DOI: 10.11817/j.issn.1672-7207.2018.07.010

基于微极理论的新型FeAl多孔材料弹性模量研究

苏淑兰1, 2,饶秋华2,贺跃辉3,张惠斌3

(1. 中南林业科技大学 土木工程学院,湖南 长沙,410004;

2. 中南大学 土木工程学院,湖南 长沙,410075;

3. 中南大学 粉末冶金研究院,湖南 长沙,410083)

摘要:针对本课题组制备的一种新型金属间化合物多孔材料即FeAl多孔材料,分析其孔隙结构的微观特征,建立六边形多孔结构模型,利用微极理论和能量法推导出多孔材料弹性模量的理论计算公式,并通过单轴拉伸实验加以验证。研究结果表明:多孔材料的相对弹性模量E1/Es随相对密度ρ*/ρs增加而增大,且弯曲剪力对E1/Es的影响也随之增大,故中、高密度的多孔材料必须考虑弯曲剪力对E1/Es的影响;采用能量法精确计算微极弹性连续介质的结构位移,且考虑弯曲剪力对相对弹性模量的影响,理论公式计算的弹性模量更接近于实验结果,从而验证了弹性模量理论公式更加准确、可靠。

关键词:FeAl金属间化合物多孔材料;弹性模量;微极理论;能量法;单轴拉伸实验

中图分类号:TB383 文献标志码:A 文章编号:1672-7207(2018)07-1643-07

Elastic modulus for new FeAl porous material based on micropolar theory

SU Shulan1, 2, RAO Qiuhua2, HE Yuehui3, ZHANG Huibin3

(1. School of Civil Engineering, Central South University of Forestry & Technology, Changsha 410004, China;

2. School of Civil Engineering, Central South University, Changsha 410075, China;

3. Powder Metallurgy Research Institute, Central South University, Changsha 410083, China)

Abstract: A new type of intermetallic porous material, FeAl porous material, was prepared by our research group. A hexagonal pore structure model was established by analyzing its pore microstructure characteristics and a new calculation formula of elastic modulus was derived by micropolar theory and energy method for FeAl porous, and moreover, the calculation formula was verified by uniaxial tensile test. The results show that the relative elastic modulus E1/Es increases with the increase of the relative density ρ*/ρs, and the effect of bending shear force on E1/Es also increases, so the shear force must be considered for the medium and high density porous material. The energy method is adopted to calculate exactly displacements of micropolar elastic continuum and the effect of bending shear force on elastic modulus is considered, and therefore, the theoretical value of elastic modulus in this study is closer to its experimental value and more accurate and reliable.

Key words: FeAl intermetallic porous material; elastic modulus; micropolar theory; energy method; uniaxial tensile test

金属多孔材料具有很多比致密材料更优的特性,如比表面积大、比力学性能好、吸附容量大等,作为一种功能和结构材料,已广泛应用于航空、机械、建筑、冶金、医药、生物、化工等领域[1-5]。本课题组[6]提出元素混合粉偏扩散—反应合成—烧结方法,制备出一种新型的金属间化合物多孔材料,即FeAl多孔材料,与金属多孔材料相比,它具有优良的高温抗氧化和抗腐蚀性能、较高的比强度和比模量、易加工成形和可焊接连接等优点,工程应用前景十分广阔[7-9]。目前,已制备一种新型的具有阶梯孔梯度的FeAl多孔材料均质过滤膜[10],可用于高温和恶劣(如强腐蚀或硫化)环境下的过滤、分离、净化和提取等工艺过程。作为一种新的金属间化合物多孔材料,FeAl多孔材料的研究尚处于起步阶段[6, 11-13],其力学性能是保证材料应用于工程实际的重要指标。目前,多孔材料的力学性能研究多数采用模型分析方法,如几何模型[14-15]、复合材料力学模型[16-17]以及基于高阶连续介质理论[18-19]的微极理论模型[20-22]等,其中微极理论应用较广。通过微极理论推导多孔材料弹性模量的理论计算公式时,确定结构位移至关重要,一般是利用几何变形关系来近似计算,且忽略弯曲剪力的影响,缺乏足够的计算精度。本文作者基于FeAl多孔材料的孔隙结构微观特征分析,建立该材料的六边形多孔结构模型,利用微极理论和能量法,推导FeAl多孔材料弹性模量的理论计算公式,并通过单轴拉伸实验加以验证,以便为新型FeAl多孔材料的优化设计和应用推广提供重要的理论依据。

1 多孔结构模型

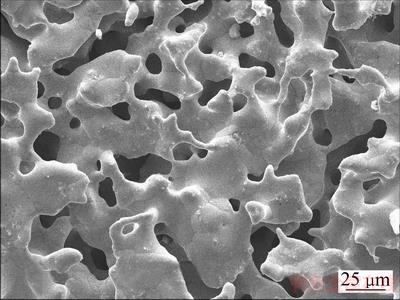

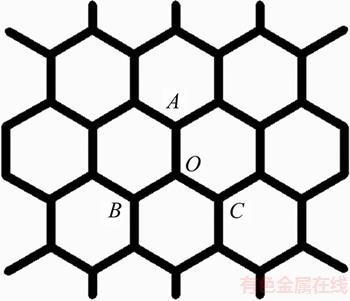

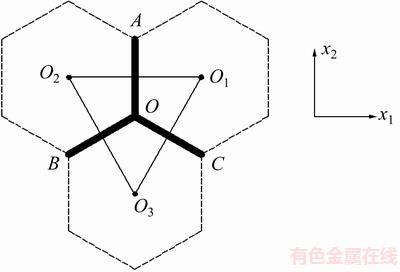

图1所示为FeAl金属间化合物多孔材料孔隙结构的SEM照片[5]。由图1可知:FeAl多孔材料的孔隙分布比较均匀,可将其抽象为图2所示的六边形多孔结构模型。将六边形多孔结构看成是弹性梁(OA, OB 和 OC),在梁的端点处通过结点(O)互相连接而成。选取图3中△O1O2O3围成的三角形部分为代表单元体,O1,O2和O3为相邻3个六边形的中心。

图1 FeAl多孔材料的微观结构形貌

Fig. 1 SEM photo of pore microstructure of FeAl intermetallic porous material

图2 六边形多孔结构

Fig. 2 Hexagonal porous structure

图3 代表单元体

Fig. 3 Representative cell

2 多孔材料弹性模量推导

为了推导出多孔材料的弹性模量,将多孔材料均匀化成微极弹性连续介质,由应变能等效原理求得微极弹性连续介质的微极刚度系数和微极弹性常数,再利用微极理论推导出多孔材料宏观弹性模量的理论计算公式。

2.1 微极理论基本方程

在ERINGEN[18]的微极理论中,假设材料中的任一微元体都是由许多连续可变形的物质点构成,每一个物质点具有6个自由度(3个平动自由度和3个转动自由度),即物质点不但能够传递力,而且能够传递力矩。微极理论的基本方程如下。

平衡方程:

(1)

(1)

本构方程:

(2)

(2)

几何方程:

(3)

(3)

其中:σij和εij分别为应力和应变张量;mij和κij分别为偶应力和扭率张量;Cijkl和Dijkl为线弹性微极理论中的刚度系数张量;uj和φj分别为物质点的平动和转动位移;ejik为三阶置换张量。

对于各向同性、中心对称的微极介质,其刚度系数张量Cijkl和Dijkl可以用2个拉梅常数(λ和μ)和4个微极弹性常数(κ,α,β和γ)表示为[23]

(4)

(4)

其中:δij为Kroneker Delta符号。

将式(4)代入式(2)可得应力张量σij和偶应力张量mij分别为

(5)

(5)

2.2 微极刚度系数和微极弹性常数

采用能量法精确计算微极弹性连续介质的变形,进而求得微极刚度系数和微极弹性常数。

将图3中的代表单元体均匀化成等效的微极弹性连续介质,由应变能等效可知,代表单元体的应变能Ucell(即单元体内各弹性梁的应变能之和)等于均匀化后微极弹性连续介质的应变能Ucon,即

(6)

(6)

(7)

(7)

其中:N为与结点相连的弹性梁总数;Fr和ur分别为第r根弹性梁所受的广义荷载和广义位移;σ和ε分别为应力和应变;m和κ分别为偶应力和扭率;V为单元体体积。

多孔结构受荷载作用时,将弹性梁看成两端固支(因梁的两端与结点相连),则弹性梁OA横截面上的内力有轴力N、剪力Q和弯矩M。且设弹性梁的位移分别为u1(x),u2(x)和φ(x),则相应的应变εkl和曲率κi可由几何方程(即式(3))得到,由此可得第r根弹性梁沿轴线方向的平均应变ε(r)、沿法线方向的平均应变ε~(r)及平均曲率κ(r)分别为

(8)

(8)

其中: 和

和 分别为坐标轴(x1和x2)方向的单位矢量沿第r根弹性梁的轴向和法向分量;下标k (k =1,2)代表坐标轴(x1和x2)。

分别为坐标轴(x1和x2)方向的单位矢量沿第r根弹性梁的轴向和法向分量;下标k (k =1,2)代表坐标轴(x1和x2)。

再根据梁理论中力-位移、力矩-转角关系,梁的内力可表示为

;

; ;

;

(9)

(9)

其中:E(r)为第r根弹性梁的弹性模量;l(r),A(r)和I(r)分别为第r根弹性梁的长度、横截面面积和惯性矩;η(r)为1个弯曲刚度与剪切刚度之比的量纲一系数,η(r)=0 表示弹性梁的剪切刚度很大,可以忽略弯曲剪切;η(r)≥1,表示弹性梁的剪切刚度较小,必须考虑弯曲剪切产生的变形。

将式(8)和式(9)代入式(7),可得代表单元体的应变能为

(10)

(10)

此外,将式(2)代入式(7),可得均匀化后微极连续介质的应变能为

(11)

(11)

利用式(6),由式(9),(10)和(11)得到均匀化后微极连续介质的刚度系数张量为

(12)

(12)

其中:

;

; ;

; (13)

(13)

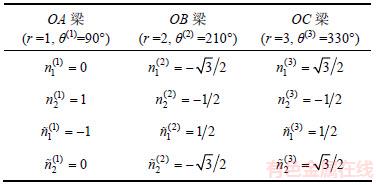

如图3所示,对于代表单元体△O1 O2 O3中与结点O相连的3根弹性梁OA,OB和OC,设n1和n2分别为x1和x2方向的单位矢量,则n1和n2沿第r根弹性梁的轴向和法向分量 和

和 (k =1, 2)如表1 所示。

(k =1, 2)如表1 所示。

表1 单位矢量沿第r根弹性梁的轴向和法向分量

Table 1 Components of unit vectors along axial and normal direction of the r-th elastic beam

设3根弹性梁OA,OB和OC完全相同,则有 ,

, ,

, 。由表1和式(12)可得到均匀化后微极连续介质的刚度系数为

。由表1和式(12)可得到均匀化后微极连续介质的刚度系数为

;

; ;

;

;

;

;

; ;

;

(14)

(14)

由式(13)可将微极刚度系数写成以下统一形式:

(15)

(15)

将式(15)与式(4)比较,可得微极连续介质的6个微极弹性常数分别为

;

; ;

; ;

;

;

; (16)

(16)

2.3 多孔材料的相对弹性模量

为了求得正六边形多孔材料在x1方向上的宏观弹性模量E1,考虑单位厚度的微极连续介质在x1方向上作用均布应力σ11,且介质内产生的应力为σ11≠0,σ22=σ33=0,应变为ε11≠0, ε22=ε33, ε12=ε23=ε13=0,则式(5)可以改写为

(17)

(17)

注意到σ22=0,则有

(18)

(18)

由式(17)和式(18)可得等效微极连续介质在x1方向上的弹性模量E1为

(19)

(19)

设图3中的弹性梁是宽为b、厚为t的矩形截面,则横截面面积A、惯性矩I分别为

;

; (20)

(20)

相对密度[3]为

(21)

(21)

式中:ρ*和ρs分别为多孔材料和致密材料的密度。

单位厚度(t=1)等效微极连续介质(各向同性)的拉梅常数λ和μ可由式(13),(16)和(20)得到:

;

;

(22)

(22)

将式(21)和(22)代入式(19),整理后得到x1方向上的相对弹性模量E1/Es与相对密度ρ*/ρs的显式表达式为

(23)

(23)

式中:Es为致密材料的弹性模量;h为弯曲和剪切刚度之比的量纲一系数(h≥1)。

现有文献中,基于复合材料力学理论[16]和微极理论[20]得到的多孔材料弹性模量理论公式分别为:

(24)

(24)

(25)

(25)

3 计算结果分析

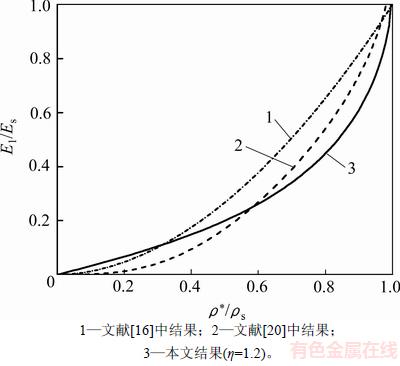

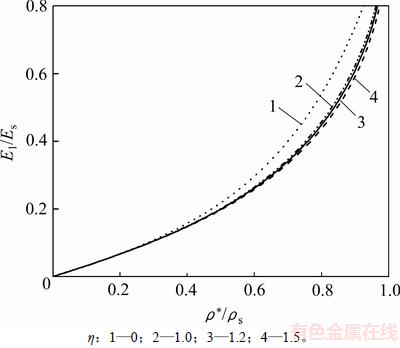

3.1 ρ*/ρs对E1/Es的影响

图4所示为文献[16]、文献[20]和本文的相对弹性模量E1/Es随相对密度ρ*/ρs的变化结果。从图4可见:相对弹性模量E1/Es随相对密度ρ*/ρs的增大而增大,这是因为相对密度增大即单位体积内固体材料增加,多孔材料抵抗弹性变形的能力也随之增大,该结论与实际情况相符。

文献[16]采用复合材料力学理论,将多孔材料看成是由致密体与孔隙2种材料组成,把孔隙的弹性模量取值为0,当相对密度较高时,从根本上无法考虑孔隙的分布及孔隙之间的相互作用对弹性模量的弱化。本文和文献[20]都考虑了材料的微结构特征,将其均匀化成微极弹性连续介质,但文献[20]是通过几何变形关系近似计算得到的结点位移和转角,而本文是通过能量法精确计算得到微极介质位移,同时还考虑了弯曲剪力对相对弹性模量的影响,故采用本文的理论公式计算FeAl多孔材料的弹性模量更为准确、可靠。

图4 E1/Es随相对密度ρ*/ρs的变化

Fig. 4 Variation of E1 /Es with ρ*/ρs

3.2 弯曲剪力对E1/Es的影响

图5所示为η=0(忽略剪力的影响)和η≥1(考虑剪力影响) 2种情况下弯曲剪力对E1/Es的影响。从图5可见:在低密度范围内,不同η的E1/Es几乎是重合的,这是因为当相对密度很小时,可将弹性梁简化为Bernoulli-Euler梁(η=0),弯曲剪力所产生的变形很小,可以忽略剪力的影响;在中、高密度范围内,弹性梁为Timoshenko梁(η≥1),弯曲剪力所产生的变形不能忽略,故相对密度较大时必须考虑剪力的影响,且相对密度越大,剪力影响(η=0和η≥1)越大,该结论与现有文献[22]中一致。显然,考虑弯曲剪切变形的E1/Es要远低于忽略剪力时的E1/Es,更偏于安全。

图5 弯曲剪力对E1/Es的影响

Fig. 5 Effects of bending shear force on E1/Es

4 实验验证

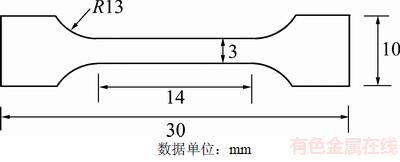

4.1 拉伸实验方案

采用本课题组制备的FeAl多孔材料和致密材料进行单轴拉伸实验,通过阿基米德法测得FeAl多孔材料的孔隙率为10.9%,相对密度为0.891,为高密度多孔材料。

按照GB/T 228—2010,将拉伸试件设计成矩形截面的比例试样,横截面长×宽为2 mm×3 mm(见图6),通过线切割加工而成。实验前将试件进行打磨抛光,且使试件充分暴露在大气环境中24 h以上。

图6 拉伸试件

Fig. 6 Tensile specimen

由于拉伸试件的尺寸太小,常规的万能试验机无法测定其准确应变,故采用MTS Insight生物力学试验机,最大荷载为30 kN。将拉伸试件夹持在试验机上且对中轴线,严格保持试件受轴向拉力作用。采用0.5 mm/min的加载速率对试件施加外载直至破坏,试验机自动记录相应的载荷与变形,以此绘制该试件的拉伸应力-应变曲线。

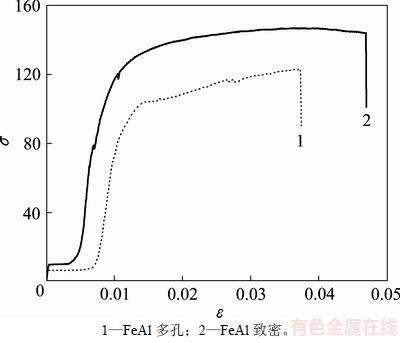

4.2 实验结果分析

图7所示为FeAl多孔材料和致密材料的拉伸应力-应变曲线。从图7可见:2条曲线具有相同的变化规律,即均由弹性、屈服、强化和破坏等4个阶段组成,但FeAl多孔材料的拉伸力学性能参数(如弹性模量、屈服极限和抗拉强度)均比FeAl致密材料的小。通过对应力-应变曲线的弹性段进行线性拟合,得到FeAl多孔材料的弹性模量E1′、致密材料的弹性模量Es分别为22.6 GPa和39.1 GPa。

图7 FeAl多孔和致密材料的应力 -应变曲线

Fig. 7 Stress-strain curves of the FeAl porous and dense materials

通过式(24),(25)和(23),可得到文献[16]、文献[20]和本文推导的FeAl多孔材料弹性模量理论值E1,如表2所示。从表2可见:所有理论值E1均高于实验值E1′,这是由于理论模型没有考虑实际孔隙的非均匀分布。本文模型不仅采用能量法精确计算了微极弹性连续介质的位移,而且同时考虑了弯曲剪力对相对弹性模量的影响,故本文理论公式计算的弹性模量值更接近于实验结果,从而验证了本文推导的FeAl多孔材料弹性模量的理论公式准确、可靠。

表2 FeAl多孔材料的弹性模量

Table 2 Elastic modulus of FeAl porous materials

5 结论

1) 与现有的弹性模量理论计算公式相比,本文利用微极理论并采用能量法精确计算微极弹性连续介质的结构位移,且考虑了弯曲剪力对相对弹性模量的影响,故本文建立的弹性模量理论公式更为准确、可靠。

2) 随着多孔材料的相对密度ρ*/ρs增加,其相对弹性模量E1/Es随之增大,且弯曲剪力对E1/Es的影响也随之增大,故对于中、高密度多孔材料必须考虑弯曲剪力对弹性模量的影响。

3) 通过比较FeAl多孔材料弹性模量的实验值与现有弹性模量计算公式的理论值,本文理论公式计算的弹性模量值更接近于实验值,从而验证了本文弹性模量理论公式的正确性。

参考文献:

[1] YAMAGUCHI A, UEJO F, YODA T, et al. Self-assembly of a silica-surfactant nanocomposite in a porous alumina membrane[J]. Nature Materials, 2004, 3(5): 337-341.

[2] 何晓宇, 刘咏, 李为, 等. 采用混合元素法制备多孔Ni3Al材料[J]. 中南大学学报(自然科学版), 2009, 40(2): 357-361.

HE Xiaoyu, LIU Yong, LI Wei, et al. Preparation of porous Ni3Al material by blend element[J]. Journal of Central South University (Science and Technology), 2009, 40(2): 357-361.

[3] GIBSON L J, ASHBY M F. Cellular solids: Structure and properties-second edition[M]. Cambridge: Cambridge University Press, 1997: 1-9.

[4] LANG Fengqun, YU Zhiming, GEDEVANISHVILI S, et al. Corrosion behavior of Fe-40Al sheet in N2-11.2O2-7.5CO2 atmospheres with various SO2 contents at 1 273 K[J]. Intermetallics, 2003, 11(2): 135-141.

[5] 王辉, 周向阳, 李昌林, 等. 真空烧结制备三维通孔不锈钢泡沫材料[J]. 中南大学学报(自然科学版), 2011, 42(8): 2178-2183.

WANG Hui, ZHOU Xiangyang, LI Changlin, et al. Vacuum sintering of stainless steel foam with 3-D open-cell network structure[J]. Journal of Central South University (Science and Technology), 2011, 42(8): 2178-2183.

[6] 高海燕. Fe-Al金属间化合物多孔材料的研究[D]. 长沙: 中南大学粉末冶金研究院, 2009: 37-47.

GAO Haiyan. Investigation on Fe-Al intermetallic compound porous material[D]. Changsha: Central South University. Powder Metallurgy Research Institute, 2009: 37-47.

[7] 沈培智, 高麟, 高海燕, 等. FeAl金属间化合物多孔材料高温硫化性能及应用[J]. 粉末冶金材料科学与工程, 2010, 15(1): 38-43.

SHEN Peizhi, GAO Ling, GAO Haiyan, et al. High-temperature sulfidation behavior and application in SO2-containing gas cleanup of porous FeAl intermetallics[J]. Materials Science and Engineering of Powder Metallurgy, 2010, 15(1): 38-43.

[8] 高海燕, 贺跃辉, 沈培智, 等. FeAl多孔材料与不锈钢的焊接[J]. 中国有色金属学报, 2009, 19(1): 90-95.

GAO Haiyan, HE Yuehui, SHEN Peizhi, et al. Welding of FeAl porous material and stainless steel[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(1): 90-95.

[9] GAO Haiyan, HE Yuehui, ZOU Jin, et al. Pore structure control for porous FeAl intermetallics[J]. Intermetallics, 2013, 32: 423-428.

[10] 贺跃辉, 江垚, 高海燕, 等. 一种制备孔径梯度FeAl金属间化合物均质过滤膜的方法: 中国, 200710035404.4[P]. 2008-01-23.

HE Yuehui, JIANG Yao, GAO Haiyan, et al. A preparation method of pore gradient homogeneous FeAl filter membrane: China, 200710035404.4[P]. 2008-01-23.

[11] SU Shulan, RAO Qiuhua, HE Yuehui. Theoretical prediction of effective elastic constants for new intermetallic compound porous material[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(4): 1090-1097.

[12] 王杰丰, 高海燕, 江垚, 等. 造孔剂(NH4)2CO3含量对FeAl多孔材料性能的影响[J]. 粉末冶金材料科学与工程, 2014, 19(4): 654-658.

WANG Jiefeng, GAO Haiyan, JIANG Yao, et al. Effect of pore-forming agent (NH4)2CO3 content on properties of porous FeAl materials[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(4): 654-658.

[13] 朱胜利, 张惠斌, 江垚, 等. 添加Cr合金化FeAl金属间化合物多孔材料的制备及性能[J]. 粉末冶金材料科学与工程, 2016, 21(3): 427-433.

ZHU Shengli, ZHANG Huibin, JIANG Yao, et al. Preparation and properties of porous FeAl intermetallics with Cr ternary additions[J]. Materials Science and Engineering of Powder Metallurgy, 2016, 21(3): 427-433.

[14] LI K, GAO X L, ROY A K. Micromechanics model for three-dimensional open-cell foams using a tetrakaidecahedral unit cell and Castigliano’s second theorem[J]. Composites Science and Technology, 2003, 63(12): 1769-1781.

[15] CHUANG C H, HUANG J S. Elastic moduli and plastic collapse strength of hexagonal honeycombs with plateau borders[J]. International Journal of Mechanical Sciences, 2002, 44(9): 1827-1844.

[16] 卢子兴, 黄筑平, 王仁. 聚氨酯泡沫塑料压缩杨氏模量的理论预测[J]. 应用力学学报, 1996, 13(2): 9-12.

LU Zixing, HUANG Zhuping, WANG Ren. The theoretical prediction of compressive Young’s moduli for polyurethane foam plastics[J]. Chinese Journal of Applied Mechanics, 1996, 13(2): 9-12.

[17] RAMAKRISHNAN N, ARUNACHALAM V S. Effective elastic moduli of porous solids[J]. Journal of Material Science, 1990, 25(9): 3930-3937.

[18] ERINGEN A C. Microcontinuum field theory[M]. New York: Springer, 1999: 101-248.

[19] 胡更开, 刘晓宁, 荀飞. 非均匀微极介质的有效性质分析[J]. 力学进展, 2004, 34(2): 195-214.

HU Gengkai, LIU Xiaoxun, XUN Fei. Micromechanics of heterogeneous micropolar mediums[J]. Advances in Mechanics, 2004, 34(2): 195-214.

[20] WANG X L, STRONGE W J. Micropolar theory for two-dimensional stresses in elastic honeycomb[J]. Proc Roy Soc Lond, 1999, A455: 2091-2116.

[21] OSTOJIA-STARZEWSKI M. Lattice models in micromechanics[J]. Applied Mechanics Review, 2002, 55(1): 35-60.

[22] KUMAR R S, MCDOWELL D L. Generalized continuum modeling of 2-D periodic cellular solids[J]. International Journal of Solids and Structures, 2004, 41(26): 7399-7422.

[23] NOWACHI W. Theory of asymmetric elasticity[M]. Oxford: Pergamon Press/Warsaw: PWN-Polish Scientific Publishers, 1986: 135-161.

(编辑 杨幼平)

收稿日期:2017-07-02;修回日期:2017-10-28

基金项目(Foundation item):国家自然科学基金资助项目(11502307);湖南省自然科学基金资助项目(2016JJ3187);湖南省教育厅一般项目(14C1189);中南林业科技大学引进高层次人才科研启动基金资助项目(2014年) (Project(11502307) supported by the National Natural Science Foundation of China; Project(2016JJ3187) supported by the Natural Science Foundation of Hunan Province; Project(14C1189) supported by Education Department of Hunan Province; Project(2014) supported by the High-level Talents Scientific Research Starting Funds of Central South University of Forestry & Technology)

通信作者:饶秋华,博士,教授,从事固体力学研究;E-mail: raoqh@csu.edu.cn