Gd含量对挤压态Mg-0.5Zr-1.8Zn-xGd生物镁合金组织及耐腐蚀性能的影响

来源期刊:中国有色金属学报2021年第8期

论文作者:姚怀 方博洋 曹嘉龙 王晓博 叶文龙 李晴 李云翔

文章页码:2101 - 2115

关键词:镁合金;挤压;微观组织;耐腐蚀性能

Key words:magnesium alloy; extrusion; microstructure; corrosion resistance

摘 要:研究了Gd含量对挤压态Mg-0.5Zr-1.8Zn-xGd(0~2.5%,质量分数)生物镁合金组织及耐腐蚀性能的影响。结果表明:挤压比为7.7、挤压温度为350 ℃时,合金发生了完全动态再结晶,其晶粒尺寸随Gd含量的增加先减小,最后趋于稳定。合金中的第二相主要由颗粒状(Mg, Zn)3Gd相和Mg2Zn11相组成,其数量、尺寸及体积分数随Gd含量的增加逐渐增大,同时,纳米级棒状(Mg, Zn)3Gd相与合金基体具有半共格界面关系。Gd含量大于2.0%(质量分数)时,部分未溶第二相以弯曲线条状在合金基体中随机分布,其尺寸及数量随Gd含量的增加逐渐增大。合金的耐腐蚀性能随Gd含量的增加先增强后减弱,Gd含量为1.0%(质量分数)时,合金具有较好的耐腐蚀性能。

Abstract: The effects of Gd content on the microstructure and corrosion resistance of the as-extruded Mg-0.5Zr-1.8Zn-xGd alloys (0-2.5%) was investigated. The results show that, when the extrusion ratio is 7.7 and the extrusion temperature is 350 ℃, the alloys have undergone complete dynamic recrystallization. The grain size decreases with the increase of Gd content and finally tends to be stable. The second phase in the alloy consists mainly of the granular (Mg, Zn)3Gd phase and the Mg2Zn11 phase, and volume of the second phase gradually increase with increasing Gd content. Meanwhile, the nano-scale granular (Mg, Zn)3Gd phase has a semi-congruent interfacial relationship with the alloy matrix. When Gd content is greater than 2.0%, a portion of the insoluble second phase is randomly distributed in the alloy matrix in the form of curved lines, and the volume and the amount gradually increase as Gd content increasing. The corrosion resistance of the alloy is enhanced and then weakened with the increase of Gd content, that the alloy has the best corrosion with a Gd content of 1.0%.

DOI: 10.11817/j.ysxb.1004.0609.2021-40033

姚 怀1, 2,方博洋3,曹嘉龙1,王晓博1,叶文龙1,李 晴1,李云翔1

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 有色金属共性技术河南省协同创新中心,洛阳 471023;

3. 西南交通大学 材料科学与工程学院,成都 610031)

摘 要:研究了Gd含量对挤压态Mg-0.5Zr-1.8Zn-xGd(0~2.5%,质量分数)生物镁合金组织及耐腐蚀性能的影响。结果表明:挤压比为7.7、挤压温度为350 ℃时,合金发生了完全动态再结晶,其晶粒尺寸随Gd含量的增加先减小,最后趋于稳定。合金中的第二相主要由颗粒状(Mg, Zn)3Gd相和Mg2Zn11相组成,其数量、尺寸及体积分数随Gd含量的增加逐渐增大,同时,纳米级棒状(Mg, Zn)3Gd相与合金基体具有半共格界面关系。Gd含量大于2.0%(质量分数)时,部分未溶第二相以弯曲线条状在合金基体中随机分布,其尺寸及数量随Gd含量的增加逐渐增大。合金的耐腐蚀性能随Gd含量的增加先增强后减弱,Gd含量为1.0%(质量分数)时,合金具有较好的耐腐蚀性能。

关键词:镁合金;挤压;微观组织;耐腐蚀性能

文章编号:1004-0609(2021)-08-2101-14 中图分类号:TG146.2 文献标志码:A

引文格式:姚 怀, 方博洋, 曹嘉龙, 等. Gd含量对挤压态Mg-0.5Zr-1.8Zn-xGd生物镁合金组织及耐腐蚀性能的影响[J]. 中国有色金属学报, 2021, 31(8): 2101-2114. DOI: 10.11817/j.ysxb.1004.0609.2021-40033

YAO Huai, FANG Bo-yang, CAO Jia-long, et al. Effect of Gd content on microstructure and corrosion resistance of as-extruded Mg-0.5Zr-1.8Zn-xGd alloys[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(8): 2101-2114. DOI: 10.11817/j.ysxb.1004.0609.2021-40033

可降解医用生物移植材料是一类在早期能够为损伤组织提供足够的力学支撑,完成组织修复后,能够以合适的速率被机体降解吸收或排出的新一代生物移植材料[1]。镁合金因与人体骨具有相近的密度(1.7~2.0 g/cm3)、弹性模量(41~45 GPa)及可降解(腐蚀)性等特点,在医用生物移植材料领域受到了科研工作者的广泛关注[2-5]。作为生物移植材料的候选材料,镁合金需要满足一定的力学性能及耐腐蚀性能[6]:1) 在37 ℃的人体模拟体液(SBF)中浸泡120 h,平均腐蚀速率小于0.5 mm/a,腐蚀模式为均匀腐蚀;2) 骨板等内固定受力件生物镁合金材料,室温屈服强度(σ0.2)应高于200 MPa,伸长率(η)大于10%;3) 心血管支架生物镁合金材料,屈服强度(YS)应高于200 MPa,η大于20%。通过对镁合金进行晶粒细化,其力学性能通常能够满足生物移植材料的要求[7],然而,由于镁的化学性质极为活泼(标准电极电位为-2.372 V),镁合金在人体环境中较快的降解速率限制了它在生物移植材料领域的应用。镁合金的降解速率主要与合金的成分、晶粒尺寸、第二相或金属间化合物的组成、尺寸、体积分数及分布等密切相关[8]。

如何提高其耐腐蚀性能已经成为镁合金生物移植材料的研究热点,选择添加和优化合适的合金化元素,能够增强合金的力学性能及耐腐蚀性能。可降解医用镁合金中的合金元素应满足对人体无毒或者低毒性,同时,降解后合金元素能够通过人体排出。如Zn和Zr是人体的营养元素[9-10]。Zn是构成人体必需的微量元素之一,几乎参与人体所有的新陈代谢过程,人体中Zn的日常需求量约为15 mg,正常成人体内含Zn量约为2~3 g[11]。Zn在镁中的含量大于2.5%(质量分数)时,会降低合金的耐腐蚀性能,原则上镁合金中Zn的含量应控制在2.5%(质量分数)以下,少量Zn(约2.0%,质量分数)的存在有助于在镁合金表面中形成保护膜,从而提高其耐腐蚀性能[12]。Zr能够有效地细化镁合金晶粒,通常与Zn、Ca或稀土元素一起添加进镁合金,提高其力学性能及耐腐蚀性能,在镁合金中加入0.5~0.8% Zr(质量分数),其晶粒细化效果最好,通常医用镁合金中Zr元素的含量应低于1.0%(质量分数)[13-14]。稀土元素Gd对镁合金能够起到晶粒细化及净化作用,进而提高其力学性能及耐腐蚀性能[15]。此外,研究发现微量的Gd对人骨肉瘤细胞及脐带血管细胞无细胞毒性,并且还具有一定的抗癌作用[16]。从生物安全性考虑,成年人(质量70 kg)每天能够吸收稀土Gd的最大安全剂量约为4.2 mg,通常移植材料表面积约为50~100 cm2,以含Gd量2.5%(质量分数)的镁合金为例,假设其降解速率为0.5 mm/a,其平均每天Gd的释放量约为0.311~0.622 mg,远低于人体每天能够吸收Gd的最大安全剂量[17]。假设含Gd量2.5%(质量分数)的镁合金移植材料质量为10 g,且其全部降解被人体吸收,所计算的半数致死量(LD50)约为0.023 mmol/kg,远低于成人LD50的安全剂量0.1~0.3 mmol/kg[18-19]。因此,当镁合金中Gd含量低于2.5%(质量分数),且降解速率低于0.5 mm/a时,合金在腐蚀过程中所释放的Gd对人体是安全的。

镁合金中较大尺寸的第二相通常作为阴极会加速其周围基体的腐蚀,导致局部腐蚀的发生,造成应力集中,使移植材料过早发生断裂[20]。对镁合金进行晶粒及第二相细化,能够大幅度改善合金的力学性能及耐腐蚀性能,并实现均匀腐蚀[21-22]。Mg-5.0Gd-1.0Zn-0.6Zr合金通过挤压变形处理后,其晶粒尺寸从挤压前的50 μm降低到约5 μm,屈服强度(σ0.2)和伸长率(η)分别从挤压前的107 MPa和14.7%提高到214 MPa和30.7%,平均腐蚀速率从挤压前的2.7 mm/a降低到1.1 mm/a[23]。Mg-3.0Gd- 2.7Zn-0.4Zr-0.1Mn合金挤压变形处理后,其晶粒尺寸从挤压前的150 μm降低到约10 μm,σ0.2和η分别从挤压前的149 MPa和18.7%增加到315 MPa和21.3%,平均腐蚀速率从挤压前的1.249 mm/a降低到0.562 mm/a[24]。上述研究结果也表明,晶粒细化能够提高镁合金的力学性能及耐腐蚀性能。

根据上述合金化原则及生物安全性原则[14],作者设计了低Gd含量的Mg-0.5Zr-1.8Zn-xGd (x=0,0.5,1.0,1.5,2.0,2.5,质量分数,%)合金,并通过挤压变形对合金晶粒及第二相颗粒进行了细化处理。研究发现了Gd在挤压态Mg-0.5Zr-1.8Zn-xGd中的最大溶解度、不同Gd含量对合金动态再结晶机制、微观组织演变及腐蚀后合金表面形貌的影响规律,同时,探讨了晶粒尺寸大小和第二相尺寸大小、形态及分布对合金耐腐蚀性能的影响规律。

1 实验

以纯度大于99.9%的Mg锭、Zn锭、Mg-20%Gd合金及Mg-25%Zr合金为熔炼Mg-0.5Zr-1.8Zn-xGd合金的原料。熔炼设备为ZGJL0.01-40-4型中频感应炉,熔炼过程在CO2+2%SF6混合气体的保护下进行。合金熔体在(780±5) ℃的温度下保温并电磁搅拌20 min,待其降温至(720±5) ℃时,在预热((300±5) ℃)的钢模具中进行浇注成型。熔炼后的合金被加工成d 50 mm×35 mm的待挤压圆柱锭,将挤压模具和待挤压圆柱锭加热到350 ℃并保温2 h后进行挤压变形,挤压速率约为5 mm/s,挤压比为7.7,挤压后的合金棒在空气中冷却,并在200 ℃的温度下对其进行4 h的退火处理。此后,挤压态Mg-0.5Zr-1.8Zn-xGd(x=0,0.5,1.0,1.5,2.0,2.5,质量分数,%)合金分别用E0、E0.5、E1.0、E1.5、E2.0及E2.5表示。

垂直于挤压方向切割试样,并对其进行微观组织观察和耐腐蚀性能测试。利用金相显微镜(OM,OLYMPUS PMG3)观察合金的金相组织;利用扫描电子显微镜(SEM,JSM-5610LV)及其附带的能谱仪(EDS,EDAX)观察分析合金腐蚀后的表面形貌及微区成分;采用透射电子显微镜(TEM,JEM-2100)及其附带的能谱仪对合金的显微组织进行观察及成分分析。

静态腐蚀实验在37 ℃的SBF[25]中进行,SBF的主要成分:NaCl (8.0 g/L),KCl (0.4 g/L),CaCl (0.14 g/L),MgCl2·6H2O (0.1 g/L),Na2HPO4·12H2O (0.06 g/L),NaHCO3 (0.35 g/L),C6H12O6 (1.0 g/L),KH2PO4 (0.06 g/L),MgSO4·7H2O (0.06 g/L)。实验所用试样尺寸为d 16 mm×3 mm,SBF体积与试样表面积比值约为30 mL/cm2,实验过程中,SBF每8 h更新一次。利用铬酸洗液(20% CrO3+1% AgNO3) (质量分数)清洗试样表面的腐蚀产物,平行试样取3个。静态腐蚀速率νw(mm/a)的计算方法如式(1)所 示[26]。

(1)

(1)

式中:m1和m2分别是试样腐蚀前、后的质量(mg);ρ是试样的密度(g/cm3);A是试样的表面积(cm2);t是浸泡时间(h)。

利用电化学工作站(Autolab PGSTAT128N)进行极化曲线和交流阻抗测试,采用三电极体系,待测试样(d 11.3 mm×5 mm)为工作电极,石墨片为对电极,饱和甘汞电极为参比电极,测试前,待测试样在37 ℃的SBF中浸泡1 h。极化曲线测试从开路电位-0.25~+0.45 V,速率为1 mV/s。交流阻抗测试频率范围为1×105~1×10-1 Hz,振幅为5 mV。

2 实验结果

2.1 微观组织

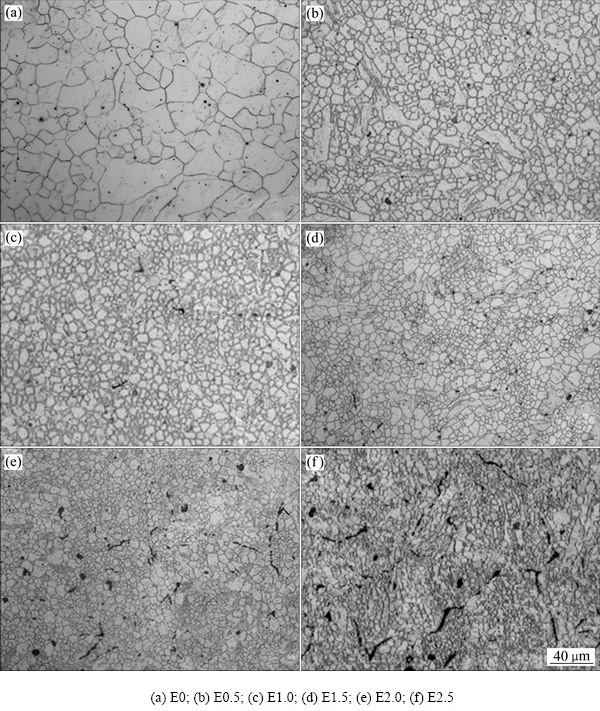

图1 挤压态Mg-0.5Zr-1.8Zn-xGd合金的显微组织

Fig. 1 Microstructures of as-extruded Mg-0.5Zr-1.8Zn-xGd alloys

图1所示为垂直于挤压方向合金的金相组织。从图1中可以看出,合金都发生了完全动态再结晶。当Gd含量小于1.5%时,晶粒尺寸随着Gd含量的增加逐渐减小;当Gd含量大于1.5%时,随着Gd含量的增加,黑色未溶第二相的体积分数逐渐增大,晶粒尺寸逐渐趋于稳定。垂直于挤压方向,合金在挤压变形过程中主要受到压应力的作用,垂直于挤压方向的基面很难发生滑移,进而在第二相附近形成局部的扭曲区域,如图1(e)和(f)所示,导致未溶的第二相以弯曲的黑色线条状在合金中随机分布[27]。

图2 E1.0合金的TEM像、对应的SAED谱及第二相的EDS谱

Fig. 2 TEM images, corresponding SAED patterns and EDS spectra of second phase of E1.0 alloy

图2所示为E1.0合金的TEM像、选区电子衍射(SAED)斑点及EDS谱。从图2(a)中能够看出,在动态再结晶晶粒中心及晶界区域分布着少量的纳米级棒状和椭圆状的第二相颗粒。对图2(a)中A点处纳米级棒状第二相颗粒进行SAED斑点(见图2(a))标定及EDS(见图2(b))分析,该棒状第二相颗粒具有面心立方结构,SAED斑点中的晶面间距0.257 nm、0.148 nm及0.257 nm与标准Mg3Gd相中的(220)、(242)及(022)晶面的晶面间距具有较好的对应关系,属于 晶带轴,且该棒状第二相颗粒主要由Mg、Zn及Gd 3种元素组成,因此,能够推断出该棒状第二相颗粒属于(Mg, Zn)3Gd相。相似的(Mg, Zn)3Gd棒状第二相颗粒在其它挤压态Mg-Zr-Zn-Gd系合金中也被发现[28]。从图2(c)中能够看出,在合金基体的部分区域,集中分布着一定数量的纳米级椭圆状第二相颗粒。对图2(c)中B点处纳米级椭圆状第二相颗粒进行SAED斑点(见图 2(c))标定及EDS(见图2(d))分析,该椭圆状第二相颗粒具有简单立方结构,SAED斑点中的晶面间距0.269 nm、0.143 nm及0.167 nm与标准Mg2Zn11相中的(013)、(442)及

晶带轴,且该棒状第二相颗粒主要由Mg、Zn及Gd 3种元素组成,因此,能够推断出该棒状第二相颗粒属于(Mg, Zn)3Gd相。相似的(Mg, Zn)3Gd棒状第二相颗粒在其它挤压态Mg-Zr-Zn-Gd系合金中也被发现[28]。从图2(c)中能够看出,在合金基体的部分区域,集中分布着一定数量的纳米级椭圆状第二相颗粒。对图2(c)中B点处纳米级椭圆状第二相颗粒进行SAED斑点(见图 2(c))标定及EDS(见图2(d))分析,该椭圆状第二相颗粒具有简单立方结构,SAED斑点中的晶面间距0.269 nm、0.143 nm及0.167 nm与标准Mg2Zn11相中的(013)、(442)及 晶面的晶面间距具有较好的对应关系,属于

晶面的晶面间距具有较好的对应关系,属于 晶带轴,且该椭圆状第二相颗粒主要由Mg和Zn两种元素组成,因此,能够推断出该椭圆状第二相颗粒属于Mg2Zn11相。

晶带轴,且该椭圆状第二相颗粒主要由Mg和Zn两种元素组成,因此,能够推断出该椭圆状第二相颗粒属于Mg2Zn11相。

镁合金在热挤压的初始阶段,组织主要以不稳定的小角度晶界和亚晶为主,这些小角度晶界和亚晶在挤压过程中会不断的吸收因变形所产生的位错,进而逐渐转变为稳定的并以大角度晶界为主的动态再结晶晶粒,同时,随着大角度晶界的迁移,导致动态再结晶晶粒的不断长大[29]。从图2(d)和(e)中能够看出,合金中部分晶粒尺寸较小的区域及部分亚晶粒内部存在较高密度的位错区,该位错区的存在可以认为由于挤压保温过程较短,挤压后期产生的位错来不及被完全吸收而形成了较高密度的位错区,因此,挤压态镁合金中,在不稳定的小角度晶界及亚晶区通常都会残留部分较高密度的位错[30]。

图3 E1.0合金的TEM像及SAED谱

Fig. 3 TEM images and SAED patterns of E1.0 alloy

图3所示为E1.0合金中纳米级棒状第二相区域的TEM像及高分辨(HRTEM)像。从图3(a)中能够看出,合金基体中存在少量的长度约为300 nm,直径约为30 nm的棒状第二相颗粒。图3(b)所示为图3(a)中圆形区域的放大像,图3(c)所示为图3(b)中A、B区域的HRTEM像。对图3(c)中α-Mg基体A区域、棒状第二相B区域及A和B交界区域进行傅立叶变换(FFT),选取区域及FFT像如图3(d)~(i)所示。图3(d)所示为α-Mg基体A区域的放大像,图3(g)所示为图3(d)的FFT像,通过对图3(g)进行标定,该区域α-Mg基体的晶带轴为 。图3(e)所示为棒状第二相B区域的放大像,图3(h)所示为图3(e)的FFT像,通过对图3(h)进行标定,该棒状第二相为(Mg, Zn)3Gd相,其晶带轴为

。图3(e)所示为棒状第二相B区域的放大像,图3(h)所示为图3(e)的FFT像,通过对图3(h)进行标定,该棒状第二相为(Mg, Zn)3Gd相,其晶带轴为 。图3(f)是α-Mg基体与棒状第二相交界处部分区域的放大像,图3(i)为图3(f)的FFT像,通过图3(f)和(i)能够看出,该区域α-Mg基体与棒状(Mg, Zn)3Gd相之间存在

。图3(f)是α-Mg基体与棒状第二相交界处部分区域的放大像,图3(i)为图3(f)的FFT像,通过图3(f)和(i)能够看出,该区域α-Mg基体与棒状(Mg, Zn)3Gd相之间存在 晶面与

晶面与 晶面近似平行的位相关系,

晶面近似平行的位相关系, 晶面与

晶面与 晶面角度差约为3.6°。根据两相界面晶格点阵错配度(δ)计算公式[31]:

晶面角度差约为3.6°。根据两相界面晶格点阵错配度(δ)计算公式[31]:

(2)

(2)

式中:XA和XB分别为两平行晶面的面间距。两近似平行晶面 和

和 的面间距分别约为0.1295 nm和0.1179 nm,通过计算,该两近似平行界面的晶格点阵错配度约为0.09,因此,可以认为该棒状(Mg, Zn)3Gd相与其相邻区域α-Mg基体具有半共格界面关系。

的面间距分别约为0.1295 nm和0.1179 nm,通过计算,该两近似平行界面的晶格点阵错配度约为0.09,因此,可以认为该棒状(Mg, Zn)3Gd相与其相邻区域α-Mg基体具有半共格界面关系。

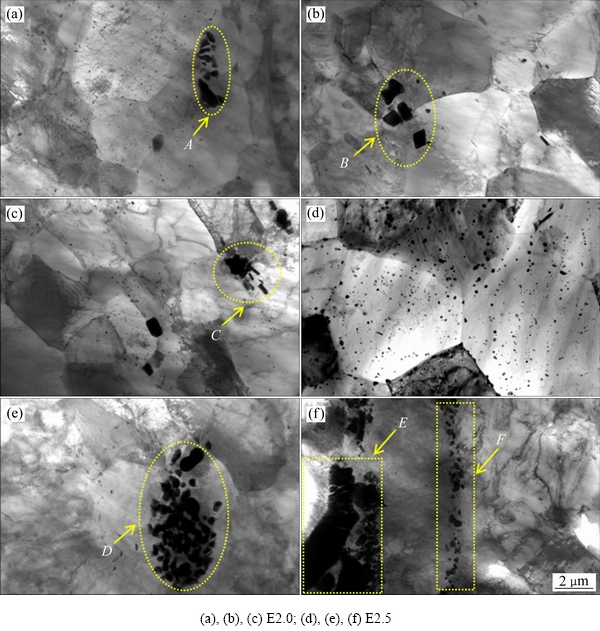

图4所示为E2.0和E2.5合金中的典型TEM像。从图4中能够看出,在合金中分布着不同形貌、尺寸及数量的第二相颗粒。图4(a)、(b)及(c)所示为E2.0合金的TEM像。从图4(a)、(b)及(c)中A、B及C区域能够看出,这些区域中黑色的微米级第二相颗粒呈密集的连续分布状态,且由这些颗粒形貌、尺寸及分布可以推断,这些区域中微米级第二相颗粒是未溶第二相在挤压过程中的破碎产物。同时,在E2.0合金中也存在一定数量的、弥散分布的纳米级析出相颗粒。图4(d)、(e)及(f)所示为E2.5合金的TEM像,从图4(d)中能够看出,在晶粒内部及晶界区域分布着大量的纳米级第二相颗粒。从图4(e)及4(f)中的D、E及F区域能够看出,合金中存在大量的、密集分布的微米级黑色第二相颗粒,其尺寸及数量明显大于E2.0合金中的微米级第二相颗粒。因此,也能够推断出E2.5合金中密集分布的微米级第二相颗粒也是未溶第二相在挤压过程中的破碎产物。

图4 典型的E2.0和E2.5合金的TEM像

Fig. 4 Typical TEM images of E2.0 and E2.5 alloys

2.2 耐腐蚀性能

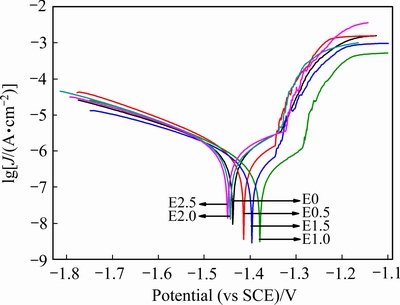

图5所示为挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡1 h后的极化曲线。表1所示为由图5通过塔菲尔外推法得到的自腐蚀开路电位(φcorr)、自腐蚀电流密度(Jcorr)及自腐蚀速率(vi)。Gd含量为0~ 2.5%(质量分数)时,随着Gd含量的增加,φcorr先正移后负移,Jcorr及vi先减小后增大,即合金的耐腐蚀性能随Gd含量的增加先增强后减弱。Gd含量为1.0%(质量分数)时,合金具有较好的耐腐蚀性能,φcorr、Jcorr和vi分别为(-1.379±0.003) V (vs SCE)、(3.339±0.004) μA/cm2和(0.150±0.003) mm/a。

图5 挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡1 h后的极化曲线

Fig. 5 Polarization curves of as-extruded Mg-0.5Zr- 1.8Zn-xGd alloys immersed in SBF for 1 h

表1 挤压态Mg-0.5Zr-1.8Zn-xGd合金的φcorr、Jcorr及vi

Table 1 φcorr, Jcorr and vi of as-extruded Mg-0.5Zr-1.8Zn- xGd alloys

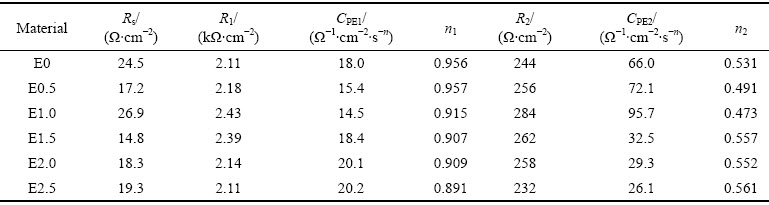

图6所示为挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡1 h后的交流阻抗谱及对应的等效电路。其中,图6(a)、(b)和(c)分别表示Nyquist图和Bode图中的阻抗模值及相位角。从图6(a)和(b)中能够看出,随着Gd含量的增加,Nyquist图的弧半径及阻抗模值变化趋势相同,先增大后减小,Gd含量为1.0%时,弧半径和阻抗模值达到最大值。弧半径及阻抗模值越大,说明合金腐蚀过程中电荷转移阻力越大,发生腐蚀反应的速率越小,合金的耐腐蚀性能越好,因此,当Gd含量为1.0%时,合金具有较好的耐腐蚀性能[32]。从图6(c)中能够看出,相位角出现了两个峰值,即交流阻抗谱包含有两个时间常数,说明图6(a)中的Nyquist图由高频段和中低频段的两个容抗弧组成,高频段容抗弧通常与合金表面氧化膜电荷转移电阻有关,中低频段容抗弧与腐蚀层中电荷的转移电阻有关[33]。为了进一步阐明该合金的腐蚀特征,对图6(a)的Nyquist图进行模拟,模拟得出的等效电路如图6(d)所示。在等效电路中,Rs表示溶液电阻;R1表示通过腐蚀层中的电阻;CPE1表示SBF与腐蚀层之间的等效电容;R2表示通过MgO膜层的电阻;CPE2表示合金基体与其表面MgO膜层的等效电容。根据图6(a)和(d),对Mg-0.5Zr- 1.8Zn-xGd合金的Nyquist图进行拟合,所得等效电路中的参数值如表2所示。Rs值分布在15~30 Ω/cm2之间,测试过程中工作电极与参比电极之间距离的变化导致Rs值在一定范围内发生波动,两电极之间距离越大,Rs值越大[34]。CPE1和CPE2的参数n1和n2均分布在0~1.0之间,说明CPE为电容等效元件[35]。从表2中还能够看出,R1和R2的值随Gd含量的增加先增大后减小,当Gd含量为1.0%时,R1和R2均为最大值,说明E1.0合金在腐蚀过程中遇到的阻力最大,具有较好的耐腐蚀性能。

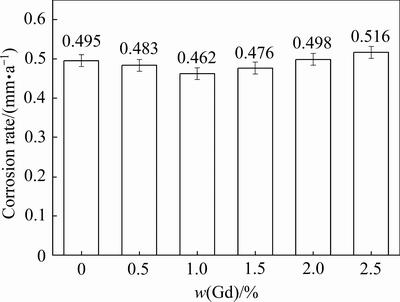

图7所示为挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡120 h后的静态腐蚀速率。由图7可看出,腐蚀速率随Gd含量的增加先减小后增大,当Gd含量为1.0%时,合金的腐蚀速率最小。通过静态腐蚀实验与电化学实验(见图5和图6)所测试合金耐腐蚀性能随Gd含量的变化规律具有相似性。

图6 挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡1 h后的交流阻抗谱和对应的等效电路

Fig. 6 Nyquist plots and corresponding equivalent circuit model of as-extruded Mg-0.5Zr-1.8Zn-xGd alloys immersed in SBF for 1 h

表2 挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡1 h后的电化学阻抗模拟值

Table 2 Electrochemical impedance spectra simulated values of as-extruded Mg-0.5Zr-1.8Zn-xGd alloys immersed in SBF for 1 h

图7 挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡 120 h内的腐蚀速率

Fig. 7 Corrosion rate of as-extruded Mg-0.5Zr-1.8Zn-xGd alloys after immersion in SBF for 120 h

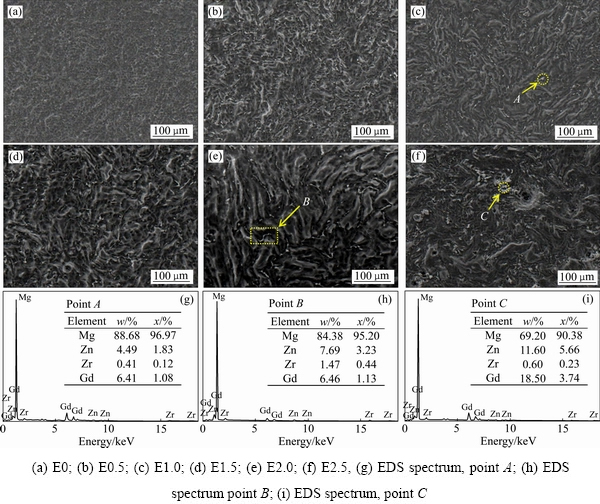

图8所示为挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡120 h,去除腐蚀产物后合金表面的腐蚀形貌。由图8可看出,Gd含量小于1.0%时,腐蚀形貌以弯曲细小的条带状为主,呈类均匀腐蚀特征,同时,合金表面残留有少量的如A点所示的细小白色颗粒状第二相,通过能谱分析,如图8(g)所示,该白色颗粒状第二相由Mg、Zn及Gd三种元素组成。Gd含量增加到1.5%和2.0%时,如图8(d)和(e)所示,腐蚀形貌以弯曲的尺寸较大的条带状为主。条带状腐蚀形貌的出现与合金元素的分布状态有关。首先,如图1(d)和(e)所示,未溶第二相以颗粒状和弯曲的线条状形式在合金中随机分布,同时,由于挤压过程较短,第二相中的合金元素溶入合金基体后来不及充分扩散,合金元素浓度较高的区域也以弯曲的线条状形式在合金中随机分布。合金元素浓度较高的弯曲线条状区域在腐蚀过程中充当阴极,其相邻区域充当阳极,阳极区域的快速溶解导致腐蚀后的合金形貌呈弯曲的条带状结构[36]。当Gd含量小于2.0%时,随着Gd含量的增加,不同区域间合金元素浓度差异变大,即不同区域间腐蚀速率差异增大,因此,条带状的腐蚀形貌随Gd含量的增加更加明显。同时,当Gd含量为2.0%时,腐蚀形貌中残留有如B区域所示的弯曲线条状白色第二相,通过EDS分析,如图8(h)所示,该弯曲线条状第二相主要由Mg、Zn及Gd三种元素组成。

当Gd含量为2.5%时,合金中条带状腐蚀形貌逐渐减弱,并出现了少量较浅的腐蚀坑及较深的腐蚀孔洞。如图1(f)及图4(d)~(f)所示,弯曲线条状第二相的增加及大量第二相颗粒的弥散分布降低了合金中不同区域间合金元素的浓度差异,即合金腐蚀速率增大的同时,又缩小了合金表面不同区域间腐蚀速率的差异,因此,条带状腐蚀形貌逐渐减弱。

图8 挤压态Mg-0.5Zr-1.8Zn-xGd合金在SBF中浸泡120 h去腐蚀层后的腐蚀形貌及能谱

Fig. 8 SEM micrographs and energy spectra showing as-extruded Mg-0.5Zr-1.8Zn-xGd samples after immersion for 120 h and corrosion product removal

部分尺寸较大且聚集的第二相颗粒的脱落导致了腐蚀后的合金表面出现了部分较浅的腐蚀坑及较深的腐蚀孔洞。腐蚀后的合金表面残留有如C点所示的白色第二相颗粒,通过能谱分析,如图8(i)所示,该白色第二相颗粒也主要由Mg、Zn和Gd三种元素组成。

3 分析与讨论

铸态Mg-Zr-Zn-Gd系合金的晶粒尺寸随Gd含量的增加逐渐减小,第二相所占体积分数随Gd含量的增加逐渐增大[37]。当挤压比、挤压速率及挤压温度相同时,动态再结晶晶粒大小主要与合金的成分及挤压前晶粒尺寸有关[38]。如图1所示,合金都发生了完全动态再结晶,说明挤压条件都达到了合金发生完全动态再结晶的临界条件。合金发生动态再结晶的过程中,晶界处易于形核,挤压前较小的晶粒能够提供较多的形核位置[39]。同时,较小的晶粒在变形过程中也能够增加晶粒细化的能量,如小角度晶界取向差的快速增加[40]。合金中破碎的第二相颗粒能够促进其附近区域变形储存能的快速增加,同时,也能够促进颗粒刺激形核而加速动态再结晶的发生。破碎的第二相颗粒对晶界也起到一定的钉扎作用,阻碍动态再结晶晶粒的长大[41]。因此,当Gd含量小于1.5%时,合金的晶粒尺寸随Gd含量的增加逐渐减小。

挤压前合金晶粒尺寸小于某一临界值时,再结晶晶粒尺寸大小与挤压比、挤压速率及挤压温度密切相关,而挤压前合金的晶粒尺寸对再结晶晶粒尺寸大小没有直接影响[42]。挤压前合金的晶粒尺寸小于一定值时,在挤压过程中合金的晶界空间会快速减小到发生几何动态再结晶的临界值,导致动态再结晶晶粒尺寸大小趋于稳定[38]。从图4中能够看出,E2.0和E2.5合金中分布着大量的破碎及分散的第二相颗粒,大量破碎及分散的第二相颗粒在挤压过程中会导致再结晶晶核数量的快速增加,同时,随着第二相颗粒的增加,单位体积内新生成的晶核数量会趋于饱和并保持恒定。因此,当Gd含量大于1.5%时,再结晶晶粒尺寸随着Gd含量的增加逐渐趋于稳定。

Mg-Zr-Zn-Gd系合金在SBF中的腐蚀过程中,合金基体通常作为阳极,第二相作为阴极[43]。从图1和2中能够看出,当Gd含量低于1.0%时,合金中第二相颗粒的数量、尺寸及体积分数较小,并呈均匀分布状态。当合金中第二相颗粒的数量、尺寸及体积分数较小时,晶粒尺寸大小对合金的耐腐蚀性能起主导作用[44]。晶界处溶质浓度通常高于晶粒内部,腐蚀过程中作为阴极的晶界区域会加速晶粒中心区域的腐蚀,降低合金的耐腐蚀性能。晶粒尺寸的减小会导致晶界增多和晶界区域平均溶质浓度的下降,相当于提高了合金基体中溶质的浓度,提高了合金基体的φcorr[45]。从表1中也能够看出,合金的φcorr随Gd含量的增加逐渐向正方向移动,Jcorr及vi逐渐减小,合金的耐腐蚀性能逐渐增强,因此,随着晶粒尺寸的减小,合金的耐腐蚀性能逐渐增强。晶粒尺寸的减小能够增强合金表面的钝化效应,在合金表面的不同区域形成一个低的电化学电位梯度,弱化合金不同区域间的电偶强度,提高其耐腐蚀性能[46]。溶入合金基体中的Gd能够在合金表面形成稳定的氧化物保护膜,改善合金的耐腐蚀性能,当Gd含量较低时,合金表面形成的氧化物保护膜随着Gd含量的增加而增厚[36]。从表2中R1的变化可知,R1随Gd含量的增加逐渐增大,说明氧化物保护膜随Gd含量的增加而逐渐增厚,逐渐增厚的氧化物保护膜导致其耐腐蚀性能逐渐增强[31]。晶粒的细化能够改善MgO膜的致密性及其与合金基体的连续性,在腐蚀过程中,致密且连续的MgO膜在保护基体的同时,又能够降低其外层Mg(OH)2层破裂的趋势[47]。表2中R2的逐渐增大说明Mg(OH)2腐蚀层分布均匀且致密性随晶粒的细化逐渐增强,合金的耐腐蚀性能逐渐增强。从微观角度出发,腐蚀过程中,细小的第二相颗粒会与其周围的合金基体形成微小的电偶腐蚀。从宏观角度出发,均匀分布的微小电偶腐蚀会使合金表面呈现出均匀腐蚀的特征[14]。因此,当Gd含量低于1.0%时,合金的耐腐蚀性能随Gd含量的增加逐渐增强,并呈现出均匀腐蚀的特征。

合金中第二相含量较高时,第二相颗粒的数量、尺寸及体积分数对其耐腐蚀性能起主导作用[48]。从图1和4中能够看出,当Gd含量大于1.0%时,合金中第二相颗粒的数量、尺寸及体积分数随Gd含量的增加而增大。尺寸较大的第二相颗粒会作为阴极加速其周围合金基体的溶解,降低合金的耐腐蚀性能,同时,第二相颗粒的脱落也会导致计算过程中腐蚀速率的增大[49]。从表中R1和R2随Gd含量的增大逐渐减小说明较大尺寸的第二相颗粒在加速其周围合金基体溶解的同时,也破坏了合金表面MgO膜和Mg(OH)2腐蚀层的致密性和完整性,加速了合金基体的腐蚀。较大尺寸第二相颗粒附近区域合金基体的快速溶解以及第二相颗粒的脱落会导致合金发生严重的局部腐蚀。从图8(f)也能够看出,E2.5合金表面出现了少量的腐蚀坑及腐蚀孔。因此,当Gd含量大于1.0%时,随着Gd含量的增加,第二相颗粒的数量、尺寸及体积分数的逐渐增大导致了合金的平均腐蚀速率不断增大。

4 结论

1) Gd在挤压态Mg-0.5Zr-1.8Zn-xGd合金中的最大溶解度小于1.0%,当Gd含量为0~1.5%时,随着Gd含量的增加,破碎第二相颗粒数量及尺寸的增大促进了再结晶晶核的形成并阻碍了晶粒的长大,导致再结晶晶粒尺寸不断减小;当Gd含量为1.5%~2.5%时,随Gd含量的增加,第二相颗粒数量的增加使单位体积内新生成晶核数量逐渐趋于恒定,导致再结晶晶粒尺寸逐渐趋于稳定。

2) 合金中的第二相由(Mg, Zn)3Gd相和Mg2Zn11相组成。Gd含量小于1.0%时,第二相主要以分散的纳米级颗粒状的形式存在。Gd含量大于2.0%时,颗粒状第二相的数量及尺寸明显增大,同时,部分未溶第二相以弯曲线条状在合金中随机分布。

3) Gd含量小于1.0%时,晶粒尺寸的逐渐减小使合金的耐腐蚀性能随Gd含量的增加逐渐增强。Gd含量为1.0%~2.5%时,第二相颗粒的数量、尺寸及体积的增大加速了其周围合金基体的溶解,导致合金的耐腐蚀性能随Gd含量的增加逐渐减弱。

4) Gd含量小于2.0%时,合金的腐蚀形貌主要以弯曲的条带状为主,同时,随Gd含量的增加,条带状的尺寸及距离逐渐增大。Gd含量大于2.0%时,合金中条带状腐蚀形貌逐渐减弱,同时,出现了少量的腐蚀坑及腐蚀孔。

REFERENCES

[1] 郑玉峰, 杨宏韬. 血管支架可降解金属研究进展[J]. 金属学报, 2017, 53(10): 1227-1237.

ZHENG Yu-feng, YANG Hong-tao. Research progress in biodegradable metals for stent application[J]. Acta Metallurgical Sinica, 2017, 53(10): 1227-1237.

[2] 张春艳, 张世雨, 柳歆鹏, 等. 镁合金表面MgF2/HA复合涂层的体外降解性能[J]. 中国有色金属学报, 2018, 28(4): 766-773.

ZHANG Chun-yan, ZHANG Shi-yu, LIU Xin-peng, et al. Degradation behavior of MgF2/HA composite coating on magnesium alloy in vitro[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(4):766-773.

[3] 陶学伟, 王章忠, 章晓波, 等. Gd离子注入对固溶态Mg-Nd-Sr-Zr合金生物腐蚀行为的影响[J]. 中国有色金属学报, 2016, 26(11): 2319-2325.

TAO Xue-wei, WANG Zhang-zhong, ZHANG Xiao-bo, et al. Effect of Gd ion implantation on biocorrosion behavior of solution treated Mg-Nd-Sr-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(11): 2319-2325.

[4] FERNANDES D, RESENDE C, CAVALCANTI J, et al. Biocompatibility of bioabsorbable Mg-Ca alloys with rare earth elements addition[J]. Journal of materials Science, 2019, 30: 134.

[5] DU B N, HU Z Y, WANG J L, et al. Effect of extrusion process on the mechanical and in vitro degradation performance of a biomedical Mg-Zn-Y-Nd alloy[J]. Bioactive Materials, 2020, 5: 219-227.

[6] ERINC M, SILLEKENS W H, MANNENS R G T M, et al. Applicability of existing magnesium alloys as biomedical implant materials[C]// Magnesium Technology 2009. Warrendale: TMS, 2009: 209-214.

[7] SABBAGHIAN M, MAHMUDI R, SHIN K S. Microstructure, texture, mechanical properties and biodegradability of extruded Mg-4Zn-xMn alloys[J]. Materials Science & Engineering A, 2020, 792: 139828.

[8] 曾荣昌, 崔蓝月, 柯 伟. 医用镁合金:成分、组织及腐蚀[J]. 金属学报, 2018, 54(9): 1215-1235.

ZENG Rong-chang, CUI Lan-yue, KE Wei. Biomedical magnesium alloys: Composition, microstructure and corrosion[J]. Acta Metallurgical Sinica, 2018, 54(9): 1215-1235.

[9] GU X N, ZHENG Y F, ZHONG S P, et al. Corrosion of , and cellular response to Mg-Zn-Ca bulk metallic glasses[J]. Biomaterials, 2010, 31: 1093-1103.

[10] LI Y C, WEN C, MUSHAHARY D, et al. Mg-Zr-Sr alloys as biodegradable implant materials[J]. Acta Biomater, 2012, 8: 3177.

[11] 王鲁宁, 孟 瑶, 刘丽君, 等. 可降解锌基生物材料的研究进展[J]. 金属学报, 2017, 53(10): 1317-1322.

WANG Lu-ning, MENG Yao, LIU Li-jun, et al. Research progress on biodegradable zinc-based biomaterials[J]. Acta Metall Sinica, 2017, 53(10): 1317-1322.

[12] 曾荣昌, 柯 伟, 徐永波, 等. Mg合金的最新发展及应用前景[J]. 金属学报, 2001, 37(7): 673-685.

ZENG Rong-chang, KE Wei, XU Yong-bo, et al. Recent development and application of magnesium alloys[J]. Acta Metall Sinica, 2001, 37(7): 673-685.

[13] LIU K, ZHANG J H, ROKHLIN L L, et al. Microstructures and mechanical properties of extruded Mg-8Gd-0.4Zr alloys containing Zn[J]. Materials Science & Engineering A, 2009, 505: 13-19.

[14] 袁广银, 牛佳林. 可降解医用镁合金在骨修复应用中的研究进展[J]. 金属学报, 2017, 53(10): 1169-1180.

YUAN Guang-yin, NIU Jia-lin. Research progress of biodegradable magnesium alloys for orthopedic application[J]. Acta Metall Sinica, 2017, 53(10): 1169-1180.

[15] SRINIVASAN A, HUANG Y, MENDIS C L, et al. Investigations on microstructures, mechanical and corrosion properties of Mg-Gd-Zn alloys[J]. Materials Science & Engineering A, 2014, 595: 224-234.

[16] FEYERABEND F, FISCHER J, HOLTZ J, et al. Evaluation of short-term effects of rare earth and other elements used in magnesium alloys on primary cells and cell lines[J]. Acta Biomaterialia, 2010, 6: 1834-1842.

[17] CHENG Y J, XU Z G, SMITH C, et al. Recent advances on the development of magnesium alloys for biodegradable implants[J]. Acta Biomaterialia, 2014, 10(11): 4561-4573.

[18] SEITZ J M, LUCAS A, KIRSCHENR M. Magnesium-based compression screws: A novelty in the clinical use of implants[J]. The Minerals, Metals & Materials Society, 2016 68(4): 1177-1181.

[19] BOUSQUET J C, SAINI S, STARK D D, et al. Gd-DOTA: Characterization of a new paramagnetic complex[J]. Radiology, 1988, 166(3): 693-698.

[20] ZHANG X B, BA Z X, WANG Z Z, et al. Microstructures and corrosion behavior of biodegradable Mg-6Gd-xZn-0.4Zr alloys with and without long period stacking ordered structure[J]. Corrosion Science, 2016, 105: 68-77.

[21] BAEK S M, KANG J S, SHIN H J, et al. Role of alloyed Y in improving the corrosion resistance of extruded Mg-Al-Ca-based alloy[J]. Corrosion Science, 2017, 118: 227-232.

[22] PARFENOV E V, KULYASOVA O B, MUKAEVA V R, et al. Influence of ultra-fine grain structure on corrosion behaviour of biodegradable Mg-1Ca alloy[J]. Corrosion Science, 2020, 163: 1083031

[23] ZHANG X B, BA Z X, WANG Z Z, et al. Effect of LPSO structure on mechanical properties and corrosion behavior of as-extruded GZ51K magnesium alloy[J]. Materials Letters, 2016, 163: 250-253.

[24] GUI Z Z, KANG Z X, LI Y Y. Mechanical and corrosion properties of Mg-Gd-Zn-Zr-Mn biodegradable alloy by hot extrusion[J]. Journal of Alloys and Compounds, 2016, 685: 222-230.

[25] YAO H, WEN J B, XIONG Y, et al. Extrusion temperature impacts on bimetallic Mg-2.0Zn-0.5Zr-3.0Gd (wt%) solid-solution alloy[J]. Journal of Alloys and Compounds, 2018, 739: 468-480.

[26] ABIDIN N I Z, ATRENS A D, MARTIN D, et al. Corrosion of high purity Mg, Mg2Zn0.2Mn, ZE41 and AZ91 in Hank’s solution at 37 ℃[J]. Corrosion Science, 2011, 53: 3542-3556.

[27] ION S E, HUMPHREYS F J, WHITE S H. Dynamic recrystallisation and the development of microsructure during the high temperature deformation of magnesium[J]. Acta Metallurgica, 1982, 30(10): 1909-1919.

[28] LIU J, YANG L X, ZHANG C Y, et al. Role of the LPSO structure in the improvement of corrosion resistance of Mg-Gd-Zn-Zr alloys[J]. Journal of Alloys and Compounds, 2019, 782: 648-658.

[29] XU S W, ZHENG M Y, KAMADO S, et al. Dynamic microstructural changes during hot extrusion and mechanical properties of a Mg-5.0Zn-0.9Y-0.16Zr (wt.%) alloy[J]. Materials Science & Engineering A, 2011, 528: 4055-4067.

[30] 何云斌, 潘清林, 刘晓艳, 等. 美金合等通道转角挤压过程中的晶粒细化机制[J]. 中国有色金属学报, 2011, 21(8): 1785-1793.

HE Yun-bin, PAN Qing-lin, LIU Xiao-yan, et al. Grain refinement mechanism of magnesium alloy during equal channel angular pressing process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1785-1793.

[31] WEI L L, CHANG L. Structure of coherent Mg3TiO4 oxide formed between TiN and MgO[J]. Materials Letters, 2018, 213: 227-230.

[32] JIANG P L, BLAWERT C, HOU R Q, et al. Microstructural influence on corrosion behavior of MgZnGe alloy in NaCl solution[J]. Journal of Alloys and Compounds, 2019, 783: 179-192.

[33] HOMAYUN B, AFSHAR A. Microstructure, mechanical properties, corrosion behavior and cytotoxicity of Mg-Zn-Al-Ca alloys as biodegradable materials[J]. Journal of Alloys and Compounds, 2014, 607: 1-10.

[34] WAHEED A B, NADIA H H, MOHMMED E R, et al. Electrochemical behavior of Mg and some Mg alloys in aqueous solutions of different pH[J]. Electrochemical Acta, 2010, 55(6): 1880-1887.

[35] ASCENCIO M, PEKGULERYUZ M, OMANOVIC S. An investigation of the corrosion mechanisms of WE43 Mg alloy in a modified simulated body fluid solution: The influence of immersion time[J]. Corrosion Science, 2014, 87: 489-503.

[36] COY A E, VIEJO F, SKELDON P, et al. Susceptibility of rare-earth-magnesium alloys to microgalvanic corrosion[J]. Corrosion Science, 2010, 52(12): 3896-3906.

[37] YAO H, WEN J B, XIONG Y, et al. Microstructures, mechanical properties and corrosion behavior of as-cast Mg-2.0Zn-0.5Zr-xGd(wt%) bioegradable alloys[J]. Materials, 2018, 11: 1564.

[38] HUANG K, LOGE R E. A review of dynamic recrystallization phenomena in metallic materials[J]. Materials and Design, 2016, 111: 548-574.

[39] WAHABI M E I, GAVARD L, MONTHEILLET F, et al. Effect of initial grain size on dynamic recrystallization in high purity austenitic stainless steels[J]. Acta Materialia, 2005, 53: 4605-4612.

[40] WU W X, JIN L, DONG J, et al. Effect of initial microstructure on the dynamic recrystallization behavior of Mg-Gd-Y-Zr alloy[J]. Materials Science & Engineering A, 2012, 556: 519-525.

[41] LUO J, YAN H, CHEN R S, et al. Effects of Gd concentration on micrstructure, texture and tensile properties of Mg-Zn-Gd alloys subjected to large strain hot rolling[J]. Materials Science & Engineering A, 2014, 614: 88-95.

[42] SAKAI T, JONAS J J. Dynamic recrystallization: Mechanical and microstructural considerations[J]. Acta Metallurgica, 1984, 32: 189-209.

[43] DING Y F, WEN C, HODGSON P, et al. Effects of alloying elements on the corrosion behavior and biocompatibility of biodegradable magnesium alloys: A review[J]. Journal of Materials Chemistry B, 2014, 2: 1912-1933.

[44] ATRENS A, LIU M, ABIDIN N I Z. Corrosion mechanism applicable to biodegradable magnesium implants[J]. Materials Science & Engineering B, 2011, 176: 1609-1636.

[45] CAO F Y, SHI Z M, SONG G L, et al. Influence of hot rolling on the corrosion behavior of several Mg-X alloys[J]. Corrosion Science, 2015, 90: 176-191.

[46] SUNIL B R, KUMAR T S S, CHAKKINGAL U, et al. In vitro and in vivo studies of biodegradable fine grained AZ31 magnesium alloy produced by equal channel angular pressing[J]. Materials Science & Engineering C, 2016, 59: 356-367.

[47] LIU D X, GUO C G, CHAI L Q, et al. Mechanical properties and corrosion resistance of hot extruded Mg-2.5Zn-1Ca alloy[J]. Materials Science & Engineering B, 2015, 195: 50-58.

[48] CAO F F, DENG K K, NIE K B, et al. Microstructure and corrosion properties of Mg-4Zn-2Gd-0.5Ca alloy influenced by multidirectional forging[J]. Journal of Alloys and Compounds, 2019, 770: 1208-1220.

[49] SHI Z M, LIU M, ATRENS A. Measurement of the corrosion rate of magnesium alloys using Tafel extrapolation[J]. Corrosion Science, 2010, 52: 579-588.

YAO Huai1, 2, FANG Bo-yang3, CAO Jia-long1, WANG Xiao-bo1, YE Wen-long1, LI Qing1, LI Yun-xiang1

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Collaborative Innovation Center of Nonferrous Metals of Henan Province, Luoyang 471023, China;

3. College of Materials Science and Engineering, Southwest Jiaotong University, Chengdu 610031, China)

Abstract: The effects of Gd content on the microstructure and corrosion resistance of the as-extruded Mg-0.5Zr-1.8Zn-xGd alloys (0-2.5%) was investigated. The results show that, when the extrusion ratio is 7.7 and the extrusion temperature is 350 ℃, the alloys have undergone complete dynamic recrystallization. The grain size decreases with the increase of Gd content and finally tends to be stable. The second phase in the alloy consists mainly of the granular (Mg, Zn)3Gd phase and the Mg2Zn11 phase, and volume of the second phase gradually increase with increasing Gd content. Meanwhile, the nano-scale granular (Mg, Zn)3Gd phase has a semi-congruent interfacial relationship with the alloy matrix. When Gd content is greater than 2.0%, a portion of the insoluble second phase is randomly distributed in the alloy matrix in the form of curved lines, and the volume and the amount gradually increase as Gd content increasing. The corrosion resistance of the alloy is enhanced and then weakened with the increase of Gd content, that the alloy has the best corrosion with a Gd content of 1.0%.

Key words: magnesium alloy; extrusion; microstructure; corrosion resistance

Foundation item: Project(20A430010) supported by the Education Department of Henan Province, China; Project (2020030) supported by the Henan University of Science and Technology College Students Training Plan, China; Project(U1804146) supported by the National Natural Science Foundation of China

Received date: 2020-08-22; Accepted date: 2020-12-22

Corresponding author: YAO Huai; Tel: +86-379-64231846; E-mail: yaohuaitougao@126.com

(编辑 李艳红)

基金项目:河南省高等学校重点科研项目(20A430010);河南科技大学大学生训练计划资助项目(2020030);国家自然科学基金资助项目(U1804146)

收稿日期:2020-08-22;修订日期:2020-12-22

通信作者:姚 怀,讲师,博士;电话:0379-64231846;E-mail:yaohuaitougao@126.com