原位Al2O3和TiB2粒子增强Al-Cu合金基复合材料的制备和性能

来源期刊:中国有色金属学报1999年第1期

论文作者:马宗义 吕毓雄 毕敬

文章页码:101 - 105

关键词:复合材料,原位,陶瓷粒子,Al2O3,TiB2

Key words:composites, in-situ, ceramic particle, Al2O3, TiB2

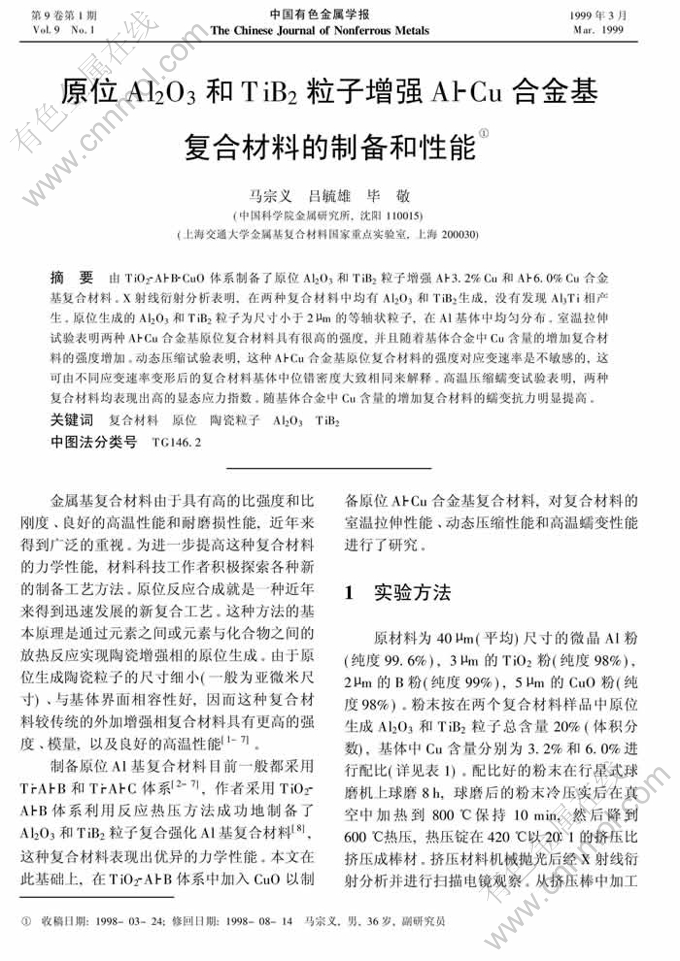

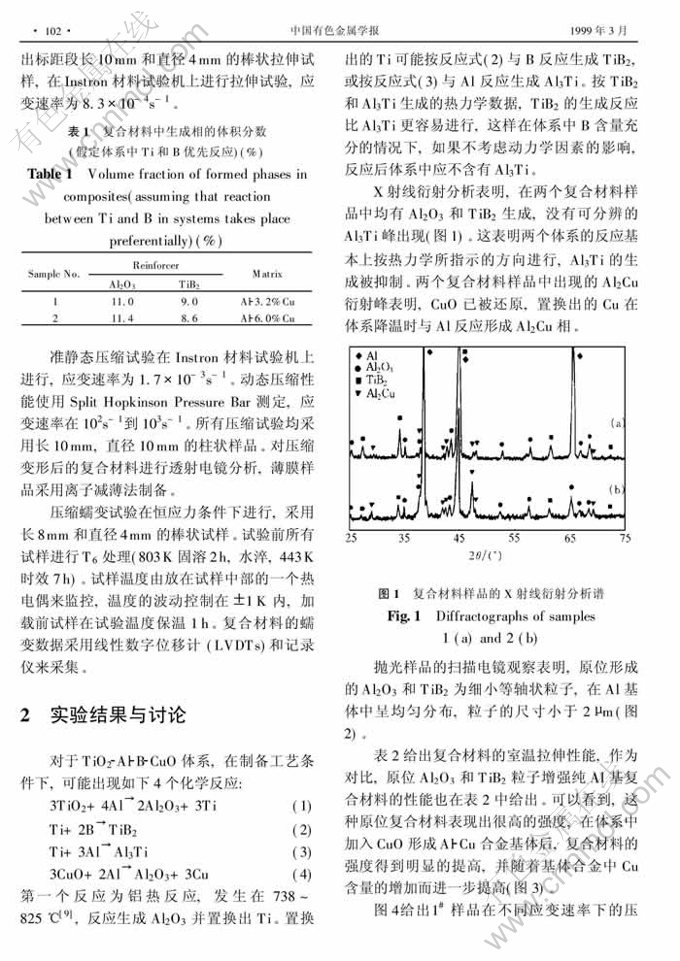

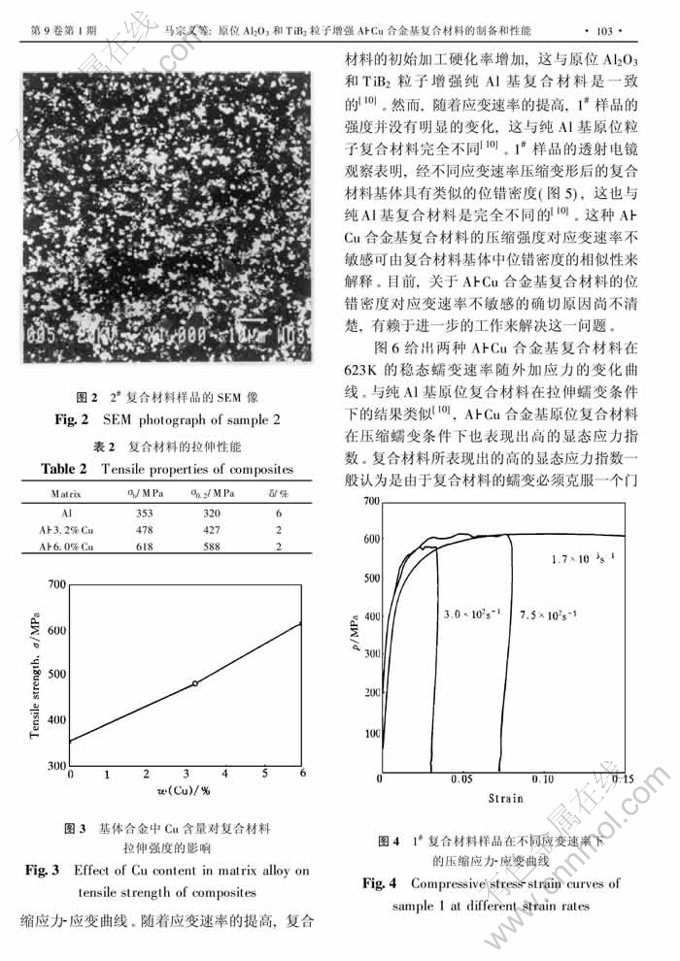

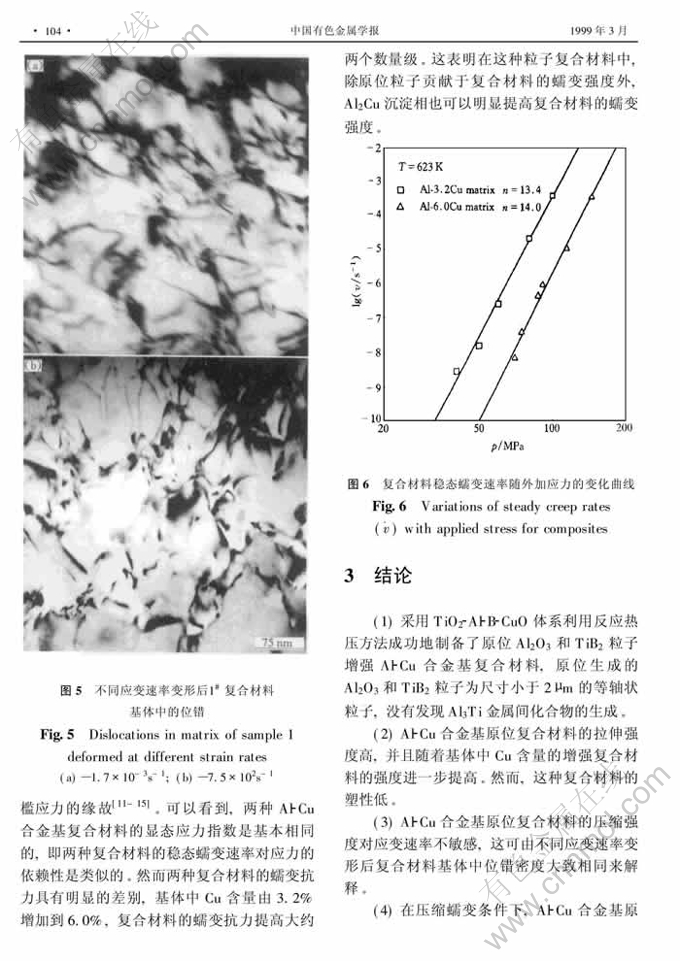

摘 要:由 TiO2-Al-B-CuO 体系制备了原位Al2O3和TiB2粒子增强Al-3.2%Cu和Al-6.0%Cu合金基复合材料。 X射线衍射分析表明, 在两种复合材料中均有Al2O3和TiB2生成, 没有发现Al3Ti相产生。 原位生成的Al2O3和TiB2粒子为尺寸小于2μm的等轴状粒子, 在Al基体中均匀分布。 室温拉伸试验表明两种Al-Cu合金基原位复合材料具有很高的强度, 并且随着基体合金中Cu含量的增加复合材料的强度增加。 动态压缩试验表明, 这种Al-Cu合金基原位复合材料的强度对应变速率是不敏感的, 这可由不同应变速率变形后的复合材料基体中位错密度大致相同来解释。 高温压缩蠕变试验表明, 两种复合材料均表现出高的显态应力指数。 随基体合金中Cu含量的增加复合材料的蠕变抗力明显提高。

Abstract: In-situ Al2O3 and TiB2 particles reinforced Al-3.2% Cu and Al-6.0%Cu alloy composites were fabricated from TiO2-Al-B-CuO system. X-ray diffraction analyses indicate that Al2O3 and TiB2 are formed in two composites and no Al3Ti appears, insitu formed Al2O3 and TiB2 particles with a size of less than 2μm are equiaxed and well-distributed in Al matrix. Tensile tests at room temperature indicate that two Al-Cu alloy matrix composites exhibit high strength, which increases with increasing Cu content of matrix alloy. Dynamic compression tests demonstrate that the strength of the Al-Cu alloy matrix composites is insensitive to the strain rates, which can be explained by approximately identical dislocation density in the matrix of the composites deformed at different strain rates. Compressive creep tests at high temperature show that both composites exhibit high apparent stress exponents and the creep resistance of the composites is obviously increased with increasing Cu content of the matrix alloy.