Trans. Nonferrous Met. Soc. China 24(2014) 2226-2231

Recrystallization behavior of cold rolled Al-Zn-Mg-Cu fabricated by twin roll casting

Yun-Soo LEE, Won-Kyoung KIM, Dong-A JO, Cha-Yong LIM, Hyoung-Wook KIM

Light Metals Division, Korea Institute of Materials Science, Changwon 642-831, Korea

Received 17 October 2013; accepted 9 April 2014

Abstract: The Al-Zn-Mg-Cu alloy strip can be successfully fabricated by twin roll casting. In order to determine the effect of thickness reduction and heat treatment temperature on the recrystallization behavior, the strips were rolled and subsequently heat treated under various conditions. As a result, a fine grained microstructure (average grain size ~13 μm, average grain aspect ratio ~1.7) and high mechanical properties (UTS ≥360 MPa, δ ≥20%) were obtained by cold rolling with thickness reduction of 60% and heat treatment at 500 °C for 1 h. Also, the effect of the microstructure on mechanical properties of the Al-Zn-Mg-Cu alloy strip was discussed. Consequently, the low cost and high strength Al-Zn-Mg-Cu alloy sheet can be fabricated by twin roll casting by proper thermo-mechanical processes.

Key words: Al-Zn-Mg-Cu; twin roll casting; cold rolling; recrystallization

1 Introduction

Aluminum alloys have attracted much attention for the automotive industry due to their significant weight reduction for several decades [1,2]. However, it is difficult to fabricate high strength aluminum alloy sheets, such as Al-Zn-Mg-Cu, by conventional processes comprising direct chill (DC) casting, homogenizing, hot rolling, cold rolling, and heat treatment. As a result, high strength aluminum alloy sheets from DC cast ingots are more expensive than steel, therefore, it has prevented their widespread application in automotive industry.

One way for solving this problem is the twin roll casting (TRC) [3-9]. TRC is well known as a cost- saving process to make an aluminum alloy strip because of its significant advantages, such as one-step processing from melt to wrought aluminum strip [3]. Furthermore, it is possible to obtain fine cast structure and second phase particles by high cooling rate, which is closely related to the mechanical properties. However, this technique is mostly limited to alloys with a narrow mushy zone [4,5]. Also, a different distribution of solutes and second phase particles through the thickness direction caused by the different cooling rate during casting can lead to microstructural gradient during post thermo-mechanical processes, which decreases the mechanical properties [6,7]. Therefore, it is important to control the microstructure by proper thermo-mechanical treatments.

In the present work, the recrystallization behavior of Al-Zn-Mg-Cu alloy strip fabricated by TRC was investigated to obtain homogeneous microstructure and improved mechanical properties. In order to determine the effect of thickness reduction and heat treatment temperature on the recrystallization behavior, the strips were rolled and heat treated under various conditions. Also, the effect of the microstructure on mechanical properties of the Al-Zn-Mg-Cu alloy strip was discussed.

2 Experimental

A horizontal type twin roll caster [9] with water-cooled Cu-Cr rolls was used to fabricate Al-Zn-Mg-Cu alloy strip. The commercial aluminum alloy 7075 ingot with chemical composition of Al-5.6Zn-1.5Cu-2.5Mg (mass fraction, %) was used with minor amount of Al-5Ti-1B for grain refining. The molten alloy heated up to 680 °C was transferred into the preheated tundish and nozzle. At this time, the casting roll speed was 5-6 r/min and the roll gap was 4 mm. The chemical composition through the thickness direction of the as-cast strip was obtained by scanning electron microscopy with energy dispersive spectroscopy (SEM-EDS).

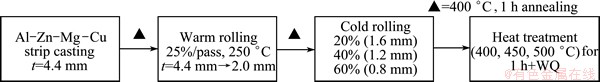

The as-cast Al-Zn-Mg-Cu alloy strip (t=4.4 mm) was annealed at 400 °C for 1 h followed by air cooling, warm rolled (t=2.0 mm) at 250 °C, and subsequently re-annealed. In order to determine the effect of thickness reduction and heat treatment temperature on the recrystallization behavior, the annealed sheets were cold rolled with thickness reduction of 20% (t=1.6 mm), 40% (t=1.2 mm), and 60% (t=0.8 mm). And then, the cold rolled sheets were heat treated at 400, 450, and 500 °C for 1 h followed by water quenching, respectively. The fabrication procedures and conditions of sheet samples are summarized in Fig. 1.

All sheet samples for optical microscopy were sectioned, polished and then electrolytic etched in 5% fluoroboric acid for 60 s. The average grain size and average grain aspect ratio (rolling direction, RD/normal direction, ND) were measured from micrographs observed on the transverse direction (TD) plane using an image analyzer. In addition, the tensile tests were carried out at the angles of 0 (RD), 45° and 90° (TD) to the rolling direction at room temperature using an universal testing machine with a crosshead speed of 1.0 mm/min according to the ASTM E8M standard.

3 Results and discussion

3.1 As-cast Al-Zn-Mg-Cu strip

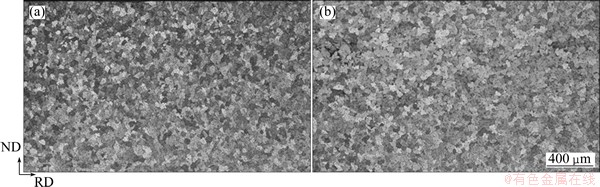

The Al-Zn-Mg-Cu alloy strip was successfully obtained by TRC, and its microstructure observed on the TD plane consisted of fine and homogenous grains compared with the conventional DC casting [10] as shown in Fig. 2. The average grain size at the vicinity of the surface (~39 μm) was smaller than that of the center (~41 μm). This microstructural gradient is related with the temperature distribution during TRC, which is lower near the subsurface because of direct contact with water cooled casting rolls [9].

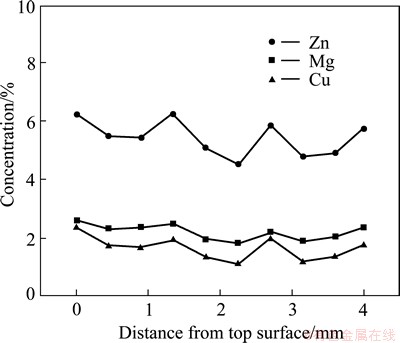

Figure 3 shows the SEM-EDS results through the thickness direction of the as-cast Al-Zn-Mg-Cu strip. It is observed that the solute elements, such as Zn, Mg and Cu, are more near subsurface region compared to the center. In order to obtain the sheets for cold rolling, as mentioned above, the as-cast Al-Zn-Mg-Cu alloy strip was annealed, warm rolled, and re-annealed.

3.2. Microstructures of thermo-mechanical treated Al-Zn-Mg-Cu strip

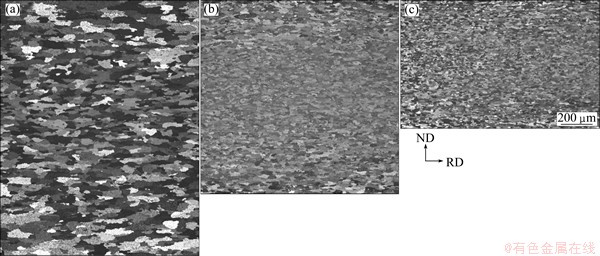

Figure 4 shows the microstructures observed on the TD plane of the cold rolled sheets with thickness reduction of 60% and subsequently heat treated at various temperatures for 1 h. When the sheets were heat treated at 400 °C for 1 h, the grains of the subsurface were relatively coarse and elongated compared with that in the center, as shown in Fig. 4(a). However, the microstructural gradient between the subsurface and the center decreased with increasing heat treatment temperature, as shown in Fig. 4(c).

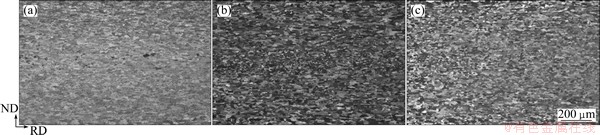

Figure 5 shows the microstructures observed on the TD plane of the sheets cold rolled with different thickness reduction and subsequently heat treated at 500 °C for 1 h. Even if heat treatment was carried out at 500 °C for 1 h, the grains of the subsurface were coarse and elongated compared with that in the center if the thickness reduction was low as shown in Fig. 5(a). Moreover, such differences were large enough compared with the microstructures of the as-cast strip as shown in Fig. 2. However, the microstructural gradient between the subsurface and the center decreased with increasing the thickness reduction as shown in Fig. 5(c).

Fig. 1 Schematic showing procedures and conditions used in this study

Fig. 2 Microstructures of as-cast Al-Zn-Mg-Cu strip observed at vicinity of surface (a) and in center (b)

Fig. 3 EDS quantitative analysis through thickness direction of as-cast Al-Zn-Mg-Cu strip

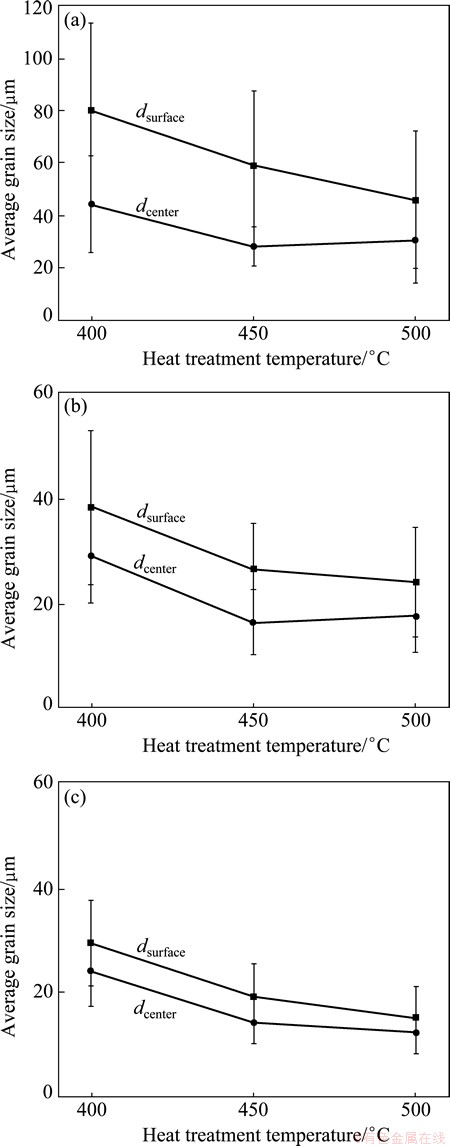

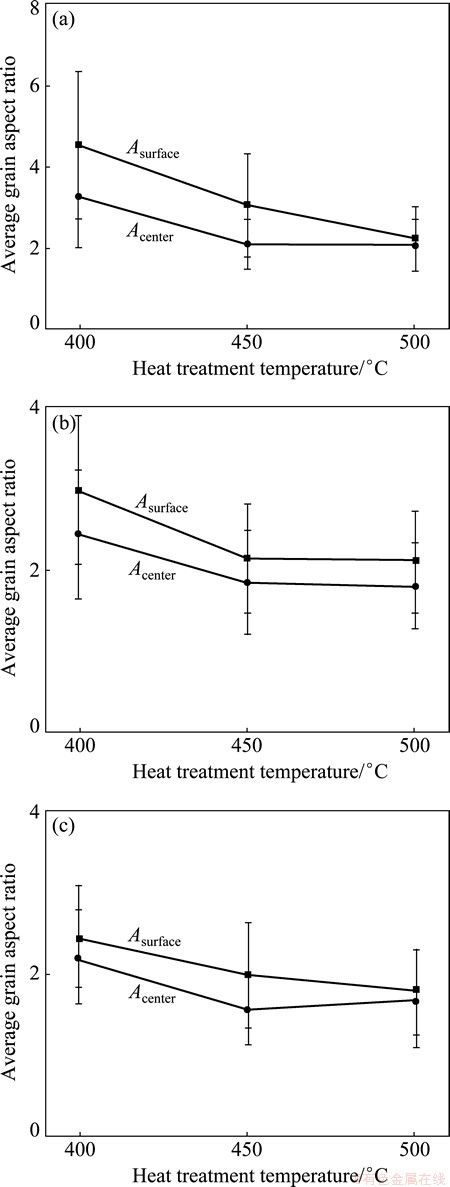

The average grain size (dsurface, dcenter) and average grain aspect ratio (Asurface, Acenter) of cold rolled sheets gradually decreased with increasing the thickness reduction and heat treatment temperature as shown in Figs. 6 and 7, respectively. It is well known that the minimum stored energy is needed to initiate recrystallization and the recrystallized grain size depends on the amount of deformation, smaller with increasing amount of deformation. Also, the temperature at which recrystallization occurs increases as stored energy decreases [11]. Therefore, sufficient thickness reduction and heat treatment temperature are needed for obtaining fine and homogenous microstructure by recrystallization. However, as mentioned above, there are microstructural inhomogeneities through the thickness direction of sheets. The d and A at the vicinity of the center (dcenter, Acenter) remains relatively stable by changing the thickness reduction and heat treatment temperature compared with subsurface (dsurface, Asurface). These results confirm that the recrystallization behavior for a given amount of deformation is different through the thickness direction of sheets.

Fig. 4 Microstructures of sheets cold rolled with thickness reduction of 60% and subsequently heat treated at 400 °C (a), 450 °C (b), and 500 °C (c) for 1 h followed by water quenching

Fig. 5 Microstructures of sheets cold rolled with thickness reduction of 20% (a), 40% (b), and 60% (c) and subsequently heat treated at 500 °C for 1 h followed by water quenching

Fig. 6 Variations of average grain size with respect to heat treatment temperature of cold rolled sheets with thickness reduction of 20% (a), 40% (b) and 60% (c)

It was reported that the microstructural gradient is significantly related to the amount and size of second phase particles [7,12]. During TRC, concentration of the alloying elements is different from surface to center [13]. Especially, the relatively high zinc and magnesium concentrations at the strip subsurface as shown in Fig. 3 will enhance the precipitation of MgZn2 between the processes used in this study by natural aging. Moreover, despite of a high cooling rate of TRC, there is temperature gradient through the thickness direction, which can cause gradient of the second phase particle size [7]. It is well known that fine particles prevent recrystallization by pinning grain boundaries while coarse particles cause recrystallization by acting as nucleation sites [11]. Therefore, in order to eliminate the microstructural gradient in Al-Zn-Mg-Cu alloy sheet fabricated by TRC and post thermo-mechanical processes, more enough stored energy and temperature to overcome the grain boundary pinning were needed. Consequently, the fine and homogenized microstructure (d ~13 μm, A ~1.7) from surface to center was obtained by cold rolling with thickness reduction of 60% and heat treatment at 500 °C for 1 h.

Fig. 7 Variations of average grain aspect ratio (A) with respect to heat treatment temperature of cold rolled sheets with thickness reduction of 20% (a), 40% (b) and 60% (c)

3.3 Mechanical properties of thermo-mechanical treated Al-Zn-Mg-Cu strip

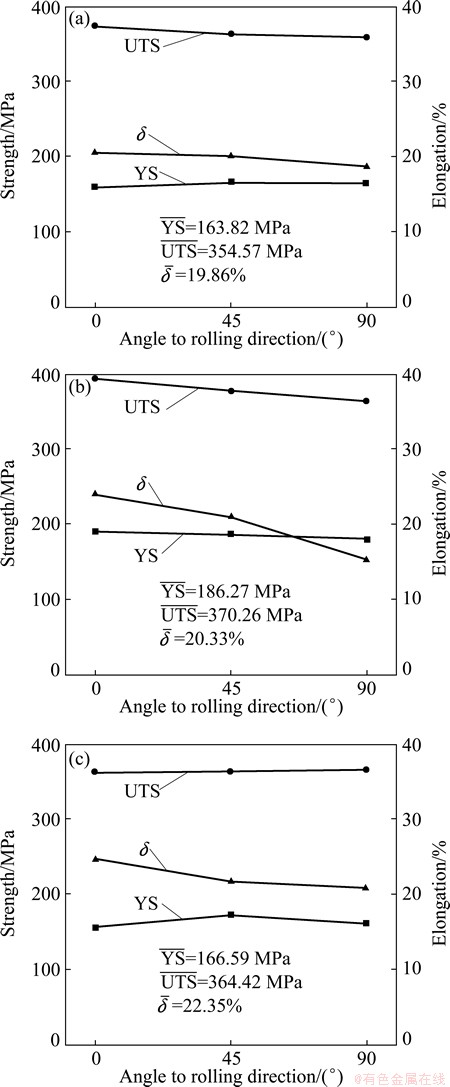

In order to evaluate the effect of recrystallized microstructure on mechanical properties of Al-Zn-Mg- Cu strip, the tensile properties of samples cold rolled with thickness reduction of 20%, 40%, 60% and subsequently heat treated at 500 °C for 1 h were measured as shown in Fig. 8. There was no significant change of the mechanical properties at the angles of 0, 45° and 90° to the rolling direction for each sheet. However, the average mechanical properties ( ,

, ,

,  ) were changed by increasing thickness reduction. It is observed that the average yield strength (

) were changed by increasing thickness reduction. It is observed that the average yield strength ( ) and ultimate tensile strength (

) and ultimate tensile strength ( ) were improved up to 40% and slightly decreased at 60% of thickness reduction. Meanwhile, the average elongation (

) were improved up to 40% and slightly decreased at 60% of thickness reduction. Meanwhile, the average elongation ( ) was gradually improved with an increase in thickness reduction as fine and homogenized microstructure is achieved [14,15]. Consequently, improved mechanical properties (UTS≥360 MPa, δ≥20%) can be obtained through the proper thermo-mechanical process for Al-Zn-Mg-Cu alloy sheet fabricated by TRC.

) was gradually improved with an increase in thickness reduction as fine and homogenized microstructure is achieved [14,15]. Consequently, improved mechanical properties (UTS≥360 MPa, δ≥20%) can be obtained through the proper thermo-mechanical process for Al-Zn-Mg-Cu alloy sheet fabricated by TRC.

Fig. 8 Mechanical properties of sheets cold rolled with thickness reduction of 20% (a), 40% (b) and 60% (c) and subsequently heat treated at 500 °C for 1 h followed by water quenching

4 Conclusions

The effect of thermo-mechanical treatment on the recrystallization behavior related to the microstructure and mechanical properties of Al-Zn-Mg-Cu alloy sheet fabricated by twin roll casting was investigated. The Al-Zn-Mg-Cu alloy sheet with microstructural homogeneity (d ~13 μm, A ~1.7) from surface to center and high mechanical properties (UTS ≥360 MPa, δ ≥20%) can be successfully fabricated by twin roll casting and proper thermo-mechanical process. The optimum condition to eliminate the microstructural gradient was cold rolling with thickness reduction of 60% and heat treatment at 500 °C for 1 h. The results can be used effectively to perform reasonable post process of the Al-Zn-Mg-Cu alloy strip fabricated by twin roll casting. Consequently, the low cost and high strength Al-Zn-Mg-Cu alloy sheet can be fabricated by twin roll casting with proper thermo-mechanical processes.

Acknowledgments

This research was supported by a grant from the Korea Institute of Materials Science (Project No. PNK 3250).

References

[1] MILLER W S, ZHUANG L, BOTTEMA J, WITTEBROOD A J, SMET P D, HASZLER A, VIEREGGEC A. Recent development in aluminum alloys for the automotive industry [J]. Material Science and Engineering A, 2000, 280(1): 37-49.

[2] CUI J R, ROVEN H J. Recycling of automotive aluminum [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(11): 2057-2063.

[3] HAGA T, SUZUKI S. A high speed twin roll caster for aluminum alloy strip [J]. Journal of Materials Processing Technology, 2001, 113(1-3): 291-295.

[4] YUN M, LOKYER S, HUNT J D. Twin roll casting of aluminum alloys [J]. Materials Science and Engineering A, 2000, 280(1): 116-123.

[5] KIM M S, KUMAI S. Effect of Si content on strip thickness and solidified structure in high-speed twin-roll cast Al-Si alloy strips [J]. Materials Transactions, 2011, 52(5): 856-861.

[6] HAGA T, TKAHASHI K, IKAWAAND M, WATARI H. Twin roll casting of aluminum alloy strips [J]. Journal of Materials Processing Technology, 2004, 153-154(1-3): 42-47.

[7] SUN N Y, PATTERSON B R, SUNI J P, SIMIELLI E A, WEILAND H, ALLARD L F. Microstructural evolution in twin roll cast AA3105 during homogenization [J]. Material Science and Engineering A, 2006, 416(1-2): 232-239.

[8] CHEN Zhong-wei, LI Shi-shun, ZHAO Jing. Homogenization of twin-roll cast A8006 alloy [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(6): 1280-1285.

[9] DAS S, LIM N S, SEOL J B, KIM H W, PARK C G. Effect of the rolling speed on microstructural properties of aluminum-magnesium alloys prepared by twin roll casting [J]. Materials and Design, 2010, 31(3): 1633-1638.

[10] HAGHAYEGHI R, ZOQUI E J, GREEN N R, BAHAI H. An investigation of DC casting of a wrought aluminum alloy at below liquidus temperature by using melt conditioner [J]. Journal of Alloys and Compounds, 2010, 502(2): 382-386.

[11] HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. 2nd ed. Oxford: Elsevier Publishers, 2004: 391-392.

[12] BERG B S, HANSEN V, ZAGIERSKI P T, NEDREBERG M L, OLSEN A,  J. Gauge reduction in twin-roll casting of an AA5082 aluminum alloy: The effects on microstructure [J]. Journal of Materials Processing Technology, 1995, 53(1-2): 65-74.

J. Gauge reduction in twin-roll casting of an AA5082 aluminum alloy: The effects on microstructure [J]. Journal of Materials Processing Technology, 1995, 53(1-2): 65-74.

[13] PARK S S, BAE G T, KANG D H, JUNG I H, SHIN K S, KIM N J. Microstructure and tensile properties of twin-roll cast Mg-Zn-Mn- Al alloys [J]. Scripta Materialia, 2007, 57(9): 793-796.

[14] DAS S, LIM N S, KIM H W, PARK C G. Effect of heat treatment on microstructure and mechanical properties of twin roll casted Al-5.5Mg-0.02Ti alloy [J]. Materials and Design, 2010, 31(6): 3111-3115.

[15] KIM H W, LIM C Y. Annealing of flexible-rolled Al-5.5wt%Mg alloy sheets for auto body application [J]. Materials and Design, 2010, 31(S1): s71-s75.

基于双辊铸轧的Al-Zn-Mg-Cu系合金冷轧后的再结晶行为

Yun-Soo LEE, Won-Kyoung KIM, Dong-A JO, Cha-Yong LIM, Hyoung-Wook KIM

Light Metals Division, Korea Institute of Materials Science, Changwon 642-831, Korea

摘 要:将双辊铸轧运用于制造Al-Zn-Mg-Cu合金带材。研究带材减薄率及热处理温度对合金再结晶行为的影响。结果表明:在冷轧率为60%、热处理制度为500 °C的条件下处理1 h时,合金带材具有细晶组织(平均晶粒尺寸约为13 μm,晶粒纵横比约为1.7)和高的力学性能(UTS≥360 MPa,δ≥20%)。研究了微观组织对Al-Zn-Mg-Cu合金带材力学性能的影响。合适的双棍铸轧热处理及加工工艺能制造低价、高强的Al-Zn-Mg-Cu合金带材。

关键词:Al-Zn-Mg-Cu合金;双辊铸造;冷轧;再结晶

(Edited by Hua YANG)

Corresponding author: Hyoung-Wook KIM; Tel: +82-55-2803307; Fax: +82-55-2803599; E-mail: hwkim@kims.re.kr

DOI: 10.1016/S1003-6326(14)63337-9