文章编号:1004-0609(2010)S1-s0927-03

TC18钛合金棒材组织与探伤的关系

乔恩利,冯永琦,李渭清,何书林

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:通过对不同锻造和热处理工艺方案得到的d100 mm TC18钛合金棒材组织和探伤结果进行研究,找出不同工艺方案得到的显微组织所对应探伤水平的变化规律。结果表明:不同工艺方案得到的典型组织,对应探伤结果存在较大差异;特别是在组织类型均为α+β两相区加工组织的情况下,随着显微组织形貌和大小的变化,探伤杂波水平发生明显变化。

关键词:TC18钛合金;显微组织;探伤

中图分类号:TG146.2+3 文献标志码:A

Relationship between microstructure and inspection for TC18 titanium alloy bar

QIAO En-li1, FENG Yong-qi2, LI Wei-qing2, HE Shu-lin2

(Baoji Titanium Industry Co., Ltd, Baoji 721014, China)

Abstract: By studying the microstructures and inspection results of d100 mm TC18 titanium alloy bar produced by different forging and heat treatment process, the variation rule of ultrasonic level corresponding to microstructures obtained by different process scheme was found. The results show that the typical microstructures obtained by different process schemes have a great effect on inspection results. Especially the microstructure type is two phase α+β region processing structure. With the variation of the microstructure morphologies and size, the ultrasonic clutter level is changed significantly.

Key words: TC18 titanium alloy; microstructure; inspection

TC18钛合金名义成分为Ti-5Al-5Mo-5V-1Cr- 1Fe,是一种具有高强和高冲击韧性的钛合金。合金的优点是在退火状态下具有很高的强度(1 080 MPa),采用强化处理后强度可达1 300 MPa[1],且其淬透性好,截面淬透厚度可达250 mm。由于截面厚度不受淬透性限制,特别适合制造飞机大型承力构件。采用普通低成本模锻(在模锻锤上进行)、热模锻和等温模锻等多种工艺生产出接近最终形状的锻件。该合金在伊尔76等飞机上获得了大量应用。

本文作者对TC18钛合金铸锭经β区开坯,然后采用4种不同锻造工艺和热处理工艺[2]处理,得到该合金d100 mm棒材不同的显微组织。对不同工艺方案所对应棒材探伤结果进行对比分析,最终获得TC18钛合金最佳探伤结果的锻造工艺。

1 实验

实验材料采用宝钛集团有限公司真空自耗电弧炉经3次熔炼的3 000 kg铸锭,其主要化学成分为(质量分数,%):Ti-5Al-5Mo-5V-1Cr-1Fe,(α+β)/β转变温度为860~870 ℃。

铸锭经3 150 t水压机在β区开坯锻造,再通过4种不同工艺(工艺1~4)进行锻造、热处理和机加等,最终制成d100 mm的棒材。对4种不同工艺制成的棒材分别取样,进行显微组织分析和探伤检验,对所得显微组织和探伤结果进行对比分析。实验过程中探伤均采用大平底孔计算方法进行,探伤仪器均使用国产仪器和5M国产探头。

2 结果与分析

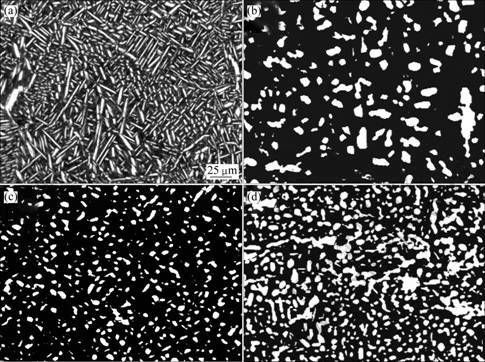

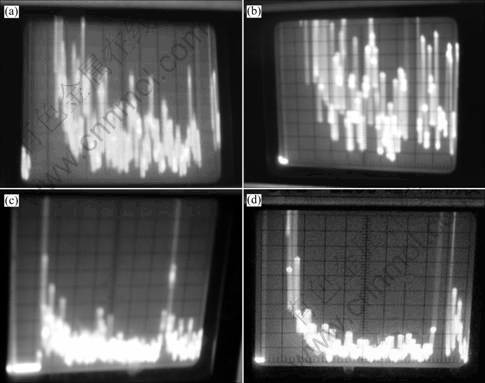

对4种不同工艺方案生产出的d100 mm棒材,取样进行相同的热处理制度处理后,其显微组织如图1所示。对4种不同工艺方案所对应棒材分别进行探伤检验,其结果如图2所示。

2.1 不同工艺方案得到的d100 mm棒材的显微组织

由图1可以看出,方案1得到均匀细小的网篮组织,方案2~4均得到典型的α+β两相区加工组织,但3种α+β两相区加工组织中的β组织含量与晶粒大小均有较明显的差异。对3种方案所得到的不同形貌α+β两相区加工组织对比分析可以看出,方案2所得到的α+β两相区加工组织,其β组织含量最多(约80%),且与另外2种工艺方案得到的α+β两相区加工组织相比,其晶粒尺寸明显较大。方案3所得到的α+β两相区加工组织,其β组织含量也相对较多(约60%),但其晶粒尺寸相对方案2的均匀细小一些。方案4所得的α+β两相区加工组织,其β组织含量最少(约20%~30%),其晶粒尺寸特别均匀细小。

2.2 不同工艺方案所得棒材对应的探伤结果

对4种不同工艺方案所得到的TC18钛合金d100 mm棒材,使用相同的国产探伤仪器,相同的国产探头,采用相同的探伤方法(大平底计算法)进行探伤,各自所对应的探伤结果如下(如图2所示):工艺1 为d1.2-3 db;工艺2为d1.2-0 db;工艺3为d1.2-9 db;工艺4为d1.2-12 db。

探伤结果由差至好顺序为:工艺2、工艺1、工艺3、工艺4。

经过对4种工艺方案所得显微组织及对应探伤结果分析可以看出,工艺1为均匀细小的网篮组织,所对应探伤结果为d1.2-3 db,探伤水平差于α+β两相区加工组织的整体水平。工艺2~4虽然均为α+β两相区加工组织,但探伤结果却存在较大差异。特别是工艺2和工艺4所得探伤结果相比,其杂波水平相差12 db。经过对工艺2~4所得显微组织分析认为,工艺2所得α+β两相区加工组织中,由于β组织含量很多(约80%),且晶粒尺寸较大,在探伤过程中,底波被大量

图1 不同锻造工艺所对应棒材的显微组织

Fig.1 Microstructures of bars prepared by different forging processes: (a) Process 1; (b) Process 2; (c) Process 3; (d) Process 4

图2 不同锻造工艺所对应棒材的探伤结果

Fig.2 Inspection results of bars prepared by different forging processes: (a) Process 1; (b) Process 2; (c) Process 3; (d) Process 4

的β组织吸收,再加上晶粒尺寸较大,对杂波影响较明显,因此,工艺2所得棒材探伤结果最差。工艺3与工艺2相比,其β组织含量要少一些,但也达到了60%,β组织对探伤底波的影响依然较大,但由于晶粒尺寸相对工艺2的要均匀细小一些,因此,其杂波水平明显优于工艺2的,达到d1.2-9 db的探伤水平。工艺4所得的α+β两相区加工组织,其β组织含量最少(达到20%~30%),且其晶粒尺寸均匀细小,因此,β组织对探伤底波吸收最少,且由于晶粒均匀细小,因此,所得到的探伤水平最好,达到d1.2-12 db。

3 结论

1) 不同锻造和热处理工艺得到不同的显微组织,其对应探伤结果也存在较大差异。

2) 不同β组织(包括组织形态、尺寸大小和均匀性等)对探伤结果的影响明显。特别是在组织类型相同(均为α+β两相区加工组织)的条件下,β组织含量越少、晶粒尺寸越均匀细小,棒材的探伤效果越好。

REFERENCES

[1] 李青云. 稀有金属材料加工手册[M]. 北京: 冶金工业出版社, 1984.

LI Qing-yun. Processing handbook for rare metal material[M]. Beijing: Metallurgical Industry Press, 1984.

[2] 沙爱学, 王庆如, 李兴无. 高强度结构钛合金[J]. 稀有金属, 2004, 28(1): 54-58.

SHA Ai-xue, WANG Qing-ru, LI Xing-wu. A high strength structure of titanium alloy[J]. Rare Metal Letters, 2004, 28(1): 54-58.

(编辑 陈爱华)

通信作者:乔恩利;电话:13892428968;E-mail: qiao20091230@163.com