DOI: 10.11817/j.issn.1672-7207.2020.11.012

粉末冶金镁合金中第二相的扩散行为

孙佳星,程开明,李培亮,刘聪,李冠宇,周吉学

(齐鲁工业大学(山东省科学院),山东省科学院新材料研究所,山东省轻质高强金属材料重点实验室,山东 济南,250014)

摘要:对传统粉末冶金和激光增材制造镁合金研究进展进行综述,并整理文献报道镁合金化合物扩散系数实验数据,从第二相金属间化合物扩散生长行为角度,研究所涉及的重要化合物动力学信息。针对镁金属间化合物扩散生长和扩散系数实验数据缺乏的现状,提出一种高通量获取化合物扩散系数的计算方法。研究结果表明:金属间化合物的“界面扩散动力学”行为不仅影响粉末烧结时的冶金结合和致密化,而且会影响其在材料中的形貌和分布。将“多元金属间化合物”及有益的“亚稳相或亚稳结构”引入粉末冶金材料是进一步提高粉末冶金镁合金性能的有效手段。

关键词:粉末冶金;镁合金;金属间化合物;扩散系数

中图分类号:TG146.2 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2020)11-3101-09

Diffusion behavior of intermetallic compounds in powder metallurgy magnesium alloys

SUN Jiaxing, CHENG Kaiming, LI Peiliang, LIU Cong, LI Guanyu, ZHOU Jixue

(Shandong Provincial Key Laboratory of High Strength Lightweight Metallic Materials, Advanced Materials Institute, Qilu University of Technology(Shandong Academy of Sciences), Jinan 250014, China)

Abstract: The research progress of traditional powder metallurgy and laser additive manufacturing of magnesium alloys were summarized. The reported experimental data on the interdiffusion coefficient of intermetallic compounds(IMCs) in magnesium alloy were reviewed. The key kinetic growth behavior of the second phase involved in the powder metallurgy process were studied. Finally, in view of the lack of experimental data on the diffusion growth and diffusion coefficient of IMCs in magnesium alloys, a high-throughput calculation method for obtaining compound diffusion coefficient was presented. The results show that the "interface diffusion" behavior of IMCs affects the alloy bonding and densification during powder sintering, which can further affect its morphology and distribution in the material. Meanwhile, The introduction of "multi-component IMCs" or "metastable phase and structure" is an effective means to further improve the properties of powder metallurgy magnesium alloys.

Key words: powder metallurgy; magnesium alloys; intermetallic compound; diffusion coefficients

镁合金作为一种重要的轻质结构材料,在交通工具、电子通信、航空航天等领域有着广阔的应用前景[1-3]。为了使镁合金适应不同的使用环境和服役场景,一方面,通常采用改变合金成分的方法调整合金相组成及微观组织结构,从而实现镁合金力学性能、铸造性能和耐腐蚀性能的提高,例如,Mg-Al合金体系作为轻质金属材料的基础合金体系,在汽车和航空航天工业等方面应用比较广泛,而其中金属间化合物Al3Mg2和Al12Mg17相的体积分数、形貌和分布都对合金的最终性能有重要影响[3-5];另一方面,传统粉末冶金及激光增材制造(3D打印)等先进材料制备技术在镁合金中的应用,正引起越来越多国内外学者的关注[6-23]。相比于传统的铸造工艺,传统粉末冶金技术制备的镁合金材料强化相分布更均匀,且不易产生偏析现象。在制备过程中不必承受高温,从而避免了熔炼过程中带来氧化和挥发的问题[6]。同时,激光增材制造(3D打印)技术对材料的利用率高,操作方便、快捷,更容易对金属间化合物的形貌和分布进行有效控制,使金属间化合物更加细小弥散地分布在基体中,能进一步提高镁合金的强度、硬度、耐腐蚀性和磨损性等[7, 16-17]。然而,目前的研究工作大多侧重于探索工艺参数对镁合金性能的直接影响,相应的合金化动力学研究也主要集中在晶粒度、孔隙率等方面,而对其中金属间化合物的溶解、析出和生长等动力学研究非常缺乏。考虑到第二相在镁合金中的形态、尺寸和分布主要由扩散动力学所控制,系统研究金属间化合物扩散行为对提升粉末冶金镁合金材料的力学性能十分重要,因此,本文通过介绍粉末冶金方法在镁合金中的应用现状,着重于不同工艺参数对第二相金属间化合物生长的影响;同时,整理已有的关于镁合金中金属间化合物扩散生长的研究数据,比较粉末冶金方法与传统铸造镁合金所关注的化合物扩散动力学数据的异同,进而对镁合金粉末冶金动力学机理进行研究。

1 粉末冶金镁合金中的第二相

1.1 传统粉末冶金

粉末冶金镁合金是将样品粉末化,然后经过一系列合金化工艺处理,从而获得的性能优异的镁合金产品。传统粉末冶金工艺并不改变合金的平衡相组成,真空热压烧结条件下制备的AZ91合金仍主要由α-Mg和Mg17Al12相组成,在烧结过程中金属粉末颗粒间产生的内凝聚和原子扩散作用下,化合物Mg17Al12相可以均匀弥散地分布在其基体中。

周亚军等[7]发现烧结温度的提高能使粉末表面和内部原子扩散加快,并指出烧结温度为550 ℃、压制压力为25 kN时所制备的材料性能最好。大量研究发现,采用球磨法制备AZ91镁合金粉末,随后进行冷压、烧结处理,粉末在高压低温烧结时,颗粒内部细小的第二相(Mg17Al12化合物)逐渐长大、数量逐渐减少,且分布在颗粒界面两侧。随着烧结时间的增加,晶粒与第二相尺寸继续增大,第二相分布在界面处,对界面起到强化作用。同时,烧结过程中合金内部出现液相,致密度提高,晶粒细小,组织致密均匀,硬度比铸态明显提高[8-11]。

郝峰晨等[12]采用放电等离子烧结方法制备了ZK61合金,发现其主要由α-Mg和Mg0.97Zn0.03相组成。随着烧结温度提高,更多的原子通过表面迁移和扩散进入颗粒间的接触面。随着接触面的扩大,颗粒间原本相互连通的孔隙逐渐收缩成闭孔,总孔隙体积减少、颗粒间距离缩短,样品致密度提高,组织均匀,晶粒细小。同时,烧结温度升高促进冶金结合,使得界面结合强度提高,从而合金抗压强度和抗拉强度提高。

周涛等[13]采用雾化-双辊急冷法和热挤压工艺,制备了快速凝固/粉末冶金的Mg-Zn-Y合金样品,并在其中发现了α-Mg固溶体以及Mg3Zn3Y2和Mg12ZnY金属间化合物相,化合物极高的热稳定性使得Mg-Zn-Y合金具有很高的室温压缩强度、屈服强度和极限抗压强度。ZHOU等[14]还采用热挤压法制备了快速凝固/粉末冶金M-6Zn和Mg-6Zn-5Ca合金,并在其中形成了稳定的金属间化合物Ca2Mg6Zn3颗粒,在高温下对位错和晶界有很好的钉扎作用,使合金的显微组织明显细化,细分散颗粒数量显著增加,抗压强度提高。

从上述工作可见,由于粉末冶金镁合金的组织晶粒非常细小,第二相金属间化合的“界面扩散动力学”对其析出行为的影响不可忽略,元素的界面扩散不仅能促进高热稳定金属间化合物的形成,而且能加快合金粉末颗粒之间界面的冶金结合及材料致密化过程。同时,镁合金中的二元、三元“金属间化合物”种类丰富,为新型粉末冶金镁合金的成分设计和开发提供更多可能性,对这些多元金属间化合物扩散行为的系统研究尤为重要。

1.2 激光增材制造

激光增材制造(3D打印)是以激光/电子束作为热源,利用“离散-堆积”原理,通过熔化粉末或丝材逐层堆积,实现金属零件的直接制造[15-16]。朱兆雨等[17]介绍了激光工艺参数对镁铝合金样品表面形貌、球化、缺陷、孔隙率的影响,并指出其中主要产生强化相Mg17Al12。赵凯华等[18]介绍了镁合金表面激光熔覆技术工艺和熔覆体系及各种熔覆层中的化合物组织及性能,其中,在Mg-Al合金激光熔覆技术中以Mg17Al12为主要生成化合物,可以提高产品的耐腐蚀性能、磨损性和硬度。在采用选择性激光熔化技术制备的AZ91D合金中, Mg17Al12沿着等轴晶α-Mg基体分布,在固溶强化和细晶强化的作用下,强度和硬度比铸态明显提高[19-20]。谢丽初等[21]发现AZ31、AZ61、AM50和AZ91镁合金激光焊接后焊缝处主要由Mg17Al12和Mg2Al3化合物组成,细小弥散的组织可提高镁合金的焊接接头的耐磨性和耐腐蚀性能。可见,激光增材制造技术与传统粉末冶金工艺类似,并不改变合金的平衡相组成。

然而,由于镁合金的高挥发性,高能激光所产生的瞬时高温往往会降低3D打印材料的致密度。高生祥等[22]发现3D打印的Mg-8Al-0.5Zn-0.3Sr-0.1Y镁合金主要是由α-Mg和Mg17Al12化合物相组成,合金坯体孔隙较多,坯体的力学性能和耐磨损性能较差,采用热等静压工艺对其进一步热致密化处理,可以通过高温扩散改善粉末合金的显微组织,提高其致密度。此外,刘畅[23]利用激光增材制造技术制备了多孔Mg-Zn-Zr合金,发现在多孔Mg-Zn-Zr合金中,Mg7Zn3相随着Zn含量的增多而增加,而且制备的多孔Mg-Zn-Zr合金的晶粒尺寸明显减小,可以提高多孔Mg-Zn-Zr合金的硬度和压缩性能,在医用材料领域表现出了极大的应用潜力。

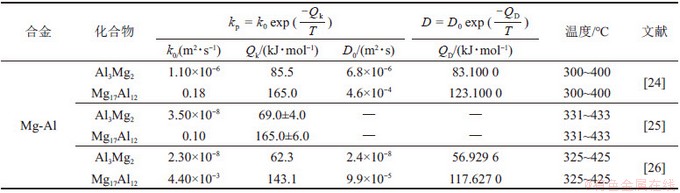

表1 镁合金中金属间化合物的扩散动力学参数

Table 1 Diffusion kinetic data of intermetallic compounds in magnesium alloys

可见,镁合金激光增材制造技术与传统粉末冶金工艺有相似之处,其所涉及的高能热源和精确数控技术不但能极大地扩展镁合金材料中可添加高熔点元素的范围,而且能在合金迅速熔化和冷却的过程中为有益“亚稳相或亚稳结构”的产生起到一定促进作用。因此,其中可能涉及非平衡亚稳相的扩散动力学行为,进一步说明了镁合金中第二相扩散行为研究的重要性。

2 镁合金化合物扩散动力学数据

本文对现有镁合金体系金属间化合物扩散生长行为的研究工作进行了整理,并采用阿伦尼乌斯表达式给出测定的化合物扩散生长系数及扩散系数(见表1)。其中,针对Mg-Al体系中金属间化合物扩散生长的研究工作最为集中,BRENNAN等[24-29]分别给出了不同温度下Mg-Al扩散偶中Al3Mg2,Al17Mg12和Al30Mg23的生长系数及计算得到的扩散系数。由于Al17Mg12具有较宽的成分范围区间,ZHONG等[28-29]给出了其随成分产生变化的扩散系数。此外,CHENG等[29]采用高温激光共聚焦显微镜原位观察到Mg-Al中金属间化合物的高温扩散生长,并结合数值反演方法计算了扩散系数与成分和温度的变化函数。

续表

同时,也有少数针对Mg-X(X=Zn,Cu,Gd,Y,Nd)二元合金体系金属间化合物扩散系数的研究工作。BRENNAN等[30-32]采用固-固扩散偶研究Mg-Zn体系中的互扩散和化合物相生长行为,发现经过长时间扩散退后MgZn2相生长层最厚,其次为Mg2Zn3相、Mg2Zn11相、Mg4Zn7相和Mg21Zn25相。由于Mg-Zn金属间化合物层的生长由元素扩散控制,化合物扩散系数的变化与生长厚度的变化相同。在Mg-Cu体系中,DAI等[33-34]研究了Mg-Cu二元扩散偶的固-固界面反应。其中,DAI等[33]计算并报道了金属间化合物的扩散系数,发现Mg2Cu的扩散系数比Cu2Mg高5个数量级,说明Mg2Cu的高温扩散行为非常剧烈。BRENNAN等[35-36]采用Mg-Nd扩散偶研究了金属间化合物形成并给出生长系数,其中PALIWAL等[36]计算了扩散偶中生成金属间化合物的互扩散系数。DAS等[37]采用单晶Mg扩散偶实验,系统测定Mg-Y和Mg-Gd合金体系中金属间化合物的扩散系数随温度的变化,并给出了沿不同晶轴方向(a轴和c轴)的扩散系数。BERMUDEZ等[38]实验测定了多晶Mg-Y合金体系中化合物层厚度及成分距离曲线。

此外,针对镁合金体系中三元金属间化合物扩散系数的研究非常少,CHENG等[39]通过相图计算方法设计并制备了Mg-τ三元扩散偶,采用高温激光共聚焦显微镜对三元金属间化合物φ-Mg5Al2Zn2的扩散生长进行原位观察,并通过数值反演首次获得了其扩散系数矩阵,计算结果说明Zn原子的扩散迁移对φ相的生长速率有主导作用。

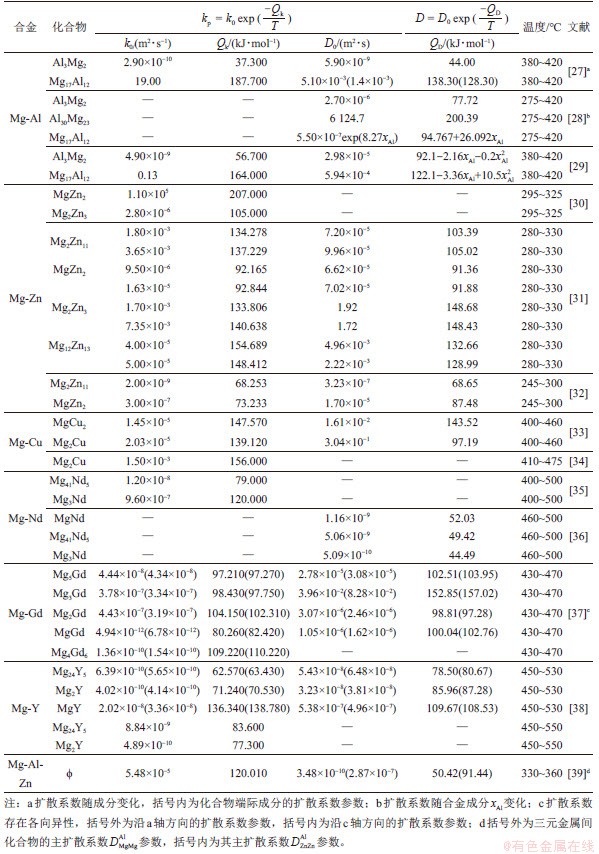

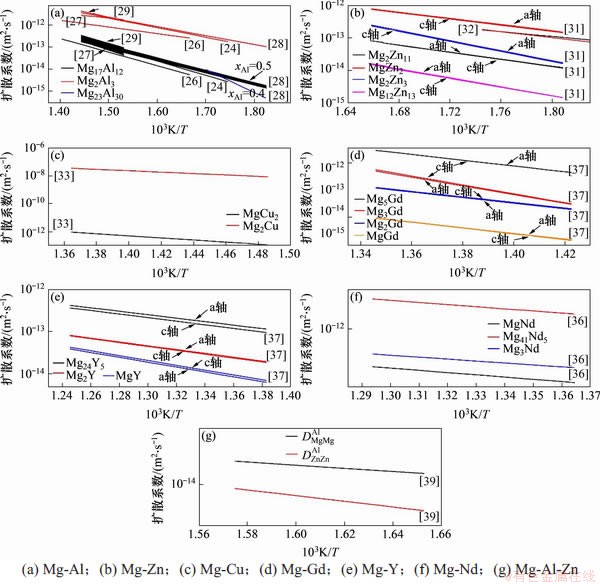

根据上述文献数据整理,所涉及的镁合金体系中化合物扩散系数随温度的变化如图1所示。文献[1]中的结果差别并不明显,且在实验温度区间内,不同含镁金属间化合物的扩散系数数量级处于10-12~10-15之间,唯一的例外是MgCu2化合物的数量级达到了10-7,需要进一步的实验确认。同时,与镁合金体系中已知包含的大量复杂金属间化合物相比较,目前镁合金化合物扩散系数的实验测定数据较为零散,且由于化合物扩散系数的测定实验工作量大,所得实验数据稀少。通常,扩散偶技术结合电子探针(EPMA)检测是主要的金属间化合物扩散生长信息获取手段,然而,该方法获取金属间化合物扩散生长关键实验信息的效率较低。可见,传统的金属间化合物扩散信息获取手段和扩散系数计算方法,难以满足系统研究镁合金化合物扩散系数的需要。为了解决这些问题,CHENG等[39]所建立的高温原位观察技术结合数值反演方法能实现多元金属间化合物扩散系数的高效、准确测定,以Mg-Al二元合金体系扩散系数的实验和计算流程为例(见图2),从高温原位实验数据高效、准确获得金属间化合物扩散生长曲线,将其与成分距离曲线同时输入数值反演算法,可获得其中金属间化合物的扩散系数与成分和温度变化的函数关系。其中,数值反演算法以能谱测定成分距离曲线(C(x))和原位实验观察抛物线生长系数(kp)为输入数据,扩散系数和实验测量数据之间的关系可以通过菲克定律的积分公式表示:

图1 文献报道的镁合金体系化合物扩散系数随温度变化曲线

Fig. 1 Reported temperature-dependent interdiffusion coefficient of intermetallic compounds in magnesium alloy system

图2 Mg-Al二元合金体系扩散系数的原位实验和数值反演计算流程

Fig. 2 Flow chart of in-situ experiment and numerical inversion calculation of diffusion coefficient of Mg-Al binary alloy system

(1)

(1)

其中: ;x为沿扩散方向的距离;

;x为沿扩散方向的距离; 和

和 由初始端点组成;x0为Matano平面。

由初始端点组成;x0为Matano平面。

式(1)的等号左侧为扩散通量的定义公式,即

(2)

(2)

等号右边是扩散系数 和成分梯度▽Cj乘积的线性加和,可以表示为

和成分梯度▽Cj乘积的线性加和,可以表示为

(3)

(3)

交互扩散系数与成分的函数关系可以用多项式展开:

(4)

(4)

其中:pij为数值反演过程中需要确定的参数。当β相是α相和γ相2个界面上形成的金属间化合物时,数值反演中需要考虑kp。β相的kp可以表示为

(5)

(5)

式中: 项是a-b界面处的

项是a-b界面处的 和

和 的乘积,

的乘积, 为交互矩阵,

为交互矩阵, 可以表示为

可以表示为 。当实验确定

。当实验确定 时,可以作为数反演方法过程中的边界条件。在数值反演过程中,使

时,可以作为数反演方法过程中的边界条件。在数值反演过程中,使 和

和 以及

以及 和

和 的偏差最小,达到最优结果。该方法可以同时处理不同条件下制备的几组扩散偶数据。在m组扩散偶中,损失函数可以构造为

的偏差最小,达到最优结果。该方法可以同时处理不同条件下制备的几组扩散偶数据。在m组扩散偶中,损失函数可以构造为

(6)

(6)

当精度 时,回归过程就会停止,并得到与成分和温度相关的互扩散系数。该方法可适用于二元金属间化合物扩散系数的研究,也可推广至多元金属间化合扩散系数矩阵的研究,目前已应用于Mg-Al-Zn-Y多元合金体系研究[29, 39-41]。

时,回归过程就会停止,并得到与成分和温度相关的互扩散系数。该方法可适用于二元金属间化合物扩散系数的研究,也可推广至多元金属间化合扩散系数矩阵的研究,目前已应用于Mg-Al-Zn-Y多元合金体系研究[29, 39-41]。

3 总结与展望

本文从综述传统粉末冶金和激光增材制造(3D打印)技术在镁合金制备中的应用入手,比较了不同加工工艺对镁合金中金属间化合物的形态、尺寸和分布的影响。相比传统铸造镁合金,粉末冶金方法制备的镁合金中第二相形态细小弥散,对位错和晶界有很好的钉扎作用,因而容易获得更好的性能。

通过研究粉末冶金镁合金中第二相分布数据发现:1) 金属间化合物的“界面扩散动力学”行为影响粉末烧结时的冶金结合和致密化,更会影响其在材料中的形貌和分布,是研究多元镁合金粉末合金化动力学不可忽略的关键动力学信息;2) 从镁合金中种类丰富的“多元金属间化合物”中筛选并引入粉末冶金材料以提高合金性能,需要掌握更多镁合金第二相的扩散动力学信息;3) 激光增材制造(3D打印)能实现高熔点元素添加以及有益“亚稳相或亚稳结构”的产生,研究其动力学机理将涉及到非平衡亚稳相的扩散动力学行为。

然而,含镁金属间化合物扩散生长实验测定及扩散系数计算的相关报道很少,大部分工作主要集中于常见的铸造镁合金体系中二元金属间化合物扩散系数的研究,采用高温原位观察技术结合数值反演方法可实现多元金属间化合物扩散系数的高效、准确测定。因此,考虑到粉末冶金材料中第二相金属间化合物的界面扩散动力学以及亚稳相扩散动力学信息的关键性,将现有的高通量化合物扩散系数获取手段扩展应用于更多的镁合金体系研究,为粉末冶金镁合金材料的成分设计和性能优化提供基础的材料物性参数,是未来相关领域的重要研究内容之一。

参考文献:

[1] VAN PHUONG N, MOON S, CHANG D, et al. Effect of microstructure on the zinc phosphate conversion coatings on magnesium alloy AZ91[J]. Applied Surface Science, 2013, 264: 70-78.

[2] MORDIKE B. Magnesium properties-applications-potential[J]. Materials Science and Engineering, 2001, 302: 37-45.

[3] ZENG Rongchang, ZHANG J, HUANG Weijiu, et al. Review of studies on corrosion of magnesium alloys[J]. Transactions of Nonferrous Metals Society of China, 2006, 16: s763-s771.

[4] CIERWINSKI F. Magnesium alloys: design, processing and properties[M]. Croatia: Intech Open Science, 2011: 2-20.

[5] YAMAMOTO N, LIAO J, WATANABE S, et al. Effect of intermetallic compound layer on tensile strength of dissimilar friction-stir weld of a high strength Mg alloy and Al alloy[J]. Materials Transactions, 2009, 50(12): 2833-2838.

[6] 邱慧, 刘建秀, 周亚军. 粉末冶金镁基复合材料研究进展[J]. 轻合金加工技术, 2012, 40(12): 22-26.

QIU Hui, LIU Jianxiu, ZHOU Yajun. Research on magnesium matrix composites prepared by powder metallurgy method[J]. Light Alloy Fabrication Technology, 2012, 40(12): 22-26.

[7] 周亚军, 张发厅, 刘建秀. 烧结工艺对粉末冶金法制备镁合金摩擦磨损性能的影响[J]. 铸造技术, 2013, 34(12): 1617-1619.

ZHOU Yajun, ZHANG Fating, LIU Jianxiu. Influence of sintering process on friction and wear properties of AZ91Mg-alloy fabricated by powder metallurgy[J]. Foundry Technology, 2013, 34(12): 1617-1619.

[8] 杨伟东, 樊建锋, 张金玲, 等. 烧结温度对粉末冶金AZ91镁合金组织及硬度的影响[J]. 材料热处理学报, 2013, 34(1): 38-42.

YANG Weidong, FAN Jianfeng, ZHANG Jinling, et al. Effect of sintering temperature on microstructure and hardness of powder metallurgy AZ91 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2013, 34(1): 38-42.

[9] 张文磊. 高压低温烧结AZ91镁合金晶粒细化及其力学性能研究[D]. 太原: 太原理工大学材料科学与工程学院, 2015: 35-38.

ZHANG Wenlei. Grain refinement and mechanical properties of AZ91Magnesium alloy processed by high-pressure and low-temperature sintering[D]. Taiyuan: Taiyuan University of Technology. College of Materials Science and Engineering, 2015: 35-38.

[10] 杨伟东. 球磨/粉末冶金法制备AZ91镁合金组织及显微硬度的研究[D]. 太原: 太原理工大学材料科学与工程学院, 2012: 39-50.

YANG Weidong. Study on microstructures and microhardness of the AZ91Alloys prepared by ball milling/powder metallurgy[D]. Taiyuan: Taiyuan University of Technology. College of Materials Science and Engineering, 2012: 39-50.

[11] 于秀娜, 罗宏宇, 郑莲婧, 等. 热压温度对粉末冶金AZ31镁合金性能的影响[J]. 铸造技术, 2017, 38(10): 2488-2489, 2499.

YU Xiuna, LUO Hongyu, ZHENG Lianjing, et al. Effect of hot-pressing temperature on the properties of AZ31 magnesium alloy prepared by powder metallurgy[J]. Foundry Technology, 2017, 38(10): 2488-2489, 2499.

[12] 郝峰晨, 崔泽琴, 王文先. 放电等离子烧结温度对ZK61镁合金组织及力学性能的影响[J]. 材料热处理学报, 2017, 38(3): 34-40.

HAO Fengchen, CUI Zeqin, WANG Wenxian. Effects of spark plasma sintering temperature on microstructure and mechanical properties of ZK61 magnesium alloy[J]. Transactions of Materials and Heat Treatment, 2017, 38(3): 34-40.

[13] 周涛, 夏华, 杨明波, 等. 快速凝固/粉末冶金镁合金的压缩变形行为[J]. 热加工工艺, 2011, 40(12): 34-37, 47.

ZHOU Tao, XIA Hua, YANG Mingbo, et al. Compressive deformation behavior of rapidly solidified/powder metallurgy magnesium alloy[J]. Hot Working Technology, 2011, 40(12): 34-37, 47.

[14] ZHOU Tao, YANG Mingbo, ZHOU Zhiming, et al. Microstructure and mechanical properties of rapidly solidified/powder metallurgy Mg-6Zn and Mg-6Zn-5Ca at room and elevated temperatures[J]. Journal of Alloys and Compounds, 2013, 560: 161-166.

[15] 杨强, 鲁中良, 黄福享, 等. 激光增材制造技术的研究现状及发展趋势[J]. 航空制造技术, 2016, 59(12): 26-31.

YANG Qiang, LU Zhongliang, HUANG Fuxiang, et al. Research on status and development trend of laser additive manufacturing[J]. Aeronautical Manufacturing Technology, 2016, 59(12): 26-31.

[16] 何凤英. 浅谈3D打印技术[J]. 矿业工程, 2016, 14(3): 66-69.

HE Fengying. Brief discussion on 3D print technology[J]. Mining Engineering, 2016, 14(3): 66-69.

[17] 朱兆雨, 陈长军, 张敏. 激光增材制造镁合金的研究现状及展望[J]. 激光与光电子学进展, 2019, 56(19): 74-86.

ZHU Zhaoyu, CHEN Changjun, ZHANG Min. Research progress and prospect of laser additive manufacturing technique for magnesium alloy[J]. Laser & Optoelectronics Progress, 2019, 56(19): 74-86.

[18] 赵凯华, 孙荣禄, 雷贻文. 镁合金表面激光熔覆研究现状[J]. 金属热处理, 2008, 33(4): 14-18.

ZHAO Kaihua, SUN Ronglu, LEI Yiwen. Research progress of laser cladding on the surface of magnesium alloys[J]. Heat Treatment of Metals, 2008, 33(4): 14-18.

[19] 郑增, 王联凤, 严彪. 3D打印金属材料研究进展[J]. 上海有色金属, 2016, 37(1): 57-60.

ZHENG Zeng, WANG Lianfeng, YAN Biao. Research progress of metal materials for 3D printing[J]. Shanghai Nonferrous Metals, 2016, 37(1): 57-60.

[20] WEI Kaiwen, GAO Ming, WANG Zemin, et al. Effect of energy input on formability, microstructure and mechanical properties of selective laser melted AZ91D magnesium alloy[J]. Materials Science and Engineering: A, 2014, 611: 212-222.

[21] 谢丽初, 全亚杰. 镁合金的激光加工现状与发展[J]. 矿冶工程, 2012, 32(6): 120-124.

XIE Lichu, QUAN Yajie. Status and development of laser processing of magnesium alloys[J]. Mining and Metallurgical Engineering, 2012, 32(6): 120-124.

[22] 高生祥, 邓丽霞. 热等静压对3D打印新型镁合金组织与性能的影响[J]. 世界科技研究与发展, 2015, 37(6): 643-645, 662.

GAO Shengxiang, DENG Lixia. Effects of hot isostatic pressing on microstructure and properties of 3D printing new magnesium alloys[J]. World Sci-Tech R & D, 2015, 37(6): 643-645, 662.

[23] 刘畅. 激光增材制造多孔镁合金成形工艺及组织性能研究[D]. 苏州: 苏州大学机电工程学院, 2018: 69-70.

LIU Chang. Study on the forming technology, microstructure and properties of porous magnesium alloys produced by laser additive manufacturing[D]. Suzhou: Soochow University. College of Mechanical and Electrical Engineering, 2018: 69-70.

[24] BRENNAN S, BERMUDEZ K, KULKARNI N S, et al. Interdiffusion in the Mg-Al system and intrinsic diffusion in β-Mg2Al3[J]. Metallurgical and Materials Transactions A, 2012, 43(11): 4043-4052.

[25] TANGUEP NJIOKEP E M, SALAMON M, MEHRER H. Growth of intermetallic phases in the Al-Mg system[J]. Defect and Diffusion Forum, 2001, 194/195/196/197/198/199: 1581-1586.

[26] FUNAMIZU Y, WATANABE K. Interdiffusion in the Al-Mg system[J]. Transactions of the Japan Institute of Metals, 1972, 13(4): 278-283.

[27] KULKARNI K N, LUO A A. Interdiffusion and phase growth kinetics in magnesium-aluminum binary system[J]. Journal of Phase Equilibria and Diffusion, 2013, 34(2): 104-115.

[28] ZHONG W, HOOSHMAND M S, GHAZISAEIDI M, et al. An integrated experimental and computational study of diffusion and atomic mobility of the aluminum-magnesium system[J]. Acta Materialia, 2020, 189: 214-231.

[29] CHENG Kaiming, XU Huixia, MA Baichang, et al. An in situ study on the diffusion growth of intermetallic compounds in the Al-Mg diffusion couple[J]. Journal of Alloys and Compounds, 2019, 810: 151878.

[30] BRENNAN S, BERMUDEZ K, KULKARNI N, et al. Diffusion couple investigation of the Mg-Zn system[C]// Magnesium Technology 2012. Cham: Springer International Publishing, 2012: 323-327.

[31] DAS S K, KIM Y M, HA T K, et al. Investigation of anisotropic diffusion behavior of Zn in hcp Mg and interdiffusion coefficients of intermediate phases in the Mg-Zn system[J]. Calphad, 2013, 42: 51-58.

[32] SAKAKURA T, SUGINO S. Fundamental study on interdiffuison in HCP alloys. Part 2: magnesium-zinc system[J] Memoris of Suzuka National College of Technology, 1977, 10: 141-153.

[33] DAI Jiahong, JIANG Bin, ZHANG Jianyue, et al. Diffusion kinetics in Mg-Cu binary system[J]. Journal of Phase Equilibria and Diffusion, 2015, 36(6): 613-619.

[34] NONAKA K, SAKAZAWA T, NAKAJIMA H. Reaction diffusion in Mg-Cu system[J]. Materials Transactions, JIM, 1995, 36(12): 1463-1466.

[35] BRENNAN S, BERMUDEZ K, SOHN Y. Intermetallic growth and interdiffusion in the Mg-Nd system[C]// The 9th International Conference on Magnesium Alloys and their Applications. Vancowver, 2012: 417-421.

[36] PALIWAL M, DAS S K, KIM J, et al. Diffusion of Nd in hcp Mg and interdiffusion coefficients in Mg-Nd system[J]. Scripta Materialia, 2015, 108: 11-14.

[37] DAS S K, KANG Y B, HA T, et al. Thermodynamic modeling and diffusion kinetic experiments of binary Mg-Gd and Mg-Y systems[J]. Acta Materialia, 2014, 71: 164-175.

[38] BERMUDEZ K, BRENNAN S, SOHN Y H. Intermetallic phase formation and growth in the Mg-Y system[C]// Magnesium Technology 2012. Cham: Springer International Publishing, 2012: 145-148.

[39] CHENG Kaiming, SUN Jiaxing, XU Huixia, et al. Diffusion growth of φ ternary intermetallic compound in the Mg-Al-Zn alloy system: In-situ observation and modeling[J]. Journal of Materials Science & Technology, 2021, 60: 222-229.

[40] CHENG Kaiming, CHEN Weimin, LIU Dandan, et al. Analysis of the Cermak-Rothova method for determining the concentration dependence of ternary interdiffusion coefficients with a single diffusion couple[J]. Scripta Materialia, 2014, 76: 5-8.

[41] CHENG Kaiming, ZHOU Jixue, XU Huixia, et al. An effective method to calculate the composition-dependent interdiffusivity with one diffusion couple[J]. Computational Materials Science, 2018, 143: 182-188.

(编辑 赵俊)

收稿日期: 2020 -08 -27; 修回日期: 2020 -09 -23

基金项目(Foundation item):国家重点研发计划项目(2017YFB0103904);山东省重点研发计划项目(2019JZZY010364, 2019JZZY020329) (Project(2017YFB0103904) supported by the National Key Research and Development Program of China; Projects(2019JZZY010364, 2019JZZY020329) supported by the Key Research and Development Program of Shandong Province)

通信作者:程开明,博士,副研究员,从事合金相图热力学及扩散动力学计算研究;E-mail:chengkm@sdas.org