Trans. Nonferrous Met. Soc. China 24(2014) s36-s41

Interface characterization of Al/Cu 2-ply composites under various loading conditions

Kwang Seok LEE, Su Eun LEE, Yong-Nam KWON

Materials Deformation Department, Light Metal Division, Korea Institute of Materials Science, Gyeongnam 642-831, Korea

Received 18 June 2013; accepted 5 April 2014

Abstract: The effects of reduction ratio during roll bonding on the microstructural evolution at interface and subsequent mechanical properties of roll-bonded Al/Cu 2-ply sheets were investigated. The interface microstructures for several Al/Cu 2-ply sheets fabricated under different reduction ratios between 30% and 65% were verified by transmission electron microscopy (TEM). Taking the difference of interface microstructure into consideration, 3-point bending and peel tests were performed for obtaining flexural and bonding strengths for Al/Cu 2-ply sheets. The effect of the quantified areas of metallurgical bonding at interfaces on the bonding strength was also discussed. The results show that both the bonding and flexural strengths for Al/Cu 2-ply sheets are reduced by decreasing the reduction ratio during the roll bonding process, which is strongly correlated with the interface microstructure. This was especially verified by observing the interface delamination from the 3-point bent samples.

Key words: Al/Cu 2-ply composite; flexural strength; roll bonding; reduction ratio; interface

1 Introduction

Al/Cu bimetal plates have attracted great intention due to their excellent exclusive properties such as reduced mass, formability and corrosion resistance without much expense of electrical and thermal conductivities as compared to monolithic pure copper or copper alloys [1]. This materials combination is also economically more attractive than monolithic Cu. So, the Al/Cu clad has been used for bus bar conductor, heat sink, armored cable and so on [2-5]. Basically laminated composites stacked in order of Cu/Al, Cu/Al/Cu and Al/Cu/Al has been understandingly fabricated by roll bonding [6-9].

However, it is difficult to bond dissimilar metals such as Al and Cu using warm roll bonding followed by typical annealing, because brittle and harmful intermetallic compound (IMC) phases such as AlCu and Al3Cu4 are easily generated at elevated temperatures [10-14]. Therefore, it is necessary for Al/Cu combination to control initial stage of roll bonding parameter and it is important to investigate the influence of rolling strain on the interface microstructure and subsequent mechanical properties of an Al/Cu 2-ply laminate [15].

The aim of this work is to investigate the influence of reduction ratio during roll bonding between Al and Cu alloys on the microstructural evolution and subsequent mechanical properties of Al/Cu laminated composite.

2 Experimental

2.1 Roll bonding of parent alloys

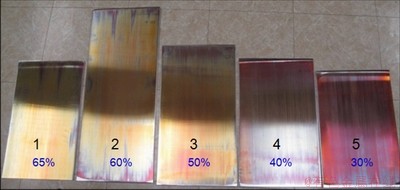

Materials used in this study are commercial aluminum alloy AA1050 and pure copper (UNS C 11000) sheets as components of the laminated alloys. After proper surface treatment by brushing and degreasing, constitutive aluminum and copper alloys with a dimension of 375 mm in width and about 500 mm in length were subjected to roll bonding with five different reduction ratios ranging from 65% to 30%, as shown in Fig. 1. The initial thickness of aluminum alloy was differently prepared in order to obtain about 3 mm-thick Al/Cu 2-ply laminated composites. All of them have the similar final thickness ratio of Al to Cu as about 8:1.

Fig. 1 Macroscopic features of roll-bonded Al/Cu sheets at different reduction ratios

2.2 Interface characterization and mechanical properties

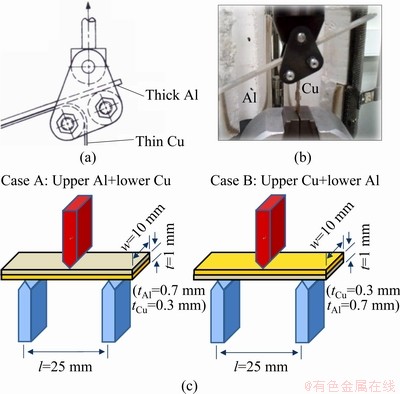

Transmission electron microscope (TEM, model JEOL JEM-2100F) operated at 200 kV was used to examine the interfaces microstructure of Al/Cu joints. After cutting 2-ply clad plate with a width of 10 mm and a length of above 180 mm, bonding strength of the Al/Cu laminated sheet was obtained by applying roller drum-type peel test (standard ASTM D3167, see Fig. 2(a)). Figure 2(b) shows the photo describing how to perform a floating drum roller-type peel test for Al/Cu 2-ply sheet according to ASTM D3167. Also, 2-ply plate with a width of 10 mm and a length of 55 mm was prepared for carrying out three-point bending under a constant deformation rate of 5 mm/min. The schematic diagrams of the 3-point bending test is shown in Fig. 2(c). Field-emission scanning electron microscope (FE-SEM, model TESKAN MIRA II) coupled with Oxford energy dispersive X-ray spectrometer (EDS) was used to reveal both the fractographs of the peel tested specimens and the microstructural evolution of the joints of the 3-point bend specimen.

Fig. 2 Schematic diagrams of floating drum roller-type peel test (a), photo of actual peel test adopted in this study (b) and schematic diagram of three-point bending test (c)

3 Results and discussion

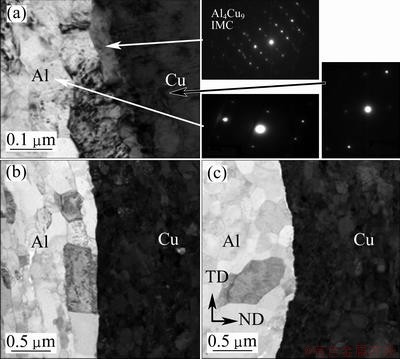

Figure 3 shows the bright-field TEM images at the bonding interfaces between Al and Cu from as-rolled Samples 1, 3, and 5, respectively. There is a discontinuously generated reaction phase ranging from 50 to 100 nm in thickness in Fig. 3(a). The outlets of Fig. 3(a) illustrate the selected area diffraction patterns from both diffusive interface and constituent alloys of sample 1, in which a distinct diffusive interlayer as thick as around 70 nm can be indexed as an Al4Cu9 IMC phase. In Sample 3, as presented in Fig. 3(b), constitutive Al alloy contains a homogeneously elongated lamellar structure with several internal voids adjacent to the joint interface. However, in the Al/Cu laminated composite roll-bonded under the lowest reduction ratio of 30%, the microstructure of Al alloy mostly consists of the equiaxed sub-μm grains as shown in Fig. 3(c). This indicates that the microstructural changes of both the parent alloy and the interface are strongly affected by the amount of shear strain induced by roll bonding.

Fig. 3 Bright-field TEM images obtained close to bonding interface of Al/Cu 2-ply Sample 1 (a), Sample 3 (b), and Sample 5 (c)

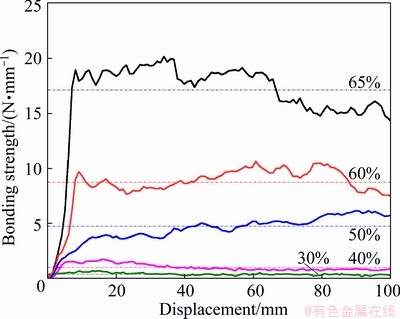

Figure 4 demonstrates the variation in the bonding strengths at Al/Cu joints as a function of peeling displacement. Average bonding strengths of Samples 1, 2, 3, 4, and 5 were marked as dot lines and determined to be 17.1, 8.7, 4.7, 1.0, and 0.4 N/mm, respectively. This means that there is a drastic improvement in the bonding strength when the reduction ratio is increased to above 50%. This may be attributed to the following two factors. The first one is the interface microstructure. According to CHEN et al [16], major cracks between Al/Cu joints generally propagate through the path near Al-side IMCs like Al2Cu, AlCu, and Al3Cu4, whose overall thickness are above 2 mm. However, the solely generation of thinner Al4Cu9 IMC layer (thickness below 100 nm) without the aforementioned harmful Al-side IMCs can provide a strong metallurgical bonding between Al and Cu for two-ply sample 1, as shown in Fig. 3(a).

Fig. 4 Interface bonding strength variation of Al/Cu 2-ply sheets as function of peel distance

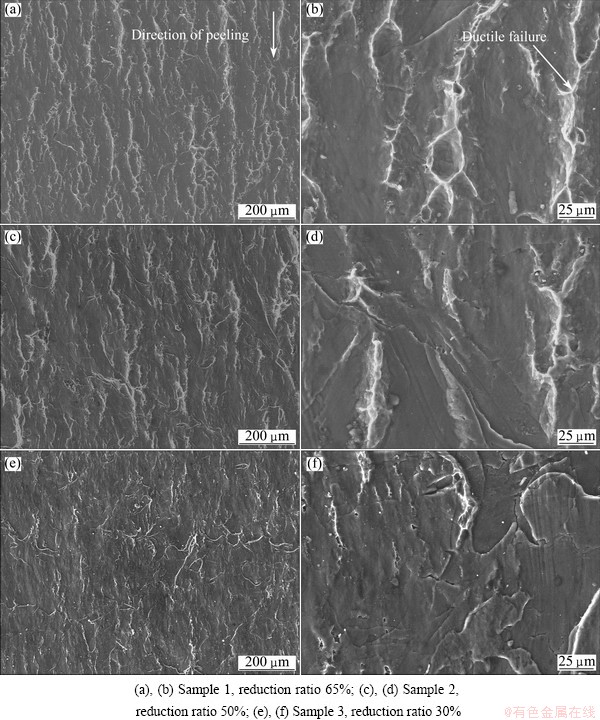

The other factor is an actual bonding area at the Al/Cu joint. In order to verify the relationship between actual contact surface area and bonding strength, separated surfaces of the peel-tested Samples 1, 3, and 5 were observed by SEM. Figure 5 exhibits the surface microstructures of peel tested specimen from aluminum side. In the case of the reduction ratios above 50%, both the length and density of vein patterns increase, indicating a ductile fracture process. On the other hand, the fraction of vein cracks is noticeably decreased and the region of brittle shear is considerably widened at the joint surface of peel-tested Al in Al/Cu laminate fabricated with a 30% reduction ratio. The reduced lengthy vein patterns together with the generation of brittle shear are consistent with the hypothesis that decreasing reduction ratio will reduce the fraction of strong metallurgical bonding area at joints between dissimilar metals [17].

Fig. 5 Fractorgaphs observed from Al surfaces of peel-tested specimens

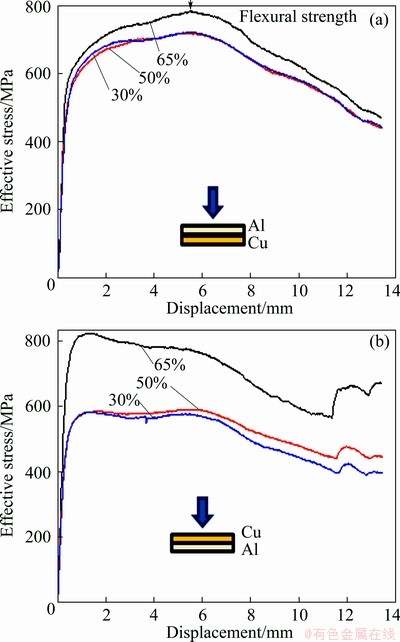

After preparing rectangular specimens of 10 mm in width and 55 mm in length, 3-point bending tests were also performed. Figure 6(a) shows the load displacement curves for the Samples 1, 3 and 5 for the case A indicating Alin/Cuout (i.e., aluminum layer is located inside the bent clad). In case A, the maximum flexural strengths for the Samples 1, 3 and 5 are determined as 783.6, 719.5 and 721.6 MPa, respectively. It is evident that the roll-bonded Sample 1 exhibits the highest flexural strength. This implies that the improvement in the maximum flexural strength is presumably attributed to the generation of a nanometer-scale metallurgical bonding layer between Al and Cu observed from Sample 1, as shown in Fig. 3(a). Figure 6(b) exhibits the flexural load-displacement curves for Samples 1, 3 and 5 for the case B indicating Cuin/Alout (i.e., copper layer is located inside the bent clad). It is interesting to note that the work hardening behavior does not take place. This phenomenon is presumably caused by local stress concentration-induced plastic deformation on the lower surface of Al. Also, the maximum flexural strengths for Samples 1, 3 and 5 are determined as 820.6, 586.8 and 581.4 MPa, respectively. With an increase in reduction ratio by 65%, the flexural strength is obviously higher than those below 50%. So, we can conclude that the higher the reduction ratio during the roll bonding is, the more the room temperature formability can be achieved for Al/Cu 2-ply sheet by applying 3-point bending.

Fig. 6 Effective stress displacement curves of roll-bonded Al/Cu 2-ply composites in bending case A (a) and case B (b)

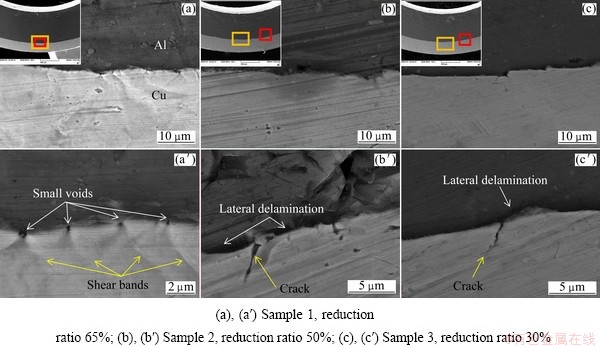

Figure 7 shows the cross-sectional FE-SEM images of the bending-induced interfacial microstructures of the 2-ply sheets for case A. Both macroscopic lateral delamination, perpendicular to the loading direction at the Al/Cu interface, and cracks within Cu/Al base plates are clearly observed for Samples 3 and 5. In contrast, there is no sign of the initiation of significant cracks or lateral delamination from the joint of Sample 1. Instead, homogeneously distributed voids with size of several-hundred nanometers in diameter were observed at interface between parent Cu and Al alloys. Interestingly, crack propagation was obviously retarded and multiple shear bands were generated. This indicates that 3-point bending of Al/Cu 2-ply sample generated under the highest reduction ratio of 65% during roll bonding resulted in a significant increase in overall bending ability, which is strength accompanied by the retardation of catastrophic crack propagation at the joint between the parent Al and Cu alloys in the direction perpendicular to transverse loading. On the other hand, relatively large voids were inhomogeneously generated at the interface between parent Cu and Al for the 2-ply sheets fabricated under the reduction ratio below 50%. Adjacent to these voids, several lateral cracks with size of about 5 μm were developed toward the loading direction. And the macroscopic delamination perpendicular toward the loading direction at Cu/Al interface was clearly observed.

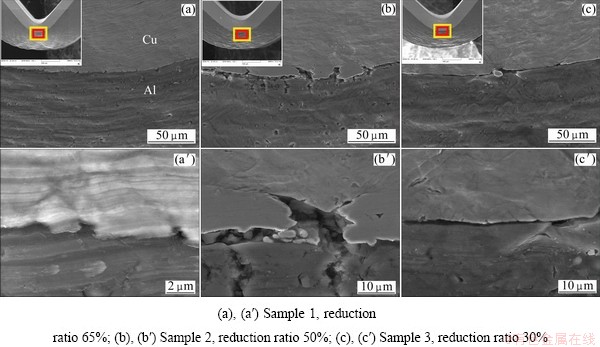

The cross-sectional interface microstructures of the two-ply samples subjected to a 3-point bending tests for case B are shown in Fig. 8. For Sample 1, which was roll-bonded by the reduction ratio of 65%, a large number of pores or voids were formed at the interface of Al/Cu, but were relatively evenly distributed. On the other hand, when the reduction ratios were as low as less than 50%, lateral delamination perpendicular to the loading direction was observed from the Al/Cu joints.

4 Conclusions

1) The influence of reduction ratio on the microstructure evolution at interface and subsequent mechanical properties of roll-bonded Al/Cu 2-ply clad metal was investigated. By using TEM, nanometer-order of interface diffusion layer was observed in the interface of Sample 1, implying metallurgical bonding seemed to be progressed during roll bonding under the reduction ratio of 65%.

2) The development of the phases or voids in the interface controls the mechanical properties of the Al/Cu 2-ply composites. 3-point bending and peel tests show that Sample 1 with the highest reduction ratio of 65% adopted in this study, exhibited excellent mechanical properties in terms of flexural and peel strengths, respectively.

Fig. 7 FE-SEM images after 3-point bending tests showing Al/Cu interface microstructure for case A

Fig. 8 FE-SEM images after 3-point bending tests showing Al/Cu interface microstructure for case B

References

[1] LAPOVOK R, NG H P, TOMUS D, ESTRIN Y. Bimetallic copper-aluminum tube by severer plastic deformation [J]. Scripta Materialia, 2012, 66: 1081-1084.

[2] VEERKAMP W E. Copper-to-aluminum transitions in high direct-current bus systems [C]//Industry Applications Society 42th Annual Petroleum and Chemical Industry Conference. 1995. Paper No. PCIC-95-20: 187-194.

[3] ABBASI M, KARIMI TAHERI A, SALEHI M T. Growth rate of intermetallic compounds in Al/Cu bimetal produced by cold roll welding process [J]. Journal of Alloys and Compounds, 2001, 319: 233-241.

[4] YU Zhen, DUAN Yu-ping, LIU Li-dong, LIU Shun-hua, LIU Xu-jing, LI Xiao-gang. Growth behavior of Cu/Al intermetallic compounds in hot-dip aluminized copper [J]. Surface and Interface Analysis, 2009, 41(5): 361-365.

[5] SHENG L Y, YANG F, XI T F, LAI C, YE H Q. Influence of heat treatment on interface of Cu/Al bimetallic composite fabricated by cold rolling [J]. Composites Part B, 2011, 42: 1468-1473.

[6] LI X, ZU G, DING M, MU Y, WANG P. Interfacial microstructure and mechanical properties of Cu/Al clad sheet fabricated by asymmetrical roll bonding and annealing [J]. Materials Science and Engineering A, 2011, 529: 485-491.

[7] LI X, ZU G, WANG P. Interface strengthening of laminated composite produced by asymmetrical roll bonding [J]. Materials Science and Engineering A, 2013, 562: 96-100.

[8] KIM I K, HONG S I. Mechanochemical joining in cold roll-cladding of tri-layered Cu/Al/Cu composite and the interface cracking behavior [J]. Materials & Design, 2014, 57: 625-631.

[9] HENESS G, WUHRER R, YEUNG W Y. Interfacial strength development of roll-bonded aluminum/copper metal laminates [J]. Materials Science and Engineering A, 2008, 483-484: 740-742.

[10] KIM H J, LEE J Y, PAIK K W, KOH K W, WON J H, CHOE S H, LEE J, MOON J T, PARK Y J. Effect of Cu/Al intermetallic compound (IMC) on copper wire and aluminum pad bondability [J]. IEEE Transactions on Component and Packaging Technologies, 2003, 26(2): 367-374.

[11] GUO Y J, LIU G W, JIM H Y, SHI Z Q, QIAO G J. Intermetallic phase formation in diffusion-bonded Cu/Al laminates [J]. Journal of Materials Science, 2011, 46: 2467-2473.

[12] LEE K S, KWON Y N. Solid-state bonding between Al and Cu by vacuum hot pressing [J]. Transactions of Nonferrous Metals Society of China, 2013, 23: 341-346.

[13] LEE W B, BANG K S, JUNG S B. Effects of intermetallic compound on the electrical and mechanical properties of friction welded Cu/Al bimetallic joints during annealing [J]. Journal of Alloys and Compounds, 2005, 390: 212-219.

[14] XIE W, YAMAGUCHI T, NISHIO K. Formation of intermetallic phases on the bond interface of aluminum-clad copper [J]. Journal of the Japan Institute of Metals, 2011, 75(3): 166-172.

[15] PENG X K, WUHRER R, HENESS G, YEUNG W Y. Rolling strain effects on the interlaminar properties of roll bonded copper/ aluminium metal laminates [J]. Journal of Materials Science, 2000, 35: 4357-4363.

[16] CHEN H L, HWANG W S. Influence of interfacial structure development on the fracture mechanism and bond strength of aluminum/copper bimetal plate [J]. Mater Trans, 2006, 47: 1232-1239.

[17] ZHANG X P, TAN M J, YANG T H, XU X J, WANG J T. Bonding strength of Al/Mg/Al alloy tri-metallic laminates fabricated by hot rolling [J]. Bulletin of Materials Science, 2011, 34(4): 805-810.

不同负载条件下Al/Cu双层复合材料的界面特征

Kwang Seok LEE, Su Eun LEE, Yong-Nam KWON

Materials Deformation Department, Light Metal Division, Korea Institute of Materials Science, Gyeongnam 642-831, Korea

摘 要:研究叠轧过程压下量对轧制Al/Cu双层板界面微观组织及力学性能的影响。采用透射电镜观察压下量为30%~65%时Al/Cu双层的界面微观组织。针对不同的界面组织,分别采用三点弯曲试验和剥离试验测试Al/Cu双层板的弯曲强度和连接强度。讨论了界面冶金接量对其连接强度的影响。结果表明,叠轧时随着压下量减小,Al/Cu双层板的弯曲强度、连接强度均降低,这主要与材料界面组织密切相关。三点弯曲试验也验证了这一点。

关键词:Al/Cu双层复合材料;弯曲性能;叠轧;压下量;界面

(Edited by Huai-zhong LONG)

Foundation item: Project (10037273) supported by the Ministry of Knowledge Economy, Korea

Corresponding author: Kwang Seok LEE; Tel: +82-55-2803380; E-mail: ksl1784@kims.re.kr

DOI: 10.1016/S1003-6326(14)63285-4