DOI:10.19476/j.ysxb.1004.0609.2018.09.11

Fe/Ni比对WC-Fe-Ni硬质合金微观组织及性能影响

张稳稳,罗兵辉,高 阳,柏振海

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:在1450 ℃下低压烧结制备5 种不同Fe/Ni比(质量比)的WC-Fe-Ni硬质合金,通过SEM、TEM、XRD、力学性能测试和电化学测试研究Fe/Ni比对硬质合金的显微组织和性能的影响。结果表明:随Fe/Ni比增大,晶粒尺寸先下降后上升; Fe/Ni比为3:1时,合金晶粒尺寸最小,为1.24 μm;合金抗弯强度变化趋势和晶粒尺寸变化呈反比;硬度不断提高,断裂韧性变化与烧结致密度变化均保持先上升后下降趋势;在Fe/Ni比为3:1时,合金断裂方式主要为沿晶断裂,在Fe/Ni比不等于3:1时会出现较多穿晶断裂;合金耐酸性溶液腐蚀能力不断变差。当Fe/Ni比为 3:1时,合金的综合性能最好,其硬度、抗弯强度、断裂韧性、腐蚀电流密度分别达到934HV、3047 MPa、23.3 MPa·m1/2、3.98×10-5 A/cm2。

关键词:WC-Fe-Ni 硬质合金;Fe/Ni比;WC 晶粒大小;微观组织;力学性能;耐蚀性能

文章编号:1004-0609(2018)-09-1798-10 中图分类号:TG135.5 文献标志码:A

硬质合金由于具有极好的耐磨性、强韧性、化学稳定性和热稳定性而广泛应用于切削工具、矿山工具、钻井等[1-2]。传统硬质合金主要以WC作为硬质相,以具有较好的润湿性和较强的机械性能的钴作为粘结相[3-4]。近年来,由于钴资源紧缺和价格昂贵的原因,部分或全部取代粘结相钴的WC-Ni、WC-Fe硬质合金开始被广泛研究[5-6]。

WC-Ni合金耐腐蚀性能最好,但是机械性能和耐磨性比WC-Co和WC-Fe合金差,MOSTAFA等[7]、SHON等[8]和CHANG等[9]通过添加Mo2C,采用高温自扩散合成烧结方法(SHS)制备的WC-Ni合金抗弯强度和耐磨性都低于WC-Co硬质合金。WC-Fe硬度和耐磨性能较好,但是由于铁的耐腐蚀性能最差,润湿性较弱,WC在铁相中的固溶度低,合金烧结性能性较差,近年通过微波烧结改善WC-Fe合金烧结致密性问题,但是成本依然较高,难以实现工业应用[10-11]。CHANG等[9]同时添加铁、镍,在1400 ℃真空烧结制备的WC-7.5Fe-7.5Ni硬质合金收缩率达到47%,抗弯强度约为2524.5 MPa,略高于传统的WC-15Co硬质合金。GONZALEZ等[12]对WC-10%(Fe, Ni, C)进行热处理,改进合金力学性能。ZHAO等[13]研究发现WC-5Fe-5Ni-xMo在Mo添加量为0.25%,烧结温度1300 ℃时综合性能最好,抗弯强度为1950 MPa。传统WC-Co硬质合金在不同成分或者处理温度下会发生粘结相钴的 HCP和FCC同素异构转变,WC-Fe相图也反映出铁含量不同、或者热处理温度不同,合金中γ-Fe和α-Fe的也会发生相互转化,进而影响合金力学性能[14-15]。SCHUBERT等[16]研究了粘结相含量为20%时WC-85Fe-15Ni和WC-70Fe-20Ni-10Co合金,其硬度与WC-20Co硬度相当,并且可以通过深冷处理使奥氏体转变为马氏体含量,从而改变合金力学性能,同时也发现在铁和镍粘接相总含量为10%时会造成两相区过窄,产生脱碳相或渗碳相,使合金性能下降。GAO等[17]对WC-Fe-Ni合金的深冷处理工艺进行了研究,发现随着深冷处理时间的延长,硬质合金粘结相γ-(Fe/Ni)不断转化成α-(Fe/Ni),合金硬度、抗弯强度和耐磨性不断升高。

目前关于铁、镍等金属部分取代钴提高合金力学性能和腐蚀性能的研究较多,关于铁、镍全部代钴研究较少,主要研究内容集中在深冷处理工艺、烧结方法和抑制剂的添加对合金力学性能影响这些方面。由于WC-(Fe、Ni)合金的两相区较窄、Fe/Ni比的改变会导致合金两相区难以控制,目前关于铁、镍全部代钴成分优化的研究较少,本文作者制备5种不同Fe/Ni比的WC-(Fe、Ni)硬质合金,探究Fe/Ni比对硬质合金的组织、WC 粒度大小、烧结性能的影响,同时还研究Fe/Ni比对合金力学性能以及耐腐蚀性能的影响。

1 实验

1.1 合金制备

以株洲硬质合金公司生产的粒径为2.68 μm的WC 粉末作为合金硬质相、湖南冶金材料研究所生产的羟基铁粉(费氏粒度<5 μm)和羟基镍粉(费氏粒度<4μm)作为粘结相。由于Fe/Ni比两相区范围较窄,烧结容易出现脱碳相,改变Fe/Ni比时应增补适量碳以控制合金两相区。制备Fe/Ni比(质量比)为1:1、2:1、3:1、4:1、85:15的5种硬质合金,具体成分配比如表1。粉末以97#汽油作为球磨介质,硬质合金球和粉末原料质量比为3:1,球磨机100 r/min,混料时间为22 h;球磨后的料浆加入1%的丁钠橡胶作为成形剂,在50 ℃下真空干燥2 h、过筛;用200 MPa压力将粉末冷压成直径为38 mm的圆柱状试样。置于排胶炉中在580 ℃下脱胶70 min,再置于工业低压烧结炉中在1450 ℃下烧结80 min,在烧结温度下通入5.0 MPa氩气以防止粘结相挥发并促进液相流动。

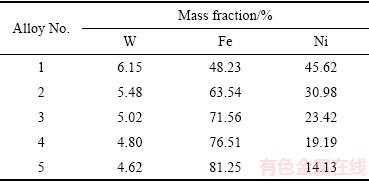

表1 WC-(Fe, Ni)合金成分

Table 1 Nominal composition of different alloys

1.2 性能检测

烧结好的合金样品经电火花线切割加工成尺寸为6.5 mm×5.25 mm×20 mm 的试样条。采用阿基米德排水法测量合金的密度,实际密度与理论密度之比为合金的致密度;使用 HV-10B型维氏硬度计测量合金维氏硬度,试验力为 98 N(砝码质量10 kg)、保压时间15 s;在INSTRON-3369 型电子万能材料试验机上利用三点弯曲法测量合金的抗弯强度,加载速度取 0.5 mm/min;为了研究合金中钨的溶解度,将样品作为阳极,暴露1 cm2区域,在电解液(4 mol/L NaOH,3%C4H6O6,2%NaClO4)中、0.4 V电压下用选择性电解腐蚀的方法腐蚀样品12 h除去WC相,并用X射线能谱仪(EDS)分析粘结相中的钨含量;合金的晶粒平均尺寸用Nano measure测得,每组测量的选区不低于5个,每个选区测得的晶粒不低于500个;用Sirion-200型扫描电镜(SEM)下观察烧结试样的微观结构和弯曲断口形貌;使用Tecnai G220透射电子显微镜(TEM)进一步观察试样微观结构,操作电压200 kV,透射电镜试样通过机械抛光、离子减薄制备;用D/max-2500 型X 射线衍射仪(XRD)分析合金的物相组成,扫描速度为 8 (°)/min,在IM6e 型电化学工作站,采用三电极测试体系测定合金的极化曲线,配制浓度为3.1%的HCl溶液,参比电极为饱和甘汞电极(SCE),辅助电极是铂,合金试样为工作电极,用2 mV/s扫描速率进行电位极化曲线测试,然后分析合金自腐蚀电流密度(Jcorr)和腐蚀电位(φcorr)。

2 结果与分析

2.1 Fe/Ni比对合金微观组织的影响

图1所示为不同Fe/Ni比硬质合金的XRD谱。铁和镍的添加量会影响WC+γ两相区的宽度和范围[19]。添加了适量碳后,合金中无明显η相和石墨相出现。在合金1~4中主要含有WC硬质相和面心立方的γ-(Fe,Ni)粘结相,而合金5中含有WC和体心立方的α-(Fe,Ni)粘结相,Fe/Ni比的改变导致粘结相结构发生变化[20]。

图1 不同硬质合金的XRD谱

Fig. 1 XRD patterns of different cemented carbides

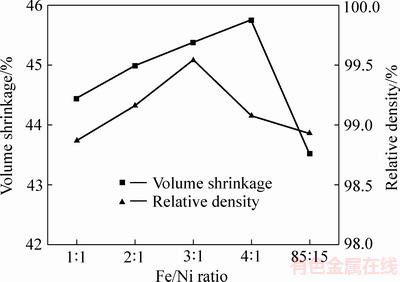

图2所示为不同硬质合金的烧结收缩率和致密度。从图2中可以看出,烧结收缩率和致密度基本上呈正相关关系。Fe/Ni比小于4:1时,烧结收缩率不断上升;Fe/Ni比为4:1时,收缩率最大达到45.7%;在Fe/Ni比为85:15时(合金5),烧结收缩率明显下降。合金致密度数据显示,所有样品烧结后致密度均达到98%以上;Fe/Ni比小于3:1时,材料致密度随Fe/Ni比增加而不断增大;Fe/Ni比为3:1时,材料致密度最大为99.9%;Fe/Ni比大于3:1时,致密度有下降趋势。

图2 不同硬质合金的烧结收缩率和致密度

Fig. 2 Volume shrinkage rate and relative density of different cemented carbides

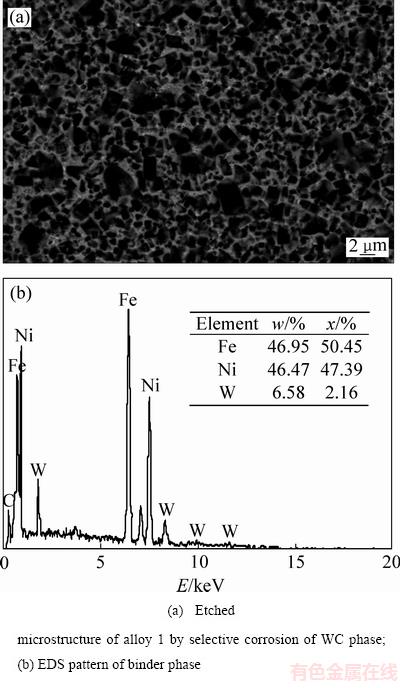

对于WC-Fe-Ni硬质合金,烧结致密度受液相烧结的液相含量、粘结相与WC之间润湿性、粘滞阻力影响。由C-Fe-Ni-W相图可知,随着Fe/Ni比增加,液相形成温度逐渐降低,在相同烧结温度下,Fe/Ni比越高,液相含量越高,所以在Fe/Ni比小于或等于3:1时,烧结致密度逐渐升高[21-22]。固相烧结密实化主要通过粒子重排来实现,驱动力源于金属的扩散,这些扩散发生在WC相和金属粘接相中间层,通过粘性流动方式扩散。扩散除了受温度影响,溶解在粘接相中钨可以减小粘结相流动粘滞阻力,促进粘接相在WC晶粒周围的流动[18]。图3所示为WC-10Fe-10Ni经过选择性电化学腐蚀WC相后的微观形貌以及EDS成分。对于5种成分硬质合金,至少选取10个微区取平均值,得到的粘结相合金成分如表2所列。从表2中可以看出,随着Fe/Ni比增加,粘结相中溶解的钨含量不断减少,液相流动黏滞阻力增加,液相流动性较差,同时铁的润湿性较差,材料烧结性能开始变差,烧结收缩率下降明显。因此,随着Fe/Ni比增加,液相形成温度、钨的溶解度和粘结相与WC之间润湿性共同决定合金密实化过程,使Fe/Ni比为3:1时具有最高致密度。

图3 WC-10Fe-10Ni(1号合金)腐蚀后的微观组织及粘接相成分

Fig. 3 Microstructure of WC-10Fe-10Ni (alloy 1) after corrosion and composition of binder phase

表2 WC-20(Fe-Ni)粘结相成分

Table 2 Composition of binder phase of WC-20(Fe-Ni)

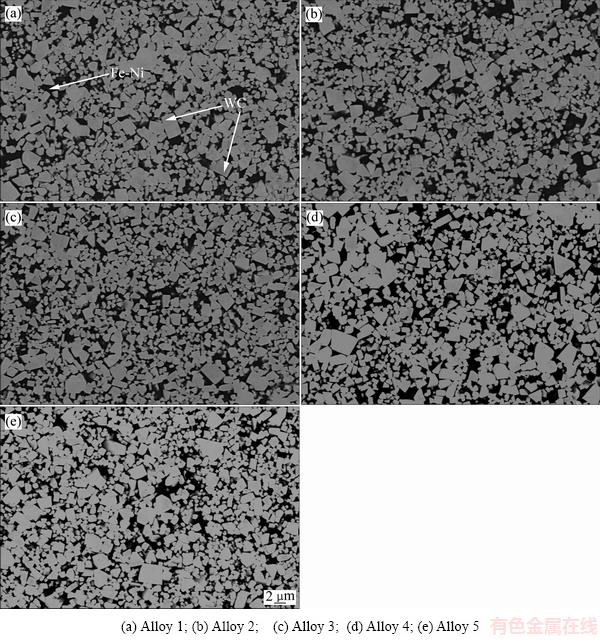

图4 硬质合金烧结后的SEM像

Fig. 4 SEM images of different cemented carbides

图4所示为合金1~5 烧结后的SEM像。由图4可以看出,烧结后的合金由灰白色的硬质相WC 和黑色的粘结相组成,无石墨相或脆性η相,无孔洞出现,组织均匀,可见烧结致密性良好。从图4中还可以看出,微观组织中含有较多的圆滑状和少部分长方形、三角形的WC颗粒。WC晶体为六方晶系,为不等轴结构,晶体生长速率由固相和液相界面间吸附解吸速率差所决定,钨在面和面吸附解吸速率之差较大,而在面较小,所以在钨在面和面生长快一些,这种各向异性导致棱柱状WC晶粒的产生[23]。在图4(d)和(e)中可以看到许多圆滑状晶粒,这是因为在高铁粘结相中由于钨在粘结相溶解度比较小,晶粒通过沿着一定方向吸附—解析作用不明显,同时铁含量增加可以降低WC颗粒与液相粘接相之间的界面能,因而可以减少WC与粘结相接触界面平直化发展可能性,导致许多圆滑状晶粒出现[24]。

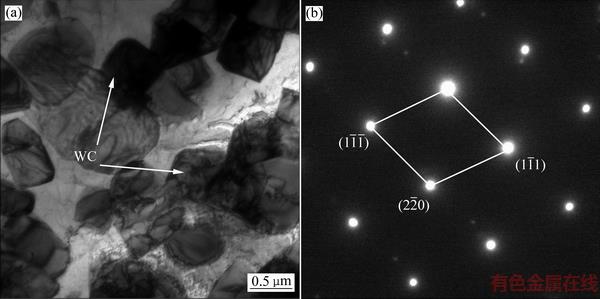

图5(a)所示为Fe/Ni比为3:1时合金的TEM明场相照片,黑色为WC相,灰白色为Fe-Ni粘结相,可见明显的晶界,晶粒边界圆润,无明显棱角,WC相分布均匀,晶粒颗粒大小相近,无明显异常长大晶粒,图5(b)为粘结相的衍射斑点,可知粘结相为FCC结构,与XRD谱中粘结相衍射峰结果一致。

图5 Fe/Ni比为3:1的合金明场像和粘结相衍射斑点

Fig. 5 Bright field TEM image(a) and diffraction spot image(b) of cemented carbide with Fe/Ni ratio of 3:1

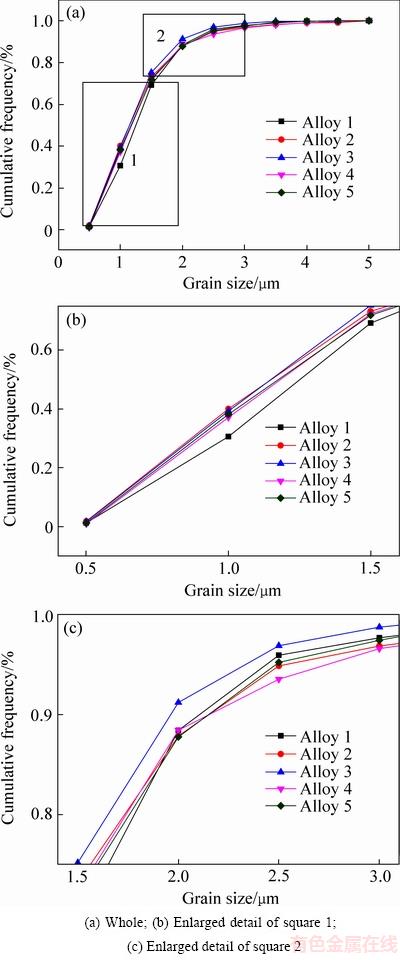

从图4测得的5种烧结合金晶粒平均尺寸大小分别为1.34、1.29、1.24、1.29、1.30 μm,WC晶粒尺寸分布如图6所示。由图6(b)可知,在晶粒尺寸为0.5~1.5 μm范围内,合金2和3的频率累积分布数值均大于合金1,所以在Fe/Ni比小于3:1时,随着Fe/Ni比增大,晶粒尺寸不断减小,晶粒尺寸越来越均匀。这是因为1450 ℃时WC在镍中的溶解度为36.2%,在铁中的溶解度为14.8%,前者比后者要高很多[25]。因此,不论是在液相烧结过程中的溶解-析出过程,还是在固相烧结过程,粘结相铁含量高的硬质合金的扩散传质能力都较差,从而导致了硬质合金的晶粒细化。当Fe/Ni比为1:1时细颗粒较少,随着Fe/Ni比增大,细颗粒越来越多;Fe/Ni比为3:1时晶粒最均匀,当Fe/Ni比 比为4:1和85:15时,WC晶粒比较圆滑,但是出现少数晶粒异常长大。如图6(c)所示,在晶粒尺寸为1.5~3 μm时,合金4与5的累积频率都小于合金3的累积频率,说明在高Fe/Ni比合金中,粗晶粒较多。这是由于铁含量的增加,晶粒越来越小,晶粒表面能较大;为降低表面能,小颗粒溶解在粘结相铁、镍中,并在大颗粒上沉淀,导致晶粒长大,发生奥斯特瓦尔德熟化过程,晶粒分布均匀性变差,晶粒尺寸有增大趋势[26-27]。

图6 不同硬质合金的WC晶粒尺寸累积分布频率

Fig. 6 Cumulative WC grain size distribution of different cemented carbides

2.2 Fe/Ni比对合金力学性能的影响

抗弯强度是硬质合金材料的重要力学性能,与材料孔隙、WC晶粒粗细、粘结相分布的均匀性有关[28]。从图7中抗弯强度和晶粒尺寸的变化可以看出两者呈负相关关系,Fe/Ni比为3:1时,晶粒平均尺寸最小,抗弯强度最高。MOSKOVITZ等[29]研究了铁和镍粘结相含量总和固定25%时,不断改变铁和镍含量,曾发现铁含量75%,镍含量25%时合金抗弯强度最高。在Fe/Ni比从1:1增大到3:1,材料抗弯强度增大原因是在Fe/Ni比低于3:1时,异常晶粒长大不断被抑制,材料晶粒不断变细,阻碍滑移的晶界变多,WC晶粒之间接触可能变小,Fe-Ni固溶体之间平均自由程变小,增加粘接相塑性变形范围,同时烧结致密性不断提高,材料抗弯强度呈上升趋势[30]。随着铁含量继续增加,抗弯强度呈现减小的趋势,在Fe/Ni比为85:15时材料抗弯强度降低至2081 MPa。当Fe/Ni比超过3:1时材料抗弯强度下降的原因如下:1) WC晶粒不断粗化导致材料力学性能下降;2) 铁的润湿性比镍的差,铁含量增大到一定范围,相界面之间结合能会减弱,降低材料抗弯强度,同时在固相烧结过程形成的缺陷也变多,导致应力的集中,材料力学性能也会下降;3) 由XRD谱可知(见图1),在Fe/Ni比为85:15时,粘接相γ-(Fe, Ni)全部转化为α-(Fe, Ni),α结构滑移系较少,导致材料抗弯强度继续下降[13]。

图7 不同配比合金的抗弯强度

Fig. 7 Bending strength of different cemented carbides

图8所示为Fe/Ni比和合金硬度之间的关系。材料的硬度随着Fe/Ni比增加始终呈现增大的趋势,在Fe/Ni比为85:15时硬度最大达到1112HV。硬质合金的硬度主要受WC和粘接相的硬度、WC的平均晶粒尺寸、合金的致密度影响。根据霍尔-佩奇公式[29]: (H0和Ky在常温下为常数,dWC为WC 平均晶粒尺寸),合金WC晶粒平均尺寸越小,合金硬度越高。除了WC晶粒尺寸,合金硬度也受Fe/Ni比配比影响。LEE等[31]提出了硬质合金中应用最广泛硬度公式:

(H0和Ky在常温下为常数,dWC为WC 平均晶粒尺寸),合金WC晶粒平均尺寸越小,合金硬度越高。除了WC晶粒尺寸,合金硬度也受Fe/Ni比配比影响。LEE等[31]提出了硬质合金中应用最广泛硬度公式: 。其中

。其中 是WC-Fe-Ni硬质合金硬度,

是WC-Fe-Ni硬质合金硬度, 是Fe-Ni固溶体硬度,VWC是WC体积分数,C是WC晶粒所有表面和邻近WC接触比率,C和VWC受WC和粘接相配比的影响。在铁和镍质量分数之和为20%的5组样品中,可以认为C和VWC一直保持不变,影响合金硬度的主要为

是Fe-Ni固溶体硬度,VWC是WC体积分数,C是WC晶粒所有表面和邻近WC接触比率,C和VWC受WC和粘接相配比的影响。在铁和镍质量分数之和为20%的5组样品中,可以认为C和VWC一直保持不变,影响合金硬度的主要为 。

。

图8 不同配比合金的硬度

Fig. 8 Hardness of different cemented carbides

由于铁硬度大于镍硬度,随着铁含量增加,Fe-Ni固溶体合金硬度也会随之增加。Fe/Ni比从1:1增大到3:1,合金晶粒不断减小,铁含量不断上升,合金硬度会不断上升。Fe/Ni比大于3:1时,虽然晶粒有粗化趋势,但是由于铁含量不断提高,所以Fe-Ni固溶体硬度也会随之增大。只要铁含量控制在一定范围内,烧结样品致密度大于99%,没有出现较大幅度的下降,材料的硬度会随着铁添加量的增加一直呈现上升的趋势。在Fe/Ni比为85:15时,材料粘结相全部转化为体心立方结构,发生马氏体硬化过程,材料硬度急剧升高[32]。

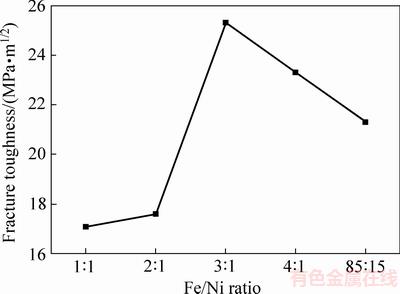

图9所示为合金的断裂韧性与Fe/Ni比的关系。合金断裂韧性对缺陷和孔洞较为敏感,所以烧结致密度越低,断裂韧性越差[28]。在Fe/Ni比小于3:1时,合金断裂韧性逐渐升高,主要由于烧结致密度不断提高。材料断裂韧性也会受平均自由程影响,平均自由程是粘结相含量和晶粒尺寸结合的参数,在粘结相含量相同时,晶粒尺寸越大,平均自由程越小,材料断裂韧性越高[30]。因此,虽然Fe/Ni比为2:1时的烧结致密度高于Fe/Ni比为1:1时的烧结致密度,但是由于Fe/Ni比为2:1时晶粒尺寸明显下降,导致裂纹在硬质相-硬质相以及硬质相-粘结相的界面扩展时平均自由程增大,消耗的能量减少,材料的断裂韧性提高不明显[33]。继续提高Fe/Ni比时,合金断裂韧性提高,在Fe/Ni比为3:1时合金断裂韧性最大,为23.3 MPa·mm1/2。随着铁含量继续增加,虽然合金晶粒尺寸粗化,但是烧结后合金中孔隙增多(见图2),合金中孔洞的存在容易产生应力集中,形成裂纹源,加速裂纹扩展,材料断裂韧性突然下降[34]。

图9 不同配比合金的断裂韧性

Fig. 9 Fracture toughness of different cemented carbides

图10所示为不同配比合金的断口SEM像。影响抗弯强度的内在因素包括WC和粘结相的成分和结构。硬质相结构参数包括WC的晶粒尺寸、形状、分布均匀性等,粘结相结构参数包括粘结相的平均自由程以及粘结相和硬质相的邻接度[35]。由图10可以看出,所有合金均为脆性断裂,断裂机理则以沿晶断裂为主,粗大WC晶粒发生穿晶断裂,粘接相可明显看到塑性变形撕裂。图10(a)中合金的Fe/Ni比最低,WC 晶粒尺寸最粗大,WC 的穿晶断裂最多;相对于图10(a),可以看到图10(b)中穿晶断裂明显减少;图10(c)中Fe/Ni比为3:1,此时合金晶粒最均匀,主要的断裂方式是沿晶断裂,可以看到细小颗粒脱落的孔洞,未看到明显粗晶粒的穿晶断裂,这也是Fe/Ni比为3:1时合金抗弯强度最高的重要原因。图10(d)和(e)中主要断裂方式为沿晶断裂,有晶粒的拔出,同时也有少量粗颗粒晶粒穿晶断裂。

图10 不同配比合金的断口SEM像

Fig. 10 SEM images of fracture surfaces of different cemented carbides

断口形貌表明,过高或者过低Fe/Ni比会使合金烧结过程晶粒粗化,粗 WC 晶粒合金穿晶断裂较多,因为晶粒尺寸较大时,晶粒内部的缺陷就会变多,这时孔隙和晶粒内部的缺陷成为裂纹源可能性较大,合金更容易发生穿晶断裂,同时大颗粒的WC晶粒由于棱角的存在会导致应力分布不均匀,从而导致应力集中,成为合金断裂的裂纹源[30]。相反,中等Fe/Ni比的合金中WC晶粒尺寸更细小,晶界更多,对滑移阻碍效果越好,合金强度会增加。

2.3 Fe/Ni比对合金耐腐蚀性能的影响

在酸性溶液中硬质合金发生的是析氢反应,有研究指出[9],相比于传统WC-Co硬质合金,WC-Fe-Ni表现出更好的耐蚀性能。硬质合金正极发生反应离子方程式为:2H++2e=H2, =0,

=0, 为腐蚀电位。以Fe-Ni为粘结相时,铁、镍的标准还原电极电位如下[36]:

为腐蚀电位。以Fe-Ni为粘结相时,铁、镍的标准还原电极电位如下[36]:

Fe2++2e=Fe, =-0.44 V (1)

=-0.44 V (1)

Ni2++2e=Ni, =-0.23 V (2)

=-0.23 V (2)

图11所示为不同Fe/Ni比合金的极化曲线,表3列出了合金的自腐蚀电流和腐蚀电位。可以看出,合金1的耐腐蚀性能最好,与其他几个合金的自腐蚀电流不在同一个数量级;随着铁含量增加,腐蚀电位呈下降趋势,自腐蚀电流随着铁含量增加不断增大,说明合金的耐酸性溶液腐蚀性能随着铁含量增加变得越来越差,合金5的自腐蚀电流密度为1.54×10-4 A/cm2,腐蚀电位为-0.142 V,耐腐蚀性最差。

Fe/Ni比的改变造成硬质合金腐蚀性能不同的原因如下:1) 标准还原电极电位越负,失去电子趋势越大。所以粘结相中铁相对于镍更容易发生氧化反应,失去电子。作为腐蚀电池的负极,随着铁含量上升,合金的自腐蚀电流不断增大,导致了耐腐蚀性能下降;2) Fe/Ni比的改变使得WC 晶粒尺寸减小,导致合金的界面增加,所以合金2的腐蚀速率发生突然上升,与合金1的腐蚀速率不在同一数量级;3) 粘结相的相结构会影响合合金腐蚀性能。α-(Fe, Ni)固溶体的耐腐蚀性能比γ-(Fe, Ni)固溶体的耐腐蚀性能差,相比于Fe/Ni比为4:1的合金,Fe/Ni比为85:15的合金虽然铁含量没有明显提高, 但由XRD谱中可以看出,粘结相全部转化为α-(Fe, Ni),自腐蚀电流密度继续上升[37-38] 。

图11 不同配比合金的电化学极化曲线

Fig. 11 Polarization curves of different cemented carbides

表3 不同合金的电化学腐蚀性能

Table 3 Electrochemical corrosive results of sintered alloys

3 结论

1) 铁含量的增大对晶粒大小的影响是双重的,Fe/Ni比低于3:1时,WC晶粒不断细化;Fe/Ni比的增大可以抑制WC晶粒长大,消除异常长大晶粒,使WC晶粒尺寸均匀化;当Fe/Ni比超过3:1时,WC晶粒不再随着铁含量的增大而减小,开始出现晶粒粗化;随着铁含量的增大,钨在粘接相中的溶解度降低,影响烧结的收缩过程,当Fe/Ni比为85:15时,合金收缩率突降,烧结性能变差,影响材料力学性能。

2) Fe/Ni比从1:1提升到3:1时,合金抗弯强度升高,当Fe/Ni比大于等于3:1时,合金抗弯强度不断下降;合金硬度随着Fe/Ni比的增大而不断增大,断裂韧性在Fe/Ni比低于4:1时不断提高;在Fe/Ni比为85:15时,由于合金烧结性变差,断裂韧性变差,Fe/Ni比为3:1时合金综合力学性能最好,其抗弯强度、硬度、断裂韧性分别达到3047 MPa、934HV和23.3 MPa·m1/2。

3) 合金的耐腐蚀性能随着Fe/Ni比增大而不断下降,当Fe/Ni比从1:1增大到85:15时,合金自腐蚀电流密度从0.093×10-5 A/cm2上升到15.4×10-5 A/cm2。

REFERENCES

[1] CHANG S H, CHANG M H, HUANG K T. Study on the sintered characteristics and properties of nanostructured WC-15wt% (Fe-Ni-Co) and WC-15wt% Co hard metal alloys[J]. Journal of Alloys and Compounds, 2015, 649: 89-95.

[2] VISWANADHAM R K, LINGDQUIST P G. Transformation- toughening in cemented carbides: Part I. Binder composition control[J]. Metallurgical Transactions A, 1987, 18(12): 2163-2173.

[3] JIANG Guo-jian, ZHUANG Han-rui, LI Wen-lan. Parameters investigation during simultaneous synthesis and densification WC-Ni composites by field-activated combustion[J]. Materials Science and Engineering A, 2003, 360(1/2): 377-384.

[4] GUO Zhi-xing, XIONG Ji, YANG Mei, JIANG Ci-jin. WC-TiC-Ni cemented carbide with enhanced properties[J]. Journal of Alloys and Compounds, 2008, 465(1): 157-162.

[5] CORREA E O, SANTOS J N, Klein A N. Microstructure and mechanical properties of WC Ni-Si based cemented carbides developed by powder metallurgy[J]. International Journal of Refractory Metals and Hard Materials, 2010, 28(5): 572-575.

[6] GENGA R M, CORNISH L A, AKDOGAN G. Effect of Mo2C additions on the properties of SPS manufactured WC-TiC-Ni cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2013, 41(11): 12-21.

[7] MOUSTAFA S F, ADEDEL-HAMID Z, BAHEIG O G, HUSSIN A. Synthesis of WC hard materials using coated powders[J]. Advanced Powder Technology, 2011, 22(5): 596-601.

[8] SHON I J, JEONG I K, KO I Y, DOH J M, WOO K D. Sintering behavior and mechanical properties of WC-10Co, WC-10Ni and WC-10Fe hard materials produced by high-frequency induction heated sintering[J]. Ceramics International, 2009, 35(1): 339-344..

[9] CHANG S H, CHEN S L. Characterization and properties of sintered WC-Co and WC-Ni-Fe hard metal alloys[J]. Journal of Alloys and Compounds, 2014, 585: 407-413.

[10] 鲍 瑞, 易健宏. 微波烧结技术在硬质合金制备中的应用[J]. 中国有色金属学报, 2014, 24(6): 1544-1561.

BAO Rui, YI Jian-hong. Application of microwave sintering technology in cemented carbide preparation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1544-1561.

[11] TAHERI-NASSAJE, MIRHOSSEINI S H. An in situ WC-Ni composite fabricated by the SHS method[J]. Journal of Materials Processing Technology, 2003, 142(2): 422-426.

[12] GONZALES R, ECHEBERRIA J, SANCHEZ J M, CASTRO F. WC-(Fe,Ni,C) hardmetals with improved toughness through isothermal heat treatments[J]. Journal of Materials Science, 1995, 30(13): 3435-3439.

[13] ZHAO Zhen-ye, LIU Jian-wei, TANG Hua-guo, MA Xian-feng, ZHAO Wei. Effect of Mo addition on the microstructure and properties of WC-Ni-Fe hard alloys[J]. Journal of Alloys and Compounds, 2015, 646: 155-160.

[14] 张武装, 刘 咏, 贺跃辉, 阳建高, 龙郑易. 具有梯度结构的涂层硬质合金刀片[J]. 中国有色金属学报, 2005, 15(5): 757-762.

ZHANG Wu-zhuang, LIU Yong, HE Yue-hui, YANG Jian-gao, LONG Zheng-yi. Coated cemented carbide with gradient structure[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 757-762.

[15] SU Wei, SUN Ye-xi, YANG Hai-lin, ZHANG Xian-qi, RUAN Jian-ming. Effects of TaC on microstructure and mechanical properties of coarse grained WC-9Co cemented carbides[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(4): 1194-1199.

[16] SCHUBERT W D, FUGGER M, WITTMANN B, USELDINGER R. Aspects of sintering of cemented carbides with Fe-based binders[J]. International Journal of Refractory Metals and Hard Materials, 2014, 49(1): 110-123.

[17] GAO Yang, LUO Bing-hui, BAI Zhen-hai, OUYANG Seng. Effects of deep cryogenic treatment on the microstructure and properties of WC-Fe-Ni cemented carbides[J]. International Journal of Refractory Metals and Hard Materials, 2016, 58: 42-50.

[18] SUWei, SUN Ye-xi, LIU Jue, FENG Jiao, RUAN Jian-ming . Effects of Ni on the microstructures and properties of WC-6Co cemented carbides fabricated by WC-6(Co, Ni) composite powders[J]. Ceramics International, 2015, 41(2): 3169-3177.

[19] 朱 斌, 柏振海, 高 阳, 罗兵辉. WC粒度对WC-15Fe-5Ni硬质合金组织与性能的影响[J]. 中国有色金属学报, 2016, 26(5): 1065-1074.

ZHU Bin, BAI Zhen-hai, GAO Yang, LUO Bing-hui. Effects of WC particle size on microstructure and properties of WC-15Fe-5Ni cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(5): 1065-1074.

[20] FERNANDES C M, SENOS A M R, VIEIRA M T. Control of eta carbide formation in tungsten carbide powders sputter-coated with (Fe/Ni/Cr)[J]. International Journal of Refractory Metals and Hard Materials, 2007, 25(4): 310-317.

[21] ZHOU Peng, PENG Ying-biao, BUCHEGGER C, DU Yong, LENGAUER W. Experimental investigation and thermodynamic assessment of the C-Co-Fe-Ni-W system[J]. Journal of Phase Equilibria and Diffusion, 2016, 54: 60-69.

[22] GAO Yang, LUO Bing-hui, HE Ke-jian, ZHANG Wen-wen, BAI Zhen-hai. Effect of Fe/Ni ratio on the microstructure and properties of WC-Fe-Ni-Co[J]. Ceramics International, 2017, 44(2). https://doi.org/10.1016/j.ceramint, 2017.10.148.

[23] RYOO H S, HWANG S K. Anisotropic atomic packing model for abnormal grain growth mechanism of WC-25wt.%Co alloy[J]. Scripta Material, 1998, 39(11): 1577-1583.

[24] RAMQUIST L. Wetting of metallic carbides by liquid copper, nickel, cobalt and iron[J]. International Journal of Powder Metallurgy, 1965, 1(4): 2-21.

[25] Fe-WSGTE2014, Ni-WSGTE2014. List of stored phase diagram[DB/OL]. http://www.crct.polymtl.ca/FACT/documentation/.

[26] GILLE G, SZESNY B, DREYER K, Berg H V D, SCHMIDT J, GESTRICH, LEITNER T. Submicron and ultrafine grained hardmetals for microdrills and metal cutting inserts[J]. International Journal of Refractory Metals and Hard Materials, 2002, 20(1): 3-22.

[27] SCHUBERT W D, NEUMEISTER H, KINGER G, LUX B. Hardness to toughness relationship of fine-grained WC-Co hardmetals[J]. International Journal of Refractory Metals and Hard Materials, 1998, 16(2): 133-142.

[28] EXNER HE, WALTER A, PABST R. Fault distributions in brittle materials[J]. Materials Science and Engineering 1974, 16(3): 231-8.

[29] MOSKOWITZ D, FORD M J, HUMENIK M Jr. High strength tungsten carbide[M]// HAUSNER H H. Modern Developments in Powder Metallurgy: Volume 5. Boston, MA: Springer-Verlag US, 1971: 225-234.

[30] FANG Z Z. Correlation of transverse rupture strength of WC-Co with hardness[J]. International Journal of Refractory Metals and Hard Materials, 2005, 23(2): 119-127.

[31] LEE H C, GURLAND J. Hardness and deformation of cemented tungsten carbide[J]. Materials Science and Engineering, 1978, 33(1): 125-133.

[32] MILMAN Y V, CHUGUNOVA S, GONCHARUNK V, LUYCKX S, NORTHROP I T. Low and high temperature hardness of WC-6wt%Co alloys[J]. International Journal of Refractory Metals and Hard Materials, 1997, 15(1/3): 97-101.

[33] FURUSHIMA R, KATOU K, SHIMOJIMA K, HOSOKAMA H, MATSUMOTO A. Control of WC grain sizes and mechanical properties in WC-Fe-Al composite fabricated from vacuum sintering technique[J]. International Journal of Refractory Metals and Hard Materials, 2015, 50: 16-22.

[34] 李晨辉, 余立新, 熊惟皓. WC的粒度对WC-Co硬着合金断裂韧性的影响[J]. 硬质合金, 2001, 18(3): 138-141.

LI Chen-hui, YU Li-xin, XIONG Wei-hao. Effect of WC particle size on WC-Co cemented carbides fracture toughness[J]. Cemented Carbide, 2001, 18(3): 138-141.

[35] 张忠健, 赵声志, 彭 文, 张倩霞, 陈 鼎. 硬质合金疲劳裂纹的萌生与扩展行为[J]. 中国有色金属学报, 2014, 24(12): 3031-3041.

ZHANG Zhong-jian, ZHAO Sheng-zhi, PENG Wen, ZHANG Qian-xia, CHEN Ding. Behavior of fatigue crack initiation and propagation of cemented carbides[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(12): 3031-3041.

[36] 易丹青, 陈丽勇, 刘会群, 王 斌, 聂 灿. 硬质合金电化学腐蚀行为的研究进展[J]. 硬质合金, 2012, 29(4): 238-253.

YI Dan-qing, CHEN Li-yong, LIU Hui-qun, WANG Bin, NIE Can. Research progress on electrochemical corrosion behavior of cemented carbide[J]. Cemented Carbide, 2012, 29(4): 238-253.

[37] 王向龙. 不锈钢耐腐蚀性测量技术的研究[D]. 杭州: 浙江工业大学, 2013: 2-3.

WANG Xiang-long. Technology research of measurement on stainless steel corrosion[D]. Hangzhou: Zhejiang University of Technology, 2013: 2-3.

[38] 王 恒. 低碳球铁的耐磨和耐腐蚀性能研究[D]. 昆明: 昆明理工大学, 2012: 77-79.

WANG Heng. Study on unwear and corrosion resistance properties of low-carbon ductile iron[D]. Kunming: Kunming University of Science and Technology, 2002: 77-79.

Effects of Fe/Ni ratio on microstructure and properties of WC-Fe-Ni cemented carbide

ZHANG Wen-wen, LUO Bing-hui, GAO Yang, BAI Zhen-hai

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: WC-Fe-Ni cemented carbides with five kinds of Fe/Ni ratio were prepared by 1450 ℃ sinter-HIP sintering to study the effects of Fe/Ni ratio on the microstructure and properties by SEM, XRD, mechanical performance test and electrochemical test. The results show that with the increase of Fe/Ni ratio, the grain size firstly decreases and then increases. The grain size reaches the finest (1.24 μm) with Fe/Ni ratio of 3:1. And with the increase of Fe/Ni ratio, the changing trend between bending strength and grain size is inverse, the hardness increases continuously, both of fracture toughness and sintering density firstly increase and then decrease. When Fe/Ni ratio is 3:1, fracture mode is mainly intergranular fracture. Except for the alloy with Fe/Ni ratio of 3:1, more transgranular fracture appears. The acidic corrosion resistance ability gets worse continuously. When Fe/Ni ratio is 3:1, WC-Fe-Ni alloy exhibits optimum properties, the hardness, bending strength , fracture toughness and corrosion current density are 3047 MPa, 934HV, 23.3 MPa·m1/2 and 3.98×10-5 A/cm2, respectively.

Key words: WC-Fe-Ni cemented carbide; Fe/Ni ratio; WC grain size; microstructure; mechanical property; corrosion property

Foundation item: Project(20120619) supported by the Hunan Nonferrous Metals Research Fund, China

Received date: 2017-07-12; Accepted date: 2017-11-14

Corresponding author: LUO Bing-hui; Tel: +86-731-88830333; E-mail: lbh@ csu.edu.cn

(编辑 何学锋)

基金项目:湖南有色研究基金资助项目(20120619)

收稿日期:2017-07-12;修订日期:2017-11-14

通信作者:罗兵辉,教授,博士;电话:0731-88830333;E-mail: lbh@ csu.edu.cn