high-efficiency melt-treatment is deformed at 573-673K with the strain rate of 0.1-1.0s-1 and the strain of 0.7.

Key words: aluminum sheet used for easy-open can; melt-treatment; hot compression deformation; microstructure; dynamic recrystallization

易拉罐用铝材(尤其是罐体材)是高精特薄铝板材的主要代表产品, 热轧是制约成品质量的一个关键中间环节[1-4]。 因此, 根据材质特点与性能要求进一步调整并优化该材料的热轧工艺参数显得更为重要。 采用动态热/力模拟实验技术对铝材进行热压缩实验可建立相应材料的高温流变应力方程, 结合组织观测可较全面地探索铝材的热变形规律, 在此方面人们已开展了较多研究[5-10]。 良好的铸锭组织对轧板及最终产品质量起到至关重要的作用, 然而, 关于铝铸锭冶金质量与热变形关系的研究报道目前尚少。 作者已对不同熔体处理的易拉罐用铝材铸态组织[11]及热压缩流变曲线特征[12]进行了系统对比分析, 本文作者进一步研究了上述铝材在不同热变形条件下的组织演变规律。

1 实验

3种熔体处理工艺分别简称为: 未处理、 常规处理与高效处理。 其中, 未处理指未经熔体处理, 常规处理指使用市售熔剂并用常规工艺进行处理, 高效处理则指加入自制的高效排杂熔剂并采用熔剂过滤净化法进行熔体净化处理, 在此基础上再进行高效晶粒细化与杂质相变质处理[13]。 试样毛坯直接取自上述3种易拉罐用铝铸锭[11], 加工成d10mm×15mm圆柱形热模拟试样(两端面铣槽以存放润滑剂)。 在Gleeble-1500型动态热/力模拟实验机上进行轴对称等温热压缩实验, 变形温度(T)为573~773K, 应变速率(ε[DD(-*2]·[DD)])为0.01~10.0s-1, 变形量(e)为50%(ε≈0.7)。 用焊在试样中部的NiCr-NiAl热电偶测量试样实时温度, 升温速率为200K/min, 当温度达到设定值后, 保温3min使试样温度均匀再开始压缩。 用横向应变引伸计实时测量试样中部直径的变化, 并由控制系统自动将载荷和变形量换算成真应力和真应变。 热压缩结束时, 立即水淬以保留其高温变形时的组织状态。

热压缩后的试样用电火花线切割机沿平行于压缩方向的纵截面切开, 观测面为纵截面, 根据文献[14]确定了“鼓形”试样径向1/4或轴向1/5处为金相观测的位置。 试样经机械抛光后进行电解抛光与阳极化复膜, 在XJG-05型卧式金相显微镜的偏光状态下观察晶粒组织。 用MTP-1A型磁力驱动双喷减薄仪制备薄膜样品, 在JEM-2000EX型和JEM-2010型透射电镜上观察微观结构。

2 结果与分析

2.1 热变形温度对易拉罐用铝材热变形组织的影响

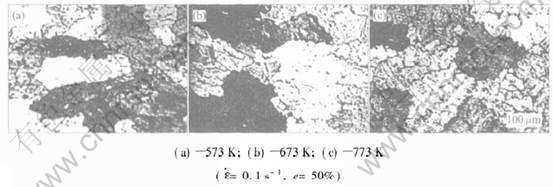

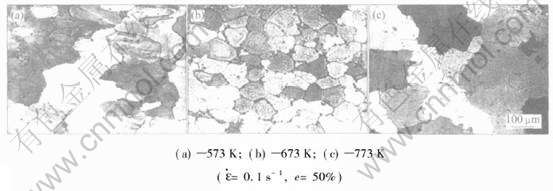

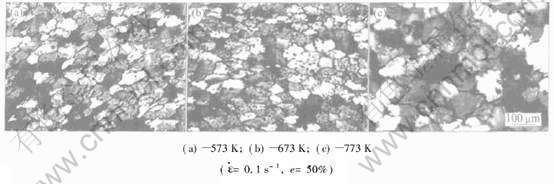

经不同熔体处理的易拉罐用铝材在T=573~773K、 =0.1s-1、e=50%的热变形条件下的偏光晶粒组织形貌如图1~3所示。 可见, 当应变速率一定时(0.1s-1), 经不同熔体处理的易拉罐用铝材(铸态)随着热变形温度的升高, 变形晶粒均发生了动态再结晶, 晶粒逐渐长大, 但具体变化规律存在差异。

=0.1s-1、e=50%的热变形条件下的偏光晶粒组织形貌如图1~3所示。 可见, 当应变速率一定时(0.1s-1), 经不同熔体处理的易拉罐用铝材(铸态)随着热变形温度的升高, 变形晶粒均发生了动态再结晶, 晶粒逐渐长大, 但具体变化规律存在差异。

图1 未处理的易拉罐用铝材在不同变形温度下的偏光晶粒组织形貌

Fig.1 Grain polarization morphologies of aluminium sheet prepared without melt-treatment at different deformation temperatures

图2 经常规处理的易拉罐用铝材在不同变形温度下的偏光晶粒组织形貌

Fig.2 Grain polarization morphologies of aluminum sheet prepared by routine melt-treatment at different deformation temperatures

图3 经高效处理的易拉罐用铝材在不同变形温度下的偏光晶粒组织形貌

Fig.3 Grain polarization morphologies of aluminum sheet prepared by high-efficiency melt-treatment at different deformation temperatures

当变形结束时, 未处理试样的热变形晶粒组织均最为粗大, 且同一取向的大晶粒内部存在枝晶网胞组织形态, 该状态随着变形温度的升高并未完全消除(图1)。 这与该材料冶金质量差有密切关系[13], 是熔铸过程中非平衡结晶与非平衡析出的结果, 也是材料中溶质分布不均的体现。 当T=573K时(图1(a)), 晶粒沿垂直于压缩方向呈拉长状, 大小不均, 是典型的热变形组织。 透射电镜观察结果表明(图4), 在该温度下形成了大量位错胞,多数呈拉长状, 形成明显的变形带。 胞壁处位错缠结, 个别胞内位错向胞壁迁移, 密度降低。 变形温度的升高促进了再结晶的进行, 当T≥673K后(图1(b)~(c)), 晶粒呈近等轴状, 并保持较大尺寸(如673K时晶粒的平均尺寸为185.7μm)。

图4 未处理的易拉罐用铝材热变形后的位错胞结构

Fig.4 Dislocation cells of aluminium sheet prepared without melt-treatment after hot deformation

由于常规熔体处理工艺中的净化处理效果也较差[13], 基体中粗大的夹杂和第二相表面虽可成为再结晶形核的有利位置, 促进再结晶, 但这些物相的存在严重割裂基体, 降低了变形的均匀性并影响晶界运动。 在573K下经历热变形后, 晶粒组织粗大且不规整, 同一大晶粒内部也发现枝晶网胞结构(图2(a)), 但该现象随温度的升高而逐渐消失; 673K时, 动态再结晶组织呈细小等轴状, 平均尺寸约86.7μm; T>673K后, 具有明显的晶粒长大趋势, 形成粗大等轴状的再结晶组织, 且在热与力的共同作用下晶粒外形再次变得不规整。

经高效处理后, 铝材的铸态晶粒最为细小[13], 可为再结晶提供丰富的形核位置, 提高形核率。 因此, 在不同热变形条件下的晶粒组织明显细小均匀, 无枝晶网胞结构。 在573~673K内, 材料已发生明显的动态再结晶, 但晶粒尺寸变化不大, 以细小等轴状晶粒为主, 晶粒尺寸整体分布较为均匀(673K时的平均晶粒尺寸为51.1μm); T>723K后, 晶粒逐渐长大, 至773K时, 仍保持规整的等轴状, 晶粒尺寸远小于同一变形条件下其它处理状态的易拉罐用铝材的测定值。

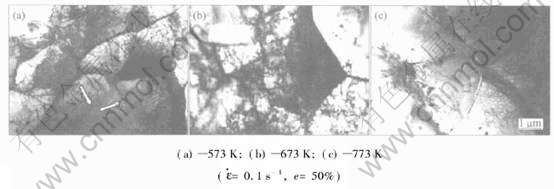

透射电镜观察结果表明, 573K时(图5(a)), 材料内部较大的亚晶晶界弯曲, 形成明显的多边化亚晶组态, 为典型的回复组织, 在晶内可见位错向晶界逐渐迁移, 导致相邻亚晶间晶界平直化, 多处晶界已呈现消失的趋势(图5(a)中箭头标识处), 说明在该温度下材料个别区域已发生动态再结晶, 并在有利的热变形条件下通过亚晶合并方式逐渐长成完整晶粒; 673K时(图5(b)), 亚晶内部位错密度已较小, 随着变形温度的升高, 亚晶界更为清晰与平直, 晶内位错逐渐脱缠, 密度降低, 并出现稳定的三角晶界, 但整体晶粒仍较小; 至773K时, 再结晶晶粒内部的亚晶组态基本消失, 呈现稳定的大角度平直三角晶界, 晶粒大且完整(图5(c))。

2.2 应变速率对易拉罐用铝材热变形组织的影响

在T=673K下考察应变速率对不同熔体处理易拉罐用铝材热变形组织特征的影响。

当 为0.01s-1时, 均已发生较充分的动态再结晶, 由于形核时间充足且晶核可充分长大, 从而获得了相对较为粗大的晶粒(图6(a)、 图7(a)、 图8(a)); 随应变速率的升高, 再结晶晶粒尺寸变化规律因熔体处理工艺的不同而存在较大差异。

为0.01s-1时, 均已发生较充分的动态再结晶, 由于形核时间充足且晶核可充分长大, 从而获得了相对较为粗大的晶粒(图6(a)、 图7(a)、 图8(a)); 随应变速率的升高, 再结晶晶粒尺寸变化规律因熔体处理工艺的不同而存在较大差异。

图5 经高效处理的易拉罐用铝材在不同变形温度下的TEM组织

Fig.5 TEM microstructures of aluminium sheet prepared by high-efficiency melt-treatment at different deformation temperatures

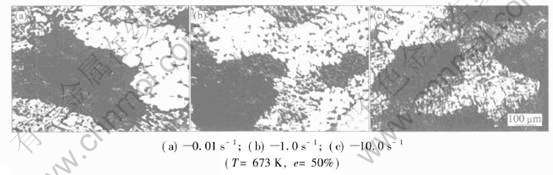

图6 未处理的易拉罐用铝材在不同应变速率下的偏光晶粒组织形貌

Fig.6 Grain polarization morphologies of aluminium sheet prepared without melt-treatment at different strain rates

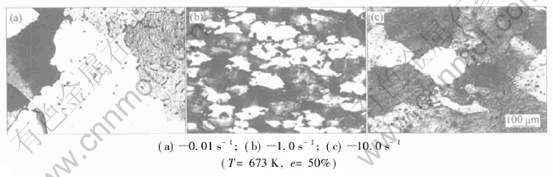

图7 经常规处理的易拉罐用铝材在不同应变速率下的偏光晶粒组织形貌

Fig.7 Grain polarization morphologies of aluminium sheet prepared by routine melt-treatment at different strain rates

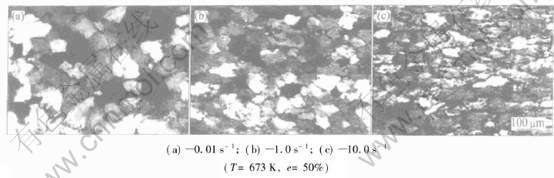

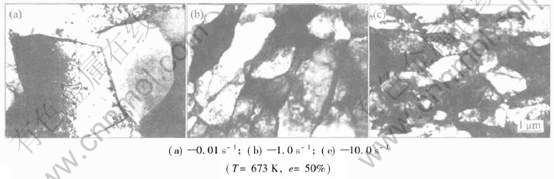

图8 经高效处理的易拉罐用铝材在不同应变速率下的偏光晶粒组织形貌

Fig.8 Grain polarization morphologies of aluminium sheet prepared by high-efficiency melt-treatment at different strain rates

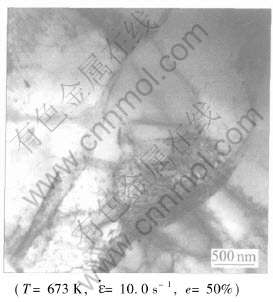

未处理试样晶粒内部的枝晶网胞结构仍然明显, 随着应变速率的提高(1.0~5.0s-1), 材料在较短时间内所承受的变形量增大, 再结晶晶粒被拉长变形且平均尺寸较大(图6(b)); 当 =10.0s-1时, 晶粒尺寸再次变小, 但大小分布不均, 可能是拉长状晶粒破碎的结果(图6(c))。 透射电镜观察表明: 在T为673K、

=10.0s-1时, 晶粒尺寸再次变小, 但大小分布不均, 可能是拉长状晶粒破碎的结果(图6(c))。 透射电镜观察表明: 在T为673K、 为10.0s-1的热变形条件下, 未处理试样中亚晶内部的位错分布较为稀疏, 相邻亚晶粒的取向趋于一致, 亚晶界逐渐减薄并最终消失, 从而发生亚晶合并, 成为再结晶晶核, 而在其它区域仍可发现位错胞的存在(图9)。 由此表明未处理状态的易拉罐用铝材在高应变速率下的热变形是较不均匀的。

为10.0s-1的热变形条件下, 未处理试样中亚晶内部的位错分布较为稀疏, 相邻亚晶粒的取向趋于一致, 亚晶界逐渐减薄并最终消失, 从而发生亚晶合并, 成为再结晶晶核, 而在其它区域仍可发现位错胞的存在(图9)。 由此表明未处理状态的易拉罐用铝材在高应变速率下的热变形是较不均匀的。

随着应变速率的提高, 经常规处理试样的晶粒组织变化规律与未处理试样基本相同。 但在 为0.1s-1时可得到相对细小且大小分布均匀的等轴状再结晶晶粒(图2(b)); 继续提高应变速率(1.0s-1), 晶粒略有拉长(图7(b)), 当

为0.1s-1时可得到相对细小且大小分布均匀的等轴状再结晶晶粒(图2(b)); 继续提高应变速率(1.0s-1), 晶粒略有拉长(图7(b)), 当 为10.0s-1时, 晶粒再次粗化(图7(c)), 可能是高应变速率下材料在热变形过程中内部原子间摩擦热效应增大而导致局部温升[9], 使再结晶晶粒迅速长大。

为10.0s-1时, 晶粒再次粗化(图7(c)), 可能是高应变速率下材料在热变形过程中内部原子间摩擦热效应增大而导致局部温升[9], 使再结晶晶粒迅速长大。

图9 未处理的易拉罐用铝材热变形后的TEM组织

Fig.9 TEM microstructure of aluminium sheet prepared without melt-treatment after deformation

经高效处理试样在各应变速率下进行热压缩后均得到细小均匀的等轴状晶粒, 动态再结晶已进行得较为充分;  为0.1~1.0s-1时所得到的晶粒大小相近(图3(b)和图8(b)), 但均小于

为0.1~1.0s-1时所得到的晶粒大小相近(图3(b)和图8(b)), 但均小于 为0.01s-1时的晶粒尺寸(图8(a)); 当

为0.01s-1时的晶粒尺寸(图8(a)); 当 ≥5.0s-1后, 晶粒沿垂直于压缩的方向被拉长, 或因机械破碎[15]而呈现局部细小近等轴晶状态(图8(c))。

≥5.0s-1后, 晶粒沿垂直于压缩的方向被拉长, 或因机械破碎[15]而呈现局部细小近等轴晶状态(图8(c))。

透射电镜观察结果进一步表明, 当 为0.01s-1时(图10(a)), 材料内部已经形成规整的再结晶晶粒, 晶界清晰而平直, 晶内密度很低, 可明显看到亚晶合并形成新的大角度晶粒后所残留的痕迹; 随着应变速率的增加(图5(b)), 亚晶仍能保持较规整的形态, 但晶内的位错密度已逐渐增大, 至1.0s-1时(图10(b)), 亚晶呈拉长状且晶界弯曲, 局部仍存在明显的位错胞结构; 当

为0.01s-1时(图10(a)), 材料内部已经形成规整的再结晶晶粒, 晶界清晰而平直, 晶内密度很低, 可明显看到亚晶合并形成新的大角度晶粒后所残留的痕迹; 随着应变速率的增加(图5(b)), 亚晶仍能保持较规整的形态, 但晶内的位错密度已逐渐增大, 至1.0s-1时(图10(b)), 亚晶呈拉长状且晶界弯曲, 局部仍存在明显的位错胞结构; 当 >5.0s-1后, 亚晶仍呈现明显的方向性, 位错密度增大, 且在

>5.0s-1后, 亚晶仍呈现明显的方向性, 位错密度增大, 且在 为10.0s-1时, 沿拉长亚晶方向上形成了一些晶界清晰且平直的规整小亚晶(图10(c)), 表明该材料的晶粒在高速热变形的同时仍可发生动态再结晶。 其原因在于高温、 短时、 大应变量的热变形条件使材料在变形初期各部分变形的不同时性增强, 硬化和软化在不同区域同时进行, 从而发生周期性不连续动态再结晶[16], 形成高应变速率下变形初期呈波浪状的σ—ε曲线特征。

为10.0s-1时, 沿拉长亚晶方向上形成了一些晶界清晰且平直的规整小亚晶(图10(c)), 表明该材料的晶粒在高速热变形的同时仍可发生动态再结晶。 其原因在于高温、 短时、 大应变量的热变形条件使材料在变形初期各部分变形的不同时性增强, 硬化和软化在不同区域同时进行, 从而发生周期性不连续动态再结晶[16], 形成高应变速率下变形初期呈波浪状的σ—ε曲线特征。

图10 经高效处理的易拉罐用铝材在不同应变速率下的TEM组织

Fig.10 TEM microstructures of aluminium sheet prepared by high-efficiency melt-treatment at different strain rates

已有研究表明[13]: 未处理铸锭的杂气含量高, 夹杂物为粗大片状, 晶界析出相呈针片状或粗大鱼骨状, 晶粒最为粗大(227.3μm); 经常规处理后, 晶粒尺寸明显减小(123.7μm), 杂气含量有所减少, 但夹杂与晶界析出相的形态与未处理铸锭相似, 存在明显的缩气孔; 而高效处理显著改善了易拉罐用铝材的冶金质量, 铸锭中的杂气含量大幅度减小, 晶界处析出相呈短小骨骼状或小球状, 晶内析出相细小弥散, 结晶组织最为细小均匀(76.5μm)。

对比本文中的热变形组织特征可知: 熔体处理效果决定了易拉罐用铝材的热变形组织形态。 夹杂物和析出相的形态与分布、 铸锭的原始晶粒尺寸以及溶质原子的浓度与分布等因素均对易拉罐用铝材的动态再结晶过程产生重要影响, 具体可体现在提供形核位置、 阻碍位错运动、 影响形核率或晶粒长大速度等方面。 作者将在后续研究中就铝材冶金缺陷对热变形组织与性能的作用机理作进一步深入探讨。

3 结论

1) 冶金质量影响易拉罐用铝材的热变形组织特征。 未处理的易拉罐用铝材在所有热变形条件下均保持原始晶粒组织中的枝晶网胞结构, 经常规处理试样在较低的热变形温度(573K)下也出现该现象, 而经高效处理试样的宏观晶粒尺寸始终保持最小且分布最为均匀。 在同样的热变形条件下(如T=673K、  =0.1s-1、 e=50%), 上述3种处理状态试样的再结晶晶粒平均尺寸分别为185.7、 86.7和51.1μm。

=0.1s-1、 e=50%), 上述3种处理状态试样的再结晶晶粒平均尺寸分别为185.7、 86.7和51.1μm。

2) 随着变形温度的升高或应变速率的降低, 经不同熔体处理的易拉罐用铝材均易发生较充分的动态再结晶, 但晶粒一般较为粗大, 要获得晶粒相对细小且分布较均匀的理想组织, 应针对熔体处理工艺选择不同的热变形条件。 在相同的变形量下(e=50%), 未处理与常规处理试样的理想热变形条件为: T=623~673K、  =0.1~0.5s-1; 高效熔体处理可使易拉罐用铝材在较宽的热变形条件范围内获得理想的再结晶晶粒组织, 其理想热变形条件是: T=573~673K、

=0.1~0.5s-1; 高效熔体处理可使易拉罐用铝材在较宽的热变形条件范围内获得理想的再结晶晶粒组织, 其理想热变形条件是: T=573~673K、  =0.1~1.0s-1。

=0.1~1.0s-1。

3) 在较低的温度下, 未处理及经常规处理的易拉罐用铝材以位错胞所组成的变形带为主要组织特征, 而经高效处理的易拉罐用铝材呈现典型的亚晶组织且局部通过亚晶合并方式开始发生动态再结晶; 随着应变速率的升高, 亚晶均呈拉长状; T为673K时, 在高应变速率(5.0~10.0s-1)下, 经高效处理试样的原始宏观晶粒或被拉长成纤维状晶粒组织, 或因机械破碎作用及不连续再结晶而形成细小的等轴晶, 而在同样条件下, 未处理试样的晶粒仍较粗大, 经常规处理试样的晶粒则有较明显增大。

REFERENCES

[1]蒋显全, 张秀锦, 张新明. 热轧温度对3004H19易拉罐各向异性和织构的影响[J]. 铝加工, 2000, 23(1): 6-18, 42.

JIANG Xian-quan, ZHANG Xiu-jin, ZHANG Xin-ming. Influence of hot-rolling temperature on anisotropy and texture of 3004H19 sheet used for easy-open can[J]. Aluminum Fabrication, 2000, 23(1): 6-18, 42.

[2]陈策, 王京海. 铝合金热轧技术的发展[J]. 轻合金加工技术, 2002, 30(4): 8-14.

CHEN Ce, WANG Jing-hai. Advance in hot rolling technology of aluminum alloy[J]. Light Alloy Fabrication Technology, 2002, 30(4): 8-14.

[3]LIU Chu-ming, JIANG Shu-nong, ZHANG Xin-ming. Continuous dynamic recrystallization and discontinuous dynamic recrystallization in 99.99% polycrystalline aluminum during hot compression[J]. Trans Nonferrous Met Soc China, 2005, 15(1): 82-86.

[4]Huh M Y, Lee K R, Engler O. Evolution of texture and strain states in AA3004 sheet during rolling with a dead block[J]. International Journal of Plasticity, 2004, 20(7): 1183-1197.

[5]Mcqueen H J, Fry E, Belling J. Comparative constitutive constants for hot working of Al-4.4Mg-0.7Mn (AA5083)[J]. Journal of Mater Eng and Performance, 2001, 10(2): 164-172.

[6]Aghaie-Khafri M. Predicting flow localization and formability of Aluminum alloy sheets[J]. Journal of Engineering Manufacture, 2004, 218(10): 1313-1322.

[7]SHEN Jian. Material constants of an Al-Li-Cu-Mg-Zr alloy during deformation at elevated temperatures[J]. Trans Nonferrous Met Soc China, 1998, 8(1): 78-82.

[8]林高用, 张辉, 郭武超, 等. 7075铝合金热压缩变形流变应力[J]. 中国有色金属学报, 2001, 11(3): 412-415.

LIN Gao-yong, ZHANG Hui, GUO Wu-chao, et al. Flow stress of 7075 aluminum alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415.

[9]傅高升. 罐用铝材的冶金质量与变形行为研究[D]. 长沙: 中南大学, 2000.

FU Gao-sheng. Study on Metallurgical Quality and Deformation Behavior of Aluminum Sheet Used for Can[D]. Changsha: Central South University, 2000.

[10]沈健, 张新明. 3004铝合金的再结晶和织构[J]. 中南工业大学学报(自然科学版), 1994, 25(6): 728-732.

SHEN Jian, ZHANG Xin-ming. Recrystallization and texture of 3004 aluminum alloy[J]. J Cent-South Inst Metal, 1994, 25(6): 728-732.

[11]陈永禄, 傅高升, 孙锋山, 等. 易拉罐用铝材经高效熔体处理后的铸态及均匀化组织特征[J]. 中国有色金属学报, 2002, 12(S1): 146-151.

CHEN Yong-lu, FU Gao-sheng, SUN Feng-shan, et al. As-cast and as-homogenized microstructure of aluminum sheet used in easy-open can produced by high-efficient melt-treatment[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 146-151.

[12]王火生, 傅高升, 陈文哲, 等. 经高效熔体处理的易拉罐用铝材的高温流变应力行为[J]. 福建工程学院学报, 2005, 3(1): 57-60, 93.

WANG Huo-sheng, FU Gao-sheng, CHEN Wen-zhe, et al. Behaviors of flow stress of aluminum sheet used for easy-open can prepared by synthetical technique of high-efficient melt-treatment during hot deformation[J]. Journal of Fujian University of Technology, 2005, 3(1): 57-60, 93.

[13]陈永禄. 经高效熔体处理的易拉罐用铝材微观组织与力学性能研究[D]. 福州: 福州大学, 2002.

CHEN Yong-lu. Study of Microstructure and Mechanical Properties of Aluminum Sheet Used for Easy-open Can Prepared by High-efficient Melt-treatment Technology[D]. Fuzhou: Fuzhou University, 2002.

[14]龚羽, 郑芳, 焦四海. 热模拟圆柱形压缩试样上金相观测点的选取[J]. 理化检验—物理分册, 2004, 40(6): 282-285.

GONG Yu, ZHENG Fang, JIAO Si-hai. Positioning the metallographic observation site in a cylinder compression specimen for the thermal simulation[J]. Physical Testing, 2004, 40(6): 282-285.

[15]朱远志, 杨扬, 杨军军. 高速变形条件下的动态再结晶机制的研究进展[J]. 铝加工, 2000, 23(3): 43-46, 54.

ZHU Yuan-zhi, YANG Yang, YANG Jun-jun. Progress of study on the mechanisms of dynamic recrystallization during high-speed deformation[J]. Aluminum Fabrication, 2000, 23(3): 43-46, 54.

[16]Ding R, Guo Z X. Coupled quantitative simulation of microstructural evolution and plastic flow during dynamic recrystallization[J]. Acta Mater, 2001, 49: 3163-3175.

(编辑陈爱华)

基金项目: 福建省教育厅重点资助项目(JA04251); 福建省自然科学基金资助项目(E0210011)

收稿日期: 2005-06-29; 修订日期: 2005-09-20

作者简介: 陈永禄(1976-), 男, 博士研究生

通讯作者: 傅高升, 教授; 电话:0591-83511287; E-mail: fugaosheng@fzu.edu.cn