文章编号:1004-0609(2007)08-1319-05

快速冷却和扩散退火对Sn-Bi-X焊料的影响

李元山1, 2,陈振华1,雷小娟1

(1. 湖南大学 材料科学与工程学院,长沙 410082;

2. 国防科技大学 计算机学院,长沙 410073)

摘 要:通过对自行研制的Sn-Bi-X(X=Ag,Cu,Ge,Ce,Sb)无铅焊料进行快速冷却及扩散退火处理,研究其显微观组织和性能的变化。结果表明,冷却速度越大,熔点越低,共晶比例越小。当甩带速度为1 000 r/min时,熔点由190.5 ℃降低至186.2 ℃,且Sn-58Bi共晶相完全消失。扩散退火能消除Bi的粗化晶体,使组织均匀,增强焊料的力学性能,并且退火后组织稳定。扩散退火可以作为表面贴装生产工艺流程的一个工序,退火工艺以125℃保温16 h为宜。

关键词:Sn-Bi系无铅焊料;偏析;快速冷却;扩散退火

中图分类号:TG 406 文献标识码:A

Influence of rapid cooling and diffusion annealing on Sn-Bi-X solder

LI Yuan-shan1, 2, CHEN Zhen-hua1, LEI Xiao-juan1

(1. School of Materials Science and Engineering, Hunan University, Changsha 410082, China;

2. School of Computer, National University of Defense Technology, Changsha 410073, China)

Abstract: A self-fabricated Sn-Bi-X(X=Ag, Cu, Ge, Ce, Sb) lead-free solder was treated by rapid cooling and diffusion annealing, the changes of its microstructures and properties were investigated. The results show that, the faster the cooling rate, the lower the melting point and the smaller the percent of eutectic is. When the melt spinning rate is up to 1 000 r/min, the melting point decreases from 190.5 ℃ to 186.2 ℃, and the eutectic phase of Sn-58Bi disappears fully. Diffusion annealing can remove the coarse crystal of Bi, uniform the microstructure and enhance the mechanical property of Sn-Bi lead-free solder. The microstructure is stable after annealing. Diffusion annealing can be a procedure of surface mounting production process. Annealing at 125 ℃ for 16 h was approved well.

Key words: Sn-Bi lead-free solders; segregation; rapid cooling; diffusion anneal

在已投入实际应用的几个无铅焊料系列中,锡?银(包括锡?银?铜)系列焊料,如Sn-3.5Ag, Sn-3.0Ag-0.5Cu, Sn-3.8Ag-0.7Cu 以及Sn-3.9Ag-0.6Cu等,因具有细微的组织结构以及优异力学性能和热性能,特别是高的焊接可靠性而被作为锡铅焊料的替代材料广泛应用[1?3],但它们最大的缺点是熔点在217 ℃左右,比传统的Sn-37Pb高34 ℃,因而无法直接用于传统的焊接工艺,必须更换设备,提高焊接温度,与此同时印制板和元器件也必须满足更高的耐热要求。相比之下,Sn-Bi系焊料由于具有熔点低、润湿性好、力学性能好以及成本低廉等优点而受到许多研究者的关注[4?5]。然而,Sn-Bi系焊料在190 ℃左右做成的焊料,容易产生凝固偏析,从而影响焊料的性能[6]。此外,Sn-Bi焊料的组织受温度的影响很大,例如在80 ℃时,合金组织非常稳定,超过140 ℃以后Bi会变得异常粗化,脆性增大[6]。因此,必须采用有效的手段来改善Sn-Bi焊料的性能才能真正达到实用的目的。本文作者以自行研制的Sn-Bi-X(x=Ag,Cu,Ge,Ce,Sb)为实验合金,通过快速冷却和扩散退火来抑制Bi的偏析及晶体粗化,改善焊料的性能。经处理后Sn-Bi-X焊料的熔点、力学性能和润湿性都与Sn-37Pb共晶合金相近,因而不需更换现有的焊接设备和工艺即可直接生产,具有很高的实用化价值[7]。

1 实验

实验合金采用质量分数均为99.99%的Sn、Bi、Ag、Cu、Ge、Ce、Sb纯金属,按设计成分比例,用电子天平称量配置,在中频炉中熔配而成,保护气氛为氩气,合金化学成分列于表1。对比实验所用锡铅合金为Sn-37Pb共晶合金。实验所用快冷焊料在铜辊上甩带制备。焊点的扩散退火在真空干燥箱中进行。

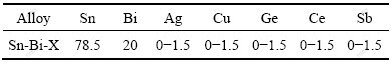

表1 实验合金的化学成分

Table 1 Chemical composition of alloy(mass fraction, %)

使用NETZSCH公司的DSC 404C差示扫描量热仪测量焊料熔化温度,保护气氛为氩气,温度范围20~250 ℃,升温速度5 ℃/min。采用BDX3300 型X射线衍射仪鉴定焊料组织。样品的显微组织采用OLYMPUS BX51M 型光学显微镜观察。使用上海申力WDW?100微机控制电子万能实验机对焊料进行力学性能测试。使用Thermo2NORAN能谱仪确定各相成分;此外,使用JSM?6700F扫描电镜观察显微组织。焊料在实际工作环境中所承受的载荷主要来自剪切力,而且焊料的剪切强度往往小于抗拉强度,所以只对焊点的剪切强度进行测试。加载速度为2 mm/min。钎焊试样的基材为50 mm×10 mm×6 mm的紫铜片。焊料加工成同等面积、厚约0.4 mm的薄片,涂覆助焊剂后置于两片试样基材之间,在高于熔点30 ℃左右的条件下钎焊。

2 结果与分析

2.1 快冷对Sn-Bi系焊料的影响

图1所示为铸态焊料、手工焊点、甩带样品的DSC曲线。可以看出,随着冷却速度的增大,136 ℃附近的吸热峰逐渐减小,当甩带速度为1 000 r/min时,该处的吸收峰消失,这说明Bi的偏析已被抑制。

图1 不同冷却速度下Sn-Bi-X合金的DSC曲线

Fig.1 DSC curves of Sn-Bi-X alloy with different cooling rates

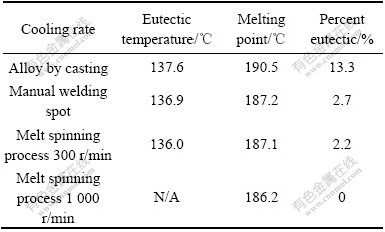

由表2可以看出,Sn-Bi-X合金的共晶点温度和熔化温度随冷却速度增大而降低,这是因为快速凝固增加了材料的固溶度,改变了原子间距。材料熔化温度的高低反映了其原子间结合力的大小,固溶度越大,原子间距越大,原子间的结合力就越小,材料的熔化温度也就越低。表中共晶比例是指Bi偏析生成的共晶组织在焊料中所占的比例。冷却速度增大,共晶比例降低,这说明快冷可以抑制Bi的偏析。

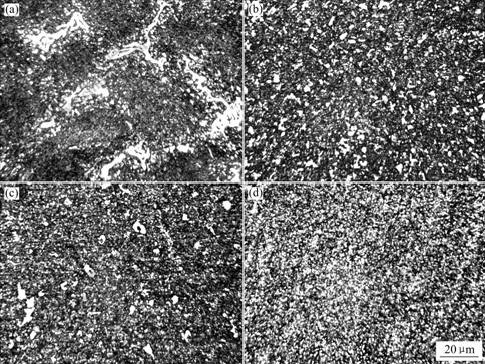

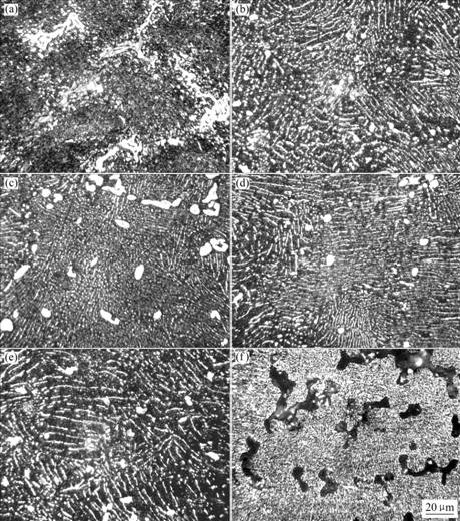

图2(a)~(d)所示分别为铸态组织、手工焊接焊点、水冷焊点和甩带焊料的显微组织。可以看出,冷却速度越大,显微组织越均匀。通过能谱分析得知,白色组织为Bi,黑色组织为Sn。铸态组织偏析生成的共晶组织分布在晶界处,有粗大块状的Bi出现。初生相Sn颜色较深,靠近晶界的地方白色增多,这是Bi在Sn中微细析出所致,是明显的枝晶偏析现象。手工焊接焊点与水冷焊点的冷却速度相近,其显微组织也相差不多。甩带焊料由于冷却速度更大,因此Bi颗粒更加细小。

表2 不同冷却速度下Sn-Bi-X合金的熔化特性

Table 2 Melting characteristic of Sn-Bi-X alloy with different cooling rates

图2 不同冷却速度下焊料的显微组织

Fig.2 Microstructures of solder under different cooling rates:

(a) Casting; (b) Manual welding; (c) Water cooling; (d) Melt spinning process 1 000 r/min

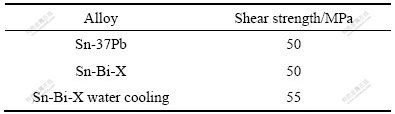

表3所示为快速冷却对合金剪切强度的影响。在相同条件下,Sn-Bi-X的剪切强度与Sn-37Pb共晶焊料相近,但脆性较大。水冷焊点剪切强度有所提高。

表3 合金的室温剪切强度

Table 3 Shear strength of alloys

综上所述,自制的Sn-Bi-X焊料在自然冷却的情况下容易产生Bi的偏析,但通过快速冷却后显微组织和力学性能都得到很大的改善。不过该焊料要用于实际工业生产还存在很大的困难,因为焊接好的印制板很难用常规方法得到如此大的冷却速度。但该焊料用于手工焊接则是可行的,因为手工焊接焊点小,冷却速度快,焊点显微组织均匀,力学性能也能满足要求。

2.2 扩散退火对Sn-Bi系焊料的影响

实际生产中由于波峰焊炉和回流焊炉都无法做到快速冷却,含Bi焊点在冷却过程中仍然会产生微观偏析从而引起焊点剥离[7?11] 。要通过快速冷却抑制偏析,就必须在焊料液相线温度以上采取急冷措施才能有效[12]。在达不到该冷却速度的条件下,焊接后可以通过扩散退火来消除Bi的粗化结晶。有研究表明,Sn-Bi系焊料在80 ℃稳定的组织当温度超过140 ℃以后Bi异常粗化,性能变脆且硬度升高[13]。但是如果将焊点在125 ℃退火6 h,由于Bi的长程扩散,大块的Bi会有消融的迹象;将焊料在125 ℃退火10 h,粗大块状的Bi继续消融、减少,周围已有片状的Bi呈发散状向外扩散;将焊料在125 ℃退火16 h,基体上层片状的Bi均匀分布(如图3(b)所示)。如果再继续延长退火时间,则显微组织不再发生变化。

提高退火温度,原子热激活能量增大,扩散系数增大,易发生迁移,减少退火时间也可以得到均匀分布的粒状Bi(见图3(c)~(e))。

但退火温度不能太高,当温度超过150 ℃以后,低熔点组织将会熔化、挥发,引起烧蚀。烧蚀部位为低熔点(136 ℃)的共晶组织(图3(f))。

图3 不同退火工艺的显微组织

Fig.3 Microstructures of alloys with different annealing parameters: (a) As-cast alloy; (b) Annealing at 125 ℃ for 16 h; (c) Annealing at 130 ℃ for 6 h; (d) Annealing at 140 ℃ for 2 h; (e) Annealing at 150 ℃ for 2 h; (f) Ablation at 160 ℃

退火完全后的组织在80 ℃和100 ℃时长时间放置没有发生明显变化,证明退火可以提高焊料的抗老化性能。

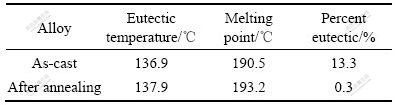

表4所列为铸态和退火态合金的熔化特性。可见共晶点温度和熔化温度在退火后均有所升高,这意味着焊点的耐热能力升高。另外,扩散退火后焊料的剪切强度提高到54 MPa,可见焊接完成后进行扩散退火是很有必要的。

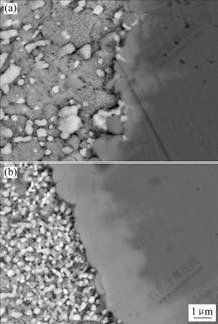

据文献[14]报道,共晶Sn-58Bi/Cu焊点于120 ℃时效后发生脆性断裂,力学性能快速下降,脆断后一侧断口为鲜亮的Cu表面。但本实验中并未发现Sn-20Bi非共晶焊点退火后有此现象发生。从本质上分析,焊点的强度和韧性值是由金属间化合物(IMC)层的厚度决定的,厚度越大,界面脆性越大。

图4所示为退火后焊点的SEM像。可以看出,退火可使IMC层变厚,但12 h的退火并未使IMC层超过3 μm,而1~3 μm厚的η相Cu6Sn5对焊接来说有一定的优越性,可使焊点结合紧密,焊点强度有所提高。只有当IMC层厚度超过5 μm以后,如果继续退火,则容易形成α相Cu3Sn,这是一种骨针状结晶,是一种恶性的脆性界面,造成不润湿现象。当受到温度循环、振动、冲击等外力作用时,即产生裂纹,导致焊点性能恶化。

表4 铸态和退火态合金的熔化特性

Table 4 Melting characteristic of as-cast alloy and after annealing

图4 扩散退火前后焊料的显微组织

Fig.4 Microstructures of solder before (a) and after annealing at 125 ℃ for 12 h (b)

3 结论

1) 采用快速冷却方式制作Sn-Bi-X焊料可以抑制Bi的偏析,使焊料组织均匀,力学性能提高。

2) Sn-Bi-X焊料在焊接过程中进行快速冷却也是有必要的。冷速缓慢使Bi偏析严重,沿着大块Bi的边界有微裂纹存在。

3) Sn-Bi-X焊料可用于手工焊接。焊点的微观结构和力学性能与快冷焊点接近。

4) 扩散退火消除了Sn-Bi-X焊料中Bi的粗化结晶,极大地改善了焊料的显微组织和力学性能。这是Sn-Bi系非共晶焊料的一个优势,在一定程度上弥补了Bi的偏析所引起的不足。且退火完全后焊料组织稳定。

5) Sn-Bi-X非共晶焊料焊接完成后于125 ℃保温16 h进行扩散退火,可使基体中的Bi均匀分布,因而可作为表面贴装生产工艺流程的一个工序。

REFERENCES

[1] Wood E P, Nimmo K L. In search of new lead-free electronic solders[J]. J Electron Mater 1994, 23(8): 709?713.

[2] Zeng K, Tu K N. Six cases of reliability study of Pb-free solder joints in electronic packaging technology[J]. Materials Science and Engineering, 2002, 38(1): 55?105.

[3] Tu K N, Gusak A M, Li M. Physics and materials challenges for lead free solders[J]. Journal of Applied Physics, 2003, 93(3): 1335?1338.

[4] Xia Z D, Chen Z G, Shi Y W, et al. Effect of rare earth element addition on the microstructure and mechanical properties of tin-sliver-bismuth solder[J]. J Electron Mater, 2002, 31(6): 564?567.

[5] Suganuma K. Microstructural features of lift-off phenomenon in through-hole circuit soldered by Sn-Bi alloy[J]. Scripta Materialia, 1998, l38(9): 1333?1340.

[6] Suganuma K. 无铅焊接技术[M]. 北京: 科学出版社, 2004: 51?144.

Suganuma K. Technology of lead free soldering[M]. Beijing: Science Press, 2004: 51?144.

[7] LI Yuan-shan, LEI Xiao-juan, CHEN Zhen-hua. A novel low melting point Pb-free solder[J]. Circuits Assembly, 2007, 18(2): 54?57.

[8] Suganuma K. Lift-off phenomenon in wave soldering[J]. Acta Materialia, 2000(48): 4475?4481.

[9] 何 鹏, 赵智力, 钱乙余. Sn-Bi-Ag-Cu钎料波峰焊焊点的剥离现象[J]. 中国有色金属学报, 2005, 15(7): 993?999.

HE Peng, ZHAO Zhi-li, QIAN Yi-yu. Fillet-lifting phenomenon of wave soldering with Sn-Bi-Ag-Cu solder[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 993?999.

[10] Vincent J H, Humpston G.. Lead-free solders for electronic assembly[J]. GEC Journal of Research, 1994, 11(2): 76?89.

[11] 何 鹏, 赵智力, 钱乙余, 等. 无铅波峰焊Sn-Bi-Ag-Cu钎料焊点剥离机制[J]. 中国有色金属学报, 2006, 16(2): 315?321.

HE Peng, ZHAO. Zhi-li, QIAN Yi-yu, et al. Fillet-lifting mechanism for Sn-Bi-Ag-Cu solder joint in lead-free wave soldering[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 315?321.

[12] Suganuma K. Application of lead-free in electrical machine and electronic parts[J]. Electronic Technology, 2000(3): 47?53.

[13] 段莉蕾, 于大全, 赵 杰. Sn-9Zn-3Bi/Cu钎焊接头在170 ℃时效过程中的显微结构[J]. 中国有色金属学报, 2004, 14(5): 842?847.

DUAN Li-lei, YU Da-quan, ZHAO Jie. Microstructures of Sn-9Zn-3Bi solder/Cu joint during long-term aging at 170 ℃[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 842?847.

[14] 刘春忠, 张 伟, 隋曼龄. 共晶SnBi/Cu焊点界面处Bi的偏析[J]. 金属学报, 2005, 41(8): 847?852.

LIU Chun-zhong, ZHANG Wei, SUI Man-ling. Bi segregation at interface of the eutectic SnBi/Cu solder joint[J]. Acta Metallurgica Sinica, 2005, 41(8): 847?852.

收稿日期:2007-01-05;修订日期:2007-04-10

通讯作者:李元山,副研究员;电话/传真:0731-4511590;E-mail: liyuanshan0528@163.com

(编辑 陈爱华)