文章编号:1004-0609(2010)S1-s0598-04

BTi62钛合金退火温度与组织和性能的关系

陈秉刚,李渭清,董 洁,杨慧丽,张 辉,孙小勇

(宝鸡钛业股份有限公司,宝鸡 721014)

摘 要:研究了退火温度对BTi62钛合金棒材显微组织及室温、高温力学性能的影响。研究表明:BTi62钛合金棒材在700~870 ℃退火,显微组织均由βT+等轴α组成,随着退火温度的升高,室温强度降低,室温塑性略有提高,高温抗拉强度、断面收缩率略有升高,屈服强度、伸长率无明显变化。与目前国内使用的同规格TC4钛合金棒材相比,BTi62合金具有略优于TC4钛合金的室温、高温拉伸性能。

关键词:BTi62钛合金;热处理制度;显微组织;力学性能

中图分类号:TG 146.2 文献标志码:A

Relationship between annealing temperature and microstructure and properties of BTi62 titanium alloy

CHEN Bing-gang, LI Wei-qing, DONG Jie, YANG Hui-li, ZHANG hui, SUN Xiao-yong

(Baoji Titanium Industry Co., Ltd., Baoji 721014, China)

Abstract: The effects of annealing temperature on the microstructure, room temperature and high temperature mechanical properties of BTi62 titanium alloy bars were studied. The results show that the microstructure of the alloy is composed of transformed β-phase and equiaxed α phase when BTi62 titanium alloy rods are annealed in the temperature range of 700-870 ℃. With the increase of annealing temperature, its room temperature strength decreases, room temperature ductility increases little, high-temperature tensile strength and area shrinkage slightly increase, while yield strength and elongation have no clear change when it is annealed in the range of 780-870 ℃. Compared with TC4 titanium alloy bars of the same specifications in domestic at present, BTi62 alloy has slightly better tensile properties at room and high temperatures.

Key words: BTi62 titanium alloy; heat treatment; microstructure; mechanical properties

BTi62钛合金是宝钛集团在工业化条件下研制的一种近α型Ti-Al-Mo-Fe系新型宇航用钛合金。该合金中Al元素的加入不但减小密度、细化晶粒而且起到固溶强化α-Ti相的作用;β相稳定元素Mo的加入对合金起到固溶强化的作用,并使钛合金组织稳定性变好;为进一步稳定β相,加入了稳定能力更强的Fe元素,考虑到Fe元素在β相中的有限溶解及作为沉淀型慢共析元素的特点,只加入了少量的Fe元素[1]。

组织与性能密切相关[2],因此,本文作者通过选择不同的退火温度研究BTi62钛合金的显微组织与室温、高温拉伸性能的变化规律,并将实验结果与目前国内大量使用的TC4钛合金进行对比分析,为该合金的使用提供实验数据。

1 实验

1.1 实验材料

实验采用宝钛集团真空自耗电弧炉3次熔炼的BTi62钛合金铸锭。将铸锭在β区和(α+β)区多火次锻造成d27.5 mm棒材,用金相法测得该合金相变点(α+β/β)为1 000~1 020 ℃。

1.2 实验方法

从棒材上切取试样,分别在700、750、780、800和870 ℃加热保温1.5 h后空冷。对热处理后的试样分别进行显微组织观察及室温、高温力学性能测试。试样经配比为V(HF):V(HNO3):V(H2O)=1:3:10金相腐蚀剂腐蚀后,在OLYMPUS GX71型光学显微镜上进行显微组织分析,室温、高温力学性能测试均在INSTRON5581型万能电子材料试验机上进行。

2 结果与分析

2.1 退火温度对显微组织的影响

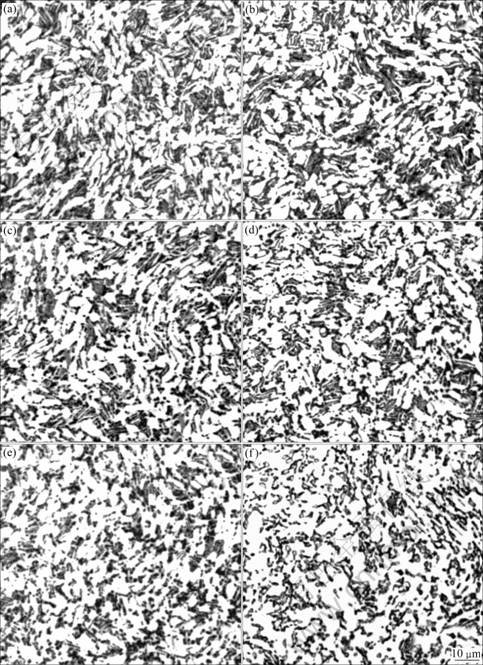

BTi62钛合金棒材锻态及经不同温度退火后的显微组织如图1所示。从图1可以看出:棒材经700~870 ℃退火处理后,均为βT+等轴α组织。在700~800 ℃,随着退火温度的升高,锻造变形时产生的拉长α相球化趋势不明显;当退火温度达到870 ℃时,组织发生较明显改变,初生α相球化及长大明显,说明该合金的再结晶温度在870 ℃左右。

图1 锻态及经不同温度退火后BTi62钛合金的显微组织

Fig.1 Microstructures of BTi62 titanium alloy under rolling state and after annealing at different temperatures: (a) Rolling state; (b) 700 ℃, 1.5 h, AC; (c) 750 ℃, 1.5 h, AC; (d) 780 ℃, 1.5 h, AC; (e) 800 ℃, 1.5 h, AC; (f) 870 ℃, 1.5 h, AC

该合金与TC4钛合金具有相似的化学组成。由钛-钒系二元相图可以看出:在固态发生的转变与钛-钼系完全相同,钼、钒与β钛合金具有同一晶格类型,这就决定了该合金具有和TC4极为相似的组织与性能。TC4再结晶起始温度为850 ℃,结束温度为 950 ℃[3],进一步验证了BTi62合金的再结晶温度在870 ℃左右。

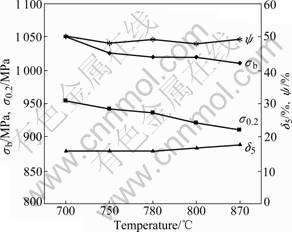

2.2 退火温度对室温力学性能的影响

BTi62钛合金棒材经不同退火温度处理后的室温力学性测试结果见图2。从图2可以看出:该合金在700~870 ℃范围内退火时,随着退火温度的升高,室温强度降低(抗拉强度σb降低约4.7%,屈服强度σ0.2降低约4.72%),塑性(伸长率δ5、断面收缩率ψ)略有提高。在该温度范围退火的BTi62合金具有抗拉强度σb≥1 010 MPa,屈服强度σ0.2≥910 MPa,伸长率 δ5≥16%,断面收缩率ψ≥45%的室温拉伸性能,说明该合金在700~870 ℃退火,具有强度与塑性匹配较好的室温拉伸性能。

图2 退火温度对BTi62钛合金棒材室温拉伸性能的影响

Fig.2 Effects of annealing temperature on room temperature tensile properties of BTi62 titanium alloy

2.3 退火温度对高温力学性能的影响

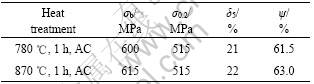

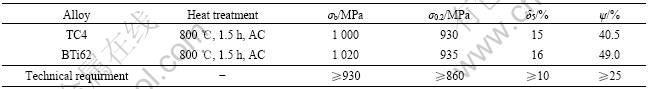

BTi62钛合金棒材经780 ℃和870 ℃两种退火温度处理后500℃高温力学性测试结果见表1。

表1 经不同退火制度处理的BTi62合金的500 ℃高温拉伸性能

Table 1 Effect of different heat treatment schedule on 500 ℃ high temperature tensile properties of BTi62 alloy

由表1可以看出:870 ℃退火试样的500 ℃高温抗拉强度、伸长率及断面收缩率均略高于780 ℃热处理试样的测试结果,屈服强度相同。

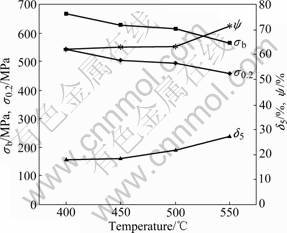

针对以上结果,进行了试样870 ℃退火后的400~550 ℃的高温拉伸性能测试,测试结果如图3所示。由图3可以看出:测试温度升高,强度降低,塑性升高,合金在400~550 ℃高温下具有抗拉强度σb≥565 MPa,屈服强度σ0.2≥460 MPa,伸长率δ5≥18%和断面收缩率ψ≥62%的高温拉伸性能。

图3 BTi62合金经870 ℃退火后的高温拉伸力学性能

Fig.3 High-temperature tensile properties of BTi62 alloy after annealing at 870 ℃

2.4 BTi62钛合金与TC4钛合金力学的性能对比

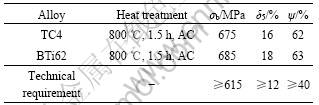

同规格TC4钛合金与BTi62钛合金棒材拉伸性能测试结果见表2和表3。

由表2和表3可以看出:BTi62钛合金棒材在700~870 ℃热处理,具有满足航空结构产品GJB493—88技术条件要求的室温和高温拉伸性能,且该合金具有与TC4钛合金相当的室温、高温拉伸性能。该合金与TC4钛合金的相似的成分组成以及组织结构决定了两种合金具有相似的力学性能。

表2 同规格 TC4与BTi62钛合金的室温拉伸性能对比

Table 2 Room-temperature mechanical properties of TC4 and BTi62 titanium alloy bars at 20 ℃

表3 同规格 TC4与BTi62钛合金的高温拉伸性能对比

Table 3 High-temperature mechanical properties of TC4 and BTi62 titanium alloy bars at 400 ℃

3 结论

1) BTi62钛合金棒材在700~870 ℃退火,显微组织均由βT+等轴α组成。随着退火温度的升高,室温强度略有降低,塑性略有提高,具有强度与塑性匹配较好的室温拉伸性能。

2) BTi62钛合金棒材400~550 ℃高温拉伸测试结果显示,随着测试温度的升高,强度降低,塑性升高,具有抗拉强度σb≥565 MPa,屈服强度σ0.2≥460 MPa,伸长率δ5≥18%,断面收缩率ψ≥62%的高温拉伸 性能。

3) BTi62钛合金具有略优于TC4钛合金的室温、高温力学性能。

REFERENCES

[1] 张喜燕, 赵永庆, 白晨光. 钛合金及应用[M]. 北京: 化学工业出版社, 2005.

ZHANG Xi-yan, ZHAO Yong-qing, BAI Chen-guang. Titanium alloys and their applications[M]. Beijing: Chemical Industry Press, 2005.

[2] 张利军, 田军强, 周中波, 寇宏超, 朱知寿. 热处理制度对TC21钛合金锻件组织及力学性能的影响[J]. 中国材料进展, 2009, 28(9/10): 84-87.

ZHANG Li-jun, TIAN Jun-qiang, ZHOU Zhong-bo, KOU Hong-chao, ZHU Zhi-shou. Effects of heat treatment on microstructures and mechanical performances of TC21 titanium alloy forgings [J]. Materials China, 2009, 28(9/10): 84-87.

[3] 王金友, 葛志明, 周彦邦. 航空用钛合金[M]. 上海: 上海科学技术出版社, 1985.

WANG Jin-you, GE Zhi-ming, ZHOU Yan-bang. Titanium alloy for aerospace [M]. Shanghai: Shanghai Science and Technology Publishing House, 1985.

(编辑 杨 兵)

通信作者:陈秉刚; 电话:0917-3386921; E-mail: chenbinggang@163.com