DOI: 10.11817/j.ysxb.1004.0609.2020-36440

界面微渗透作用下浸堆内部渗流场无损探测

薛振林1,甘德清1,张友志1,刘志义1,黄明清2

(1. 华北理工大学 矿业工程学院,唐山 063210;

2. 福州大学 紫金矿业学院,福州 350116)

摘 要:为了揭示矿石与溶液界面微渗透作用对矿石间细观流场分布影响,基于堆内实测结构构建了浸矿结构物理模型,利用粒子图像测速技术(PIV)对结构内溶液渗流场进行无损探测。结果表明:在矿-液界面持续的微渗透作用下,速度场的均衡性显著提高,优势流的发生得到抑制,浸出盲区大幅降低,最大流速下降50%;界面的微流动使得流场中有漩流动区域大幅提高,涡量值分布呈现贴壁性,涡量同向聚集且边缘方向突变时形成漩涡;在实验的喷淋强度范围内,结构内流速分布均匀性和最大流速值会随着喷淋强度的增加而提高。

关键词:堆浸;微渗透;渗流;优先流;无损探测

文章编号:1004-0609(2020)-07-1730-08 中图分类号:TD862 文献标志码:A

矿石堆浸技术具有设计简单、基建时间短、达产快、处理量大等优点,对于低品位的铜、金、银等金属的开采回收具有独到的优势,得到日益广泛的应用[1]。在浸矿药剂一定的前提下,堆浸过程中目标矿物的浸出率和浸出速率主要受堆内渗透效果的影响。目前的浸矿生产中还存在的诸多渗透性的问题,如堆内溶液分布不均、存在浸出盲区、优势流、沟流等,这些问题制约着堆浸技术进一步推广应用[2-3]。因此,开展矿堆内溶液渗透性方面的研究日益重要。早期的堆浸渗流方面的理论研究以达西定律为基础,从宏观连续介质假设入手,关注外部条件设置与渗透效果间的关系。陈喜山等[4]假定在常压下溶液为不可压缩流体,建立了矿堆饱和区和非饱和区渗流方程。丁德馨等[5]研究了铀矿堆浸过程中饱和渗流规律,分析了粒径分形维数对渗透率的影响,建立了基于支持向量机的渗透率和流态指数预测模型。CARIAGA等[6]假设溶液为不可压缩流体,建立了铜矿堆浸条件下固液两相流模型,模拟了矿堆内饱和水压力、流速分布规律。DOUNFFARD等[7]研究了堆浸过程中溶液渗流动力学行为,建立了基于对流时间、动水与不动水比率、扩散时间、孔径等变量的PSPD模型。随着研究的深入,发现利用“黑箱”理论只能分析宏观参数与浸出效果间的关系,难以揭示内部渗透的规律。

为了探究矿堆内部渗透规律,近年来一些学者基于X-ray CT、MRI等新型的实验手段,对介质结构和渗流场开展了无损伤探测研究。LIN等[8]基于CT技术重构了柱浸三维结构并分析了渗流规律,发现浸矿过程中渗流通道减少,渗透系数从14×10-4 cm2降为4×10-4 cm2。MIAO等[9-10]基于工业CT获取了高精度散体结构,分析矿石间与矿石内的不同流动形式,建立了多重流动模型。ILANKOON等[11]构造了非柱浸结构渗透模型,分析了孔隙率对溶液扩散规律以及对矿石持液能力的影响。SEDERMAN等[12]以玻璃球为多孔介质骨架结构,利用MRI技术非接触地探究了多孔介质内单相流和两相流的分布规律。尹升华等[13]采用MRI技术对柱浸渗流过程进行探测,分析了溶液速度场均匀性问题。FAGAN等[14-16]利用MRI技术研究了不同滴灌条件下渗流场特征,结果表明溶液喷淋强度的增大会扰动原有溶液分布,有益于浸矿。以上研究手段各具特点,但仍具局限性,应用CT技术只能获取疏干的结构特征;采用MRI技术能够获得饱和状态下溶液和流速分布,但目前实验结果精度较低,费用较高。

PIV技术是一种瞬态、多点、无接触式的流体力学测速方法,能够提供瞬时全场流动的定量信息,逐步应用于多孔介质流动和细观流动的研究[17-18]。尹升华等[19]采用PIV技术对细观矿堆模型内渗流场进行了无扰动探测,结果表明将PIV技术应用于渗流探测是有效的。然而由于浸矿散体结构复杂,应用PIV技术时易出现错点,目前开展研究多忽略矿-液界面间溶液渗透作用,这会在一定程度上影响渗流研究的准确性[21]。

本文在考虑矿-液界面微渗透作用基础上,联合激光诱导荧光技术(Laser induced fluorescence, LIF)和粒子的图像测速技术(Particle image velocimetry, PIV)开展堆内溶液渗流场无损探测及可视化研究,重点分析矿-液界面微渗透作用对流场的作用规律,为提高堆内渗流场的均匀性奠定理论基础。

1 LIF联合PIV测速原理

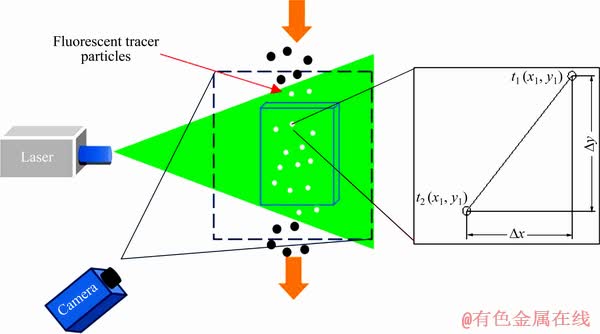

PIV是一种瞬态、多点、非接触式的激光测速方法,利用激光双脉冲技术计算极短的时间间隔内示踪粒子的位移来探测流场分布。LIF联合PIV测速技术是利用某些分子或原子在激光照射下能够发荧光的特性,采用荧光示踪粒子,提升复杂结构内示踪效果,其测量精度更高,能够获得更为准确的渗流场。浸矿条件下矿石间复杂结构内流场探测的基本原理是在流场中加入适量荧光示踪粒子,在第一个时间点t1时刻激光照亮流场中一个平面,利用相机记录荧光示踪粒子的位置(x1, y1);极短间隔后的t2时刻,另一束激光照亮同一个平面,获得粒子的位置(x2, y2)[21],如图1。

由于时间差很小,该点的运动状态可近似用下式描述:

(1)

(1)

(2)

(2)

,

, (3)

(3)

式中:ux、uy为记录点在x轴和y轴上的速度分量;u为记录点速度; 为速度偏角。通过高频相机不断重复该过程,记录下图像组,基于互相关原理计算全场粒子位移,从而获得了目标结构区域内的渗流速度场特征。

为速度偏角。通过高频相机不断重复该过程,记录下图像组,基于互相关原理计算全场粒子位移,从而获得了目标结构区域内的渗流速度场特征。

2 实验

2.1 实验设备

本实验设备为国产PIV-2D2C PIV系统,型号SM3-5M200。基本组成为:示踪粒子添加装置、双脉冲激光器+片光系统、CCD相机、信息处理系统四部分组成。

2.2 实验模型

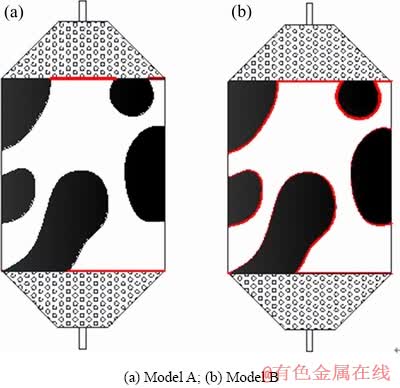

实验模型依据无损伤获取的柱浸内部结构,采用高透光有机玻璃板等比例制作成适用于PIV探测的物理模型,如图2所示。模型外尺寸为长×宽×厚=18 cm×15 cm×1 cm,模型中红色线条表示界面允许溶液通过。实验模型分为两组,A组矿石外表面为封闭状态,矿-液界面间不存在溶液渗透。B组考虑矿-液界面间的微渗透作用,在矿石模型采用空心有机玻璃封闭,在封闭界面上均匀制作一排0.5 mm微孔隙来模拟溶液在矿-液界面微渗透的通道。

图1 LIF联合PIV测速原理

Fig. 1 Speed measurement principle of LIF combined with PIV

图2 实验物理模型

Fig. 2 Experimental physical model

2.3 实验方案及过程

实验方案:实验对象为A和B两组模型,喷淋强度设置为20、30和40 L/h。实验过程如下。连接各实验部分,模型垂直于水平面,溶液从模型顶端流入,底端流出,将模型进行饱和处理,排尽模型中气泡,静置后准备实验。开启设备,调节模型与光源位置,光源对准模型1 cm厚的一面,使激光面平行穿过模型,并在模型中实现最窄激光面。调整相机与模型位置,使相机与激光面垂直,调焦,调节光圈获得粒子清晰显示图像。本实验模型固定且为饱和状态,溶液依靠重力流动,模型底部连接流量计,喷淋强度分别设置为20、30和40 L/h,待流场稳定后连续拍摄200张图像,记录并不同实验条件下流场图像。

3 结果与讨论

3.1 界面微渗透对渗流速度场分布的影响

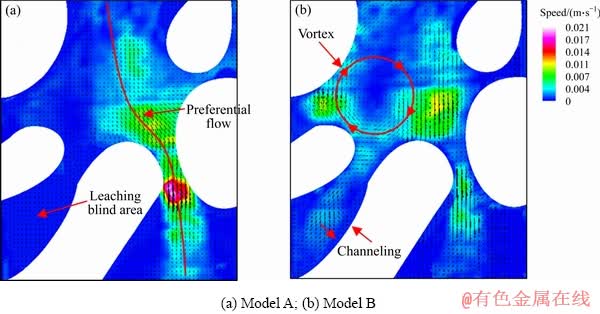

利用 Micro Vec 软件对溶液在模型内流动的图像进行批量处理,计算出稳态下的标记粒子的运动规律。将实验结果导入Tecplot 软件进行可视化绘图,得到了稳态状态下模型内部流体流动速度分布矢量云图,以喷淋强度40 L/h为例,如图3所示。

结果表明,PIV联合LIF技术能够实现浸堆内复杂结构溶液渗流场的无损伤探测。图3(a)表明矿-液界面封闭时,复杂结构内渗流速度场分布不均匀;溶液经过矿石间孔隙快速穿过结构,在喉道处出现流速极值,达到0.021m/s,并且形成了贯穿结构的优势流;结构中存在较大的浸出盲区,左侧溶液不能流动或极为缓慢的流动。流场的分布不均衡影响结构内部的传质过程,在优势流路径上,能够快速的完成溶液的更迭交换,浸出的有用矿物快速运移出矿堆。然而在浸出盲区内,溶液不能流动,溶质的传递只能通过扩散作用完成,无法实现有效的交换更迭,导致浸出效率降低。图3(b)表明在矿-液界面间的微渗透作用下,整个结构渗流速度场分布的均匀性显著增强;溶液仍主要通过喉道贯穿结构,但不构成优势流;在微渗透作用下左侧区域内溶液在矿石表面窜流,溶液可以在矿石界面交换,使得结构左侧浸出盲区转变为流动状态;流场中现了漩涡流,使得溶液在结构内流动迹线显著增长,流场中最大流速的位置由喉道转移到旋涡外端,最大流速下降至0.011m/s。由于流动更为均衡,结构内大部分区域可完成溶液快速更迭,传质速率增大,有助于浸出率和浸出速率的提升。对比分析表明,矿-液界面的微渗透作用能够显著提高结构内流场的均匀性,有效控制优势流的出现,浸出盲区大幅降低,最大流速降低50%,有效加速结构内的传质作用。

图3 流场矢量分布图

Fig. 3 Flow field vector distribution

3.2 界面微渗透对漩涡分布的影响

考虑矿-液界面为渗透作用下矿石散体复杂结构内出现了漩涡流,这种有漩运动为溶质的运移提供了良好的媒介,量化表征旋涡的分布有助于揭示渗流场分布规律。通常用涡量表征涡旋的强度和方向,涡量定义流体速度矢量的旋度,单位是(s-1)。本文采用如下方法计算流场中的涡量:

1) 在获取结构内矢量速度场的条件下分别计算得到速度分量u和v,再分别计算切应变率 和

和

(4)

(4)

(5)

(5)

2) 计算涡量

(6)

(6)

式中: 为涡量;u和v为速度分量;

为涡量;u和v为速度分量; 为y方向的切应变率,

为y方向的切应变率, 为x方向的切应变率。

为x方向的切应变率。

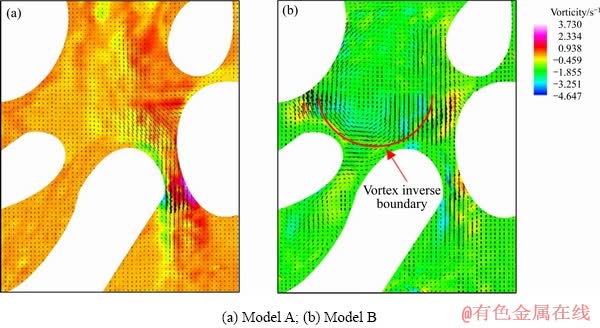

图4所示为两结构内涡量的分布,结果表明界面微渗透作用对结构内涡量分布产生了显著影响。在图 4(a)所示流场中,很大区域涡量值约为0,仅在喉道处涡量值急剧升高,以正值为主。而在图4(b)所示流场中,涡量大面积出现,且以负值为主,二者方向相反。分析可知涡量大小表征两方向上切应变率的差值,涡量的出现说明了此处的流动为有漩流动;在界面微渗透的作用下,结构内的有漩流动分布迅速增多,有漩流动增多使得结构内流速降低,进而涡量值较低。图4(a)中喉道附近的涡量值较高,具有显著贴壁性。在矿石阻碍下,溶液流经喉道流速方向会随着矿石表面发生偏移,喉道左侧流速向左下方流行,涡量指向平面内,为负值;喉道右侧贴向右侧偏移,涡量指向平面外,为正值。由图4(b)可知,漩涡顺时针旋转,涡量指向平面内,涡量值由中心向边缘增大;漩涡延伸至矿石附近,在界面微渗透作用下,溶液流动方向与原方向发生偏转且速度下降,涡量指向外部为负值。分析可知,只有当涡量在较大区域内方向一致并且边缘值反向增大时才说明漩涡流的出现;在界面微渗透作用下,流场中存在漩流动区域的大幅增加,使得溶液在结构内部流动的迹线增加,有利于结构内部的传质作用,且不易形成优势流。

3.3 喷淋强度对界面微渗透结构内流场分布影响

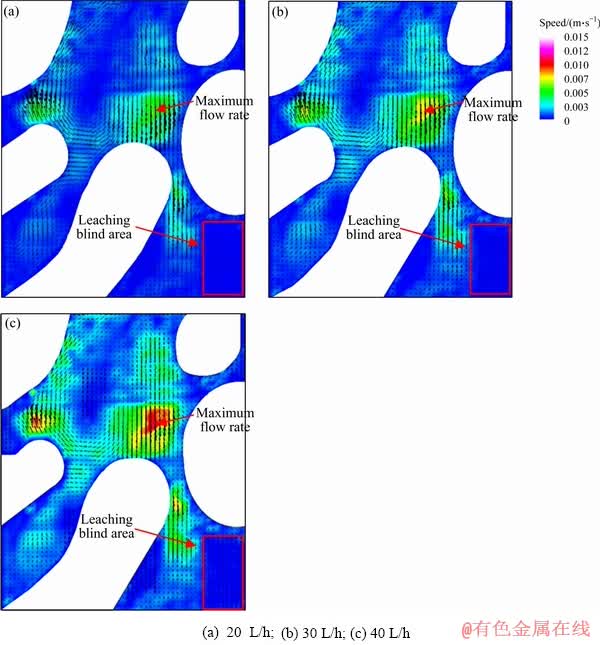

喷淋强度是浸矿实验的重要参数,表征单位时间内给单位矿石喷洒溶液的质量。不同喷淋强度下考虑 矿-液界面微渗透结构内渗流速度流场分布如图5所示。随着喷淋强度由20 L/h增大至40 L/h,浸出盲区显著减小,溶液的流速和流动区域都随之增大,但结构中流速极大值的位置没有改变。在喷淋强度为40 L/h时,结构中漩涡流最显著,矿石周边的流速明显增强,流场的吸壁性也最显著。在实验条件下,喷淋强度的增加使得溶液在结构内部流动迹线增长,进而提高了溶质交换速率,改善传质作用,有助于提高浸出速率和效果。不同喷淋强度下,右下方区域内流场中均存在浸出盲区,且盲区的位置和大小也并无明显变化。因此,影响流场分布最主要的因素来自结构自身的特征,孔隙分布的均匀性和良好连通性是流场均匀分布的前提,改变喷淋强度等外在设置的条件只能对流场起到调节作用。

图4 涡量分布图

Fig. 4 Vorticity distribution

图5 不同喷淋强度下流场的分布

Fig. 5 Flow field distribution under different spray intensities

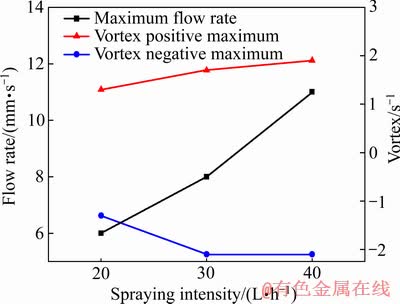

为了进一步量化喷淋强度对流场的影响,绘制了流速和涡量极值与喷淋强度的关系图,如图6所示。结果表明,流速的极值与喷淋强度呈正相关性,喷淋强度由20 L/h增加至40 L/h时,流速极值由0.06 m/s增加至0.11 m/s。涡量的极大值也与喷淋强度呈正相关,变化范围较小;极小值先增大,后维持不变,喷淋强度增大到一定值后流场内负方向的涡量不再发生变化。

图6 流场参数与喷淋强度关系

Fig. 6 Relationship between flow field parameters and spray intensity

图7 界面微渗透对流场影响的叠加效应

Fig. 7 Superposition effect of interface micro-infiltration on flow field

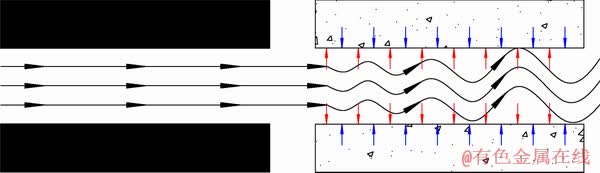

3.4 界面微渗透对流场影响机制分析

矿-液界面上溶液的微渗透作用受孔隙水压力、岩石孔隙率和渗透率等因素影响,在不同的浸出条件下微渗透速率也会不同,但与矿石间溶液的流动相比较,界面微渗透作用下的流动较为缓慢。当界面间微渗透持续发生时,对结构内流动会产生一种叠加效应,导致微流动的作用不容忽视(见图7)。

溶液自左向右在矿石间流动,左侧流动区域矿-液接触面封闭,溶液流经矿石时对原有流动的方向影响很小。溶液到达右侧区域时,考虑矿石表面和内部分布着大量的微孔隙和微裂隙,浸出过程中在毛管力、表面张力等微观作用力下矿-液界面存在着持续的微渗透作用,这种交换作用沿着界面不断累积,对原有流动方向产生持续的改变,使得溶液流动迹线拉长,有漩流动增强。此外,在浸矿过程中,矿石中的目标矿物不断被浸出,孔隙率持续升高,溶液在界面间流动的通道不断增大,微渗透的速率上升,综合的影响足以改变了整个流场的分布。这种影响在流场的探测实验中具体体现为:微渗透作用促进了矿石与周围溶液的交换,使得浸出盲区内溶液由静止转为缓慢流动,浸出盲区的降低。在微渗透的持续影响下,优势流路径上流速不能持续增大,而且流速方向也发生改变,优势流的发生和发展得到抑制。此外,原流场的方向发生改变,有漩流动增大了结构内的传质作用。基于此,耦合矿石间的流动和矿-液界面的微渗透作用的溶液流动探测,能够更有效地揭示浸堆内溶液流动的一般规律。

4 结论

1) PIV联合LIF技术能够实现浸矿复杂结构溶液渗流场的无损伤探测。在界面微渗透作用下,矿石间渗流速度场分布更均衡,优势流消失,浸出盲区大幅降低,最大流速降低50%,能有效增强内部传质作用。

2) 在界面微渗透作用下,流场中有漩流动增多,涡量的同向聚集形成漩涡,涡量值分布呈现贴壁性,并在在界面处改变方向;在实验的喷淋强度范围内,结构内流速分布均匀性会随着喷淋强度的增大而提高,流速极值与喷淋强度呈正相关。

3) 界面的微渗透对流场的影响具有持续叠加效应,足以改变整个结构流场的分布;耦合矿石间的流动和界面微渗透作用能够更准确地反映浸矿细观流场分布特征。

REFERENCES

[1] 吴爱祥, 王洪江, 杨保华, 尹升华. 溶浸采矿技术的进展与展望[J]. 采矿技术, 2006, 6(3): 39-48.

WU Ai-xiang, WANG Hong-jiang, YANG Bao-hua, YIN Sheng-hua. Leaching mining technology progress and prospect[J]. Mining Technology, 2006, 6(3): 39-48.

[2] PRADHAN N, NATHSARMA K, SRINIVASA R, SUKLA L B, MISHRA B K. Heap bioleaching of chalcopyrite: A review[J]. Minerals Engineering, 2008, 21(5): 355-365.

[3] ILANKOONl I, NEETHLING S. Hysteresis in unsaturated flow in packed beds and heaps[J]. Minerals Engineering, 2012, 35: 1-8.

[4] 陈喜山, 梁晓春, 荀志远. 堆浸工艺中溶浸液的渗透模 型[J]. 黄金, 1999, 20(4): 30-33.

CHEN Xi-shan, LIANG Xiao-chun, XUN Zhi-yuan. The infiltration models of leach solution in heap leaching process[J]. Gold, 1999, 20(4): 30-33.

[5] 叶勇军, 丁德馨, 李广悦, 宋键斌, 李 峰. 堆浸铀矿堆液体饱和渗流规律的研究[J]. 岩土力学, 2013, 34(8): 2243-2248.

YE Yong-jun, DING De-xin, LI Guang-yue, SONG Jian-bin. LI Feng. Regularities for liquid saturated seepage in uranium ore heap for heap leaching[J]. Rock and Soil Mechanics, 2013, 34(8): 2243-2248.

[6] CARIAGA E, CONCHA F, SEPULVEDA M. Convergence of a MFE-FV method for two phase flow with applications to heap leaching of copper ores[J]. Computer Methods in Applied Mechanics and Engineering, 2007, 196(25): 2541-2554.

[7] DOUNFFARD S, DIXON D. Investigative study into the hydrodynamics of heap leaching processes[J]. Metallurgical and Materials Transactions B, 2001, 32(5): 763-776.

[8] LIN C, MILLER J, GARCIA C. Saturated flow characteristics in column leaching as described by LB simulation[J]. Minerals Engineering, 2005, 18(10): 1045-1051.

[9] MIAO X, NARSILIO G A, WU A, YANG B. A 3D dual pore-system leaching model. Part 1: Study on fluid flow[J]. Hydrometallurgy, 2017, 167: 173-182.

[10] MIAO X, GREKE K M, SIZONENKO T O. A new way to parameterize hydraulic conductances of pore elements: A step towards creating pore-networks without pore shape simplifications[J]. Advances in Water Resources, 2017, 105: 162-172.

[11] ILANKOON I, NEETHLING S. Liquid spread mechanisms in packed beds and heaps. The separation of length and time scales due to particle porosity[J]. Minerals Engineering 2016, 86: 130-139.

[12] SDEDRMAN A, GLADDEN L. Magnetic resonance visualisation of single-and two-phase flow in porous media[J]. Magnetic Resonance Imaging, 2001, 19(3): 339-343.

[13] 尹升华, 薛振林, 吴爱祥, 刘 超, 李 红. 基于核磁共振成像技术的堆浸细观渗流速度场特性[J]. 工程科学学报, 2015, 37(3): 275-280.

YIN Shen-ghua, XUE Zhen-lin, WU Ai-xiang, LIU Chao, LI hong. Mesoscopic seepage velocity characteristics during heap leaching based on magnetic resonance imaging[J]. Chinese Journal of Engineering, 2015, 37(3): 275-280.

[14] FAGAN M A, SEDERMAN A J, JOHNS M L. MR imaging of ore for heap bioleaching studies using pure phase encode acquisition methods[J]. Journal of Magnetic Resonance, 2012, 216: 121-127.

[15] FAGAN M A, SEDERMAN A J, HARRISON S, JOHNS M L. Phase distribution identification in the column leaching of low grade ores using MRI[J]. Minerals Engineering, 2013, 48: 94-99.

[16] FAGAN M A, HARRISON S, JOHNS M, SEDERMAN A J. Magnetic resonance imaging characterization of the influence of flowrate on liquid distribution in drip irrigated heap leaching[J]. Hydrometallurgy, 2015, 158: 157-164.

[17] BISWAS N, ROY P C, MANNA N K, MUKHOPADHYAY A, SEN S. Experimental studies of flow through radial channels using PIV technique[J]. Journal of Visualization, 2014, 17(3): 221-233.

[18] ALIMOHAMMADI S, FANNING E, PERSOONS T, MURRAY D B. Characterization of flow vectoring phenomenon in adjacent synthetic jets using CFD and PIV[J]. Computers & Fluids, 2016, 140: 232-246.

[19] 尹升华, 陈 勋, 吴爱祥, 王雷鸣, 刘 超. 基于PIV技术的细观矿堆溶液渗流场无扰动测试[J]. 中南大学学报(自然科学版), 2015, 46(7): 2597-2604.

YIN Sheng-hua, CHEN Xun, WU Ai-xiang, WANG Lei-ming, LIU Chao. Undisturbed test on mesoscopic solution seepage field in ore heap based on PIV[J]. Journal of Central South University(Science and Technology), 2015, 46(7): 2597-2604.

[20] 吴爱祥, 李希雯, 尹升华, 艾纯明. 矿堆非饱和渗流中的界面作用[J]. 北京科技大学学报, 2013, 35(7): 844-849.

WU Ai-xiang, LI Xi-wen, YIN Sheng-hua, AI Chun-ming. Interface effects of unsaturated seepage in dump leaching[J]. Journal of University of Science and Technology Beijing, 2013, 35(7): 844-849.

[21] MEINHART C D, WERELEY S T, SANTIAGO J G. A PIV algorithm for estimating time-averaged velocity fields[J]. Journal of Fluids Engineering, 2000, 122(2): 285-289.

Non-destructive detection of solution flow behavior during heap leaching considering interface micro-infiltration

XUE Zhen-lin1, GAN De-qing1, ZHANG You-zhi1, LIU Zhi-yi1, HUANG Ming-qing2

(1. College of Mining Engineering, North China University of Science and Technology, Tangshan 063210, China;

2. College of Zijin Mining, Fuzhou University, Fuzhou 350116, China)

Abstract: In order to reveal the effect of micro-infiltration at the interface between ore and solution on the microscopic flow field distribution in the ore particles, the leaching structure model was established based on the measured structure in leaching heap, and the solution flow behavior during heap leaching was detected in a non-destructive detection way by using PIV technique. The results show that, under the continuous micro-infiltration at the mineral-liquid interface, the equilibrium of the velocity field is significantly improved, the occurrence of the preferential flow is suppressed, the leaching blind zone is greatly reduced, and the maximum flow velocity is reduced by 50%. The swirling flow area is greatly improved under the effect of micro-infiltration, and the vorticity distribution presents adherent. A vortex is formed when the vortices gather in the same direction and the edge direction changes. Within the spray intensity range of the experiment, the uniformity of flow velocity distribution and the maximum flow velocity value will increase with the increase of spray intensity.

Key words: heap leaching; micro-infiltration; seepage; preferential flow; non-destructive detection

Foundation item: Projects(51804121, 51804079, 51774137) supported by the National Natural Science Foundation of China; Project(E2016209277) supported by the Natural Science Foundation of Hebei Province, China

Received date: 2019-06-26; Accepted date: 2019-11-05

Corresponding author: GAN De-qing; Tel: +86-315-8805401; E-mail: ncstgandeqing@163.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51804121,51804079,51774137);河北省自然科学基金资助项目(E2016209277)

收稿日期:2019-06-26;修订日期:2019-11-05

通信作者:甘德清,教授,博士;电话:0315-8805401;E-mail:ncstgandeqing@163.com