氯化铵-氯化焙烧红土镍矿工艺及其热力学计算

符芳铭1,胡启阳1,李新海1,王志兴1,李金辉1, 2,李灵均1

(1. 中南大学 冶金科学与工程学院,湖南 长沙,410083;

2. 江西理工大学 材料与化学工程学院,江西 赣州,341000)

摘 要:通过对使用氯化铵焙烧法处理云南元江地区红土镍矿的相关化学反应进行热力学计算,并在此基础上研究氯化铵与红土镍矿质量比、焙烧温度、焙烧时间等工艺条件对红土镍矿氯化焙烧效果的影响。研究结果表明:随着焙烧温度的提高,镍、钴、锰的铁酸盐的氯化程度降低;而镍、钴、锰的硅酸盐和蛇纹石的氯化程度受焙烧温度的影响很小;镍、钴、锰、铁的氧化物除二氧化锰外,氯化程度均随焙烧温度提高而降低;当焙烧温度为673 K、焙烧时间为15 min、氯化铵与矿料质量比为0.8?1.0时,镍、钴、锰、铁、镁在常温下用水浸出5 min的浸出率分别为80%,60%,99%,58%和19%。

关键词:红土镍矿;氯化焙烧;热力学;浸出

中图分类号:TF815 文献标志码:A 文章编号:1672-7207(2010)06-2096-07

Thermodynamics and chloridizing roasting conditions of laterite through ammonium chloride

FU Fang-ming1, HU Qi-yang1, LI Xin-hai1, WANG Zhi-xing1, LI Jin-hui1, 2, LI Ling-jun1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. School of Materials and Chemical Engineering, Jiangxi University of Science and Technology,

Ganzhou 341000, China)

Abstract: On the basis of thermodynamics with NH4Cl as chloridizing agent, the chloridizing roasting conditions of laterite obtained from Yunan Province including the mass ratio of NH4Cl/ore, roasting temperature and roasting time were researched. The results show that the chloride degree of ferrite of nickel, cobalt and manganese descends gradually with the increase of roasting temperature, the chloride degree of silicate of nickel, cobalt and manganese and serpentine are not influenced nearly by roasting temperature, and the chloride degree of oxide of nickel, cobalt, manganese and iron decreases with the increase of temperature besides manganese dioxide. The optimal conditions are as follows: roasting temperature is 673 K, roasting time is 15 min, the mass ratio of NH4Cl to ore is 0.8?1.0, the dissolution yields of nickel, cobalt, manganese, iron and magnesium using water as leaching reagent in 5 min at room temperature are 80%, 60%, 99%, 58% and 19%, respectively.

Key words: laterite; chloridizing roasting; thermodynamics; leaching

云南元江地区的红土镍矿中镍、钴、锰等有价金属主要以铁酸盐和硅酸盐的形式存在,同时有非常少量的镍、钴、锰以氧化物的形式存在。因其成分复杂,目前主要采用高压酸浸法进行处理,不但对设备要求高,损耗大,而且耗酸量大,环境污染严重[1-4],因此,人们一直在寻找新工艺条件对其进行处理。采用氯化铵焙烧法处理云南元江地区红土镍矿是处理红土镍矿的一种绿色提取新工艺,该工艺具有氯化选择性好,氯化率高,条件温和等优点[5-9]。在该工艺中,先将氯化铵和云南元江地区的红土镍矿按一定的质量比混合均匀,放入马弗炉中焙烧,通过氯化铵在一定温度下分解成HCl[10-13],使云南元江地区红土镍矿中的镍、钴、锰等有价金属转化为氯化物,最后用水浸出。本文作者对使用氯化铵焙烧法处理云南元江地区红土镍矿的相关化学反应进行热力学计算,并在此基础上研究氯化铵与红土镍矿质量比、焙烧温度、焙烧时间等工艺条件对红土镍矿氯化焙烧效果的影响,以期获得氯化铵焙烧法处理云南元江地区红土镍矿的最佳 工艺。

1 红土镍矿氯化焙烧的热力学分析

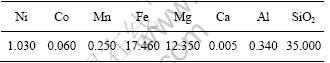

采用云南元江地区的低品位红土镍矿为原料,其化学成分(质量分数)如表1所示。

表1 云南元江地区的低品位红土镍矿化学成分

Table 1 Chemical composite of low level nickel laterites from Yuanjiang, Yunnan %

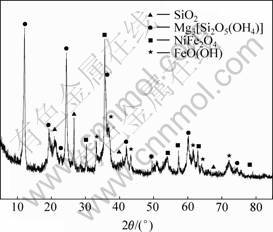

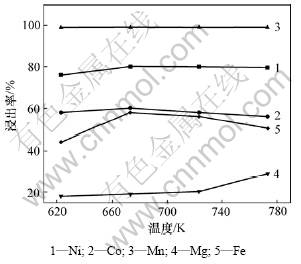

云南元江地区的红土镍矿的物相分析如图1所示。

图1 云南元江低品位红土镍矿X线衍射图谱

Fig.1 XRD pattern of low grade nickel laterites from Yuanjiang slag

物相分析结果表明:矿料中的主要物相有NiFe2O4,SiO2,Mg3[Si2O5(OH)4]和FeO(OH)。

红土镍矿在氯化焙烧过程中会发生一系列的反应,其中,主要反应有:

NH4Cl(s) NH3(g)+HCl(g) (1)

NH3(g)+HCl(g) (1)

NiFe2O4(s)+2HCl(g) NiCl2(s)+Fe2O3(s)+H2O(g) (2)

NiCl2(s)+Fe2O3(s)+H2O(g) (2)

CoFe2O4(s)+2HCl(g) CoCl2(s)+Fe2O3(s)+H2O(g) (3)

CoCl2(s)+Fe2O3(s)+H2O(g) (3)

MnFe2O4(s)+2HCl(g) MnCl2(s)+Fe2O3(s)+H2O(g) (4)

MnCl2(s)+Fe2O3(s)+H2O(g) (4)

2NiO?SiO2(s)+4HCl 2NiCl2(s)+SiO2(s)+2H2O(g) (5)

2NiCl2(s)+SiO2(s)+2H2O(g) (5)

2CoO?SiO2(s)+4HCl 2CoCl2(s)+SiO2(s)+2H2O(g) (6)

2CoCl2(s)+SiO2(s)+2H2O(g) (6)

MnO?SiO2(s)+2HCl(g) MnCl2(s)+SiO2(s)+H2O(g) (7)

MnCl2(s)+SiO2(s)+H2O(g) (7)

2MnO?SiO2(s)+4HCl(g) 2MnCl2(s)+SiO2(s)+2H2O(g) (8)

2MnCl2(s)+SiO2(s)+2H2O(g) (8)

MgO?SiO2(s)+2HCl(g) MgCl2(s)+SiO2(s)+H2O(g) (9)

MgCl2(s)+SiO2(s)+H2O(g) (9)

2MgO?SiO2(s)+4HCl(g) 2MgCl2(s)+SiO2(s)+2H2O(g) (10)

2MgCl2(s)+SiO2(s)+2H2O(g) (10)

3MgO?2SiO2?2H2O(s)+6HCl(g)

3MgCl2(s)+2SiO2(s)+5H2O(g) (11)

3MgO?2SiO2?2H2O(s)

2MgO?SiO2(s)+MgO?SiO2(s)+2H2O(g) (12)

NiO(s)+2HCl(s) NiCl2(s)+H2O(g) (13)

NiCl2(s)+H2O(g) (13)

CoO(s)+2HCl(s) CoCl2(s)+H2O(g) (14)

CoCl2(s)+H2O(g) (14)

MnO(s)+2HCl(g) MnCl2(s)+H2O(g) (15)

MnCl2(s)+H2O(g) (15)

MnO2(s)+4HCl(g) MnCl2(s)+Cl2(g)+2H2O(g) (16)

MnCl2(s)+Cl2(g)+2H2O(g) (16)

4MnO2(s) 2Mn2O3(s)+O2(g) (17)

2Mn2O3(s)+O2(g) (17)

Mn2O3(s)+6HCl(g) 2MnCl2(s)+3H2O(g)+Cl2(g) (18)

2MnCl2(s)+3H2O(g)+Cl2(g) (18)

MgCl2(s)+H2O(g) MgO(s)+2HCl(g) (19)

MgO(s)+2HCl(g) (19)

Fe2O3(s)+6HCl(g) 2FeCl3(s)+3H2O(g) (20)

2FeCl3(s)+3H2O(g) (20)

Fe2O3(s)+6HCl(g) 2FeCl3(g)+3H2O(g) (21)

2FeCl3(g)+3H2O(g) (21)

Fe3O4(s)+2HCl(g) FeCl2(s)+Fe2O3(s)+H2O(g) (22)

FeCl2(s)+Fe2O3(s)+H2O(g) (22)

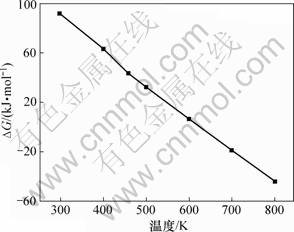

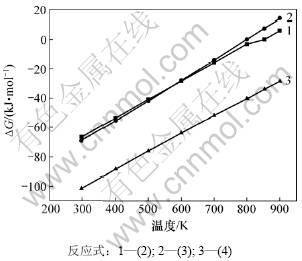

在所研究的温度范围内,氯化镍、氯化钴、氯化锰、氯化镁均为固体,只有氯化铁可能为气体,因此,在进行热力学计算时,氯化镍、氯化钴、氯化锰、氯化镁均定为固体,氯化铁则分气体和固体分别进行研究。红土镍矿中的镍、钴、锰等有价金属可能存在的矿相在氯化过程中的吉布斯自由能?G和温度T的关系如图2~6所示。

图2 反应式(1)的?G-T关系

Fig.2 Relationship between ?G and T for reaction(1)

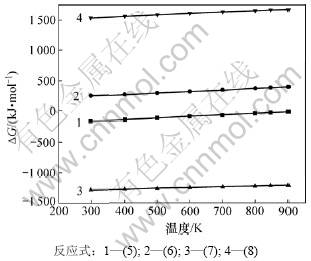

图3 反应式(2),(3)和(4)的?G-T关系

Fig.3 Relationship between ?G and T for reactions (2), (3) and (4)

图4 反应式(5)~(8)的?G-T关系

Fig.4 Relationship between ?G and T for reactions (5)-(8)

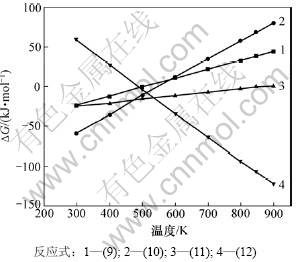

图5 反应式(9)~(12)的?G-T关系

Fig.5 Relationship between ?G and T for reactions (9)-(12)

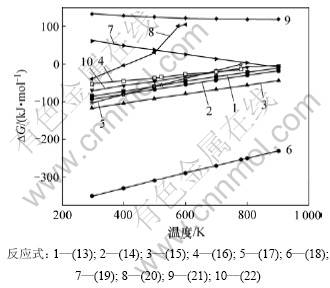

图6 反应式(13)~(22)的?G-T关系

Fig.6 Relationship between ?G and T for reactions (13)-(22)

从图2和图3可见:当温度在623 K以上时,反应(1)是可以发生的;反应(2)~(4)随着温度的升高,其进行的程度越来越小;在温度达到850 K以上时,反应(2)和(3)就不会发生,而反应(4)在所研究的温度范围内均可以发生。所以,当反应温度控制在800 K以下时,镍、钴、锰的铁酸盐均可以被氯化,其中,铁酸锰氯化的程度最完全,而铁酸镍和铁酸钴被氯化的程度相差不大。从图4可以看出:反应(5)~(8)的?G的变化受温度的影响很小,在所研究的温度范围内,反应(6)和(8)完全不能发生,其余的反应均有可能发生,这表明除了钴、锰的正硅酸盐外,镍的正硅酸盐和锰的偏硅酸盐在研究的温度范围内均可以被氯化,镍的正硅酸盐的氯化程度小于锰的偏硅酸盐氯化程度[14-15]。从图5可知:随着温度的提高,反应(9),(10)和(11)进行的程度越来越小,而反应(12)进行的程度越来越大。从图6可以看出:当温度控制在800 K以下时,反应(19)不能发生;反应(20)在400 K以上不能发生;在所研究的温度范围内,反应(21)无法发生,而其他反应均可以发生,但是,随着反应温度的提高,反应进行的程度越来越小。这说明镍、钴、锰的氧化物在所研究的温度范围内均可以被氯化,而铁的氧化物这很难被氯化,同时,蛇纹石被氯化而生成的氯化镁在800 K以下时不可能分解。反应(16)和(18)产生的氯气也可能会参与氯化反应,但是由于氯气的含量相对于实验中氯化铵分解产生的氯化氢的含量是很小的,故氯气与主要物质的氯化反应可以忽略不计。

镍、钴、锰的铁酸盐被氯化后,铁主要以三氧化二铁的形式存在。三氧化二铁的氯化产物是氯化铁和水蒸气,氯化铁又分为气相和固相2种。当产物氯化铁为固相时,在400 K以上就无法氯化;当产物氯化铁为气相时,在所研究的温度范围内,氯化反应均不可能发生。所以,三氧化二铁在所研究的温度范围内是不能被氯化的。蛇纹石被氯化后镁主要以氯化镁的形式存在,但是,其氯化反应进行的程度比镍和锰的硅酸盐所进行的程度更小,其生成的氯化镁的含量不高[16-22]。因此,在氯化时只要控制好条件,是可以实现选择性氯化的。使用水浸出时,镍、钴、锰等有价金属浸出,而铁、镁很少浸出。

2 实验

2.1 实验设备与试验试剂

实验中使用的设备有:100 mL瓷坩埚,马弗炉,磁力搅拌器,研钵,250 mL烧杯。实验中使用的试剂为氯化铵(分析纯)和去离子水。

2.2 实验方法

分别称取一定量的氯化铵和粒度为0.15 mm的矿料10 g置于研钵内磨匀,将其放入100 mL瓷坩埚中,盖上瓷坩埚盖。然后,将瓷坩埚放入马弗炉中在一定温度下焙烧一定时间。将焙砂取出放入250 mL烧杯中,加入100 mL去离子水后,放入磁力搅拌器中,以500 r/min在303 K搅拌浸出一定时间。最后,抽滤得到浸出液,定容后用使用原子吸收仪测定浸出液中镍、钴、锰、铁和镁的含量。

3 结果与讨论

3.1 氯化铵加入质量与矿料质量比对红土镍矿浸出的影响

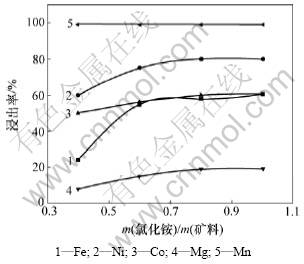

分别称取4,6,8和10 g氯化铵与粒度为0.15 mm的矿料10 g置于研钵内磨匀,接着将其放入100 mL瓷坩埚中,盖上瓷坩埚盖。然后,将瓷坩埚放入马弗炉中在673 K焙烧15 min。考察不同氯化铵加入质量与矿料质量比对镍、钴、锰、铁、镁浸出率的影响,结果如图7所示。

图7 氯化铵加入质量与矿料质量比对镍、钴、锰、铁和镁浸出率的影响

Fig.7 Effect of mass ratio of NH4Cl to ore on leaching rate of Ni, Co, Mn, Fe and Mg

由图7可知:随着氯化铵加入质量与矿料质量比的增加,镍、钴、铁、镁的浸出率都提高,在氯化铵加入量与矿料质量比达到0.8以上时,镍、钴、铁、镁的浸出率变化很小。这是因为随着氯化铵加入量的增加,其分解产生氯化氢的质量也越多,有利于氯化反应的进行,能氯化的物质的量也就越多。锰的浸出率基本上不随氯化铵加入量的提高而变化,均为99%。由热力学计算可知:在铁酸盐中,铁酸锰氯化反应进行的程度是最大的,而在硅酸盐中,偏硅酸锰的氯化反应进行的程度也是最大的。即使氯化铵加入量较少,锰的氯化反应进行的也很完全。考虑到氯化铵加入量太大,成本太高,以后实验中氯化铵加入量与矿料质量比均定为0.8。

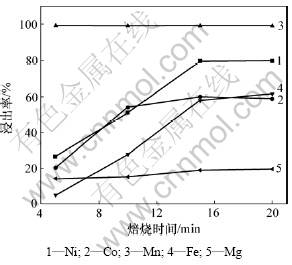

3.2 焙烧温度对红土镍矿浸出的影响

称取粒度为0.15 mm的矿料10 g与8 g氯化铵置于研钵内磨匀,接着将其放入100 mL瓷坩埚中,盖上瓷坩埚盖。然后,将瓷坩埚放入马弗炉中,分别在623,673,723和773 K焙烧15 min。考察不同焙烧温度对镍、钴、锰、铁、镁浸出率的影响,结果如图8所示。

图8 焙烧温度对镍、钴、锰、铁、镁浸出率的影响

Fig.8 Effect of roasting temperature on leaching rate of Ni, Co, Mn, Fe and Mg

从图8可以看出:随着焙烧温度的提高,镍、镁的浸出率均提高。镍的浸出率在673 K以后几乎没有变化,这可能是由于镍主要富集在硅酸盐中,而温度对镍的硅酸盐氯化的影响并不明显。镁的浸出率在623, 673和723 K时变化不明显,在773 K时有较大的提高。由图6可知:在所研究的温度范围内,氯化镁不会分解生成氧化镁和氯化氢。由图2可知:随着焙烧温度的提高,吉布斯自由能降低,根据反应(1),氯化铵分解产生的氯化氢增多,与蛇纹石反应的氯化氢也就越多,这使得蛇纹石的氯化较完全,导致镁的浸出率上升。从图8可见:在所研究的温度范围内,锰的浸出率几乎没有变化,均为99%。这可能是因为在铁酸盐中,铁酸锰氯化程度是最大的。在硅酸盐中,除了钴、锰的正硅酸盐外,其余的硅酸盐均可以被有效氯化,而且偏硅酸锰的氯化程度也最大。钴的浸出率基本上为60%,随着温度的提高略有所下降。这可能是由于在所研究的温度内,钴只有其铁酸盐可以被氯化而其硅酸盐是不可能被氯化的,同时,随着温度的提高,铁酸钴氯化反应进行的程度越来越小,从而使钴的浸出率偏低。根据热力学计算可知:在所研究的温度范围内,铁酸盐被氯化而产生的三氧化二铁是不能被氯化的,四氧化三铁随着温度的提高,其氯化反应进行的程度越来越小,所以,铁的浸出率应该是逐步降低的。但是,随着温度上升,铁的浸出率确是先上升而后下降。这可能是因为在623 K时氯化铵分解产生的氯化氢的含量较少,导致只有部分四氧化三铁被氯化,使铁的浸出率在623 K时较低;当温度达到673 K以上时,氯化铵分解产生的氯化氢越来越多,导致铁的浸出率提高。但是,由于四氧化三铁的氯化反应随着温度的提高越来越难以进行,所以,铁的浸出率又逐步下降。考虑到温度太高不利于大规模工业化生产,以后的实验氯化温度定为673 K。

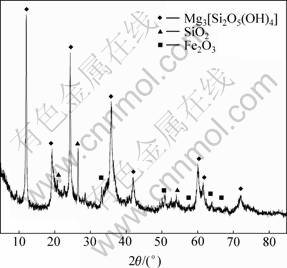

3.3 焙烧时间对浸出率的影响

称取粒度为0.15 mm的矿料10 g与8 g氯化铵置于研钵内磨匀,接着将其放入100 mL瓷坩埚中,盖上瓷坩埚盖。然后,将瓷坩埚放入马弗炉中,在673 K焙烧5,10,15和20 min。考察不同焙烧时间对镍、钴、锰、铁和镁浸出率的影响,结果如图9所示。

图9 焙烧时间对镍、钴、锰、铁、镁浸出率的影响

Fig.9 Effect of roasting time on leaching rate of Ni, Co, Mn, Fe and Mg

从图9可知:随着焙烧时间的延长,镍、钴、铁、镁的浸出率都得到提高;在焙烧时间达到15 min后,镍、钴、铁和镁的浸出率基本保持不变,这可能是由于焙烧时间太短,导致氯化铵分解产生的氯化氢的含量不足,使氯化反应进行不完全;当焙烧时间达到15 min以上时,氯化铵分解产生的氯化氢可以使氯化反应进行较完全;锰的浸出率随着焙烧时间的延长没有变化,均为99%。由热力学计算可知:在铁酸盐中,铁酸锰氯化反应进行的程度最大。而在硅酸盐中,偏硅酸锰的氯化反应进行的程度也最大。虽然反应时间短,但是,氯化铵分解产生的氯化氢仍然能使得锰的氯化反应进行最完全。考虑到焙烧时间太长时,生产成本太高,将焙烧时间定为15 min。

3.4 氯化焙烧后水浸出渣的物相分析

称取粒度为0.15 mm的矿料10 g与8 g氯化铵,在673 K焙烧15 min反应以后,将焙砂取出,在303 K用水浸出5 min,浸出渣的物相图谱如图10所示。

图10 氯化焙烧后水浸出渣物相图谱

Fig.10 XRD pattern of leaching residue

图10表明:氯化焙烧后水浸出渣的主要物相是SiO2,Mg3[Si2O5(OH)4]和Fe2O3。这说明氯化焙烧反应是按式(2),(3),(4),(5),(7),(9),(10),(11),(12)和(22)进行的,因此,采用氯化铵氯化焙烧水浸出的方法来处理红土镍矿是可行的。

4 结论

(1) 使用氯化铵氯化焙烧方法处理红土镍矿可以实现选择性氯化。使用水浸出时,将镍、钴和锰等有价金属浸出,而铁和镁很少浸出。

(2) 通过实验验证了热力学分析的正确性,并确定了氯化铵氯化焙烧方法处理红土镍矿适合的工艺条件:氯化铵和矿料质量比为0.8?1.0,焙烧温度为673 K,焙烧时间为15 min。在最佳工艺条件下获得的焙砂在常温下用水浸出5 min,得到镍、钴、锰、铁和镁的浸出率分别达到80%,60%,99%,58%和19%。

(3) 氯化焙烧后,水浸出渣的主要物相是SiO2,Mg3[Si2O5(OH)4]和Fe2O3。

(4) 实验中氯化铵用量较大的问题有待进一步 研究。

参考文献:

[1] 刘兴芝, 宋玉林, 武荣成, 等. 碲化铜法回收碲的物理化学原理[J]. 广东有色金属学报: 稀散金属专辑, 2002, 12(S1): 55-58.

LIU Xing-zhi, SONG Yu-lin, WU Rong-cheng, et al. Physicochemical principle for recovering tellurium by copper telluride method[J]. Journal of Guangdong Non-ferrous Metals: Dissipated Metals Special, 2002, 12(S1): 55-58.

[2] 杨声海, 唐谟堂. Zn(Ⅱ)-NH3-NH4Cl-H2O体系热力学研究[J]. 中国有色金属学报, 2000, 10(6): 830-833.

YANG Sheng-hai, TANG Mo-tang. Thermodynamics of Zn(Ⅱ)-NH3-NH4Cl-H2O system[J]. Trans Nonferrous Met Soc China, 2000, 10(6): 830-833.

[3] 钟竹前, 梅光贵. 化学位图在湿法冶金和废水净化中的应用[M]. 长沙: 中南工业大学出版社, 1986.

ZHONG Zhu-qian, MEI Guang-gui. Application of diagrams of chemical potential in hydrometallurgy and purification of waste water[M]. Changshan: Central South University of Technology Press, 1986.

[4] 冯其明, 何东升, 张国范. 石煤提钒过程中钒氧化和转化对钒浸出的影响[J]. 中国有色金属学报, 2007, 17(8): 1348-1352.

FENG Qi-ming, HE Dong-sheng, ZHANG Guo-fan, et al. Effect of vanadium oxidation and conversion on vanadium leaching in extraction process of vanadium from stone coal[J]. The Chinese Journal of Nonferrous Metal, 2007, 17(8): 1348-1352.

[5] 梁英教, 车荫昌. 无机物热力学数据手册[M]. 沈阳: 东北大学出版社, 1993: 102-125.

LIANG Ying-jiao, CHE Yin-chang. Thermodynamic data book of inorganic matter[M]. Shengyang: Northeastern University Press, 1993: 102-125.

[6] 李正山, 何良惠, 郑昌琼. 钨矿及钨锡中矿碳酸钠加压浸出热力学分析[J]. 稀有金属, 1992(1): 1-6.

LI Zheng-shan, HE Liang-hui, ZHENG Chang-qiong. Thermodynamic analysis of autoclave soda digestion of tungsten ore and tungsten-tin middle concentrate[J]. Chinese Journal of Rare Metals, 1992(1): 1-6.

[7] 刘茂盛, 李洪桂, 孙培梅, 等. 机械活化苏打溶液分解白钨中矿试验研究[J]. 中南工业大学学报: 自然科学版, 1994, 25(3): 321-325.

LIU Mao-sheng, LI Hong-qui, SUN Pei-mei, et al. Study on mechanical activated decomposition with soda solution of scheelite middle concentrate[J]. Journal of Central South University of Technology: Natural Science, 1994, 25(3): 321-325.

[8] 杨彧, 贾殿赠, 葛炜炜, 等. 低热固相反应制备无机纳米材料的方法[J]. 无机化学学报, 2004, 8(8): 881-888.

YANG Yu, JIA Dian-zeng, GE Wei-wei, et al. Synthetic of inorganic nano-materials by solid state reaction at low-heating temperature[J]. Chinese J Inorg Chem, 2004, 8(8): 881-888.

[9] 刘晓华, 隋智通. 含钛高炉渣加压酸解[J]. 中国有色金属学报, 2002, 12(6): 1281-1284.

LIU Xiao-hua, SUI Zhi-tong. Leaching of Ti-bearing blast furnace slag by pressuring[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(6): 1281-1284.

[10] 王明华, 都兴红, 隋智通. H2SO4分解富钛精矿的反应动力学[J]. 中国有色金属学报, 2001, 11(1): 131-134.

WANG Ming-hua, DU Xing-hong, SUI Zhi-tong. Kinetics of acidolysis of rich titanium concentrate by H2SO4[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(1): 131-134.

[11] LI Chun, LIANG Bin, CHEN Sheng-pin. Combined milling- dissolution of Panzhihua ilmenite in sulfuric acid[J]. Hydrometallurgy, 2006, 82(1/2): 93-99.

[12] 张小云, 田学达, 刘小玲, 等. 银锰矿中银的回收新工艺[J]. 中国有色金属学报, 2006, 16(5): 914-918.

ZHANG Xiao-yun, TIAN Xue-da, LIU Xiao-ling, et al. A novel technique for silver recovery from silver-manganese ore[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(5): 914-918.

[13] JIANG Tao, YANG Yong-bin, HUANG Zhu-cheng, et al. Leaching kinetics of pyrolusite from manganese-silver ores in the presence of hydrogen peroxide[J]. Hydrometallurgy, 2004, 72(1/2): 129-138.

[14] 林传仙. 矿物及有关化合物热力学数据手册[M] . 北京: 科技出版社, 1985: 112-185.

LIN Chuan-xian. The handbook of mineral and the related compounds thermodynamic data[M]. Beijing: Science and Technology Press, 1985: 112-185.

[15] 张荣良, 丘克强, 谢永金, 等. 铜冶炼闪速炉烟尘氧化浸出与中和脱砷[J]. 中南大学学报: 自然科学版, 2006, 37(1): 73-78.

ZHANG Rong-liang, QIU Ke-qiang, XIE Yong-jin, et al. Treatment process of dust from flash smelting furnace at copper smelter by oxidative leaching and neutralization process from leaching solution[J]. Journal of Central South University: Science and Technology, 2006, 37(1): 73-78.

[16] 朱国才, 田君, 池汝安, 等. 氯化铵法处理氟化碳铈原矿提取稀土[J]. 中国有色金属学报, 2000, 10(5): 701-704.

ZHU Guo-cai, TIAN Jun, CHI Ru-an, et al. Extraction of rare earth with NH4Cl roasting from bastnasite rough ore[J]. Trans Nonferrous Met China, 2000, 10(5): 701-704.

[17] 朱国才, 池汝安, 徐盛明, 等. 选择性氯化法提取白云鄂博中品位混合精矿中稀土[J]. 稀土, 2002, 23(1): 20-22.

ZHU Guo-cai, CHI Ru-an, XU Sheng-ming, et al. Recovery of RE with selective chlorinating from intermediate Baiyunebo concentrate[J]. Chinese Rare Earth, 2002, 23(1): 20-22.

[18] SHI Wen-zhong, ZHU Guo-cai, HU Jie, et al. Recovery of RE from Baotou rare earth concentrate with chlorination roasting[J]. Trans Nonferrous Met Soc China, 2003, 13(2): 438-442.

[19] 王成彦. 元江贫氧化镍矿氯化离析[J]. 矿冶, 1997, 3(6): 55-59.

WANG Cheng-yan. Chloridizing segregation of Yuanjiang lean nickel oxide ore[J]. Mining & Metallurgy, 1997, 3(6): 55-59.

[20] 王成彦, 江培海. 云南中低品位氧化锌矿及元江镍矿的合理开发利用[J] .中国工程科学, 2005, 7(增刊): 147-150, 206.

WANG Cheng-yan, JIANG Pei-hai. The rational exploitation of middle & low grade zinc oxide ore and Yuanjiang nickel oxide ore in Yunnan[J]. Engineering Science, 2005, 7(Suppl): 147-150, 206.

[21] 张昱, 陈晓鸣. 从氧化镍矿硅酸镍矿回收镍钴的方法: 中国, 200610010774.8[P]. 2006-09-06.

ZHANG Yi, CHEN Xiao-ming. A method of extraction nickel and cobalt from nickel oxide ore and silicate ore: China, 200610010774.8[P]. 2006-09-06.

[22] 叶大伦, 胡建华. 实用无机物热力学数据手册[M]. 北京: 冶金工业出版社, 2002: 584.

YE Da-lun, HU Jian-hua. Thermodynamic data manual of inorganic matters[M]. Beijing: Metallurgical Industry Press, 2002: 584.

(编辑 赵俊)

收稿日期:2009-10-22;修回日期:2010-01-08

基金项目:国家重点基础研究发展计划(“973”计划)项目(2007CB613607)

通信作者:胡启阳(1963-),男,湖南宁乡人,副教授,从事冶金物理化学研究;电话:15116461226;E-mail: fuyangguang8@163.com