文章编号:1004-0609(2013)05-1248-07

热浸渗铝球墨铸铁合金层组织的演变规律

陈 江,赵君文,黄兴民,程 乾,韩 靖,张 鲲,戴光泽

(西南交通大学 材料科学与工程学院,成都 610031)

摘 要:为了探索热浸渗铝球墨铸铁合金层的组织演变规律以及基体中Ni含量对渗铝合金层组织的影响,利用激光共聚焦显微镜(LCM)、场发射扫描电子显微镜(FESEM)以及能谱仪(EDS)对不同渗铝时间制备的球墨铸铁渗铝试样以及不同Ni含量的球墨铸铁渗铝试样的合金层组织进行观察和定量分析。结果表明:在本实验条件下,热浸渗铝球墨铸铁合金层组织由厚度较大的“舌状”Fe2Al5和厚度很小的FeAl3组成,合金层和表面纯铝层中存在石墨球分布;在0~15 min内,渗铝试样合金层经过短暂的过渡阶段后随渗铝时间的延长按抛物线规律扩散生长,15 min后合金层厚度达65 μm以上;基体Ni含量由0增加至1.5%(质量分数)后,合金层厚度由88 μm减小至49 μm,合金层与基体的“舌状”界面程度变小。此外,对热浸渗铝球墨铸铁合金层组织演变机理进行了探讨。

关键词:球墨铸铁;热浸渗铝;组织演变;Ni含量

中图分类号:TG174.443 文献标志码:A

Microstructure evolution of intermetallic layer of hot dip aluminized ductile cast iron

CHEN Jiang, ZHAO Jun-wen, HUANG Xing-min, CHENG Qian, HAN Jing, ZHANG Kun, DAI Guang-ze

(School of Materials Science and Engineering, Southwest Jiaotong University, Chengdu 610031, China)

Abstract: To study the microstructure evolution of intermetallic layer of hot dip aluminized ductile cast iron and the effect of Ni content on the microstructure of the intermetallic layer, laser confocal microscope (LCM), field emission scanning electron microscope (FESEM) and X-ray energy dispersive spectrometer (EDS) were used to carry out the microstructure observation and quantitative analysis of the intermetallic layer of hot dip aluminized ductile cast iron with different hot-dip times as well as specimens with different Ni contents. The results show that the intermetallic layer consists of a “tongue-shape” Fe2Al5 layer and a FeAl3 layer of which the thickness is much thinner than that of the former. At the same time, graphite spheroids disperse in the outer Al topcoat and the inner Fe-Al intermetallic layer; within 0-15 min, the growth rate of the intermetallic layer approximately obeys the parabolic rate law after a short transition phase, and the layer is thicker than 65 μm after 15 min. Furthermore, the thickness of the intermetallic layer decreases from 88 to 49 μm with the increase of Ni content from 0 to 1.5% (mass fraction), and the “tongue-shape” interface between the substrate and Fe2Al5 phase becomes smooth. In addition, the microstructure evolution of intermetallic layer of hot dip aluminized ductile cast iron was also discussed.

Key words: ductile cast iron; hot dip aluminizing; microstructure evolution; nickel content

钢铁材料经热浸渗铝后在试样表面形成保护层,能显著提高其抗高温氧化及抗热腐蚀性能等[1-3]。与相似力学性能相似的钢材相比,球墨铸铁易加工、减震性能好、生产成本低,可以通过加入Al、Si、Cr和Ni等元素来提高球墨铸铁的抗高温氧化及耐腐蚀性能,使其可以在高温环境下应用。而通过热浸渗铝达到以上目的的工艺成本更低,并可大幅度提高零件高温耐蚀性能及工作温度。因此,球墨铸铁渗铝工艺在石油化工、锅炉配件等领域具有广阔的应用前景。

钢件热浸渗铝工艺的大量研究表明,基体成分和组织对渗铝合金层的组织特征和组织演化过程有着重要影响[3-13] 。由于球墨铸铁的成分和微观组织与钢的显著不同,所以其热浸渗铝后的合金层微观组织及演化过程必然与钢的不同,而目前尚无此方面的系统研究。同时,铸铁中加入Ni可以改善材料的力学性能及耐蚀性能,但基体中Ni对热浸渗铝合金层组织影响尚缺乏研究。为此,本文作者对球墨铸铁的合金层组织演变规律以及Ni含量对合金层组织的影响进行研究,为球墨铸铁渗铝工艺的应用奠定基础。

1 实验

实验所用基体材料为不同Ni含量(0,0.5%, 0.7%,0.9%,1.5%,质量分数)的球墨铸铁,试样尺寸为20 mm×10 mm×2 mm,热浸渗铝所用纯铝为工业纯铝(纯度≥99.5%)。利用OBLF-QSN-750型电火花直读光谱仪和CS-8800C高频红外碳硫分析仪对球墨铸铁和纯铝的化学成分进行检测,结果如表1所列。

表1 球墨铸铁试样及纯铝的主要化学成分

Table 1 Chemical compositions of ductile cast iron samples and pure aluminum

采用VK-9710型激光共聚焦显微镜和JSM-7001F场发射扫描电子显微镜观察热浸渗铝球墨铸铁合金层的微观组织及合金层厚度。

未添加Ni的球墨铸铁试样在恒温750 ℃下热浸渗铝时间分别为0.5、1、2、5、8、10、12和15 min;不同Ni含量(0,0.5%,0.7%,0.9%,1.5%)的球墨铸铁在770 ℃下热浸渗铝12 min,通过测量合金层的厚度并结合微观组织观察分别研究合金层的组织演变规律及Ni含量对球墨铸铁热浸渗铝合金层的影响。

2 结果与讨论

2.1 球墨铸铁热浸渗铝合金层的微观组织

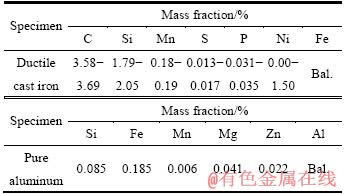

以不含Ni的球墨铸铁试样作为基体材料,对于恒温750 ℃下热浸渗铝的球墨铸铁试样,不管渗铝时间长短,都可以观察到如图1(a)所示的典型微观组织:合金层由厚度较大且呈“舌状”的Fe2Al5(与基体邻近的一层)和厚度很小的FeAl3(与纯铝层邻近的一层)组成;而不均匀分布在表面纯铝层中的针杆状化合物通过EDS分析也为FeAl3相。另外,热浸渗铝球墨铸铁特有的一个现象则是在纯铝层与合金层中均出现了石墨球。

图1 热浸渗铝球墨铸铁合金层的EDS谱

Fig. 1 EDS spectra of hot dip aluminized ductile cast iron

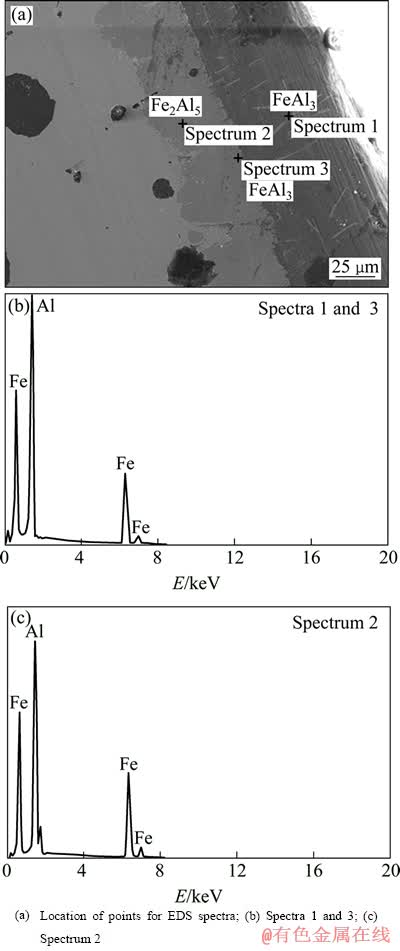

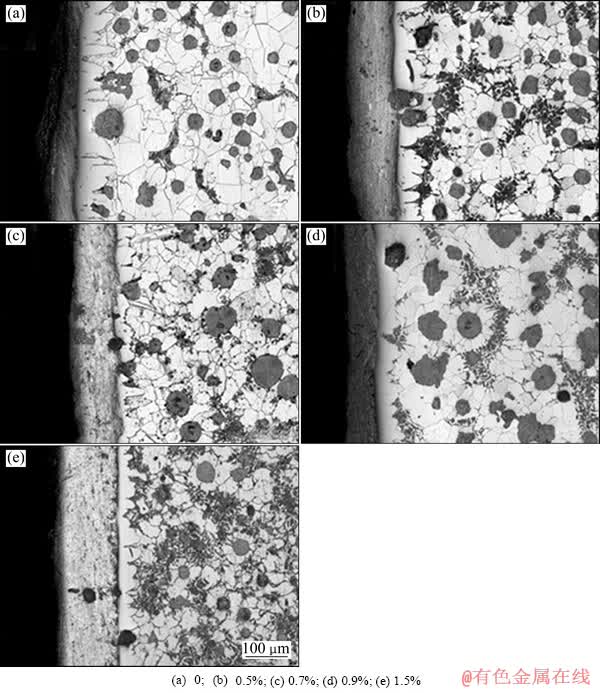

为了更好地了解球墨铸铁热浸渗铝合金层组织的演变规律,对不同渗铝时间下的试样进行金相观察,结果如图2所示。

由图2(a)可知,当热浸渗铝时间为0.5 min时,合金层与基体的界面较为平滑,仅看到极少量“舌状”Fe2Al5的“舌尖”伸向基体。当热浸时间增加到1 min后,如图2(b)所示,可观察到较多“舌状”Fe2Al5的“舌尖”伸向基体。随着热浸时间的延长,“舌状”Fe2Al5越来越明显,合金层的平均厚度也逐渐增加。

由图2可知,任意热浸渗铝时间后合金层中“舌状”Fe2Al5相的“舌尖”的延伸方向在石墨球不存在的区域均垂直于基体表面,这可能是由于Fe2Al5特殊的晶体结构决定的。这些现象与已报道的一些针对低碳钢、不锈钢的研究结果[3-4]类似,不同之处在于Fe2Al5的“舌尖”延伸在基体中的程度较前两者的小,产生这种现象的原因可能是球墨铸铁中含有较多的Si。一般认为,Si的存在会减少铝原子在固相中的扩散速率和程度[14],这就阻碍了Fe2Al5的生长;相反地,在Si含量很低或者几乎不含有Si的基体中,Fe2Al5选择性快速地生长,形成“舌状”特别明显的Fe2Al5层,毗邻于基体。

图2 750 ℃下不同热浸渗铝时间合金层的微观组织

Fig. 2 Microstructures of aluminized layer at 750 ℃ for different hot-dip times

另外,球墨铸铁本身含有球状石墨这种特殊微观组织,产生了两个不同的现象:一是在球状石墨存在的条件下,Fe2Al5的生长遇阻而改变原来垂直于基体表面的方向并偏转一定的角度继续生长(图2(h)),而且在遇阻“舌状”组织的相邻组织也会因此受到影响而生长角度发生微量偏转,这可能也是导致“舌状”Fe2Al5延伸在基体中的程度较其他钢铁基体小的原因;二是当热浸渗铝时间稍长时,可观察到纯铝层和合金层均有球状石墨存在。由于铁原子的扩散速率比铝原子的扩散速率快[15],合金层会逐渐向内生长即基体材料消耗,其厚度逐渐减小,由此在热浸渗铝过程中石墨球被逐渐包裹在合金层中。同时在基体消耗的过程中,石墨球也会游离在基体表面而与铝液接触,当试样提升出铝液时石墨球被包裹在表面的纯铝层中,因此,产生了石墨球分布于合金层和纯铝层中的现象,而石墨球的数量比基体的少。

2.2 球墨铸铁热浸渗铝合金层生长动力学

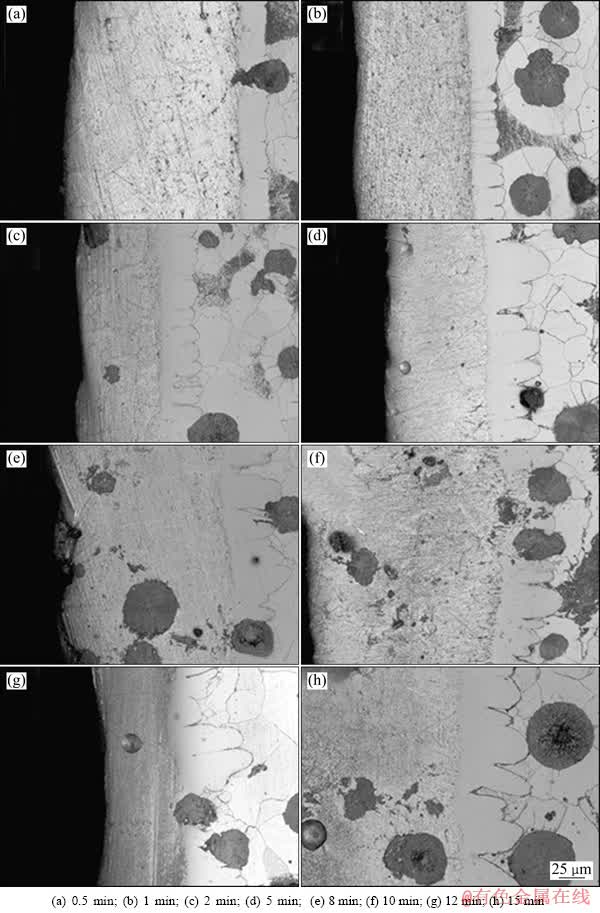

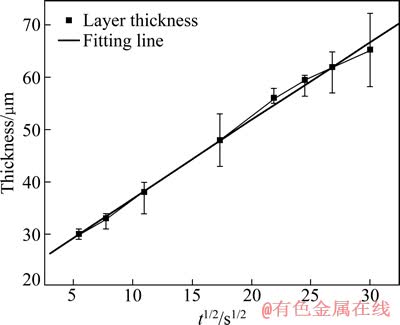

通过测量以上实验中各试样合金层的厚度并绘制厚度随热浸渗铝时间的变化曲线,研究合金层的生长动力学。750 ℃及不同热浸渗铝时间下合金层平均厚度随时间的变化关系如图3所示。为确定合金层生长所遵循的规律,对热浸渗铝时间进行开平方处理,合金层厚度对时间平方根的曲线如图4所示。

图3 750 ℃下合金层厚度与热浸渗铝时间的关系

Fig. 3 Dependence of hot dip aluminized layer thickness on hot-dip time at 750 ℃

图4 750 ℃下合金层厚度与热浸渗铝时间平方根的关系

Fig. 4 Dependence of hot dip aluminized layer thickness on t1/2 at 750 ℃

图5 不同含Ni量球墨铸铁热浸渗铝合金层的微观组织

Fig. 5 Microstructures of hot dip aluminized ductile cast iron with different Ni contents (mass fraction)

由图4可以看出,合金层厚度对热浸渗铝时间平方根的曲线基本符合线性规律,如图4中线性矫正曲线所示,由此判定热浸渗铝合金层遵循抛物线规律进行扩散生长。但观察图4,若线性矫正曲线左侧延伸至纵坐标后初始点并不符合抛物线规律的初始条件(在热浸渗铝时间t=0时,合金层厚度x=0),因此,可以推测在合金层遵循抛物线生长规律之前存在一个初始过渡期,这个过渡期的生长动力比抛物线扩散规律更快。所以,在热浸渗铝过程初期对合金层生长起控制作用的是界面反应而非扩散。在此过渡阶段结束后合金层则遵循抛物线规律进行扩散生长。对于界面反应,生成物的种类决定于化合物的吉布斯自由能,铁铝化合物(FeAl3,Fe2Al5,FeAl2,FeAl,Fe3Al)形成的吉布斯自由能随着Al含量的降低逐渐升高,即FeAl3的吉布斯自由能最低[16-17]。根据铁铝相图[4]可以得出,当基体材料进入熔融铝液瞬间,发生铁铝之间的界面反应生成Fe含量最低的FeAl3相,所以,对于界面反应控制的初始阶段,按照热力学规律首先会形成FeAl3相;随后铁原子在FeAl3相中的扩散产生了浓度变化,会出现浓度相当于Fe2Al5相的微小区域。如上所述,Fe2Al5相具有特殊的晶体结构,使铝原子在特定的最佳结晶学方向有较大的选择扩散生长性[6, 18],因此,后续Fe2Al5相快速生长,同时也抑制了FeAl3相的继续生长,因此出现如图1所示现象,在750 ℃下热浸渗铝不管时间长短,其FeAl3层厚度均比Fe2Al5层厚度小很多。

由于这个过渡阶段的时间极短,所以,在本实验中测得的合金层厚度数据并没有区分该阶段。结合上述分析,由合金层厚度随热浸渗铝时间的变化曲线可以计算出抛物线速率常数 ,并得到合金层生长过程的数学表达式如下:

,并得到合金层生长过程的数学表达式如下:

(1)

(1)

式中: 表示在抛物线生长规律阶段合金层的厚度;Xi表示实验测得的合金层平均厚度;

表示在抛物线生长规律阶段合金层的厚度;Xi表示实验测得的合金层平均厚度; 表示过渡阶段结束时合金层的厚度;t0表示过渡阶段结束时间;t表示热浸渗铝总时间。

表示过渡阶段结束时合金层的厚度;t0表示过渡阶段结束时间;t表示热浸渗铝总时间。

根据图4的拟合校正曲线,计算出抛物线速率常数 ,其值为1.57 μm/s1/2。

,其值为1.57 μm/s1/2。

综合分析,球墨铸铁热浸渗铝合金层的生长过程大致可以分为3个阶段:第一阶段即在过渡阶段形成平滑合金层(FeAl3相),靠基体一侧开始有少量“舌状”Fe2Al5相生成,如图2(a)~(c)所示;第二阶段即随着热浸渗铝时间的延长,“舌状”Fe2Al5相的舌尖延伸到球墨铸铁基体的程度增加,同时“舌状”Fe2Al5相的宽度也随之增加,由于基体的特殊组织即石墨球的存在,一些Fe2Al5相“舌状”触碰到石墨球后其生长方向会发生微量偏移,同时有将石墨球包裹在合金层中的趋势,如图2(d)和(e)所示;第三阶段随着热浸渗铝时间的增加,Fe2Al5相的宽度继续增加,将整个石墨球包裹于合金层中,并且合金层的平均厚度增加,在此基础上Fe2Al5相“舌尖”再次向基体延伸进行生长。

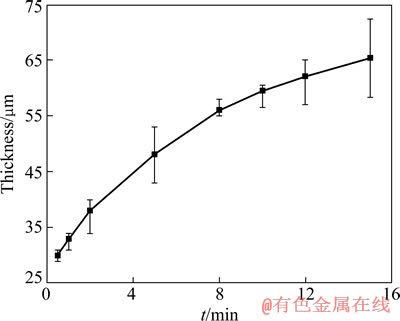

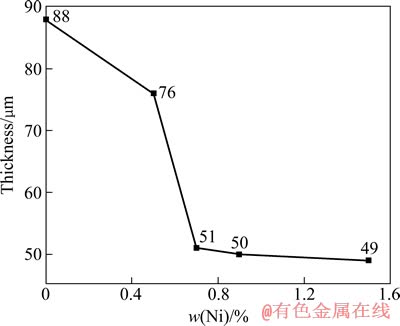

2.3 含Ni球墨铸铁热浸渗铝合金层的微观组织

不同Ni含量的球墨铸铁在770 ℃下热浸渗铝12 min,其微观组织如图5所示。由图5可见,Ni含量对球墨铸铁热浸渗铝合金层的影响较大:随着Ni含量从0增加到1.5%,在Ni含量较低或者不含Ni的情况下,合金层的“舌状”组织比较明显,同时“舌状”组织触及基体的程度也不同,而且其连续性也较差,每个或者每几个“舌状”组织间存在间隙;相反地,当Ni含量较高时,合金层的“舌状”组织没有Ni含量低时明显,合金层的厚度变得均匀,且连续性较好,没有观察到断续或者存在间隙的现象。

图6 不同Ni含量球墨铸铁试样热浸渗铝合金层的厚度

Fig. 6 Thickness of hot dip aluminized layer of ductile cast iron with different Ni contents

不同Ni含量球墨铸铁热浸渗铝合金层的厚度如图6所示。随着球墨铸铁基体中Ni含量从0增加到1.5%,合金层厚度从88 μm减小到49 μm,但厚度减小与Ni含量的增加呈非线性关系,当Ni含量从0增加至0.7%时,合金层厚度的降低程度较大;而当Ni含量从0.7%增加至1.5%时,合金层厚度的降低程度非常平缓,只有1~2 μm的变化趋势。

产生上述现象的原因可能是:Ni是稳定珠光体的元素[19],从图5也可以看出,随着Ni含量的增加,基体的珠光体含量逐渐增加,由于珠光体的组织构成为铁素体薄层和渗碳体薄层交替重叠的层状复相物,对合金层的生长起到了阻碍作用,因此,随着基体球墨铸铁中Ni含量的增加,合金层的厚度变小。而随着Ni含量的增加,珠光体含量增加,并且在基体上的分布更加均匀,因此对合金层生长的阻碍作用也更加均匀,使合金层中“舌状”组织延伸到基体的程度减小并均匀化。从另一个角度讨论,Ni在稳定珠光体组织的同时,对基体也有固溶强化作用,Ni在铁素体中以置换原子的方式固溶,而对于铝原子,由于Ni的置换固溶作用对铝原子的扩散产生了阻碍,与铁原子扩散生长得到化合物的几率降低,因此,随着Ni含量的增加,合金层呈现以上变化规律。

3 结论

1) 球墨铸铁热浸渗铝合金层主要由厚度较大且呈“舌状”的Fe2Al5层、厚度很小且位于纯铝层与Fe2Al5层间的FeAl3层以及分布于表面纯铝层中的针杆状FeAl3组成,同时在合金层与纯铝层中还包裹了球状 石墨。

2) 随着热浸渗铝时间的延长,球墨铸铁热浸渗铝合金层厚度生长经过极短暂的过渡段后按照抛物线规律进行扩散生长。

3) 随着球墨铸铁中Ni含量的增加,合金层的厚度变得均匀,连续性变好,并且Fe2Al5相的“舌状”变得不明显;但是,合金层厚度随着Ni含量的增加而减小,且在Ni含量达到0.7%后合金层厚度减小缓慢。

REFERENCES

[1] 李新华, 李国喜, 吴 勇. 钢铁制件热浸镀与渗镀[M]. 北京: 化学工业出版社, 2009: 24-28.

LI Xin-hua, LI Guo-xi, WU Yong. Hot-dip technology of steel and iron parts[M]. Beijing: Chemical Industry Press, 2009: 24-28.

[2] 李铁藩. 金属高温氧化和热腐蚀[M]. 北京: 化学工业出版社, 2003: 270-274.

LI Tie-fan, High temperature oxidation and hot corrosion of metal[M]. Beijing: Chemical Industry Press, 2003: 270-274.

[3] CHENG W J, WANG C J. Growth of intermetallic layer in the aluminide mild steel during hot-dipping[J]. Surface and Coatings Technology, 2009, 204(6/7): 824-828.

[4] BOUCHE K, BARBIER F, COULET A. Intermetallic compound layer growth between solid iron and molten aluminium[J]. Materials Science and Engineering A, 1998, 249(1): 167-175.

[5] AWAN G H. The morphology of coating/substrate interface in hot-dip-aluminized steels[J]. Materials Science and Engineering A, 2008, 472(1/2): 157-165.

[6] 张 伟, 范志康, 郭献军. 热浸镀铝钢渗铝层的微观组织及其形成机理研究现状[J]. 机械工程材料, 2006, 30(1): 9-11.

ZHANG Wei, FAN Zhi-kang, GUO Xian-jun. Summary of coating formation mechanism and microstructure during hot dip aluminizing on steel[J]. Materials for Mechanical Engineering, 2006, 30(1): 9-11.

[7] CHANG Y Y, CHENG W J, WANG C J. Growth and surface morphology of hot-dip Al-Si on 9Cr-1Mo steel[J]. Materials Characterization, 2009, 60(2): 144-149.

[8] CHENG W J, WANG C J. Microstructural evolution of intermetallic layer in hot-dipped aluminide mild steel with silicon addition[J]. Surface and Coatings Technology, 2011, 205: 4726-4731.

[9] CHENG W J, WANG C J. EBSD study of crystallographic identification of Fe-Al-Si intermetallic phases in Al-Si coating on Cr-Mo steel[J]. Applied Surface Science, 2011, 257(10): 4637-4642.

[10] FRUTOS E,  J A, HOUBAERT Y. Development of hard intermetallic coatings on austenitic stainless steel by hot dipping in an Al-Si alloy[J]. Surface and Coatings Technology, 2009, 203(19): 2916-2920.

J A, HOUBAERT Y. Development of hard intermetallic coatings on austenitic stainless steel by hot dipping in an Al-Si alloy[J]. Surface and Coatings Technology, 2009, 203(19): 2916-2920.

[11] CHENG W C, JAW J H, WANG C J. A study of aluminum nitride in a Fe-Mn-Al-C alloy[J]. Scripta Materialia, 2004, 51(4): 279-283.

[12] YOUSAF M, IQBAL J, AJMAL M. Variables affecting growth and morphology of the intermetallic layer (Fe2Al5)[J]. Materials Characterization, 2011, 62: 517-525.

[13] SASAKI T, YAKOU T, MOCHIDUKI K, ICHINOSE K. Effects of carbon contents in steels on alloy layer growth during hot-dip aluminum coating[J]. ISIJ International, 2005, 45(12): 1887-1892.

[14] LIN M B, WANG C J, VOLINSKY A A. Isothermal and thermal cycling oxidation of hot-dip aluminide coating on flake/spheroidal graphite cast iron[J]. Surface and Coatings Technology, 2011, 206: 1595-1599.

[15] KOBAYASHI S, YAKOU T. Control of intermetallic compound layers at interface between steel and aluminum by diffusion-treatment[J]. Materials Science and Engineering A, 2002, 338(1): 44-53.

[16] SHAHVERDI H, GHOMASHCHI M, SHABESTARI S, HEJAZI J. Microstructural analysis of interfacial reaction between molten aluminium and solid iron[J]. J Mater Process Tech, 2002, 124(3): 345-352.

[17] RICHARDS R, JONES R, CLEMENTS P, CLARKE H. Metallurgy of continuous hot dip aluminizing[J]. International Materials Reviews, 1994, 39(5): 191-212.

[18] 夏 原, 姚 枚, 李铁藩. 热浸铝镀层的微观结构及形成机理[J]. 中国有色金属学报, 1997, 7(4): 154-158.

XIA Yuan, YAO Mei, LI Tie-fan. Coating formation process and microstructure during hot dip aluminizing(HDA) on steel[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 154-158.

[19] 孙玉福, 尤三三, 肖志云, 赵靖宇, 杨会龙. 镍对低温高韧性球墨铸铁组织及性能的影响[J]. 铸造, 2011, 60(2): 120-125.

SUN Yu-fu, YOU San-san, XIAO Zhi-yun, ZHAO Jing-yu, YANG Hui-long. Effect of nickle on microstructure and mechanical properties of low-temperature high-toughness ductile iron[J]. Foundry, 2011, 60(2): 120-125.

(编辑 陈卫萍)

基金项目:国家“十一五”科技支撑计划资助项目(2009BAG12A07);国家自然科学基金资助项目(51201144);中央高校基本科研业务费专项资金资助项目(2682013CX003,SWJTU12CX011, SWJTU12CX012, SWJTU11CX051)

收稿日期:2012-07-26;修订日期:2013-01-26

通信作者:戴光泽,教授,博士;电话:028-87610531;E-mail:g.dai@163.com