DOI: 10.11817/j.issn.1672-7207.2016.01.024

最小粒径截距对颗粒体数值模拟的影响

马幸1, 2,周伟1, 2,马刚1, 2,常晓林1, 2

(1. 武汉大学 水资源与水电工程科学国家重点实验室,湖北 武汉,430072;

2. 武汉大学 水工岩石力学教育部重点实验室,湖北 武汉,430072)

摘要:基于颗粒流离散单元法,采用2种压实度控制标准,生成3种不同最小粒径的颗粒体试样,分别对其进行多组、多种数值试验,从而揭示颗粒体最小粒径与其宏观力学特性及细观力学响应的关系,并分析最小粒径对数值试验结果精度的影响。研究结果表明:颗粒集合体试样各力学参量与最小粒径呈单调关系,经推求可得出不同最小粒径截距对应的试样抗变形能力;配位数与最小粒径的对数呈较好的线性递增关系,从细观层面解释了最小粒径对试样密实度及强度特性的影响;采用相对密度控制以及选择较低的围压均能缩小由最小粒径引起的试验结果的差异。

关键词:颗粒体;双轴试验;离散元;最小粒径;压实度控制标准

中图分类号:TV311 文献标志码:A 文章编号:1672-7207(2016)01-0166-10

Effect of minimum particle size on assembly in numerical simulation

MA Xing1, 2, ZHOU Wei1, 2, MA Gang1, 2, CHANG Xiaolin1, 2

(1. State Key Laboratory of Water Resources and Hydropower Engineering Science,

Wuhan University, Wuhan 430072, China;

2. Key Laboratory of Rock Mechanics in Hydraulic Structural Engineering of Education Ministry,

Wuhan University, Wuhan 430072, China)

Abstract: The effect of the minimum size of particles on the strength properties and deformation characteristics of particles and the accuracy of simulations were simulated by the particle flow code in two dimensions (PFC2D). Three specimens with different minimum size of particles were analyzed, and two different compactness control standards were considered. The results show that the mechanical parameters are monotone function about the minimum particle size, and that the anti-distortion capacity of assemblies with different minimum particle sizes can be calculated through the function. On the other hand, linearly increasing relationship was found between coordination number and logarithmic minimum particle size, the impact of minimum particle size on density and strength properties was explained from the micro level. Finally, the influence of the minimum particle size on the results of the simulation were reduced by using relative density control standard and low confining stress.

Key words: assembly; biaxial compression test; discrete element; minimum particle size; compactness control standard

近年来,我国高堆石坝建设的迅速发展,对堆石料等粗粒土的力学特性研究提出了更高要求。从现有测定堆石料力学特性的试验条件来看,常规三轴压缩试验是一种比较成熟的方法,该方法可得到试样的一些重要的变形和强度参数,如弹性模量、黏聚力和内摩擦角等。但堆石体的宏观力学性能还受到颗粒形状和大小[1]、颗粒表面的粗糙程度、颗粒的含水率等细观因素的影响,而常规三轴压缩试验仅能得到堆石体的宏观力学表现,无法探明堆石体在颗粒层面上的细观力学本质。离散单元法是一种广泛使用的分析离散颗粒体的数值模拟方法,能够从细观角度对颗粒体的力学特性进行研究[2-5],并且还能克服试验仪器的尺寸限制和加载难以控制等缺点。在对颗粒体进行离散元数值试验时,受到计算机运行速度和计算容量的限制,通常将粒径小于某一定值的小颗粒用粒径为该值的颗粒等体积替换[6-9],这样必然导致数值试验的级配与试验级配不一致,从而导致数值计算结果与室内试验结果存在差异。BAGHERZADEH-KHALKHALI等[10]通过室内试验和数值试验对比分析,指出颗粒的粒径在很大程度上影响了颗粒体的力学特性,并且数值模拟会放大颗粒粒径的影响。由此看来,小颗粒的等体积替换会对数值模拟结果造成明显影响。因此,为了提高数值模拟结果的准确性,有必要对最小粒径截距对颗粒集合体的影响进行深入探究。目前,对颗粒粒径及其分布的影响的探究主要集中于研究颗粒体整体级配的改变对其力学性质的影响:刘军等[11]通过二维离散元模拟研究了不同尺寸分布对颗粒堆积过程的影响;HWANG等[12-13]分别通过数值试验和物理试验研究了颗粒级配和结构对砂土力学性质的影响;HAMIDI等[14]通过室内试验与数值模拟结果对比分析了颗粒级配对其抗剪强度的影响;邱贤德等[15]通过室内试验研究了堆石体粒径特征对其渗透性的影响;傅华等[16-18]则对堆石体尺寸效应进行了研究。由于当整体级配发生改变时,最大颗粒尺寸对试验结果的影响尤为明显,因此这些研究普遍关注最大粒径对试样力学性质的影响。但颗粒最小粒径最终会对数值模拟产生何种程度的影响,以及如何控制数值模拟的其他条件来减小由最小粒径截距引起的计算结果的差异,提高计算精度,对这些问题的研究目前尚不明确。本文作者采用基于离散单元法的PFC2D程序[19],用圆形颗粒生成3组最小粒径不同的颗粒体,并采用2种不同的试样压实度控制标准进行双轴压缩试验,从宏观和细观2方面分析数值模拟结果,深入研究最小粒径截距对试样的抗剪强度、应力-应变、体积应变等力学特性的影响,为提高数值计算精度提供有效参考依据。

1 数值试样

1.1 试样制备与加载方式

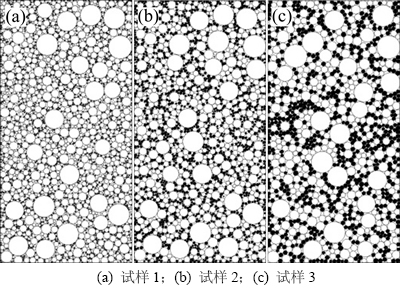

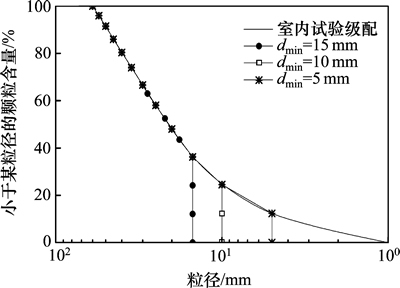

试样的高×宽为700 mm×350 mm,试样的最大颗粒粒径dmax为60 mm,为了使试验结果的差异性更突出,将最小粒径截距设为差值较大的5,10和15 mm,采用等体积替换法将级配中粒径小于该取值的颗粒分别用粒径为5,10和15 mm的颗粒替换,生成3种最小粒径不同的试样,如图1所示(图1中黑色颗粒为最小粒径颗粒),确定3组试样的级配曲线,如图2所示。

为了排除其他因素的影响,在生成颗粒的过程中除了级配分布会略有不同外,应尽量保持其余控制条件一致。在数值计算中,通常采用孔隙率作为颗粒体压实度控制标准,但是,当颗粒的级配分布发生变化时,处于同一孔隙率的颗粒体的松紧状态也会存在差异[17],因此,本文分别考察2种不同的压实度控制标准下,最小粒径对颗粒体的影响。分别采用孔隙率控制和相对密度控制的标准生成6组颗粒试样。在二维颗粒流数值计算中,颗粒体为单位厚度的圆盘[20-21],在计算孔隙率的过程中,可以将颗粒体的体积计算简化为颗粒体的面积计算,因此,孔隙率的定义为

式中:n为孔隙率;Ap为颗粒体的面积;A为试样面积。相对密度的定义为

式中:Dr为相对密度;e为试样孔隙比;emax为试样最大孔隙比;emin为试样最小孔隙比。由于PFC2D程序中颗粒的生成是以孔隙率为控制标准的,因此需根据孔隙率与孔隙比的关系确定相对密度与孔隙率的关系。经过孔隙比与孔隙率的转换,相对密度可表示为

式中:nmax为试样最大孔隙率;nmin为试样最小孔隙率。

图1 不同最小粒径数值试样

Fig. 1 Numerical samples with different smallest particle diameters

图2 颗粒级配曲线

Fig. 2 Particle size distribution curves

PFC2D模型中,颗粒体的双轴压缩是在上、下、左、右4面墙体所围成的区域内进行的[19]。利用伺服机制控制左右墙体的移动,保持侧向应力恒定,控制上下墙体的移动实现对颗粒体的竖向应力加载。

1.2 细观参数取值

数值试验采用线性接触刚度模型,接触力可通过接触刚度和相对位移的关系确定。法向刚度为割线刚度,与位移和力的总量相对应,关系式如下:

式中:Fn为法向总力;kn为接触点处法向刚度;Un为法向总位移。切向刚度为切线刚度,与位移和力的增量相对应,关系式如下:

式中: 为切向位移增量;

为切向位移增量; 为接触点切向刚度;

为接触点切向刚度; 为切向位移增量。

为切向位移增量。

对于线性接触刚度模型,模型由接触颗粒的法相刚度 和切向刚度

和切向刚度 通过串联接触的方式相互作用决定。其颗粒间接触的法向割线刚度和切向切线刚度为:

通过串联接触的方式相互作用决定。其颗粒间接触的法向割线刚度和切向切线刚度为:

式中:上标[A]和[B]分别为相互接触的2个颗粒。

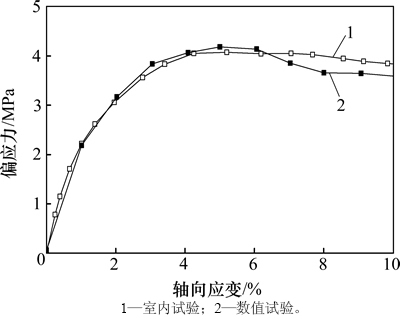

颗粒接触刚度和摩擦因数 的取值采用类比或试算的方法间接确定[22],通过调整细观参数,使数值试验得到的应力-应变曲线接近室内三轴试验结果,室内试验成果来自长江科学院所做的双江口堆石料三轴试验,如图3所示,表1所示为最终的细观参数。

的取值采用类比或试算的方法间接确定[22],通过调整细观参数,使数值试验得到的应力-应变曲线接近室内三轴试验结果,室内试验成果来自长江科学院所做的双江口堆石料三轴试验,如图3所示,表1所示为最终的细观参数。

图3 数值试验与室内试验对比图

Fig. 3 Contrast figure between numerical test and experimental test

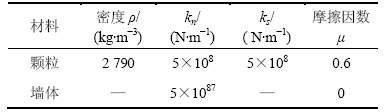

表1 数值试验的细观参数

Table 1 Micro-parameters of numerical test

1.3 最大和最小孔隙率的确定

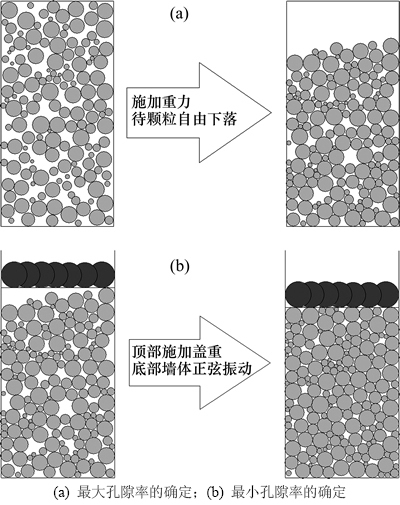

为了确定颗粒集合体的相对密度Dr,首先要确定颗粒集合体的最大孔隙率nmax和最小孔隙率nmin。本文在常用方法[23]的基础上加以改进,使数值模拟的过程与室内试验[24]过程更接近,具体采用如下步骤确定颗粒体的最大和最小孔隙率。

确定颗粒集合体的最大孔隙率nmax。模拟松填法过程[25],首先生成初始孔隙率n=0.3的试样,由于孔隙率较大,颗粒在空间内随机分布且相互无接触,然后给颗粒赋以Y方向上的重力加速度g=-9.8 m/s2,使其在自重作用下自由下落,待颗粒体在自然状态下达到稳定平衡后,即可得到试样的最大孔隙率nmax。

确定颗粒集合体的最小孔隙率nmin。模拟振动台工作过程[25],在确定最大孔隙率的试样基础上,在试样顶部通过设置颗粒簇单元施加盖板重力荷载,通过底部墙体的正弦振动模拟振动台振动过程,直至试样中各颗粒接触总数趋于稳定,即认为试样达到最小孔隙率nmin。

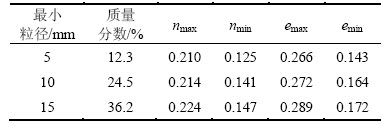

图4所示为颗粒体最大和最小孔隙率的确定。确定的最大和最小孔隙率如表2所示。从表2可以看出:nmax,nmin,emax和emin均随着最小粒径的增大而增大,并且最小粒径为5 mm试样的nmin和emin明显较小,表现出小颗粒较强的填充能力。

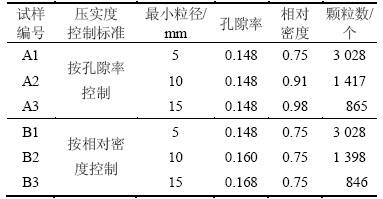

以孔隙率为压实度控制标准时,拟定试验考察孔隙率为0.148;以相对密度为压实度控制标准时,拟定试验考察相对密度为0.75。根据表2中颗粒体的最大和最小孔隙率,计算得出的各组试样的孔隙率和相对密度如表3所示。表3中颗粒数随最小粒径的增大明显减少,因此相应计算速率也能得到提高,表明颗粒级配中最小粒径截距的合理取值确实能有效提高数值模拟计算效率。

图4 颗粒体最大和最小孔隙率的确定

Fig. 4 Determination of maximum and minimum porosity of numerical samples

表2 颗粒集合体最大和最小孔隙率

Table 2 Maximum and minimum porosity of numerical samples

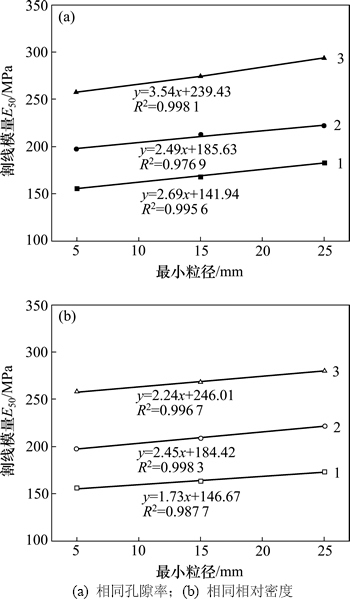

表3 按孔隙率和相对密度控制的数值试样

Table 3 Numerical samples controlled by porosity and relative density

2 数值模拟结果及分析

2.1 应力-应变关系

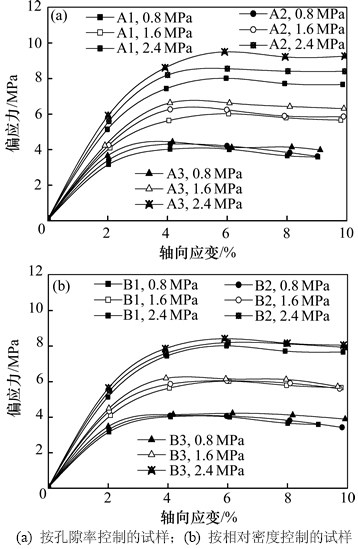

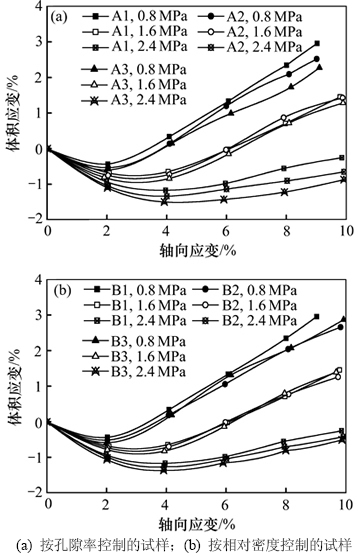

对6组试样进行相同加载方式的双轴压缩试验,控制围压分别为0.8,1.6和2.4 MPa,试样的偏应力 与轴向应变

与轴向应变 关系曲线如图5所示,体积应变与轴向应变关系曲线如图6所示。

关系曲线如图5所示,体积应变与轴向应变关系曲线如图6所示。

图5 相同孔隙率和相对密度试样的偏应力-轴向应变关系

Fig. 5 Relationship between deviational stress-axial strain of samples with the same porosity and relative density

图6 相同孔隙率和相对密度试样的体积应变-轴向应变关系

Fig. 6 Relationship between volumetric strain and axial strain of samples with the same porosity and relative density

从图5和图6可以看出:6组试样的偏应力、体积应变与轴向应变关系曲线的变化规律相似,但相同围压下,不同最小粒径试样的应力-应变曲线和体积应变曲线并不重合,表明最小粒径对数值模拟计算影响的客观存在。相同围压下,不论采用哪种压实度控制标准,试样均表现出随着最小粒径增大,其应力-应变和体积应变曲线初始段的斜率增大,偏应力峰值和体积收缩程度也增大的现象,表明其初始切线模量和抗剪强度提高,剪胀现象减弱。

不同的压实度控制标准下,试样最小粒径对应力-应变曲线的影响程度不同:采用相同孔隙率控制的3组试样,不同最小粒径试样的初始模量和峰值强度差异较大,随着围压的增加,这种差别逐渐增大;而采用相对密度控制的3组试样,其初始模量和峰值强度的差别较小。对于体积应变曲线,2种控制标准亦有同样的影响。

2.2 强度特性

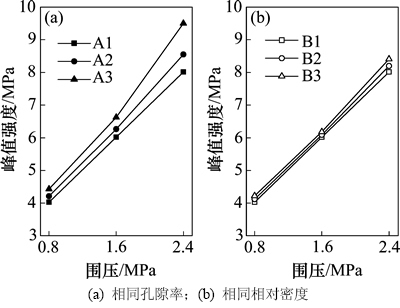

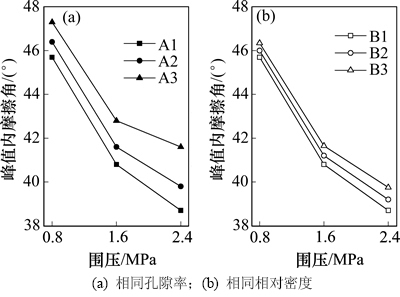

不同围压下6组试样的峰值强度 和峰值内摩擦角

和峰值内摩擦角 如图7和图8所示。从图7和图8可以看出:峰值强度

如图7和图8所示。从图7和图8可以看出:峰值强度 随着围压的增加而增大,而峰值内摩擦角

随着围压的增加而增大,而峰值内摩擦角 随着围压的增加而减小,反映了围压的约束作用对颗粒材料强度的影响。不同最小粒径对峰值强度产生了一定的影响,随着最小粒径的增大,试样强度有所提高,并且围压的增加使得试样强度提高的程度更加明显。试样最小粒径对峰值内摩擦角的影响也表现出同样的规律。说明最小粒径的增大,提高了整体结构的承载能力。当围压从0.8MPa增至2.4MPa时,采用孔隙率控制生成的试样A2和A3的

随着围压的增加而减小,反映了围压的约束作用对颗粒材料强度的影响。不同最小粒径对峰值强度产生了一定的影响,随着最小粒径的增大,试样强度有所提高,并且围压的增加使得试样强度提高的程度更加明显。试样最小粒径对峰值内摩擦角的影响也表现出同样的规律。说明最小粒径的增大,提高了整体结构的承载能力。当围压从0.8MPa增至2.4MPa时,采用孔隙率控制生成的试样A2和A3的 较试样A1的增幅分别从4.08%和10.05%增长至6.71%和18.58%,

较试样A1的增幅分别从4.08%和10.05%增长至6.71%和18.58%, 的增幅分别从1.53%和3.50%增长至2.84%和7.49%;而采用相对密度控制生成的试样B2和B3的

的增幅分别从1.53%和3.50%增长至2.84%和7.49%;而采用相对密度控制生成的试样B2和B3的 较试样B1的增幅分别从1.19%和2.74%增长至2.30%和4.95%,

较试样B1的增幅分别从1.19%和2.74%增长至2.30%和4.95%, 的增幅分别从0.66%和1.29%增长至1.42%和2.71%。说明压实度控制标准对强度增长的程度有一定的影响,通过相对密度控制压实的颗粒体,最小粒径对试样峰值强度和峰值内摩擦角的影响明显较小,在低围压下,甚至能控制在3%以内。

的增幅分别从0.66%和1.29%增长至1.42%和2.71%。说明压实度控制标准对强度增长的程度有一定的影响,通过相对密度控制压实的颗粒体,最小粒径对试样峰值强度和峰值内摩擦角的影响明显较小,在低围压下,甚至能控制在3%以内。

图7 峰值强度-围压关系曲线

Fig. 7 Relationship between peak strength and confining stress

图8 峰值内摩擦角-围压关系曲线

Fig. 8 Relationship between peak internal friction angle and confining pressure

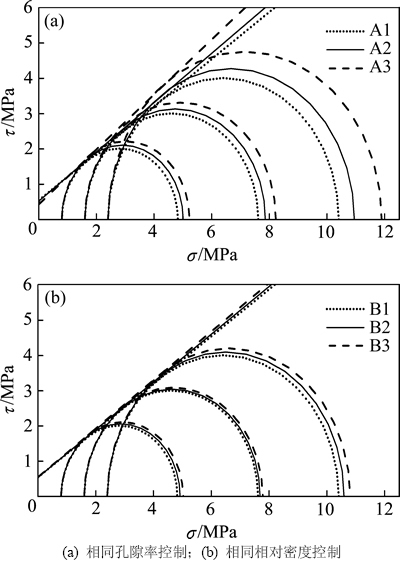

为了研究试样最小粒径对颗粒体强度特性指标的影响,绘制各组试验破坏时的莫尔圆和强度包线(如图9)并分析各组试样的强度指标。常用的线性抗剪强度指标是用摩尔库仑破坏准则来描述颗粒体的抗剪强度 与法向应力

与法向应力 的线性关系:

的线性关系:

(8)

(8)

式中:c为黏聚力; 为内摩擦角。而在工程实际中也常用邓肯非线性强度理论来分析颗粒体的强度特性:

为内摩擦角。而在工程实际中也常用邓肯非线性强度理论来分析颗粒体的强度特性:

(9)

(9)

式中: 为围压为

为围压为 时的内摩擦角;

时的内摩擦角; 为

为 关系曲线上的斜率,反映了强度随着围压的降低;

关系曲线上的斜率,反映了强度随着围压的降低; 为大气压。由式(8)和式(9)整理得到的强度指标如表4所示。

为大气压。由式(8)和式(9)整理得到的强度指标如表4所示。

图9 相同孔隙率和相对密度试样的莫尔圆和强度包线

Fig. 9 Mohr circles at failure and strength envelops of samples with the same porosity and relative density

表4 强度指标

Table 4 Strength indicator of samples

由图9和表4可以看出:强度指标黏聚力c和 随着试样最小粒径的增大而减小,此处c反映了颗粒间的咬合力,可视为表观黏聚力,即最小粒径的增大使得颗粒间的咬合力减弱,表明了小颗粒的存在使得颗粒间摩擦力增强,加大了颗粒间相互滑移的难度,

随着试样最小粒径的增大而减小,此处c反映了颗粒间的咬合力,可视为表观黏聚力,即最小粒径的增大使得颗粒间的咬合力减弱,表明了小颗粒的存在使得颗粒间摩擦力增强,加大了颗粒间相互滑移的难度, 的减小再次表明了围压的升高对最小粒径的影响的放大作用;内摩擦角

的减小再次表明了围压的升高对最小粒径的影响的放大作用;内摩擦角 和

和 随着试样最小粒径的增大而增大,与峰值强度和峰值内摩擦角的变化规律相同,而它们与c和

随着试样最小粒径的增大而增大,与峰值强度和峰值内摩擦角的变化规律相同,而它们与c和 的变化规律不同,是由于在高低围压下颗粒体强度随着最小粒径变化的增减幅度不同。采用相对密度控制试样的压实度时,试样最小粒径对c,

的变化规律不同,是由于在高低围压下颗粒体强度随着最小粒径变化的增减幅度不同。采用相对密度控制试样的压实度时,试样最小粒径对c, ,

, 和

和 的影响程度较小,最大变化程度分别为0.55%,2.37%,0.18%和9.24%,而采用孔隙率控制时,影响程度较大,最大变化程度分别达到20.73%,12.46%,2.00%和17.64%。

的影响程度较小,最大变化程度分别为0.55%,2.37%,0.18%和9.24%,而采用孔隙率控制时,影响程度较大,最大变化程度分别达到20.73%,12.46%,2.00%和17.64%。

从采用不同压实度控制标准时试样最小粒径对各项强度指标的影响程度可以看出:选取适当的最小粒径截距和压实度控制标准,可以在将数值试验与室内试验结果的差异控制在一定范围内的基础上提高计算速率,扩大对连续宽级配颗粒体数值模拟的应用范围。

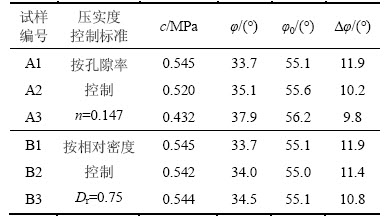

2.3 变形特性

通常取对应峰值强度一半处应力-应变曲线的割线斜率来计算割线变形模量,记作E50。计算得到不 同最小粒径试样在各围压下的割线模量E50如图10 所示。

由图10可以看出:试样的割线模量E50随着最小粒径的增大而增大。对割线模量随最小粒径变化的规律进行线性拟合。从拟合结果来看,割线模量与最小粒径满足良好的线性关系。虽然对最小粒径的样本取值较少,但此处最小粒径的取值范围为5~15 mm,占最大粒径60 mm的1/12到1/4,涵盖了最大粒径为 60 mm的试样进行数值计算时最小粒径截距的大部分取值,因此,此处线性拟合结果的可信度较高,对于确定的粒径截距便可由拟合公式推求相应割线模量。

图10 不同最小粒径试样的割线模量

Fig. 10 Secant modulus of samples with different minimum particle diameters

从线性拟合的斜率可以看出:围压的增大同样提高了割线模量的增长幅度,并且采用相对密度为控制标准时,割线模量随最小粒径的增长幅度较小。

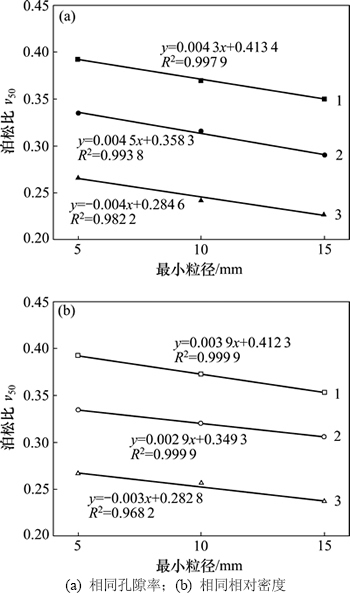

为了较全面地分析堆石体的变形特性,还需要研究其体积变形模量或泊松比,本文拟对颗粒体的泊松比进行研究。类似上述E50的计算,取对应峰值强度一半的轴向应变与径向应变的比值计算泊松比,记作 。计算得到不同最小粒径试样在各围压下的泊松比

。计算得到不同最小粒径试样在各围压下的泊松比 及其线性拟合结果如图11所示。

及其线性拟合结果如图11所示。

由图11可以看出:6组试样的泊松比随最小粒径的变化规律与变形模量的变化规律所反映的变形特性一致,在相同压实度下,泊松比随着颗粒最小粒径的增大而减小且满足良好的线性关系,围压的增加也加大了泊松比的减小幅度,采用相对密度为控制标准时泊松比的减小幅度相比采用孔隙率为控制标准时的减小幅度较小。

图11 不同最小粒径试样的泊松比

Fig. 11 Poisson ratio of samples with different minimum particle diameter

从上述最小粒径对颗粒体试样变形特性的影响可以初步认为:在低围压下,采用相对密度为控制标准时颗粒体最小粒径对其变形模量和泊松比的影响较小,此时数值试验的变形特性计算结果与实际室内试验的结果更为接近。

2.4 细观力学响应

配位数Cn指试样中颗粒的平均接触点数,反映了颗粒体细观接触的特性,配位数越大,说明颗粒体越密实,结构越稳定,配位数定义如下:

(9)

(9)

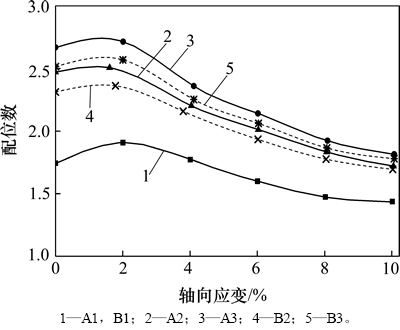

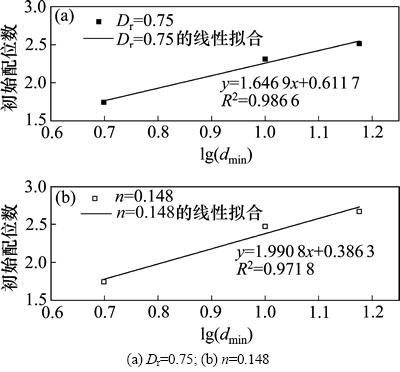

图12所示为围压1.6 MPa时试样配位数随轴向应变的变化曲线。从图12可以看出:6组试样配位数变化规律相似:在剪切初始阶段,试样出现一定体缩,颗粒体更加密实,配位数略有上升,随后试样逐渐发生破坏,体积膨胀,配位数开始不断减小,并且减小的趋势逐渐变缓。图12中配位数曲线不重合,再次表明了最小粒径对数值试验的影响。采用同种压实度控制标准时,配位数随着最小粒径的增加而增大,并且当试样最小粒径为5 mm时,其配位数明显小于最小粒径为10 mm和15 mm的试样,说明当试样最小粒径较小时,由于小颗粒的数量较多,颗粒平均接触点数减少,颗粒体结构相对不稳定,这从细观层面解释了此时试样抗剪强度较低的原因。

为了进一步定量表达配位数与最小粒径的经验公式,整理出6组试样的初始配位数 与

与 的关系,如图13所示。从图13可以看出:2种压实度控制标准下,

的关系,如图13所示。从图13可以看出:2种压实度控制标准下, 与

与 的关系都可近似采用线性拟合,最小粒径增大时,颗粒间接触数增加,颗粒体结构更加密实稳定。比较2种压实度控制标准,可以看出采用相对密度控制的颗粒体

的关系都可近似采用线性拟合,最小粒径增大时,颗粒间接触数增加,颗粒体结构更加密实稳定。比较2种压实度控制标准,可以看出采用相对密度控制的颗粒体 与

与 的线性关系更好,并且

的线性关系更好,并且 的增长幅度较小。

的增长幅度较小。

图12 配位数与轴向应变关系曲线

Fig. 12 Relationship between coordination number and axial strain

图13 Cni与lg(dmin)关系图

Fig. 13 Relationship between Cni and lg(dmin)

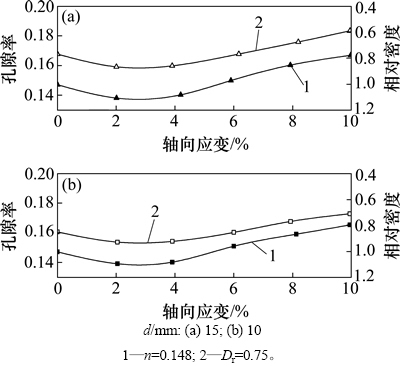

颗粒体的体积变形在细观上可以通过试样孔隙率的变化来体现。分析围压1.6 MPa下最小粒径分别为10 mm和15 mm的试样在加载过程中孔隙率与相对密度的变化,如图14所示。从图14可以看出:试样孔隙率在加载过程中,表现出与体积应变相同的规律,先减小后增大,即随着应力的增大,颗粒体先出现体积收缩变得密实,孔隙率减小,在应力增大到颗粒体趋于破坏时,迫使颗粒间发生滑移和翻越,颗粒体体积膨胀,孔隙率增大。孔隙率n=0.148时颗粒体较相对密度Dr=0.75时更加密实,因此表现出更明显的剪胀性,孔隙率的变化程度也更加明显。对比图14中不同最小粒径试样的孔隙率和相对密度的变化,dmin=15 mm时的变化稍明显,说明了小颗粒对大颗粒间空隙的填充能力强,颗粒体最小粒径较小时,试样在加载过程中的体积变化也较小。

图14 孔隙率与轴向应变关系曲线

Fig. 14 Relationship between porosity and axial strain

由于试样选用的是连续宽级配的颗粒,粒径差异较大,可能出现一些小颗粒位于较大颗粒的孔隙中而自身不受力的情况,它们对整体结构的应力变形和强度特性不产生影响,为无效颗粒,可视为孔隙,为了进一步研究颗粒体细观孔隙的变化,对试样的结构孔隙率ns进行分析。结构孔隙率定义为

(10)

(10)

式中: ,

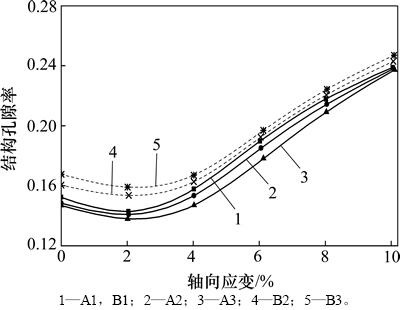

, 为无效颗粒的面积。试样的结构孔隙率随轴向应变的变化如图15所示,此时围压为1.6 MPa。

为无效颗粒的面积。试样的结构孔隙率随轴向应变的变化如图15所示,此时围压为1.6 MPa。

图15 结构孔隙率与轴向应变关系曲线

Fig. 15 Relationship between structure porosity and axial strain

从图15可以看出:结构孔隙率随着加载的进行呈现先减小再增大的趋势,加载初始阶段,颗粒体变得密实,无效颗粒也随之减少,随着加载的进行,试样逐渐发生破坏,体积开始膨胀,无效颗粒数明显增多,结构孔隙率明显增大。当dmin=5 mm和dmin=10 mm时,初始结构孔隙率稍大于初始孔隙率,表明颗粒体的承载能力主要取决于大颗粒,最小粒径较小时,颗粒体中更容易出现无效颗粒,因此,在数值计算中选取极小的最小粒径截距,力求与室内试验级配完全一致并不一定能提高计算结果的精度,反而降低了计算效率。

3 结论

1) 在同一级配曲线的基础上选取不同最小粒径截距,以PFC2D为工具,生成了3种不同最小粒径的颗粒试样,对其进行了多组数值试验,得出了一些关于最小粒径截距的宏、细观规律。

2) 颗粒体最小粒径对其密实度产生一定影响,随着最小粒径的增加,试样密实程度指标nmax,nmin,emax和emin逐步增大。其细观层面则表现为配位数与最小粒径的对数呈较好线性递增关系。

3) 颗粒体最小粒径对试样的力学特性有一定的影响。强度方面,随着最小粒径的增大,试样的 ,

, ,

, 和

和 逐渐增大,c和

逐渐增大,c和 逐渐减小,同一相对密度下,最小粒径对各强度指标的影响程度较小,大部分在5%以内。变形方面,随着最小粒径的增加,E50逐步增大,

逐渐减小,同一相对密度下,最小粒径对各强度指标的影响程度较小,大部分在5%以内。变形方面,随着最小粒径的增加,E50逐步增大, 逐步减小,且均与最小粒径呈较好的线性关系,经拟合可得出其他最小粒径截距时对应的E50和

逐步减小,且均与最小粒径呈较好的线性关系,经拟合可得出其他最小粒径截距时对应的E50和 。

。

4) 采用相对密度为压实度控制标准,并且降低围压,能减小最小粒径对试样力学特性的影响,此时选取较大的最小粒径截距,不仅能保证数值模拟结果的可信度,同时也提高了计算效率,为数值试验中最小粒径截距的合理选取提供了有效依据。

参考文献:

[1] SZARF K, COMBE G, VILLARD P. Polygons vs. clumps of discs: a numerical study of the influence of grain shape on the mechanical behaviour of granular materials[J]. Powder Technology, 2011, 208(2): 279-288.

[2]  O, KRUYT N P, LUDING S. Micro-mechanical analysis of deformation characteristics of three-dimensional granular materials[J]. International Journal of Solids and Structures, 2010, 47(17): 2234-2245.

O, KRUYT N P, LUDING S. Micro-mechanical analysis of deformation characteristics of three-dimensional granular materials[J]. International Journal of Solids and Structures, 2010, 47(17): 2234-2245.

[3] ZHANG Xiao. Simulation of permanent deformation of unbound granular materials under repeated loading by DEM[J]. Procedia-Social and Behavioral Sciences, 2013, 96: 505-511.

[4] 罗勇, 龚晓南, 连峰. 三维离散颗粒单元模拟无黏性土的工程力学性质[J]. 岩土工程学报, 2008, 30(2): 292-297.

LUO Yong, GONG Xiaonan, LIAN Feng. Simulation of mechanical behaviors of granular materials by three-dimensional discrete element method based on particle flow code[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(2): 292-297.

[5] 周健, 池永. 土的工程力学性质的颗粒流模拟[J]. 固体力学学报, 2004, 25(4): 377-382.

ZHOU Jian, CHI Yong. Simulating soil properties by particle flow code[J]. Acta Mechanica Solida Sinica, 2004, 25(4): 377-382.

[6] 马刚, 周伟, 常晓林, 等. 堆石料缩尺效应的细观机制研究[J]. 岩石力学与工程学报, 2012, 31(12): 2473-2482.

MA Gang, ZHOU Wei, CHANG Xiaolin, et al. Mesoscopic mechanism study of scale effects of rockfill[J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(12): 2473-2482.

[7] 周伟, 花俊杰, 马刚, 等. 堆石坝初次蓄水变形机理研究[C]// 李锡夔. 颗粒材料计算力学研究进展. 大连: 大连理工大学出版社, 2012: 273-282.

ZHOU Wei, HUA Junjie, MA Gang, et al. Study on deformation mechanism of rockfill dams during an initial impoundment process[C]// LI Xikui. Development of Computational Mechanics of Granular Materials. Dalian: Dalian University Press,2012: 273-282.

[8] 周伟, 谢婷蜓, 马刚, 等. 基于颗粒流程序的真三轴应力状态下堆石体的变形和强度特性研究[J]. 岩土力学, 2012, 33(10): 3008-3012.

ZHOU Wei, XIE Tingting, MA Gang, et al. Stress and deformation analysis of rockfill in true triaxial stress conditions based on PFC[J]. Rock and Soil Mechanics, 2012, 33(10): 3008-3012.

[9] 周伟, 刘东, 马刚, 等. 基于随机散粒体模型的堆石体真三轴数值试验研究[J]. 岩土工程学报, 2012, 34(4): 748-755.

ZHOU Wei, LIU Dong, MA Gang, et al. Numerical simulation of true triaxial tests on mechanical behaviors of rockfill based on stochastic granule model[J]. Chinese Journal of Geotechnical Engineering, 2012, 34(4): 748-755.

[10] BAGHERZADEH-KHALKHALI A, MIRGHASEMI A A. Numerical and experimental direct shear tests for coarse-grained soils[J]. Particuology, 2009, 7(1): 83-91.

[11] 刘军, 于刚, 赵长兵, 等. 不同尺度分布散粒材料砂堆形成过程的二维离散元模拟[J]. 计算力学学报, 2008, 25(4): 568-573.

LIU Jun, YU Gang, ZHAO Changbing, et al. 2D DEM simulation on the sandpile formation for granular materials with different grain size distributions[J]. Chinese Journal of Computational Mechanics, 2008, 25(4): 568-573.

[12] HWANG S I. Effect of texture on the performance of soil particle-size distribution models[J]. Geoderma, 2004, 123(3): 363-371.

[13] 王淑云, 鲁晓兵, 时忠民. 颗粒级配和结构对粉砂力学性质的影响[J]. 岩土力学, 2005, 26(7): 1029-1032.

WANG Shuyun, LU Xiaobing, SHI Zhongmin. Effects of grain size distribution and structure on mechanical behavior of silty sands[J]. Rock and Soil Mechanics, 2005, 26(7): 1029-1032.

[14] HAMIDI A, AZINI E, MASOUDI B. Impact of gradation on the shear strength-dilation behavior of well graded sand-gravel mixtures[J]. Scientia Iranica, 2012, 19(3): 393-402.

[15] 邱贤德, 阎宗岭, 刘立, 等. 堆石体粒径特征对其渗透性的影响[J]. 岩土力学, 2004, 25(6): 950-954.

QIU Xiande, YAN Zongling, LIU Li, et al. Effect of particle-size characteristics on seepage property of rockfill[J]. Rock and Soil Mechanics, 2004, 25(6): 950-954.

[16] 傅华, 韩华强, 凌华. 堆石料级配缩尺方法对其室内试验结果的影响[J]. 岩土力学, 2012, 33(9): 2645-2649.

FU Hua, HAN Huaqiang, LING Hua. Effect of grading scale method on results of laboratory tests on rockfill materials[J]. Rock and Soil Mechanics, 2012, 33(9): 2645-2649.

[17] 王永明, 朱晟, 任金明, 等. 筑坝粗粒料力学特性的缩尺效应研究[J]. 岩土力学, 2013, 34(6): 1799-1807.

WANG Yongming, ZHU Sheng, REN Jinming, et al. Research on scale effect of coarse-grained materials[J]. Rock and Soil Mechanics, 2013, 34(6): 1799-1807.

[18] 朱俊高, 翁厚洋, 吴晓铭, 等. 粗粒料级配缩尺后压实密度试验研究[J]. 岩土力学, 2010, 31(8): 2394-2398.

ZHU Jungao, WENG Houyang, WU Xiaoming, et al. Experimental study of compact density of scaled coarse-grained soil[J]. Rock and Soil Mechanics, 2010, 31(8): 2394-2398.

[19] CUNDALL P A, STRACK O D L. Particle Flow Code in 2 Dimensions. PFC2D Version 3.0[M]. Minneapolis: Itasca Consulting Group Inc, 2002(3): 1-96.

[20] 周健, 廖雄华, 池永, 等. 土的室内平面应变试验的颗粒流模拟[J]. 同济大学学报, 2002, 30(9): 1044-1050.

ZHOU Jian, LIAO Xionghua, CHI Yong, et al. Simulating plane strain test of soils by particle flow code[J]. Journal of Tongji University, 2002, 30(9): 1044-1050.

[21] NICOT F, HADDA N, SIBILLE L, et al. Some micromechanical aspects of failure in granular materials based on second-order work[J]. Comptes Rendus Mécanique, 2014, 342(3): 174-188.

[22] 周健, 池毓蔚, 池永, 等. 砂土双轴试验的颗粒流模拟[J]. 岩土工程学报, 2000, 22(6): 701-704.

ZHOU Jian, CHI Yuwei, CHI Yong, et al. Simulation of biaxial test on sand by particle flow code[J]. Chinese Journal of Geotechnical Engineering, 2000, 22(6): 701-704.

[23] 常在, 杨军, 程晓辉. 砂土强度和剪胀性的颗粒力学分析[J]. 工程力学, 2010(4): 95-104.

CHANG Zai, YANG Jun, CHENG Xiaohui. Granular mechanical analysis of the strength and dilatancy of sands[J]. Engineering Mechanics, 2010(4): 95-104.

[24] 日本土质工学会. 粗粒料的现场压实[M]. 郭熙灵, 文丹, 译. 北京: 中国水利水电出版社, 1998: 1-17.

Japanese Society of Soil Mechanics and Foundation Engineering. Field compaction of coarse-grained materials[M]. GUO Xiling, WEN Dan, translate. Beijing: China Water Power Press, 1998: 1-17.

[25] SL 237—1999, 土工试验规程[S].SL 237—1999, Soil test procedures[S].

(编辑 罗金花)

收稿日期:2014-12-24;修回日期:2015-02-12

基金项目(Foundation item):国家自然科学基金资助项目(51379161);国家优秀青年科学基金资助项目(51322905) (Project(51379161) supported by the National Natural Science Foundation of China; Project(51322905) supported by the National Science Foundation for Excellent Young Scholars of China)

通信作者:周伟,教授,博士生导师,从事高坝结构数值仿真研究;E-mail: zw_mxx@163.com