文章编号:1004-0609(2013)S1-s0667-06

不同初始组织TiAl合金轧制板材的组织演化

王 震,刘仁慈,刘 冬,崔玉友,杨 锐

(中国科学院 金属研究所,沈阳 110016)

摘 要:研究锻态组织及其后续热处理得到的近γ等轴组织和全片层组织的TiAl合金板坯在1 280 ℃多道次轧制过程中的组织演化。结果表明:不均匀锻态组织经过6道次轧制变形后组织仍不均匀,而经过热处理的板坯通过6道次轧制,轧态组织较为均匀,其中全片层组织的板坯在整系列轧制道次中,轧态组织最均匀。采用EBSD方法分析TiAl合金中γ相与α2相在轧制过程中的取向差分布,全片层组织板坯在轧制变形中,γ相与α2相的有效应变均高于近γ等轴组织的板坯;在道次变形量为10%~15%条件下,γ相主要发生了动态再结晶,而α2相仍在位错密度累积过程中。

关键词:TiAl合金;轧态组织;组织演化

中图分类号:TG146.2 文献标志码:A

Microstructure evolution of TiAl alloy sheet with different original microstructures

WANG Zhen, LIU Ren-ci, LIU Dong, CUI Yu-you, YANG Rui

(Institute of Metal Research, Chinese Academy of Sciences, Shenyang 110016, China)

Abstract: The TiAl alloy blank with as-forged microstructure and post heat treatment microstructures, including near γ and fully lamellar microstructure, was rolled at 1 280 ℃ by multi-pass rolling schedule. The effects of different original microstructures on their microstructure evolution in the multi-pass rolling processes were investigated. The results show that the microstructure of the sheet is nonhomogeneous when the plate slab with forged microstructure was rolled with 6 passes. However, it is homogeneous when the slabs with heat treatment microstructure were deformed under the same conditions. The deformation of the slab with fully lamellar microstructure is more uniform in the whole rolling passes than that of the one with near γ microstructure. The misorientation angle distributions of α2 and γ phase were analyzed. The dynamic recrystallization of γ phase happens and the dislocation density of α2 phase is increasing in the condition that the rolling reduction is 10%-15% per pass.

Key words: TiAl alloy; rolling microstructure; microstructure evolution

TiAl合金板材具有高比强度、高比刚度、良好的抗蠕变、抗氧化和阻燃性能[1-2],可应用于航空航天飞行器的热结构件及热防护系统中,以实现飞行器的轻量化。TiAl合金的室温塑性差、热加工窗口窄,因此TiAl合金板材制备难度非常大。20世纪80年代开始,美国、欧洲相继对TiAl合金板材进行系统的工艺研究,如美国的国家航天飞机计划(NASP)、高速民用运输计划(HSCT),欧洲的Hermes和 计划[3-4]。先后开展等温轧制、包套轧制和化学沉积等成形方法,其中包套轧制是研究最多、工艺较为成熟,是可行的TiAl合金板材制备技术[5]。

计划[3-4]。先后开展等温轧制、包套轧制和化学沉积等成形方法,其中包套轧制是研究最多、工艺较为成熟,是可行的TiAl合金板材制备技术[5]。

本文作者主要研究了TiAl合金在板材轧制过程中的组织演变规律。TiAl合金铸锭通过包套锻造制备轧制板坯,铸锭发达的柱状晶分布和锻造一维镦粗变形均导致锻态组织不均匀。对于本征脆性的TiAl合金,在轧制过程中,这种不均匀组织发生不协调变形往往会诱发微裂纹萌生;此外,锻态组织的遗传性也会导致TiAl合金板材性能不稳定性。本文作者对板坯进行轧制前均一化热处理,得到均匀组织的板坯,有效的降低板材缺陷的产生并提高组织的均匀性,并分析TiAl合金中γ相与α2相在轧制过程中的演化规律。

1 实验

实验采用TiAl合金的名义成分为:Ti-46.5A1-2Cr- 2Nb-0.15B(摩尔分数,%),tα=(1 320±5) ℃,经过两次真空自耗电弧熔炼和一次冷壁铜坩埚真空感应熔炼得到d 80 mm铸锭。经过1 260 ℃、130 MPa、4 h热等静压处理,以消除铸锭中少量缩孔和疏松。采用304ss不锈钢包套进行多步近等温锻造,锻造温度为1 280 ℃,总变形量为80%。去应力退火处理后,从TiAl合金饼饼中线切割取板坯,并对板坯进行不同制度热处理(表1)。随后TiAl合金板坯表面磨制抛光,重新采用304ss不锈钢包套进行轧制变形,轧机轧辊直径为d 260 mm,轧辊线速度为40 mm/s,轧制温度为1 280 ℃,每道次变形量控制在10%~15%范围内,共6道次,总变形量为60%,轧制后立即进行油淬处理,以保留轧态组织。解除TiAl合金板材包套后,在板材中心部位取样制备金相,采用ZEISS-Axiovert200 MAT光学显微镜进行微观组织分析。在FEI/Nova NanoSEM 430扫描电镜上采集EBSD实验数据,扫描步长为0.2 μm,数据在HKL-Channel 5软件上分析处理。

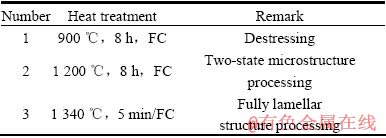

表1 TiAl合金板坯热处理制度

Table 1 Heat treatment schedule of TiAl alloy slabs

2 结果与讨论

2.1 合金的锻态组织

TiAl合金铸锭经过热等静压处理后,铸锭中心的组织为双态组织,约占铸锭体积的1.6%,铸锭其他部位是片层组织,片层取向垂直于凝固方向[6]。在片层晶界处有少量的等轴γ晶粒。

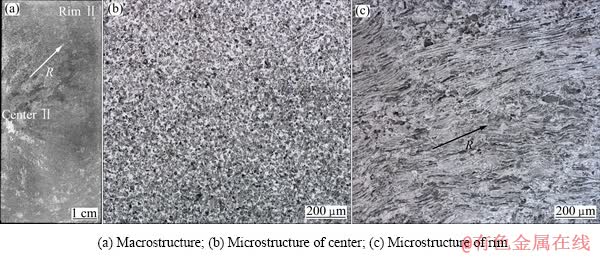

铸锭经过包套锻造后,粗大铸态组织发生扭曲破碎,晶粒得到明显细化,相对粗大铸态组织,预锻造处理扩大轧制变形工艺窗口。沿TiAl合金锻饼径向切取板坯,板坯的宏观照片如图1(a)所示,锻饼的变形组织极不均匀,流线由锻饼中心沿半径呈发散状。中心区域Ⅰ的显微组织(图1(b))为双态组织。从中心到边部,残余片层组织体积分数逐渐增加。锻饼的边缘区域Ⅱ(图1(c)),组织主要由残余片层组成,该区域在锻造过程中处于自由变形区,受到轴向压应力和径向拉应力的共同作用,片层取向平行于半径方向,即拉应力方向。在锻压过程中,当TiAl合金片层组织惯习面法向与压力方向呈一定角度,片层组织发生偏转,直至压力方向垂直于惯习面[7]。同时随变形量的增加,片层组织发生动态再结晶,片层中的位错发生缠结形成亚晶界,最终形成细小的等轴γ晶粒。

2.2 合金的热处理组织

锻造板坯经过等轴组织热处理的显微组织如图2(a)所示,由等轴γ晶粒和少量的细小α2相颗粒组成,但是γ晶粒尺寸与其分布都不均匀,这主要是由凝固过程中成分微观偏析造成的,粗大等轴γ晶粒区域的Al含量低而Nb含量高,导致α2相含量降低,减弱了对γ晶粒的钉扎作用。经过1 340 ℃热处理的显微组织如图2(b)所示,得到均匀全片层组织,尺寸约为200 μm,片层无取向性。α单相区热处理极大的提高了成分均匀化的速率,消除在α2+γ两相区很难完成的成分偏析[8]。

图1 TiAl合金锻态组织

Fig.1 Microstructures of TiAl alloy after forging

图2 TiAl合金热处理组织

Fig.2 Microstructures of forged TiAl alloy after following heat treatments

2.3 合金的轧制组织

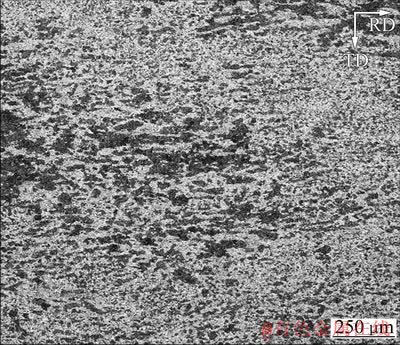

1号板坯经过6道次轧制60%变形量后,仍遗传了不均匀的锻造组织特征(图3),粗大的γ晶粒沿轧向分布,γ晶粒周围存在大量细晶。由于TiAl合金板材轧制的每道次变形量小,不均匀组织在塑性变形过程中,细小组织容易协调整体变形,承担主要的变形,从而粗大γ晶粒未得到充分的破碎,对于脆性的TiAl合金,粗大晶粒在变形过程中容易在晶界处形成应力集中,诱发裂纹萌生,降低合金的塑性变形能力。此外,仍有少量与轧制方向平行的残余片层。

图3 锻态组织TiAl合金板坯的轧态组织

Fig.3 As-rolled microstructure after sixth rolling step of TiAl alloy slab

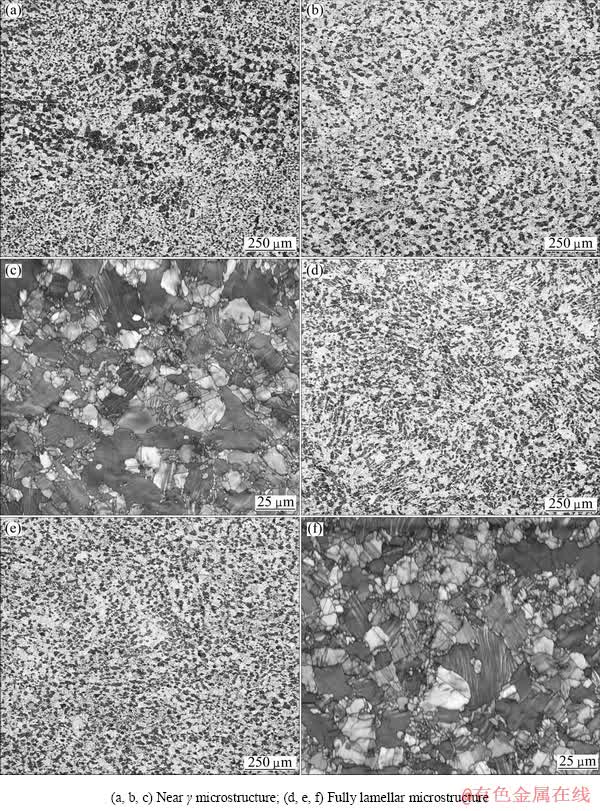

2号板坯在轧制前,1 280 ℃保温过程中,γ相部分转化为α相,α相含量逐渐增多,保温后板坯从炉中移出至第一道次轧制结束,整个板坯温度下降,α相中析出细小片层组织,并在后续轧制过程中片层组织参与变形。经过3道次轧制30%变形量后(图4(a)),大尺寸γ晶粒仍未破碎完全,但粗大晶体体积分数显著下降,组织不均匀程度降低,同样粗晶周围存在大量细晶现象。6道次轧制后得到均匀的双态组织(图4(b)),由等轴γ晶粒(黑色)与片层组织(白色,由于冷速较快而析出厚度细小片层)组成,等轴γ晶粒体积分数约为30.7%,尺寸约为12 μm,主要分布在片层组织晶界处(图4(c)),此外,由于片层组织参与变形,在连续变形和退火过程中,γ片层发生动态再结晶和静态再结晶,少量γ晶粒在片层组织中析出。

3号板坯在轧制前保温过程中仍保留着全片层组织,经过3道次轧制后片层组织完全碎化(图4(d)),形成双态组织,但部分γ晶粒保留着原始片层取向。经过6道次变形后(图4(e)),组织进一步均匀化,γ晶粒基本球化,体积分数约为39.2%,有效阻碍在中间退火过程中片层组织的粗化,因此相比2号板坯,片层组织尺寸减小,且变形后细小γ晶粒比例增加(图4(f))。

图5所示为TiAl合金板坯经过不同道次轧制后α2相与γ相的取向差分布,计算两种相的小角度(<10°)所占数量百分比(fLABs)以及高角度晶界的平均取向差(θHABs)。定量分析得出α2相的fLABs远高于γ相的。动态再结晶的难易与相的层错能大小有关,层错能低,交滑移和攀移均很困难,动态回复速率较慢,局部位错密度增加,从而有利于发生动态再结晶。FU等[9-10]采用第一原理计算出γ相(111)面的层错能高于α2相(0001)面的,说明γ相与α2相在同等变形量下,α2相应先发生动态再结晶,α2相的fLABs小于γ相。γ相具有面心四方L10结构,α2相为D019结构,在TiAl合金变形过程中,γ相的滑移系相比α2相更容易开动,γ相为协调整体变形,承受大部分的变形量。因此,在道次变形量为10%~15%时,γ相的有效应变量大而发生动态再结晶,而α2相有效应变量小,仍在位错密度累积的过程中。

图4 两种热处理组织TiAl合金板坯在不同道次的轧态组织

Fig.4 Microstructures after the third (a, d) and sixth (b, c, e, f) rolling steps of TiAl alloy slabs with two kinds of heat treatment microstructure

3号板坯变形后的α2相与γ相的fLABs都要高于2号板坯,表明均匀的全片层组织在变形过程中,两种相均匀变形,变形程度高。而3号板坯变形后的α2相高角度平均取向差低于2号板坯,γ相反之,这仍是γ相发生动态再结晶,α2相还未发生的结果。此外,同种组织的板坯随着道次的增加,平均取向差变化不大,说明道次间的10 min退火较完全,晶粒内的亚结构无累积效应。

图5 两种热处理组织TiAl合金板坯在不同道次的α2相和γ相的取向差分布

Fig.5 Misorientation angle distributions of α2 phase (a, b, c, d) and γ phase (e, f, g, h) after the third (a, c, e, g) and sixth (b, d, f, h) rolling steps of TiAl alloy slabs with two kinds of heat treatment microstructure

3 结论

1) 锻态组织的TiAl合金板坯在两相区多道次轧制后,板材组织仍遗传锻态组织的不均匀性。

2) 锻态组织的板坯经过热处理得到近γ等轴组织和全片层组织,轧制变形后组织均匀性明显改善,其中全片层组织的板坯在整系列轧制道次中,变形更均匀,从而降低微裂纹的产生。

3) 在道次变形量为10%~15%时,γ相发生了动态再结晶,而α2相仍在位错密度累积的过程中。全片层组织板坯在轧制变形中,γ相与α2相的有效应变程度高于近γ等轴组织的板坯。

REFERENCES

[1] KIM Y W. Intermetallic alloys based on gamma titanium aluminide[J]. JOM, 1989, 41(7): 24-30.

[2] APPEL F, BROSSMANN U, CHRISTOPH U, EGGERT S, JANSCHEK P, LORENZ U, MULLAUER J, OEHRING M, PAUL J D H. Recent progress in the development of gamma titanium aluminide alloys[J]. Advanced Engineering Materials, 2000, 2(11): 699-720.

[3] LORIA E A. Gamma titanium aluminides as prospective structural materials[J]. Intermetallics, 2000, 8: 1339-1345.

[4] DAHMS M. Gamma titanium aluminide research and applications in Germany and Austria[J]. Advanced Performance Materials, 1994, 1: 157-182.

[5] CLEMENS H. Intermetallic γ-TiAl based alloy sheet materials – Processing and mechanical properties[J]. Zeitschrift Fur Metallkunde, 1995, 86(12): 814-822.

[6] BARTELS A, SCHILLINGER W, GRASSL G, CLEMENS H. Texture formation in γ-TiAl sheets[C]//KIM Y W, CLEMENS H, ROSENBERGER A H. Gamma Titanium Aluminides 2003. Pennsylvania: The Minerals, Metals & Materials Society, 2003: 275-285.

[7] STARK A, BARTELS A, CLEMENS H, KREMMER S, SCHIMANSKY F P, GERLING R. Microstructure and texture formation during near conventional forging of an intermetallic Ti-45Al-5Nb alloy[J]. Advance Engineering Materials, 2009, 11(12): 976-981.

[8] 张永刚, 韩雅芳, 陈国良, 郭建亭, 万晓景, 冯 涤. 金属间化合物结构材料[M]. 北京: 国防工业出版社, 2001, 713.

ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang, WAN Xiao-jing, FENG Di. Structure intermetallics[M]. Beijing: National Defence Industry Press, 2001, 713.

[9] FU C L, ZOU J, YOO M H. Elastic constants and planar fault energies of Ti3Al, and interfacial energies at the Ti3Al/TiAl interface by first-principles calculations[J]. Scripta Metallurgica et Materialia, 1995, 33(16): 885-891.

[10] FU C L, YOO M H. Interfacial energies in two-phase TiAl-Ti3Al alloy[J]. Scripta Metallurgica, 1997, 37(10): 1453-1459.

(编辑 王 超)

收稿日期:2013-07-28;修订日期:2013-10-10

通信作者:崔玉友;电话:024-23971961;E-mail: yycui@imr.ac.cn